SICK RFU6 Series Manual

Technical information

SICK

RFU6xx function block

SICK RFU6xx PROFIBUS / PROFINET

function block for Mitsubishi iQ PLCs

(GX Works2)

Technical information

RFU6xx FB for

GX Works 2 (PNDP)

Page 2

Version history

Version

Date

Description

V1.0

29.09.2017

Initial version

Table of contents

1 About this document........................................................................................................ 3

1.1 Function of this document............................................................................................ 3

1.2 Target group................................................................................................................ 3

2 General information ......................................................................................................... 4

2.1 Supported PLC controls............................................................................................... 4

2.2 PROFINET / PROFIBUS configuration ........................................................................ 4

3 Module description........................................................................................................... 5

3.1 Block specifications...................................................................................................... 5

3.2 Method of function ....................................................................................................... 6

3.3 Timing.......................................................................................................................... 7

3.4 Behavior in the case of an error................................................................................... 7

3.5 Value transfer .............................................................................................................. 8

3.5.1 Mode..................................................................................................................... 9

3.5.2 Single-Tag mode: SOPAS object trigger control...................................................11

3.5.3 Single-Tag mode: SOPAS output format..............................................................11

3.5.4 Read tag...............................................................................................................13

3.5.5 Write tag...............................................................................................................15

3.5.6 Reading result......................................................................................................17

4 Parameter.........................................................................................................................18

5 Error codes......................................................................................................................20

6 Examples .........................................................................................................................24

6.1 Read tag.....................................................................................................................28

6.2 Write tag.....................................................................................................................30

Technical information

RFU6xx FB for

GX Works 2 (PNDP)

Page 3

1 About this document

Please read this chapter carefully before working with this documentation and the

FB_SICK_RFU6xx_PNDP function block.

1.1 Function of this document

This operating instruction explains how to use the FB_SICK_RFU6xx_PNDP function block.

1.2 Target group

This technical instruction is intended for qualified personnel such as planning engineers, de-

velopers and operators of machines and systems who needs a communication between a

SICK RFU6xx device and a Mitsubishi iQ-Serie PLC via PROFINET / PROFIBUS.

Technical information

RFU6xx FB for

GX Works 2 (PNDP)

Page 4

2 General information

The function block FB_SICK_RFU6xx_PNDP supports data exchange between a SICK

RFU6xx RFID interrogator and a Mitsubishi Q-Series PLC via PROFIBUS or PROFINET.

Functionality of the function block:

- Send a software trigger via the PLC

- Receive telegrams sent by the device which can be configured in the SOPAS

i

output

format (reading results)

- Read and write transponder content (Single-Tag / Multi-Tag mode)

2.1 Supported PLC controls

This function block can be used in combination with iQ-Series PLC which is able to connect a

PROFIBUS or PROFINET device directly or via a gateway module (e.g. QJ71PB92D).

2.2 PROFINET / PROFIBUS configuration

Before starting with the function block, it is necessary to setup the hardware in the I/O con-

figuration. The function block communicates with connected device via process data varia-

bles. These variables contain the cyclic process data of the fieldbus device. The length of the

selected containers indicates the amount of data, which can be exchanged in one fieldbus

cycle.

Please note!

The FB is only compatible with the following process data containers:

- 32 byte input

- 32 byte output

Other modules can be plugged (e.g. parameter modules or Control In/Out

modules) and have no influence on the functionality of the FB.

If a telegram is longer than the projected module, the data will be transmitted fragmented

over several PLC cycles. The data flow is managed via a handshake mechanism by the func-

tion block.

Please use a free address for the data mapping with a global variable.

Figure 1: Example PROFIBUS configuration

Figure 2: Global label settings

i

SOPAS is an engineering tool used for configuring SICK sensors.

Technical information

RFU6xx FB for

GX Works 2 (PNDP)

Page 5

3 Module description

The FB_SICK_RFU6xx_PNDP function block simplifies the usage of a SICK RFU6xx RFID

interrogator on Mitsubishi iQ-Series PLCs.

The function block is working asynchronously, which means the processing is done via vari-

ous function block call ups. Therefore it is necessary that the function block is called cyclical-

ly in the user program.

The RFU library can only be used in combination with the SICK_AutoIdentBase_PNDP li-

brary. This library contains the FB_SICK_CCOM_PNDP, which facilitates the communication

between the PLC and the device. The F_SICK_GetValue/F_SICK_SetValue functions are

used internally to serialize and de-serialize device telegrams.

