Trine 4100 Electric Strike User manual

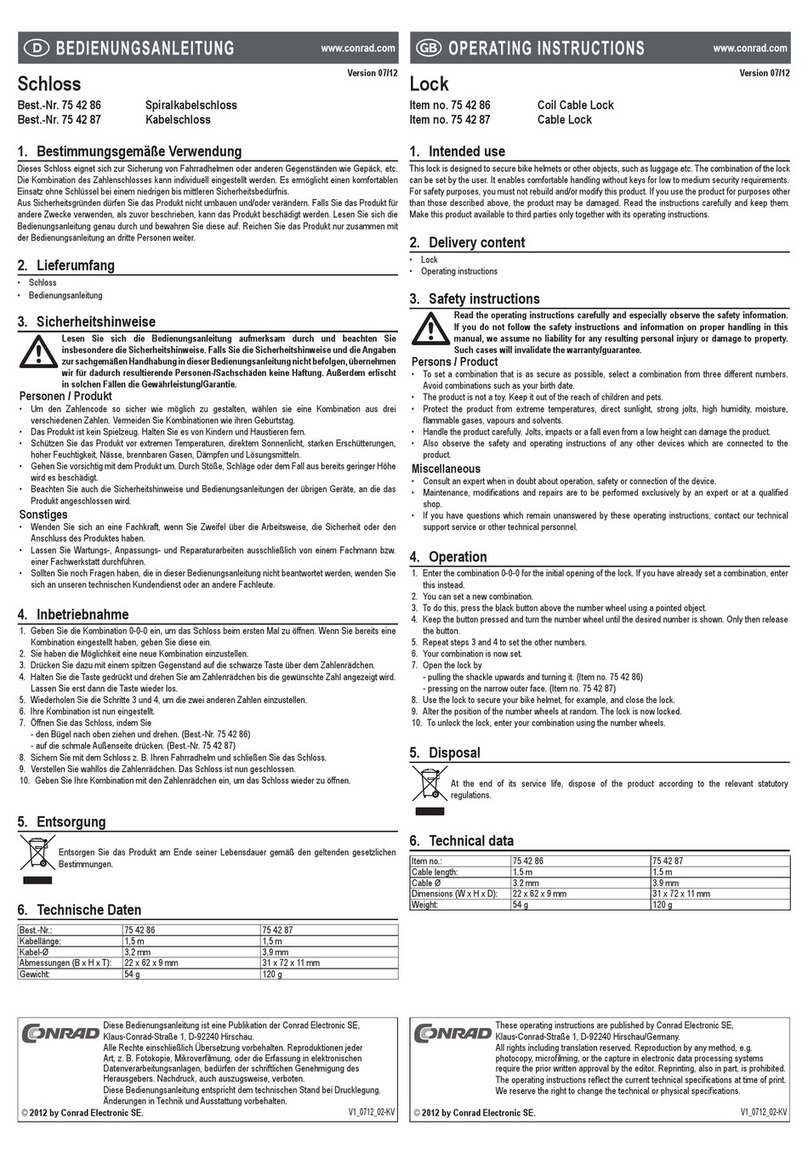

TRINE 4100

THE ONE BOX SOLUTION

FOR CYLINDRICAL AND MORTISE LOCKS

Congratulations on the purchase of this quality TRINE security

product. This product has been designed to install easily,

perform reliably, and provide years of trouble free security.

BEFORE PROCEEDING

with your installation, please review the

following list of features. If you have any questions after reading

this document please call TRINE's TECHNICAL SUPPORT (718)

