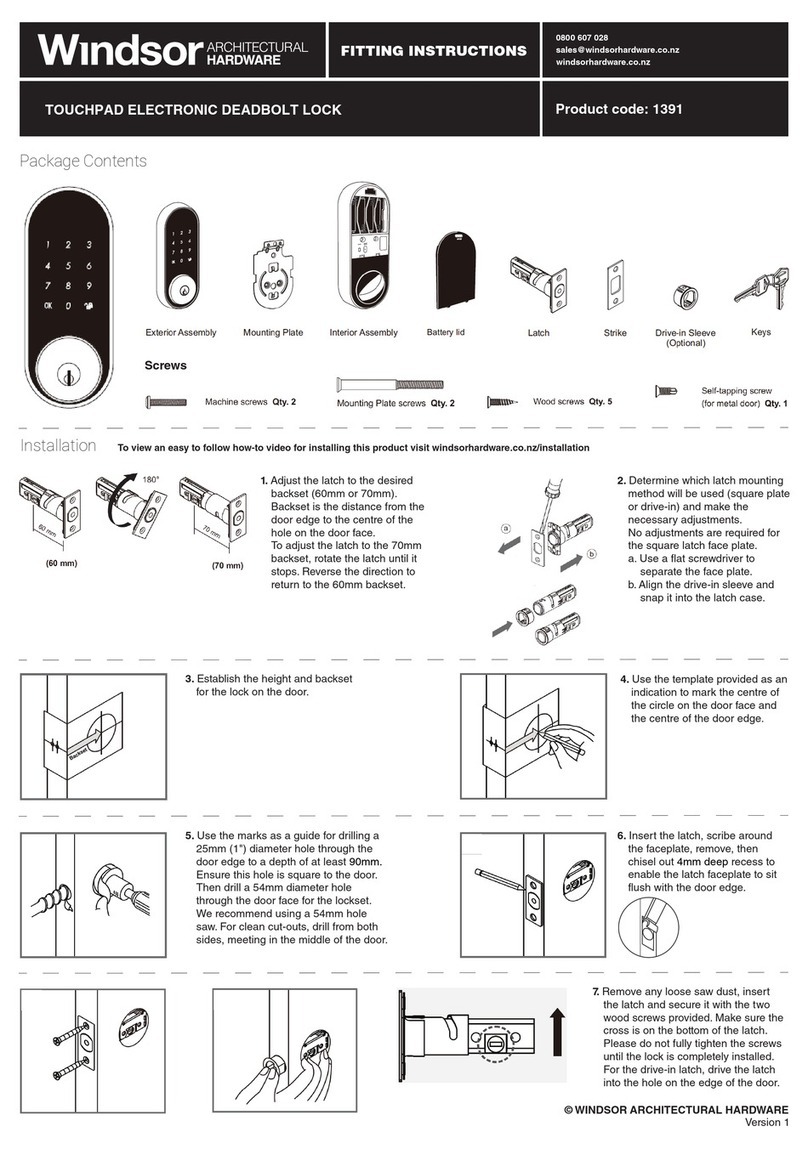

IDEM SAFETY SWITCHES UGB2-KLT-SS-RFID User manual

Gate Box with Safety Interlocking & RFID

WARNING:

DO NOT D F AT, TAMP R, OR BYPASS TH

SAF TY FUNCTION. FAILUR TO DO SO CAN

R SULT IN D ATH OR S RIOUS INJURY.

Original Instructions

To request this datasheet in other languages p

lease contact

Um dieses Datenblatt in Deutscher Sprache wenden Sie sich bitte anfordem info@idemsafety.com

Pour obtenir cette fiche en Francais, euillez contacter inf[email protected]

Para solicitor esta hoja de datos en Espanol, por contacto con info@idemsafety.com

AV RTISS M NT:

N PAS D SACTIV R, MODIFI R, R TIR R, OU

CONTOURN R C TI INT RV RROUILLAG IL

P UT N R SULT R D S BL SSUR S

GRAV S DU P RSONN L UTILISAT UR

Appl

ication:

The UGB-KLT Gate Box (incorporating an RFID interlock switch) is designed to fit to the leading edge of machine guard doors to pro ide robust guard locking and pro ide a double

tamper resistant interlock mechanism. They are designed to pro ide position interlock detection for mo ing guards and will keep the guard locked until a oltage is applied to the switch

solenoid. They will hold guards closed up to 4000N .They can be used in conjunction with delay timers to pro ide the solenoid energise signal only after a pre-determined the time has

run down.

The UGB-KLT housings incorporate standard 22mm pushbuttons, switches or lamps to facilitate machine request functions and diagnostics all in one housing.

