IDEC KW2D Series User manual

ø22 SMART RFID READER

KW2D SERIES

Smart RFID Reader

Manage user authority for machines and equipment

Control and track access to production sites

ø22 KW2DSeries

Compact and smart design ideal for factory automation environments

IP65/67-rated to

protect from

washdowns and

oil spills.

Mounts on ø22mm

panel cut-out

Designed to

work on metal

surfaces often

used at factory

automation sites.

* Actual size

Front unit:

43.6 × 43.6mm

Panel front height: 9.0mm

Back unit:

40.0 × 40.0mm

Depth: 48.5mm

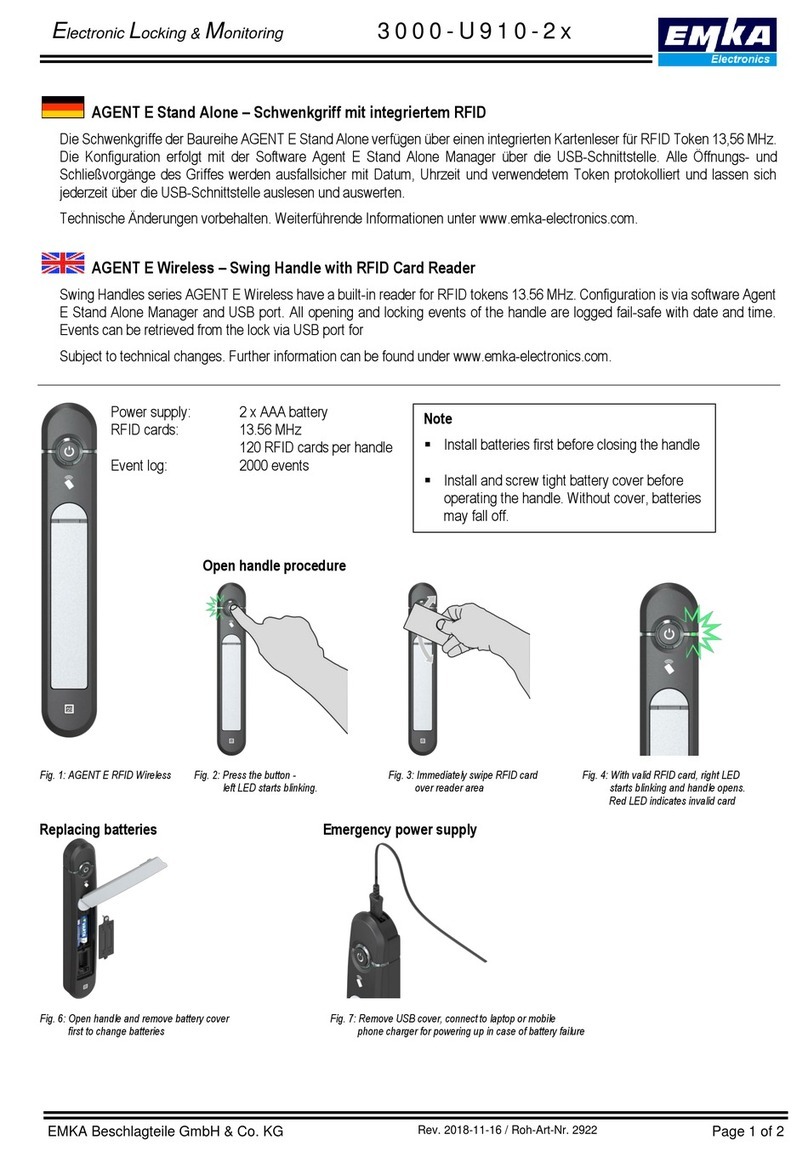

Equipped with an LED easily

visible from the side and an

auxiliary buzzer, the RFID reader

enables visible and audible

feedback on operation status.

Verification -Success Verification -ErrorStandby

Front Side

* Can be controlled from a host device (such as a

touch panel or PLC).

Can be used for IC

cards, such as

employee IDs (*1).

*1 Mifare, FeliCa, etc.

2

Holder feature available for mounting RFID tags

With a verication function inside, the

veried result can be communicated to

the host device as data.