3.1 Block specifications

Block name: FB_SICK_RFU6xx_PNDP

Version: 1.0

Used libraries: SICK_AutoIdentBase_PNDP

Used structures: ST_SICK_RFU6xx

Uses special registers: -

Block call: Cyclic

Block language: ST (Structured text)

Developed under: GX Works2 V1.536J

The following figure shows how the function block is represented in the function block dia-

gram (FBD) view.

Figure 3: Represenation of the function block in FBD

Technical information

RFU6xx FB for

GX Works 2 (PNDP)

Page 6

3.2 Method of function

The following parameters must be specified before the FB_SICK_RFU6xx_PNDP function

block can be used.

InputData: Data link to the 16 Word (32Byte) input module of the fieldbus device

OutputData: Data link to the 16 Word (32Byte) output module of the fieldbus device

TOut: Timeout (e.g. T#5s). The process will be interrupted if this time is

elapsed without obtaining a valid device response.

Data: The function block requires a variable from the data type

ST_SICK_RFU6xx. This data type describes input and output parame-

ters for the individual block functions. Please create a variable and link it

to the “Data” input of the function block.

To carry out a function (TriggerOn, ReadTag etc.), the desired function bit must be selected

first. Only one function can be carried out at the same time. The “Req”parameter must be

triggered with a rising edge (signal change from logic zero to one) in order to carry out the

selected function. As long as no valid response has been received, the “ReqBusy”parameter

is used to signal this.

The output parameter “ReqDone” indicates that the function has been successfully complet-

ed. If data was requested from the device during this function (e.g. ReadTag), this data is

copied to the linked data structure (Data).

Data sent via trigger command (TriggerOn, TriggerOff) or directly by the device (e.g. direct

trigger via a photoelectric sensor) is stored in the data structure “ReadResult_Result”. The

“RdDone” output parameter indicates for one PLC cycle that new data has been received.

The data sent by the device can be changed or adapted in SOPAS output format.

Technical information

RFU6xx FB for

GX Works 2 (PNDP)

Page 7

3.3 Timing

Figure 4: Timing diagram

1: The selected function (in this case “TriggerOn”) is executed if the “Req” input is triggered

by a rising edge. The “TriggerOn” bit must be selected at the same time/in advance. Only

one function can be executed at the same time, otherwise an error will terminate the se-

quence.

2: The “ReqDone” flag indicates that the sequence has been successfully completed. If an

error occurred, the sequence is terminated with “Error”. The parameter “Errorcode” contains

the error code.

3.4 Behavior in the case of an error

If the function module has an incorrect input value or faulty input circuit, an error bit (Error) is

set and an error code (Errorcode) is output. In this case, no further processing is carried out.

The parameters (Error, Errorcode) of the function module retain their value until a new com-

mand is started.

Technical information

RFU6xx FB for

GX Works 2 (PNDP)

Page 8

3.5 Value transfer

The “Data” parameter of the function block contains all input and output parameters for the

supported block functions. The data structure has a fixed definition and may not be modified.

Figure 5: ST_SICK_RFU6xx PLC data type

Technical information

RFU6xx FB for

GX Works 2 (PNDP)

Page 9

3.5.1 Mode

The RFU can only communicate with a single transponder at the same time. For this reason,

read and write commands are always addressed. The function block uses the transponder

UII (Unique Item Identifier) in order to identify the transponder.

The function block supports two different modes in order to determine which transponder UII

is to be communicated with:

Single-Tag mode:

The system always communicates with the transponder which is currently in the reading

field. This mode can only be used when precisely one tag is located in the reading field. A

special configuration of the RFU output format with SOPAS (see chapter 3.5.3) is required

for this mode. If the Single-Tag mode is active, a trigger is automatically activated to read the

UII and the antenna with the best signal strength (RSSI).

Multi-Tag mode:

A user defined transponder UII is used for purposes of communication. The antenna to be

used must be defined in the respective read/write parameters.

Parameter

Declara-

tion

Data type

Description

Mode

Input

Bit

Addressing mode.

FALSE: Single-Tag mode active

TRUE: Multi-Tag mode active

Mode_

UIILength

Input /

Output

Word

[Signed]

Word length of the UII.

0 = Unaddressed

1...16 = Word length of the UII defined in

the Mode_UII array.

Technical information

RFU6xx FB for

GX Works 2 (PNDP)

Page 10

Parameter

Declara-

tion

Data type

Description

Mode_UII

Input /

Output

Word

[Signed]

(0..15)

Transponder Identification (UII) in a hexa-

decimal format.

The length of the UII must be defined by the

Mode_UIILength parameter.

The UII is automatically determined in

the Single-Tag mode and does not have

to be assigned.