Operation:

The UGB-KLT is rigidly mounted to the fixed frame of the guard or machine. The actuator is fitted to the mo ing part (frame) of the guard and is aligned to the switch entry aperture. The

mechanical tongue actuator profile is designed to match a cam mechanism within the switch head and pro ides a positi ely operated not easily defeatable mechanical interlock.

There is also an RFID coded actuator which aligns with a programmed recei er inside the switch housing during closing of the guard. Only when both actuators are in place and the

RFID coding is erified correctly can the safety contacts close and allow the machine start circuit to be enabled. When the solenoid is energised the safety contacts are positi ely

opened and the machine control circuit is broken. Optional features are Sliding Handles, Rotary Handles and Rear Escape function

UGB

-

KLT

-

SS

-

RFID

Operating Instructions

I

mportant:

Record any RFID codes as required by factory rules or with reference to any risk assessment for the particular application.

The risk assessment for the particular application should include the risk of spare actuators. Spare actuators should not be readily a ailable and must be securely controlled.

The safety functions and mechanics must be tested regularly. For application where infrequent guard access is foreseeable, the system must ha e a manual function test to detect a

possible accumulation of faults. At least once per month for PLe Cat 3/4 or once per year for PLd Cat 3 (ISO13849-1). Where possible it is recommended that the control system of the

machine demands and monitors these tests, and stop or pre ents the machine from starting if the test is not done (see ISO14119).

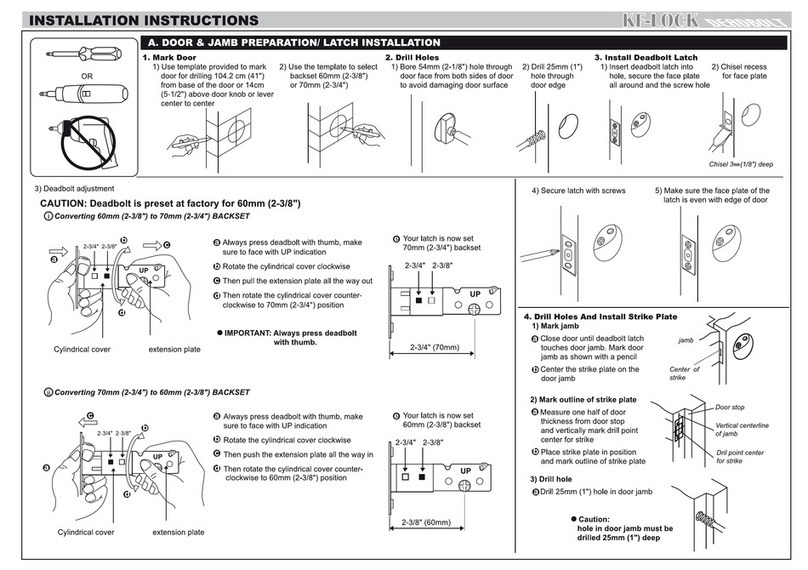

Installation:

1. Installation of all IDEM interlock switches must be in accordance with a risk assessment for the indi idual application.

Installation must only be carried out by competent personnel and in accordance with these instructions.

2. M5 mounting bolts must be used to fix the switch and actuator mounting. The tightening torque to ensure reliable fixing is 4.0 Nm.

Tightening torque for the lid screws and cable glands must be 1.5 Nm to ensure the IP seal. The actuator entry position (Front or End) can be selected by using the internal

slide switch inside the switch co er (See Fig.1). Always fit the aperture plug to the unused entry aperture to pre ent debris entering the switch mechanism.

3. If installing the UGB-KLT without using a Sliding or Rotary Handle then always fit a mechanical stop to the guard to pre ent damage to the front of the switch.

Always ensure correct alignment of actuator and handle with front apertures of the switch and guide. Use alignment guides to ensure that the actuator enters the switch

without interfering with the sides of the aperture.

If fitted, the Manual o erride function is achie ed by use of a tool and is to be used in exceptional circumstances.

The release can be protected by use of a tamper coating to protect against unintended operation.

If operated this tamper protection must be restored.

4. If fitting Sliding or Rotary Handles, ensure that M6 mounting bolts are used to fix the appropriate mounting plates. The tightening torque to ensure reliable fixing is 4.0 Nm.

5. The Front and Rear Rotary Handles can be adjusted for desired position by loosening the locking bolt which fixes the handle to the switch body.

6. The RFID code is factory set. For instances where replacement of the RFID actuator is required please contact IDEM ia e-mail: technical@idemsafety.com

7. The Interlock Switch is supplied with remo able conductor links fitted 41/42 and 31/32. If required by the control circuit these may be remo ed to offer independent monitoring

of the solenoid locking function or the actuator position.

8. Always check the electrical ratings of any 22mm de ices fitted. Ne er exceed these ratings.

9. After installation check operation of all control circuits, the locking function and rear escape functions.

For applications with a run down time after remo ing power, ensure that the correct timing allowance has been made before the solenoid is energised.