An Ethernet port enhances connection

compatibility with host devices

• Supported protocol: Modbus TCP (server)

* EtherNet/IP and CC-LINK IE FB will be supported soon.

Panel Mount RFID Reader

* If the verication function is not used, a communication error will

occur if the result is not sent back to the RFID main unit.

Verication result (Success/Error)

Authority level, etc.

UID

Name 1, 2

* 5 types are available (sold separately).

3

Application Examples

Inadvertent operation and

setting changes are prevented,

reducing equipment

malfunctions and failures.

Mount the RFID reader on the operation

panel of a machine and register the

workers in the RFID reader. ID cards can

then be used to authenticate each worker.

Anyone can operate the machines.

BEFORE

AFTER

Manage user authority for machines and devices

By recording entry/exit logs,

workers can be prevented

from being trapped or left

behind in a work area.

Worker's names are linked to ID cards such

as employee ID cards, and that data is sent

when a card is read. Logs are recorded on the

host device to track entry/exit.

Do not know if workers are left inside.

BEFORE

AFTER

Track entry/exit at work areas

Occupied

There are ___ people inside!

4

After inspection work,

employee ID cards are read

and data is recorded.

Inspection details are recorded as

electronic data and linked to worker

data. The time and work details are

recorded on a touch panel or PLC to

ensure reliable traceability.

Inspection reports were written by hand.

BEFORE

AFTER

Manage inspection history

KW2D SERIES

By connecting with devices such as touch panels and

PLCs, the RFID reader can be used for wide variety of

applications.

5

RFID Reader Conguration Screen

Intuitive operation allows settings to be congured on a single screen.

* The conguration tool can be downloaded from the IDEC website.

Conguration Tool KW RFID Congurator

Screen 1

Only the

IP address

is required.

Only the

IP address

is required.

Operating Environment

Item Details

OS Windows10

CPU 1.0GHz or more

Memory 1GB or more

Environment Microsoft.NET Framework4.0 or later

Tag reading distance

and response speed can be

adjusted.

Tag reading distance

and response speed can be

adjusted.

6

Conguration Tool KW RFID Congurator

* Connect to a computer when

conguring settings.

LAN cable

Tag List Registration Screen

The RFID reader is equipped with a verication function, enabling output of

arbitrary data.

Screen 2

Monitor function

enables data to be

registered directly

to the tag list.

Monitor function

enables data to be

registered directly

to the tag list.

• Up to 500 items

• Import and

export as CSV le

Connection diagram

KW2D SERIES

ASCII and Japanese (S-JIS)

can be displayed.

ASCII and Japanese (S-JIS)

can be displayed.

Lastly, click "Download"Lastly, click "Download"

7

Supported character codes

UTF-8, ASCII, Japanese (Shift-JIS), Chinese (GB2312), Western Europe (ISO 8859-1)

The following data can be acquired via ModbusTCP communication

* The same conguration is also used for EtherNet/IP and

CC-LINK IE FB.

Communication via Ethernet with host devices such as touch panels and PLCs

When using a supported communication protocol

KW2D series

RFID Reader

UID: 123456789

0ABCDEF Switching hub

Verication -Success

PLC or

controller

External device

-Inverter, motor,

etc.

Employee ID card

IoT

Touch panel

System Conguration Example KW2D SERIES

• UID Input register (300004 to 300008)

• Name 1 Input register (300012 to 300020)

• Name 2 Input register (300022 to 300030)

• Authority level Input register (300002)

• Verication success Input relay (100001)

• Verication error Input relay (100002)

Next, simply enter the required data via the touch panel or PLC.

Verication success

Verication error

UID

Name 1, 2

Authority level

8

9

KW2DSeries ø22 Smart RFID Reader

Main Unit Package Quantity: 1

Model Appearance Power Supply Approval Part No. (Ordering No.)

Without holder

24V DC

IEC/EN61131-2 2007 (Zone B)

EN301-489-3

UL61010-1/CAN/CSA C22.2

No. 61010-1-12

UL 61010-2-201

EN50364

KW2D-R100Q4E

With holder KW2D-RH100Q4E

RFID Tags When ordering, specify the Ordering No.