Example:

UII (hex)= 1234 0000 0000 0000 0000 0002

Mode_RSSI

Output

Word

[Signed]

(0..3)

Outputs the RSSI values (reception

strength) of the transponder in the reading

field (only in Mode 1).

[1] = RSSI value from antenna 1 (internal)

[2] = RSSI value from antenna 2 (external)

[3] = RSSI value from antenna 3 (external)

[4] = RSSI value from antenna 4 (external)

Table 1: Mode parameters

Technical information

RFU6xx FB for

GX Works 2 (PNDP)

Page 11

3.5.2 Single-Tag mode: SOPAS object trigger control

The object trigger control settings define the status of reading gate (open / closed). The de-

vice sends a reading result to the PLC after each reading gate. The function block uses this

mechanism in order to read the UII, the PC-Word and RSSI values of the corresponding

transponder.

The SOPAS settings under menu item Parameter

Reading configuration

Object trigger

control must be defined, that the trigger window is opened via a "Command" and closed

when a "Good Read" result is received or after a defined period of time (e.g. 1000ms).

Figure 6: Object Trigger settings (SOPAS)

3.5.3 Single-Tag mode: SOPAS output format

The output format defines the content of the telegram that is sent by the device as soon as

the trigger window is closed. This telegram is evaluated by the PLC. Afterwards the function

block used the information to create addressed read / write commands. The SOPAS output

format must be structured as shown in Figure 7 in order to use the function block with the

Single-Tag mode.

Figure 7: Output format configuration (SOPAS)

Technical information

RFU6xx FB for

GX Works 2 (PNDP)

Page 12

Please ensure that the format of the blocks "RSAVG1...4" are set to hexadecimal format

(double-click the respective block). The "PCUII" block may not be changed.

Figure 8: Settings for RSSI blocks (RSAVG1...4)

Depending on the number of tags located in the receiving range of the RFU and the config-

ured RSSI threshold, the following ASCII telegrams are sent by the device:

Case 1: (Only one tag in the field):

[STX]01;[RSSI Antenna 1] [RSSI Antenna 2] [RSSI Antenna 3] [RSSI Antenna 4]

[PC+UII][ETX]

Case 2: (More than one tags in the field):

[STX]0X[ETX]

Case 3: (No tag in the field):

[STX]00[ETX]

Technical information

RFU6xx FB for

GX Works 2 (PNDP)

Page 13

3.5.4 Read tag

The “Read Tag”function is used to read a defined data area of the tag. The selected mode

determines which transponder should be used by the system (see chapter 3.5.1).

The following parameters must be defined before you can start a read request:

Parameter

Declaration

Data

type

Description

ReadTag_

Bank

Input

Word

[Signed]

Selection of the memory bank that should

be used.

0 = Reserved

1 = UII/EPC

2 = TID

3 = User memory

ReadTag_

StartWord

Input

Word

[Signed]

First word (16Bit) that should be read.

ReadTag_

WordCount

Input

Word

[Signed]

Number of words (16Bit) that should be

read.

Valid value range:

[1..32]

ReadTag_

Retry

Input

Word

[Signed]

Number of read attempts to be carried out.

Valid value range:

Lo Nibble (retries on one channel) 16#[0..7]

Hi Nibble (retries on different channels)

16#[0..5]

Example:

Retry = 16#0032 executes 3 changes of the

channel (4 channels) with 2 retries per

channel in each case (3 repetitions), i.e. a

total of 4x3= 12 attempts.

Technical information

RFU6xx FB for

GX Works 2 (PNDP)

Page 14

Parameter

Declaration

Data

type

Description

ReadTag_

Antenna

Input /

Output

Word

[Signed]

Antenna selection for the current read re-

quest. Only one antenna can be selected

per request.

A1 = Antenna 1 (internal/external, depend-

ing on device type)

A2 = Antenna 2 (external)

A3 = Antenna 3 (external)

A4 = Antenna 4 (external)

Value

A4

A3

A2

A1

1

X

2

X

4

X

8

X

In the Single-Tag mode, the antenna is

selected automatically (antenna with the

best signal strength).

Valid value range:

[1…15]

ReadTag_

DataLength

Output

Word

[Signed]

Valid length of read content in words

(16Bit). Required in order to define which

content of the array "ReadTag_Data" is

valid.

ReadTag_

Data

Output

Word

[Signed]

(0..31)

Tag content.

Table 2: Read tag parameters

Please note!

If you want to read out more than 32Words (64Byte) tag data, please execute

this function several times with different offsets (ReadTag_StartWord).