Maintenance:

E ery month: Check correct operation of all circuits and the Lock function. If any part of the UGB-KLT displays mechanical damage then remo e and replace.

IDEM will not accept responsibility for failure of the switch functions if the installation and maintenance requirements shown in this sheet are not implemented.

E ery 6 months: Isolate power and remo e co er. Check screw terminal tightness and check for signs of moisture ingress. Re-check Installation conditions abo e.

Ne er attempt to repair any switch.

TH S INSTRUCTIONS FORM PART OF TH PRODUCT WARRANTY.

UGB4

-

KLT

-

SS

-

RFID

with Sliding Handle

UGB4

-

KLT

-

SS

-

RFID with Rotary Front Handle

UGB4

-

KLT

-

SS

-

RFID

UGB

2

-

KLT

-

SS

-

RFID

Gate Box with Safety Interlocking & RFID

L D DIAGNOSTICS (Interlock switch)

Switch State

L D 1 (Green

/Yellow

)

Comment

Solenoid State

L D 2

(Red)

Guard Open

Off

Energised

ON

Guard Closed + Locked

Steady Green

Saf

ety outputs ON

De

-

energised

OFF

Guard Closed + Unlocked

Flashing Green

Guard Closed + Misalligned / Wrong Actuator

Alternate Flashing Green/Yellow

Fault

Steady Yellow

See reset procedure

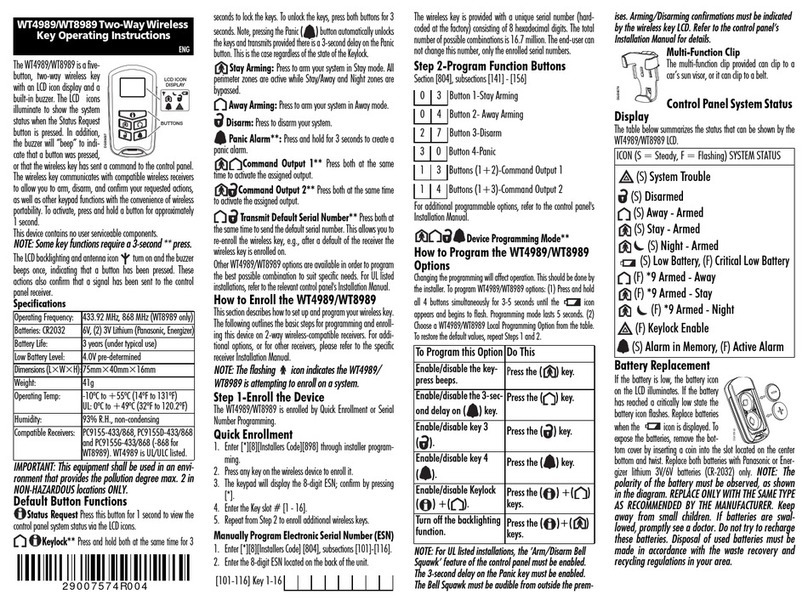

SP CIAL INSTRUCTION: RFID actuator

–

R S T.

In the e ent that a Fault condition requires reset, follow the reset instructions:

1) Turn off all power to the switch and open the guard.

2) Remo e the switch co er.

3) Using a 2mm terminal screwdri er hold down the RESET button inside the switch housing and turn on the switch

power (see Fig.2).

4) Release the RESET button, the yellow LED will flash, close the guard and the yellow LED will turn steady yellow.

(If yellow LED continues to flash check for mechanical fault (e.g. damaged actuator or switch head)).

5) Turn power off and then on, the green LED will illuminate.

6) Re-fit the switch co er.

7) Open and close the guard ensuring all safety functions are correct –refer to any risk assessment for the particular

guard application.

Slide Switch Position 2:

FRONT ntry

Slide Switch Position 1:

ND ntry

Technical Data: Standards IEC60947

-

5

-

1 ISO14119 ISO13849

-

1

IEC62061

UL508

ntry Selector Switch

Select Front or End sensing. (See

Fig 1)

R S T button

(If required press and hold using a 2mm

terminal screw dri er)

Supply Voltage

24Vdc (+/

-

10%)

Power Consumption

R+ 1.2W (50mA Max.)

S+ 12W (500mA Max.)

Safety Circuits (11

-

31 & 21

-

41)

240V 3A. A300 Pilot Duty Fuse externally 10A.(FF)

Safety Circuits (32

-

12 & 42

-

22)

2

4V 2.5A (RFID Coding)

Auxiliary Circuits (34 & 44)

24Vdc 0.2A Max.