Tag Type Shape Color Part No. (Ordering No.) Package Quantity

KEYFOB

Green KW9Z-T1X1G 1

Yellow KW9Z-T1X2Y 1

Red KW9Z-T1X3R 1

Blue KW9Z-T1X4S 1

Black KW9Z-T1X5B 1

Card N/A KW9Z-T2X0 2

Maintenance Parts When ordering, specify the Ordering No.

Name/Appearance Specication/Dimension Part No. Ordering No. Package Quantity Remarks

Cover (withot holder)

For KW2D-R KW9Z-CV KW9Z-CV 1

Cover (with holder)

For KW2D-RH KW9Z-CVH KW9Z-CVH 1

Gasket

Rubber (black)

Nitrile rubber HW9Z-WM HW9Z-WMPN10 10

ø21.6

±0.15

ø28.0

±0.15

t 0.5

Locking Ring

Polyamide resin (black) CW9Z-LN CW9Z-LNPN05 10

Locking Ring

Wrench Metal

(brass/nickel-plated)

Weigh: Approx. 150g

MW9Z-T1 MW9Z-T1 1

·Used to tighten the locking ring when mounting onto a

panel.

ø28

110

Compact RFID reader with integrated functions for the factory automation industry

• For more information about certied products, see the IDEC website.

Note: Approvals apply only to the main unit.

Without holder With holder

KW2D Series ø22 Smart RFID Reader

10

General Specifications

Electrical Specications

Rated Input Voltage 24V DC

Power Fluctuation Range 20.4 to 28.8V DC (incl. ripples)

Power Consumption 2.4W maximum (24V DC)

Rated Insulation Voltage 50V DC

Allowable Momentary Power

Interruption 1ms (at rated power supply voltage)

Withstand Voltage 500V AC, 1 minute

Insulation Resistance 100MΩ or higher (500V DC insulation

resistance tester)

Inrush Current 25A maximum

Environmental Specications

Operating Temperature -25 to +55°C

(no freezing)

Storage Temperature -40 to +80°C

(no freezing)

Operating Humidity 10 to 95% RH

(no condensation)

Storage Humidity 10 to 95% RH

(no condensation)

Degree of

Protection

(*1)

Front Unit (*2) IP65/67 (IEC60529)

Back Unit IP20 (IEC60529)

Impact

Test (*1) Front Unit (*2) 5J (Equal to IK08)

Corrosion Resistance No corrosive gas

Operating Environment Indoors

Mechanical Specications

Vibration Resistance 5 to 55Hz, amplitude 0.5mm, on 3

mutually perpendicular axes

Shock Resistance 100m/s2, 11ms, six directions on 3

mutually perpendicular axes

Power

Supply

Terminal

Wire Pull Force

AWG24: 10N maximum

AWG22: 15N maximum

AWG20: 20N maximum

AWG18: 30N maximum

AWG16: 40N maximum

Insertion/Removal

Durability 25 times minimum

Recommended

Operation Force of

Pusher

20N (40N maximum)

Tag

Holder

Insertion/Removal

Durability 10,000 times minimum

Indicators LED colors (red: 2, green: 2 white: 4)

Buzzer Single tone

PCB FR, 94V-0

Case

Materials

Front Cover

Back Cover PBT

Front Base

Back Base PA66

Lens PCT

Weight (Approx.) 70g

*1 IP performance and IK ratings are not subject to UL certication.

*2 Front of the panel only.

Ethernet Communication Specifications

Communication Ethernet

Electrical Characteristics IEEE802.3 compliant

Connector

Connector RJ45

Pull Force 15N

Insertion/

Removal

Durability

100 times minimum

Transmission Speed 10BASE-T, 100BASE-TX

Communication Functions Modbus TCP Server

Cable CAT.5 STP, with a maximum length of 100m

RFID Interface Specifications

Communication Standards

ISO/IEC14443 Type A (Type A),

ISO/IEC18092 (Type F), JIS X6319-4 (Type F),

ISO/IEC 15693 (Type V)

Communication

Speed

Type F

(Felica) 212kbps

Type A

(Mifare) 106kbps

Type V

(I-CODE) 26.5kbps

Carrier Frequency 13.56MHz (HF band)