Technical information

RFU6xx FB for

GX Works 2 (PNDP)

Page 15

3.5.5 Write tag

The "Write Tag" function is used to write values to a defined data area of the tag. The select-

ed mode determines which transponder should be used by the system (see chapter 3.5.1).

The following parameters must be defined before you can start a write request:

Parameter

Declaration

Data type

Description

WriteTag_

Bank

Input

Word

[Signed]

Selection of the memory bank that should

be written.

0 = Reserved

1 = UII/EPC

2 = TID (Read only)

3 = User memory

WriteTag_

StartWord

Input

Word

[Signed]

First word (16Bit) that should be written.

WriteTag_

WordCount

Input

Word

[Signed]

Number of words (16Bit) that should be

written.

Valid value range:

[1..32]

WriteTag_

Retry

Input

Word

[Signed]

Number of write attempts to be carried out.

Valid value range:

Lo Nibble (retries on one channel) 16#[0..7]

Hi Nibble (retries on different channels)

16#[0..5]

Example:

Retry = 16#32 executes 3 changes of the

channel (4 channels) with 2 retries per

channel in each case (3 repetitions), i.e. a

total of 4x3= 12 attempts.

Technical information

RFU6xx FB for

GX Works 2 (PNDP)

Page 16

Parameter

Declaration

Data type

Description

WriteTag_

Antenna

Input/Output

Word

[Signed]

Antenna selection for the current write re-

quest. Only one antenna can be selected

per request.

A1 = Antenna 1 (internal/external, depend-

ing on device type)

A2 = Antenna 2 (external)

A3 = Antenna 3 (external)

A4 = Antenna 4 (external)

Value

A4

A3

A2

A1

1

X

2

X

4

X

8

X

In the Single-Tag mode, the antenna is

selected automatically (antenna with the

best signal strength).

Valid value range:

[1…15]

WriteTag_

Data

Input

Word

[Signed]

(0..31)

Data that should be written to the selected

tag area. The length must be defined by the

WriteTag_WordCount parameter.

Table 3: Write tag parameters

Please note!

If you want to write more than 32Words (64Byte) tag data, please execute this

function several times with different offsets (WriteTag_StartWord).

Technical information

RFU6xx FB for

GX Works 2 (PNDP)

Page 17

3.5.6 Reading result

The "ReadResult_Result" array stores data that is sent via a trigger command (TriggerOn,

TriggerOff) or directly from the device (e.g. direct trigger via photoelectric sensor). The output

parameter “RdDone”indicates that new data arrived for one PLC cycle.

Parameter

Declaration

Data type

Description

ReadResult_

Counter

Output

Word

[Signed]

This counter is incremented when a

new telegram is arrived.

Value range:

[0..32767]

ReadResult_

Length

Output

Word

[Signed]

Byte length of received reading result.

ReadResult_

Result

Output

Word

[Signed]

(0..99)

Received data (can be defined in

SOPAS).

The maximum length of the received

data is 200Bytes (100Words).

Table 4: Reading result parameters

Technical information

RFU6xx FB for

GX Works 2 (PNDP)

Page 18

4 Parameter

Parameter

Decla-

ration

Data type

Description

InputData

Input

Word[Signed]

(0..15)

Data link to the 16 Word (32Byte) input module

of the fieldbus device.

OutputData

Output

Word[Signed]

(0..15)

Data link to the 16 Word (32Byte) output mod-

ule of the fieldbus device.

TOut

Input

Time

Time, after which a timeout error will be set

(e.g. T#5s).

Req

Input

Bit

Rising edge: Start the selected block function.

TriggerOn

Input

Bit

Block function: Open a reading gate

This function requires the following SOPAS

setting:

Object Trigger ControlStart by “Command”

The result sent from the device (defined in the

SOPAS output format) is stored in the

"ReadResult_Result" array.

TriggerOff

Input

Bit

Block function: Close a reading gate.

This function requires the following SOPAS

setting:

Object Trigger ControlStop by “Command”

The result sent from the device (defined in the

SOPAS output format) is stored in the

"ReadResult_Result" array.

ReadTag

Input

Bit

Block function: Read tag data.

Please define the parameters defined in chap-

ter 3.5.4.

WriteTag

Input

Bit

Block function: Write tag data.

Please define the parameters defined in chap-

ter 3.5.5.

Data

Input /

Output

ST_SICK_

RFU6xx

This In- /Output variable needs a link to param-

eter from the data type ST_SICK_RFU6xx.

This data type describes input and output pa-

rameters for the individual block functions.

RdDone

Output

Bit

Rising edge: New reading result received.