Rated Insulation Voltage

500VAC

Rated Impulse withstand

1000VAC

Holding Force

F1Max 4

000N

Fzh

3076

N

Operating Frequency

1Hz

Actuator entry minimum radius

175mm

Body Ma

terial

Stainless Steel 316

Head Material

Stainless Steel 316

Mechanical Actuator Material

Stainless Steel 316

Enclosure Protection

IP66

Operating Temperature

-

25°C to +40°C

Mechanical Life Expectancy (B10d)

2.5 x 10

6

cycles at 100mA load

Vibration

IEC68

-

2

-

6, 10

-

55Hz+1Hz

Excursion: 0.35mm, 1 octa e/min

Fig. 2. Co er Remo ed

Characteristic data according to IEC62021 (used as a subsystem)

Interlock Switch Circuit

–

Terminal connections.

(Use 16-28AWG copper conductors. Terminal Torque 6 lb ins. (0.7Nm)).

0V

Supply 0V.dc

R+ 24V.dc

Supply 24V.dc

S+ 24V.dc

Unlock signal (solenoid) apply +24V.dc

11/12

Safety

interlock

and lock monitoring circuit

21/22

Safety

interlock

and lock monitoring circuit

44

Guard open signal

+24V.dc out

34

Unlocked signal +24V.dc out

12

Earth bonding connection

Safety Integrity Le el

SIL 3

PFH (1/h)

4.77E

-

10

Corresponds to 4.8% of SIL3

PFD

4.18E

-

05

Corresponds to 4.2% of SIL3

Proof Test Inter al T

1

20a

Character

istic data according to EN ISO13849

-

1

Performance Le el e

If both channels are used in conjunction with

a SIL3/PLe control de ice.

Category

Cat 4.

MTTF

d

1100a

Diagnostic Co erage DC

99% (High)

Number of operating days per year:

d

op

= 365d

Number of operating hours per day:

h

op

= 24h

When the product is usage differs from these assumptions (different load, operating frequency, etc.) the alues

ha e to be adjusted accordingly

ND

FRONT

Head of

the s

witch

this way.

Fig. 1. Entry Selector Switch

Information with regar

d to UL 508: Type 1 enclosure.

Maximum temperature 40°C.

Use 16-28AWG copper conductors (rated 90°C). Terminal Torque 6 lb ins. (0.7Nm).

Intended for same polarity use.

A300 Pilot Duty. 240V. 3A. PF 0.38 or greater tested for 6,000 cycles endurance.

Use one polymeric conduit connection. Not suitable for connection to rigid metal conduit.

(Earth bonding terminal inside enclosure if required – use 16-12AWG conductors).

Interlock Schemat

ic

-

(internal wire links not remo ed)

.

Note: Circuits 21/41 and 11/31 are lock monitoring contacts. (Closed when switch is locked).

Circuits 42/22 and 32/12 are interlock monitoring circuits (Closed when guard is closed).

Specification:

Gate Box with Safety Interlocking & RFID

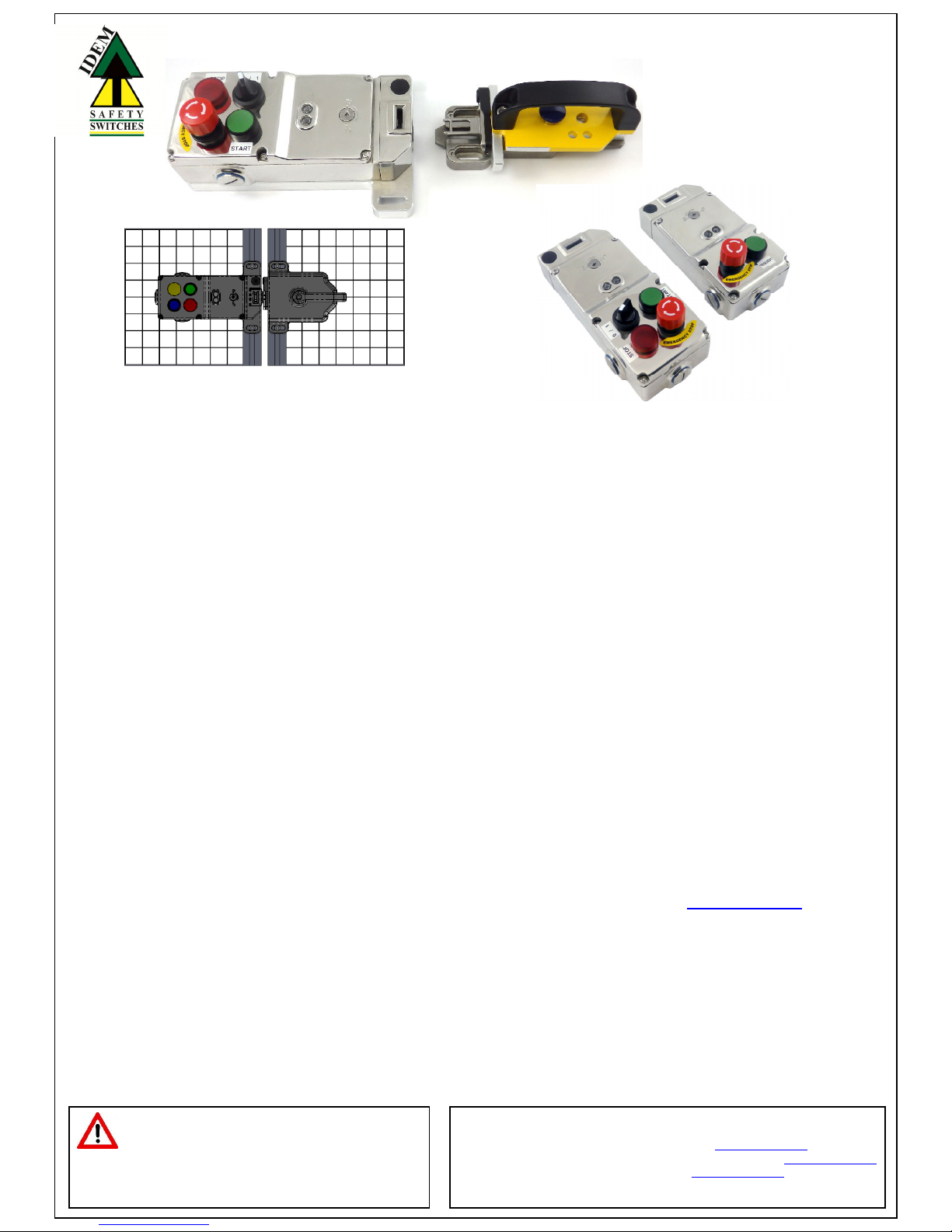

Application xample: 4 STATION (UGB4) with Front Rotary Handle, Rear

scape Button and Rear scape Rotary Handle

Viewed from OUTSID GUARD D AR A

Viewed from IN

SID GUARD D AR A

Gate Box with Safety Interlocking & RFID

Application xample: 2 STATION (UGB2) with Front Rotary Handle, Rear scape