Wireless

Standards Countries Japan, United States, Canada, EU, China, Taiwan

(Planned support: India, Thailand)

Supported

Tags (*1)

Card

Type

ISO/IEC14443 Type A, ISO/IEC18092,

JIS X6319-4, ISO/IEC15693

KEYFOB

Type ISO/IEC14443 Type A

Tag Reading

Distance (*2)

Card

Type 0 to 15mm

KEYFOB

Type 0 to 5mm

Tag Reading Position (*3) Center of tag stationary in center of front unit

Tag Reading Time 300 to 3000 [msec] (adjustable with [Reading

Time] in the KW RFID Congurator)

*1 Multiple tags cannot be read.

*2 The tag reading distance is a value that was measured using the tags listed in “Names

of LSIs in Tested Tags” (on page 2-3 of the User’s Manual) that IDEC has tested. The tag

reading distance will vary depending on the tag that is actually used and the operating

environment.

*3 The tag reading position is the value using a standard IDEC tag placed near the center of

the reader. The tag reading distance changes with the tag and operating environment.

Mounting Hole Layout

Drill a mounting hole in the panel with the dimensions shown in the

following diagram.

* See the manual for examples of mounting pitch.

* See the manual for minimum mounting pitch.

RFID Tag Specifications

Applicable

Standard

Card ISO/IEC14443 Type A

KEYFOB

Operating

Temperature

Card 0°C to 50°C

KEYFOB -25°C to 55°C

Storage

Temperature

Card -20°C to 50°C

KEYFOB -25°C to 75°C

Operating

Humidity

Card 20% RH to 90% RH or less

KEYFOB 60% RH or less

Storage

Humidity

Card 90% RH or less

KEYFOB 60% RH or less

Reading

Distance

Card 0 to 10mm

KEYFOB 0 to 5mm

Operating Environment Indoors

+0.4

0

ø22.3

KW2D Series ø22 Smart RFID Reader

11

Dimensions (Units: mm)

Main Unit

Without holder: KW2D-R100Q4E

43.6

43.6

48.59.0

Panel thickness: 0.8 to 4.0

25.0

40.0

40.0

With holder: KW2D-RH100Q4E

43.6

43.6

48.516.5

9.0

4.8

5.5 Panel thickness: 0.8 to 4.0

25.0

40.0

40.0

KW2D Series ø22 Smart RFID Reader

12

Dimensions (Units: mm)

Tag

KEYFOB type: KW9Z-T1X1G, KW9Z-T1X2Y, KW9Z-T1X3R, KW9Z-T1X4S, KW9Z-T1X5B

*1 Minimum size with KEYFOB attached.

Card type: KW9Z-T2X0

Cover

KW9Z-CV KW9Z-CVH

43.3

43.3 8.9

16.443.3

43.3

40.0

ø31.0

4.7

48.0

40.0 (*1)

43.6 3.8

7.0

3.6

54.0

85.7 0.8

54.0

85.7

54.0

85.7

43.3

43.3 8.9

16.443.3

43.3

KW2D Series ø22 Smart RFID Reader

13

Installation and Wiring Precautions

Installation Space

Metal around the front unit will affect the reading distance of RFID tags.

If the front unit is surrounded with metal, separate the metal from the

front unit by 20mm or more.

Metal Metal

X: 20mm or more

(42mm or more from the center)

X

X

X

X

XX

When Multiple Tags Are in the Reading Area

The wrong tag may be detected. Keep tags that should not be read

150mm or more from the area around the front unit.

Other tagTag to be read

150mm or more

Removing the Back Unit

1) To remove the back unit from the front unit, press the lock lever (①)

while turning it to the left.

①

②

Lock lever

2) To attach the back unit, align the TOP marks on the front unit and

the back unit, and then insert the back unit into the front unit. Turn

the lock lever to the right to lock it.

• Be sure to turn off the power before starting installation, removal, wiring, maintenance, and inspection work. Failure to turn power off may cause

electrical shocks or fire hazard.

Panel Mounting Method

Insert the front unit into the mounting hole from the front side of the

panel, and install the locking ring from the back side of the panel.

Locking ring recommended tightening torque: 2.0N·m

Locking ring

Panel

TOP mark

Gasket

Attaching the Front Cover

1) Attach hook section B (long) of the front cover to the front unit.