829-2332 EXT. 447, or visit the TRINE Web site at

www.trineonline.com

1440 Ferris Place l Bronx l New York l 10461

4100

ELECTRIC

STRIKE

INSTALLATION INSTRUCTIONS

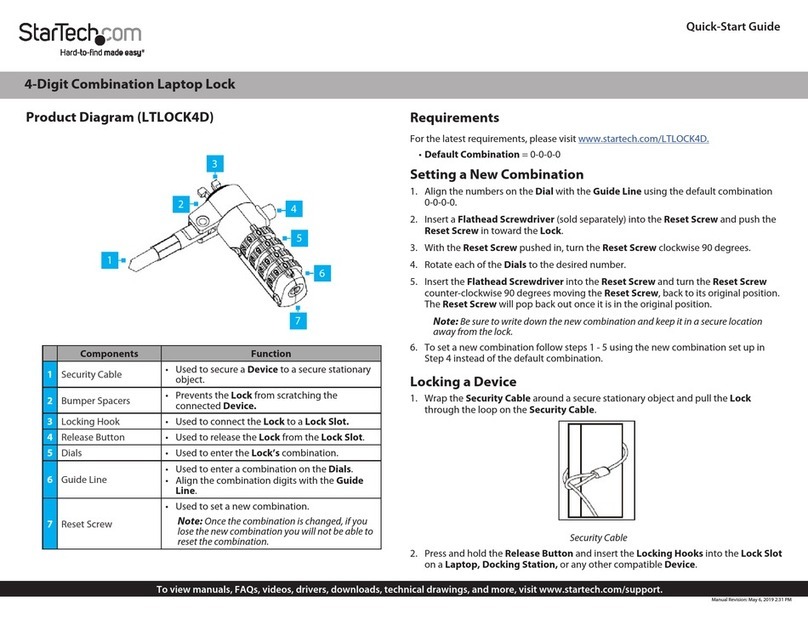

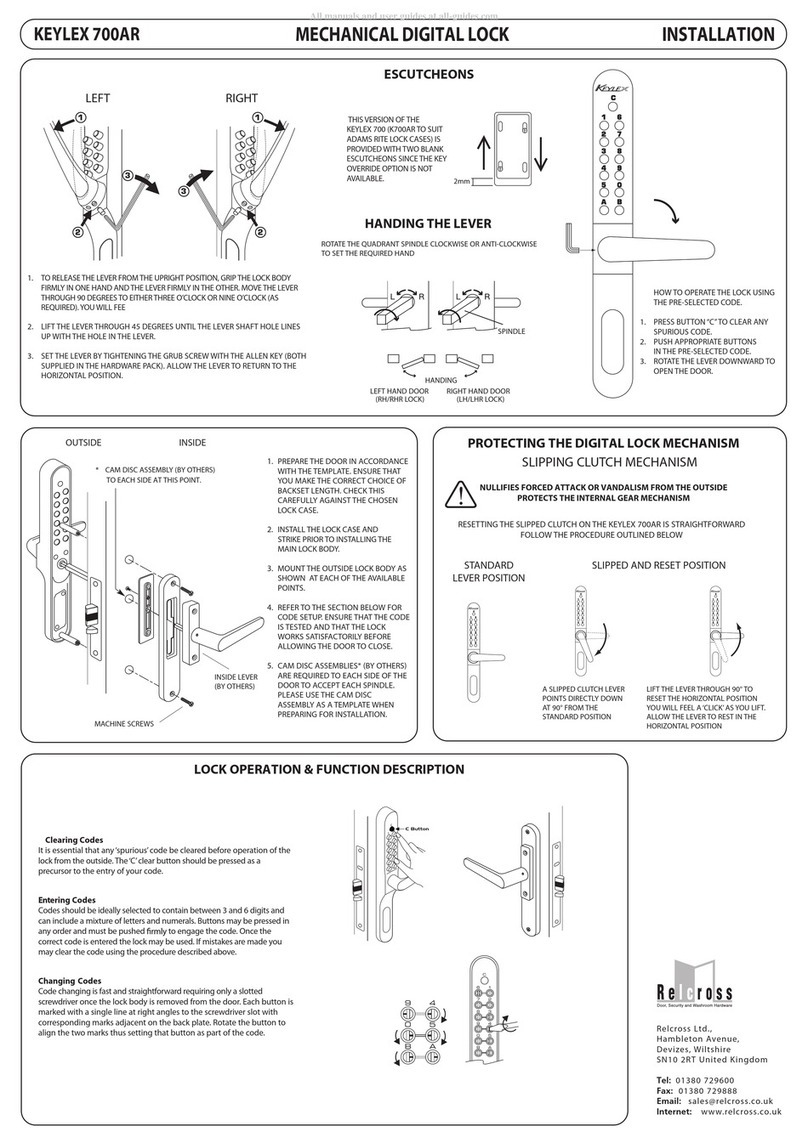

CC Faceplate

(centered opening)