Button and Rear scape Rotary Handle

Viewed from OUTSID GUARD D AR A

Viewed from INSID GUARD D AR A

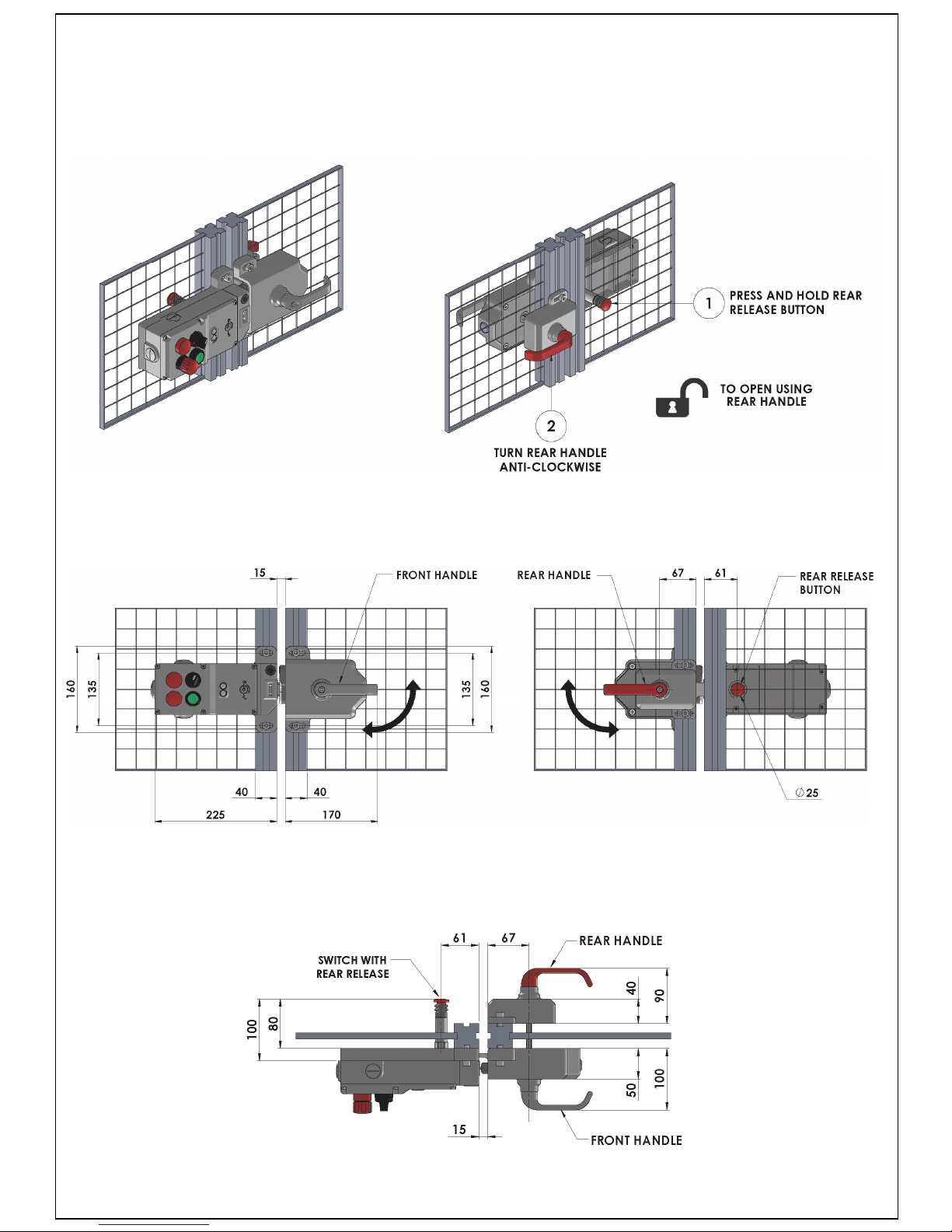

Gate Box with Safety Interlocking & RFID

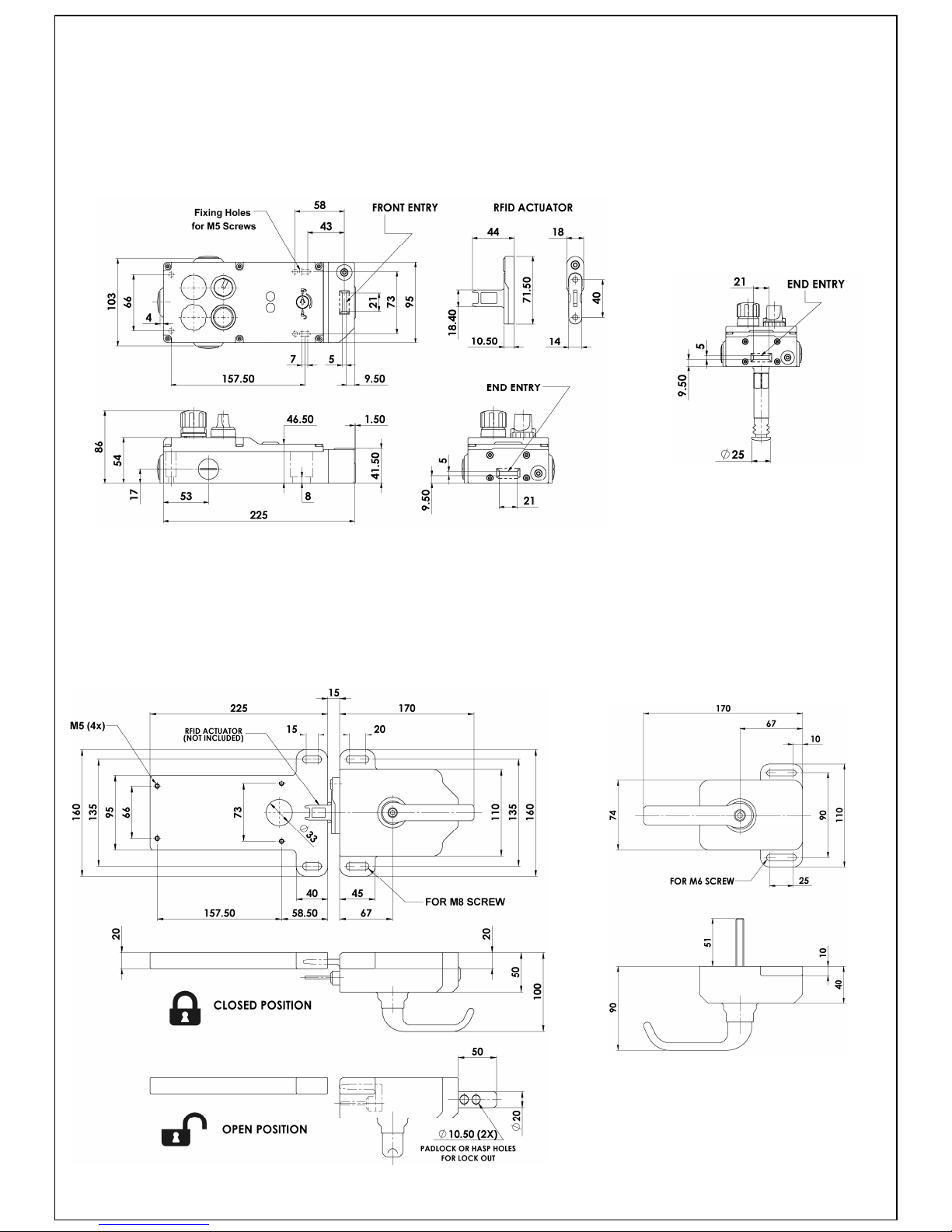

Product Dimensions

–

Type: UGB 4

-

KLT

-

SS

-

RFID

Rear Release

Product Dimensions

–

Type: UGB 4 Rotary Handle SS (4 x APP)