2) Push hook section A (short) onto the front unit.

3) The cover (without holder) and cover (with holder) are installed in the

same way.

Hook

section B

Hook section A (short)

Hook section A (short)

Hook section B (long)

The front cover can be attached with a pitch of 90°.

Precautions for Use

Safety Precautions

KW2D Series ø22 Smart RFID Reader

14

Instructions

Applicable Wire

Power Supply Wiring

• The KW2D Series RFID Reader has a push-in style terminal block.

• An inrush current of 25A or lower (when input is 24V DC) ows when

the power is turned on. Use a power supply with sufcient capacity.

• To prevent induction, keep the power line as short as possible, and as

far away as possible from motor lines.

• The following table shows the signals that correspond to the signal

codes. Be careful not to mistake the connections.

Label/Symbol Signal Wire

24V Power supply (+24V)

0V Power supply (0V)

Functional ground (FE)

When wiring, use the applicable wires shown below.

Applicable Wire and Specifications

Applicable Wire 0.25 to 1.5mm2(AWG16 to 24)

Wire Strip Length (*1) 8 ± 1mm (*2)

Ferrule Size

(*1)

H0.5 to H1.5 (without insulated cover)

H0.25 to H0.75 (with insulated cover)

*1 For details on ferrules, see the “Wire Size and Recommended Ferrules” table below.

*2 Strip the sheath of the wire 8±1mm from the end.

Note: Make sure that the stranded wires do not loosen

when using wiring without ferrules.

- +

24V DC external

power supply

24V DC power input

+24V0VFE

Bottom of pack unit

8

±

1mm

Wire Size and Recommended Ferrules

Ferrules without insulated covers

Applicable Wire

(Stranded Wire) Wire Strip

Length

Weidmüller

Recommended

Part No.

AWG mm2

20 0.50 10 to 11mm H0.5/10

18 0.75 10 to 11mm H0.75/10

17 1.00 10 to 11mm H1.0/10

16 1.50 10 to 11mm H1.5/10

Ferrules with insulated covers

Applicable Wire

(Stranded Wire) Wire Strip

Length

Weidmüller

Recommended

Part No.

AWG mm2

24 0.25 10 to 11mm H0.25/12 HBL

22 0.34 10 to 11mm H0.34/12 TK

20 0.50 10 to 11mm H0.5/14 OR

20 0.50 10 to 11mm H0.5/14S OR

20 0.50 10 to 11mm H0.5/14S W

18 0.75 10 to 11mm H0.75/14 W

*1 UL wire compatible with insulated cover

Recommended Tools (Optional)

The following recommended tools can be used. The recommended

tools are manufactured by Weidmüller.

Name Weidmüller Recommended Part No.

Flat blade

screwdriver

Normal type SDS 0.4 × 2.5 × 75

With insulated cover SDS 0.4 × 2.5 × 75

Crimping tool PZ6/5

0.4mm

2mm

Crimping of Ferrules and Wiring

• Choose an appropriate ferrule for the wire.

• Cut the wire carefully to get a at end.

• Make sure that ferrule sleeve is completely lled by the conductor.

Depending on the cross section, the conductor should protrude

approx. 0 to 1mm from the ferrule sleeve.

0~1mm

• When crimping, refer to the instructions of the crimping tool.

Max. 1.48mm

Max. 2.1mm

Faults which can occur during crimping:

• Cracks along the sides and die impressions

• Splitting of the ferrules

• Asymmetrical crimping shape

• Extreme burrs formed along the sides

• Ferrule not lled by conductor

• Single conductors pushed back by protruding from the insulated cover

• Single conductors squeezed off

• Insulation cover damaged by the crimping jaw

• Conductor insulation not pushed into the insulated cover

• Ferrule bent longitudinally after crimping

Single conductor squeezed off

Single conductor protruding

Asymmetrical crimping shape, burr

formation on one side

Asymmetrical crimping shape, burr

formation on one side

Formation of cracks at the

impressions of the crimping jaw

Formation of cracks at the sides,

sides split open

KW2D Series ø22 Smart RFID Reader

15

1. Notes on contents of Catalogs

(1) Rated values, performance values, and specification values of IDEC products

listed in this Catalog are values acquired under respective conditions in

independent testing, and do not guarantee values gained in combined

conditions.