The 4100 is WH recognized for:

Class A, 3 Hour Single door / frame configuration

- UL10C, Fire Tests of Door Assemblies

- UBC 7-2, Uniform building Code

- CAN4 S104,

Standard Method for Fire Tests of Door Assemblies

NFPA 252 -

Issue: 1999/01/01 Standard Methods of Fire Tests of Door Assemblies

NOTE: WH fire listing is void when using fail safe action.

ANSI/BHMA A156.5 - 1992 - 4-7/8" x 1-1/4" Fits

Cutout Specification A115.1 (with Slight Jamb Modification)

BHMA - Grade 1

TROUBLESHOOTING THE COMPLETED INSTALLATION:

WIRING DIAGRAMS

DO NOT APPLY AN OVER VOLTAGE OF MORE THAN 10%

OVER THE RATED OPERATING VOLTAGE OF THE STRIKE OR

THE SOLENOID WILL BE DAMAGED

SYMPTOM: Electric release is not actuating:

1. Verify proper voltage is present AT THE STRIKE. If voltage is

present, the strike may have been affected during the

installation, or dirt or debris may be preventing proper

operation. Ensure that all moving parts are clean. DO NOT

LUBRICATE THE SOLENOID.

2. If voltage IS NOT present:

· Verify Circuit breaker is on

· Verify voltage at the transformer/power supply output.

· Verify that there are no additional, external switches or

devices which may be interrupting your circuit.

· Check for damaged wiring or bad wire splices.

SYMPTOM: Door will not open but strike is working

· First, check to see if the electric strike works properly

while the door is open.

· Check for proper lock-latch engagement

· Check for pressure from the door on the electric strike

by following these steps:

Push the door from the outside, try and relieve the bolt

to latch pressure and actuate the 4100. While the

4100 is unlatched swing the door open. If the door

opens, then the bolt maybe applying pressure to the

latch. Adjust the position of the 4100 to relieve the

pressure.

Possible remedies include:

1. Re-adjust door closer.

2. Remove door silencers.

3. Remove, or trim, weather stripping around the door.

4. Adjust electric strike position if possible.

5. Correct excessive warping of door.

USING THE LATCH SPACER SHIMS (CONTINUED...)

For locks not aligning to the vertical center of the strike, mount

the shims as shown below. Most if not all mortise locks will

work with the latch shims mounted this way.

Mount the shims with the

steps positioned away from

the top of the latch like this.

Auxilliary

Deadlocking Trigger

PHONE: (718) 829-2332

FAX: (718) 829-6405

1440 FERRIS PLACE

BRONX, NY 10461

email: customerservice@trineonline.com

website: www.trineonline.com

4

Current Power

Voltage Draw Consumption Resistance

12DC .240 A 2.90 W 50 Ω

24DC .114 A 2.74 W 210 Ω

12AC

@ 50-60Hz

.210 A 2.50 W 50 Ω

16AC

@ 50-60Hz

.281 A 4.48 W 50 Ω

24AC

@ 50-60Hz

.420 A 10.08 W 50 Ω

4100 ELECTRICAL CHARACTERISTICS:

4 7/8"

4 1/8"

1 3/4"

1/4"

25/32"

1 1/4"

3/4" CAVITY DEPTH

1 5/8"

3 3/8"

1 3/8"

Mount the shims with the steps

positionedaligned with the top

of the latch like this.

This position will ensure that the cylindrical

lock's auxilliary trigger will function properly.

USING THELATCH SPACER SHIMS

The latch spacer shims are used to make adjustments to

minimize the space between the door's inside face and the

door stop or reduce door play. For cylindrical locks aligning to

the vertical center of the strike mount

the shims as shown below.