Product Dimensions

–

Type: UGB Rotary Rear Handle

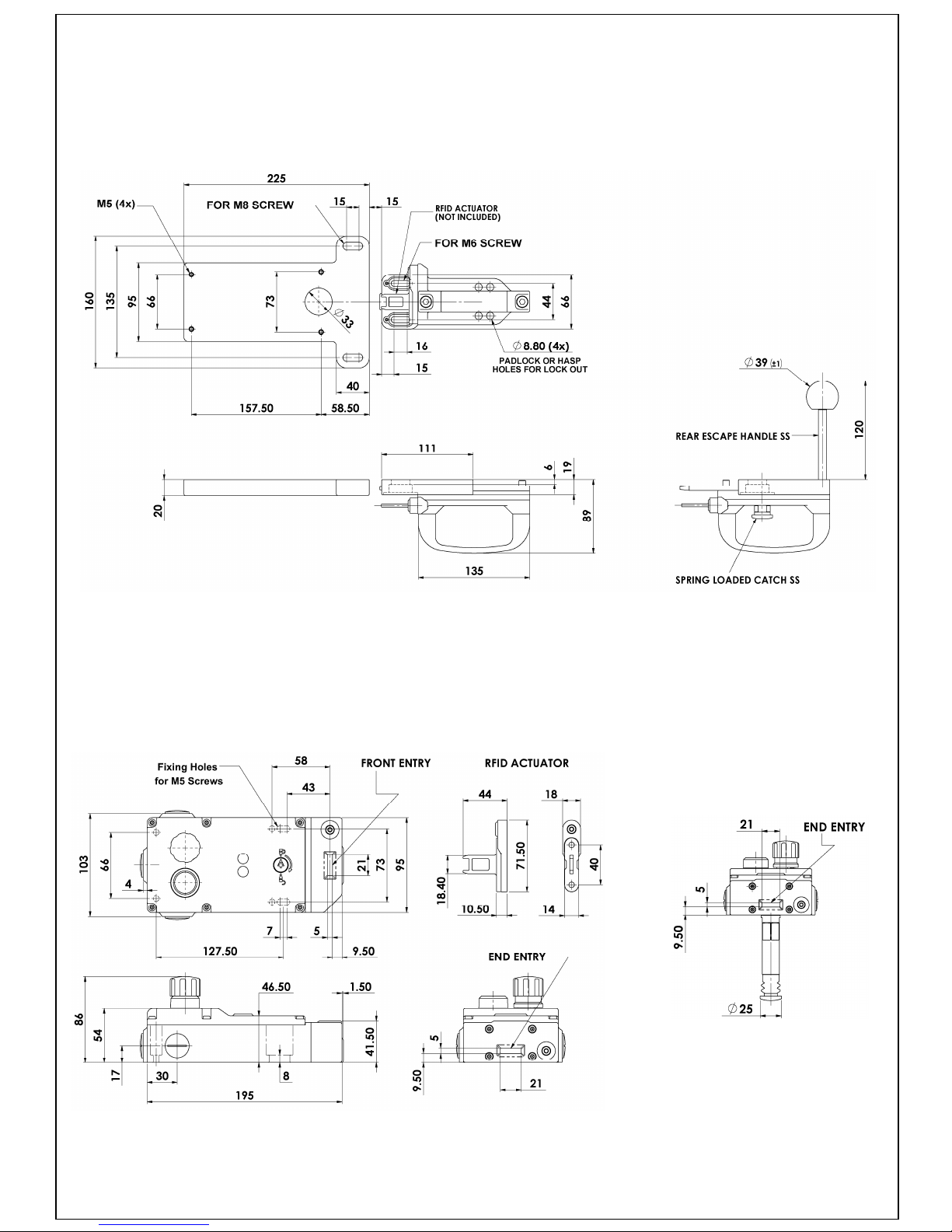

Gate Box with Safety Interlocking & RFID

Product Dimensions

–

Type: UGB 4 Sliding Handle SS (4 x APP)

Product Dimensions

–

Type: UGB

2

-

KLT

-

SS

-

RFID

Rear Release

Gate Box with Safety Interlocking & RFID

Product Dimensions

–

Type: UGB 2 Rotary Handle SS (2 x APP)