Also, durability varies depending on the usage environment and usage

conditions.

(2) Reference data and reference values listed in Catalogs are for reference

purposes only, and do not guarantee that the product will always operate

appropriately in that range.

(3) The specifications / appearance and accessories of IDEC products listed in

Catalogs are subject to change or termination of sales without notice, for

improvement or other reasons.

(4) The content of Catalogs is subject to change without notice.

2. Note on applications

(1) If using IDEC products in combination with other products, confirm the

applicable laws / regulations and standards.

Also, confirm that IDEC products are compatible with your systems, machines,

devices, and the like by using under the actual conditions. IDEC shall bear no

liability whatsoever regarding the compatibility with IDEC products.

(2) The usage examples and application examples listed in Catalogs are for

reference purposes only. Therefore, when introducing a product, confirm the

performance and safety of the instruments, devices, and the like before use.

Furthermore, regarding these examples, IDEC does not grant license to use

IDEC products to you, and IDEC offers no warranties regarding the ownership

of intellectual property rights or non-infringement upon the intellectual

property rights of third parties.

(3) When using IDEC products, be cautious when implementing the following.

i. Use of IDEC products with sufficient allowance for rating and

performance

ii. Safety design, including redundant design and malfunction prevention

design that prevents other danger and damage even in the event that an

IDEC product fails

iii. Wiring and installation that ensures the IDEC product used in your

system, machine, device, or the like can perform and function according

to its specifications

(4) Continuing to use an IDEC product even after the performance has

deteriorated can result in abnormal heat, smoke, fires, and the like due to

insulation deterioration or the like. Perform periodic maintenance for IDEC

products and the systems, machines, devices, and the like in which they are

used.

(5) IDEC products are developed and manufactured as general-purpose products

for general industrial products. They are not intended for use in the following

applications, and in the event that you use an IDEC product for these

applications, unless otherwise agreed upon between you and IDEC, IDEC shall

provide no guarantees whatsoever regarding IDEC products.

i. Use in applications that require a high degree of safety, including nuclear

power control equipment, transportation equipment (railroads / airplanes

/ ships / vehicles / vehicle instruments, etc.), equipment for use in outer

space, elevating equipment, medical instruments, safety devices, or

any other equipment, instruments, or the like that could endanger life or

human health

ii. Use in applications that require a high degree of reliability, such as

provision systems for gas / waterworks / electricity, etc., systems that

operate continuously for 24 hours, and settlement systems

iii. Use in applications where the product may be handled or used deviating

from the specifications or conditions / environment listed in the Catalogs,

such as equipment used outdoors or applications in environments

subject to chemical pollution or electromagnetic interference

If you would like to use IDEC products in the above applications, be sure

to consult with an IDEC sales representative.

3. Inspections

We ask that you implement inspections for IDEC products you purchase without

delay, as well as thoroughly keep in mind management/maintenance regarding

handling of the product before and during the inspection.

4. Warranty

(1) Warranty period

The warranty period for IDEC products shall be one (1) year after purchase or

delivery to the specified location. However, this shall not apply in cases where

there is a different specification in the Catalogs or there is another agreement

in place between you and IDEC.

(2) Warranty scope

Should a failure occur in an IDEC product during the above warranty period

for reasons attributable to IDEC, then IDEC shall replace or repair that

product, free of charge, at the purchase location / delivery location of the

product, or an IDEC service base. However, failures caused by the following

reasons shall be deemed outside the scope of this warranty.

i. The product was handled or used deviating from the conditions /

environment listed in the Catalogs

ii. The failure was caused by reasons other than an IDEC product

iii. Modification or repair was performed by a party other than IDEC

iv. The failure was caused by a software program of a party other than

IDEC

v. The product was used outside of its original purpose

vi. Replacement of maintenance parts, installation of accessories, or the like

was not performed properly in accordance with the user’s manual and

Catalogs

vii. The failure could not have been predicted with the scientific and

technical standards at the time when the product was shipped from

IDEC

viii. The failure was due to other causes not attributable to IDEC (including

cases of force majeure such as natural disasters and other disasters)

Furthermore, the warranty described here refers to a warranty on the IDEC

product as a unit, and damages induced by the failure of an IDEC product are

excluded from this warranty.