The reading result and the valid length are

stored in the variable "ReadResult_Length” /

“ReadResult_Result".

ReqDone

Output

Bit

Indicates whether a request has been success-

fully completed.

TRUE: Successfully completed

FALSE: Not completed

Technical information

RFU6xx FB for

GX Works 2 (PNDP)

Page 19

Parameter

Decla-

ration

Data type

Description

ReqBusy

Output

Bit

Request in progress.

Error

Output

Bit

Error flag.

FALSE: No error

TRUE: Error occurred

Errorcode

Output

Word[Signed]

(0..1)

Error status (see Error codes)

Table 5: Function block parameter list

Technical information

RFU6xx FB for

GX Works 2 (PNDP)

Page 20

5 Error codes

The “Errorcode”parameter contains the following error information:

- Errors of the FB_SICK_RFU6xx_PNDP function block

- Errors of the FB_SICK_CCOM_PNDP function block

- Errors of the F_SICK_GetValue / F_SICK_SetValue functions

- Errors sent by the device

Error code

Brief description

Description

[0] = 16#0000

[1] = 16#0000

No error

No error

[0] = 16#0001

[1] = 16#0000

Time out detected

(FB_SICK_CCOM_PNDP)

The command could not be executed within

the defined timeout period.

Possible causes:

- Device is not connected to the PLC

- Device is not sending command re-

sponses (echo)

- Processing time of the command >

timeout period

[0] = 16#0002

[1] = 16#0000

Reserved

(FB_SICK_CCOM_PNDP)

Reserved

[0] = 16#0003

[1] = 16#0000

Reserved

(FB_SICK_CCOM_PNDP)

Reserved

[0] = 16#0004

[1] = 16#0000

Reserved

(FB_SICK_CCOM_PNDP)

Reserved

[0] = 16#0005

[1] = 16#0000

Reserved

(FB_SICK_CCOM_PNDP)

Reserved

[0] = 16#0006

[1] = 16#0000

Received telegram

> Record size

(FB_SICK_CCOM_PNDP)

The received command response does not

completely fit into the record array.

[0] = 16#0007

[1] = 16#0000

Invalid input parameter

(CommandLength)

(FB_SICK_CCOM_PNDP)

The command length value is less or equal

than 0.

[0] = 16#0008

[1] = 16#0000

Invalid input parameter

(CommandLength)

(FB_SICK_CCOM_PNDP)

The command length value is greater than

the size of the command array.

[0] = 16#0009

[1] = 16#0000

Fragmentation error

(FB_SICK_CCOM_PNDP)

Data fragmentation error occurred.

[0] = 16#000A

-

16#000F

[1] = 16#0000

Reserved

(FB_SICK_CCOM_PNDP)

Reserved

[0] = 16#0010

[1] = 16#0000

Time out detected

The command could not be executed within

the defined timeout period.

Possible causes:

- Device is not connected to the PLC

- Device is not sending command re-

sponses (echo)

- Processing time of the command >

timeout period

Table of contents

Other SICK RFID System manuals

Popular RFID System manuals by other brands

Siemens

Siemens SIMATIC RF1000 Series Configuration manual

Solo

Solo 5010V1 user manual

HID

HID Technology solutions 1101 user guide

Rockwell Automation

Rockwell Automation Allen-Bradley 58UHF user manual

Feig Electronic

Feig Electronic OBID i-scan ID ISC.LRM2500-A installation manual

IFM

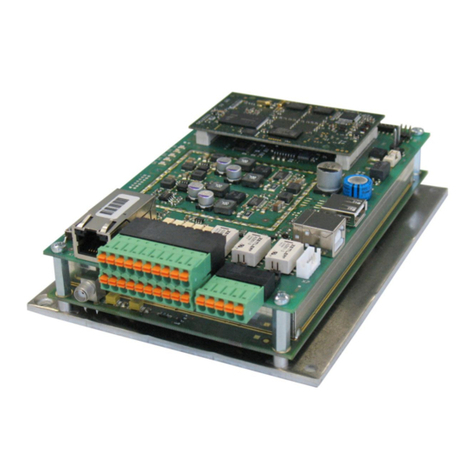

IFM DTM424 operating instructions

Panasonic

Panasonic FZ-VFP401 Series operating instructions

Datalogic

Datalogic DLR-BT001 Series Quick reference guide

HID

HID iCLASS SE U90 Series installation guide

IFM

IFM ANT600 installation instructions

Feig Electronic

Feig Electronic ID LRU500i-BD Series Installation

Dormakaba

Dormakaba Quantum II RFID ECU installation instructions