Product Dimensions

–

Type: UGB Rotary Rear Handle

Product Dimensions

–

Type: UGB 2 Sliding Handle SS (2 x APP)

Gate Box with Safety Interlocking & RFID

ID M SAF TY SWITCH S Ltd., 2 Ormside Close, Hindley Industrial state, Hindley Green, Wigan, WN2 4HR UK. Tel: +44 (0)1942 257070 Fax.: +44 (0)1942 257076

ID M (USA) 4416 Technology Drive, Fremont, CA 94538 Tel:510-445-0751 Fax:1866-431-7064 email: [email protected]om Web: www.idemsafety.com

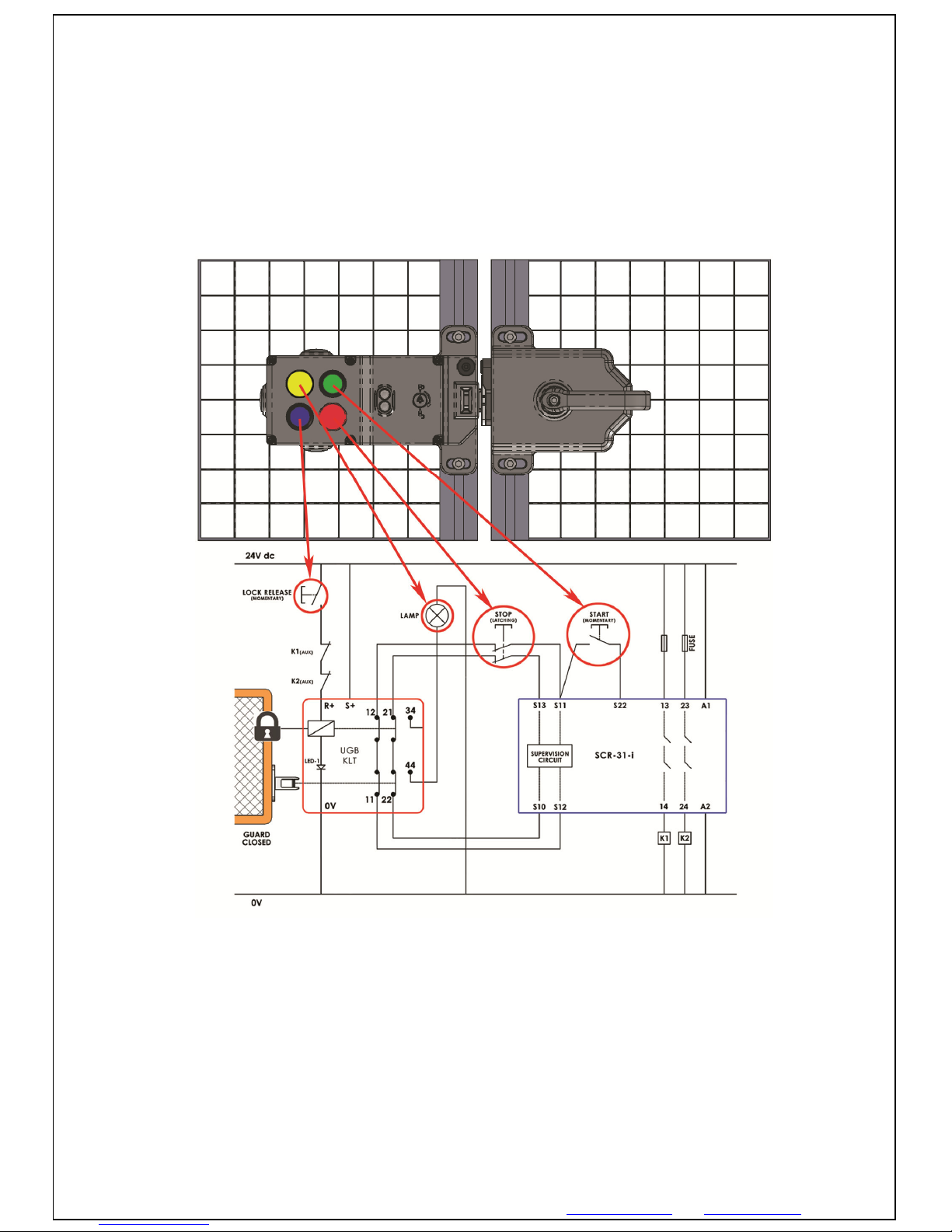

Connection xample:

Connected to ID M VIP R SCR-31-I Safety Relay (internal wire links not removed).

UGB 4-KLT-SS-RFID shown with Rotary Handle and fitted with Latching STOP, START and R S T BUTTONS and INDICATOR LAMP

Doc: 102574

April 2017

This manual suits for next models

1

Table of contents