5. Limitation of liability

The warranty listed in this Agreement is the full and complete warranty for IDEC

products, and IDEC shall bear no liability whatsoever regarding special damages,

indirect damages, incidental damages, or passive damages that occurred due to an

IDEC product.

6. Service scope

The prices of IDEC products do not include the cost of services, such as dispatching

technicians. Therefore, separate fees are required in the following cases.

(1) Instructions for installation / adjustment and accompaniment at test operation

(including creating application software and testing operation, etc.)

(2) Maintenance inspections, adjustments, and repairs

(3) Technical instructions and technical training

(4) Product tests or inspections specified by you

The above content assumes transactions and usage within your region. Please

consult with an IDEC sales representative regarding transactions and usage outside

of your region. Also, IDEC provides no guarantees whatsoever regarding IDEC

products sold outside your region.

Ordering Terms and Conditions

Thank you for using IDEC Products.

By purchasing products listed in our catalogs, datasheets, and the like (hereinafter referred to as “Catalogs”) you agree to be bound by these terms and conditions. Please read

and agree to the terms and conditions before placing your order.

KW2D Series ø22 Smart RFID Reader

For details on installation, wiring, and maintenance, see the Instruction Sheet and

User’s Manual from the URL below.

URL: https://product.idec.com/?product=KW2D

IDEC recommends the use of the RFID reader with the following products.

Flush Silhouette Switches PLCs/Controllers/Operator Interfaces

USB/RJ45 Relay Ports Ethernet Switches Smart Relays PLCs/Controllers

CW

ø22

SX5E FL1F FC6A Plus/All-in-One

Projects only 2mm from

the panel. Ideal for panels that

require cleanliness and safety.

Rugged design.

Suitable for a range of applications.

Unmanaged Ethernet switches

equipped with various features.

Equipped with convenience and

high functionality. Multiple power

supply variations.

FC6A Plus is ideal for controlling not

only large-size machines, but also

entire small-size production lines.

FC6A All-in-One has high

performance and easy programming

features.

PLCs/Controllers/Operator Interfaces Safety Products

PLC / Controllers Operator Interfaces Interlock Switches Safety Switch

FT1A Touch

3.8

inch

HG Series HS5L HS1T

Built-in LCD enables control and

display with high visibility.

Excellent visibility by super-bright

LED backlight. Withstands harsh

environments.

Interlock switch with solenoid.

2-contact: ideal for use on applications

such as food machines and injection

molding machines. 4-contact: ideal for

use on limited mounting spaces such

as small doors.

Interlock switch with solenoid.

Ideal

for use on large doors and large

equipment requiring strong locking

force (5000N). Equipped with head

rotating structure.

www.idec.com

USA IDEC Corporation Tel:

+1-408-747-0550

Germany

APEM GmbH

Singapore IDEC Izumi Asia Pte. Ltd. Tel: +65-6746-1155

Thailand

IDEC Asia (Thailand) Co., Ltd

Australia IDEC Australia Pty. Ltd. Tel:

+61-3-8523-5900

India

IDEC Controls India Private Limited

Taiwan IDEC Taiwan Corporation Tel: +886-2-2577-6938 [email protected]

Hong Kong IDEC Izumi (H.K.) Co., Ltd. Tel: +852-2803-8989

China

IDEC (Shanghai) Corporation Tel:

+

86-21-6135-1515

Beijing Branch

Guangzhou Branch Tel: +86-20-8362-2394 [email protected]

Japan IDEC Corporation Tel:

+81-6-6398-2527

Head Office

6-64, Nishi-Miyahara-2-Chome, Yodogawa-ku, Osaka 532-0004, Japan

Specications and other descriptions in this brochure are subject to change without notice.

Information in this brochure is current as of September, 2020.

2020 IDEC Corporation, All Rights Reserved.

EP1741-0

Other manuals for KW2D Series

3

This manual suits for next models

2

Table of contents

Other IDEC RFID System manuals