Auxilliary Trigger

OPERATING TEMP RANGE: -20°C TO +40°C

DO NOT APPLY AN OVER VOLTAGE OF MORE THAN 10%

OVER THE RATED

OPERATING VOLTAGE OF THE

STRIKE OR THE SOLENOID WILL BE DAMAGED.

When removing the connector andusing the wires direct;

Red & Blue Wire accepts 12DC & 12-16 AC,

Brown & Blue Wire accepts 24DC.

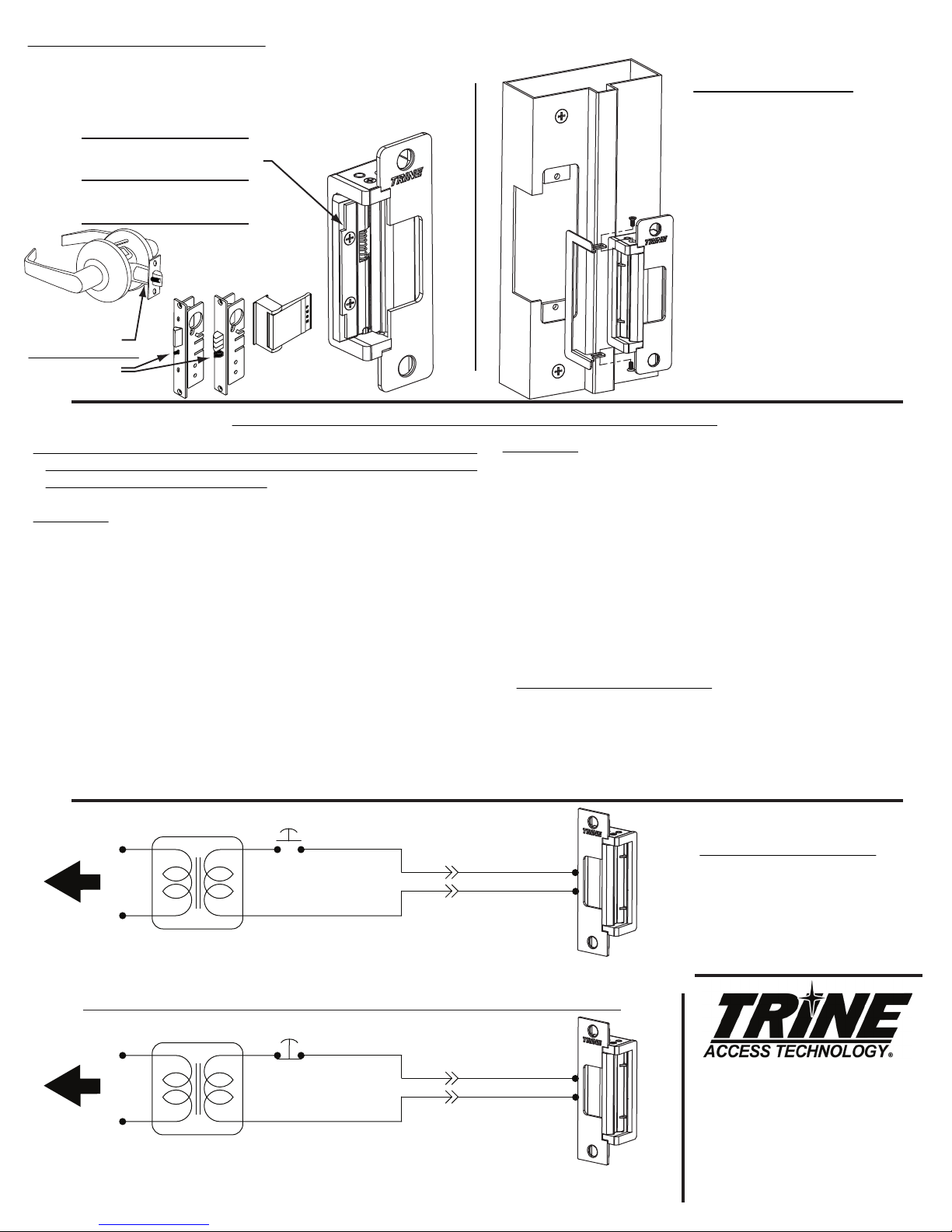

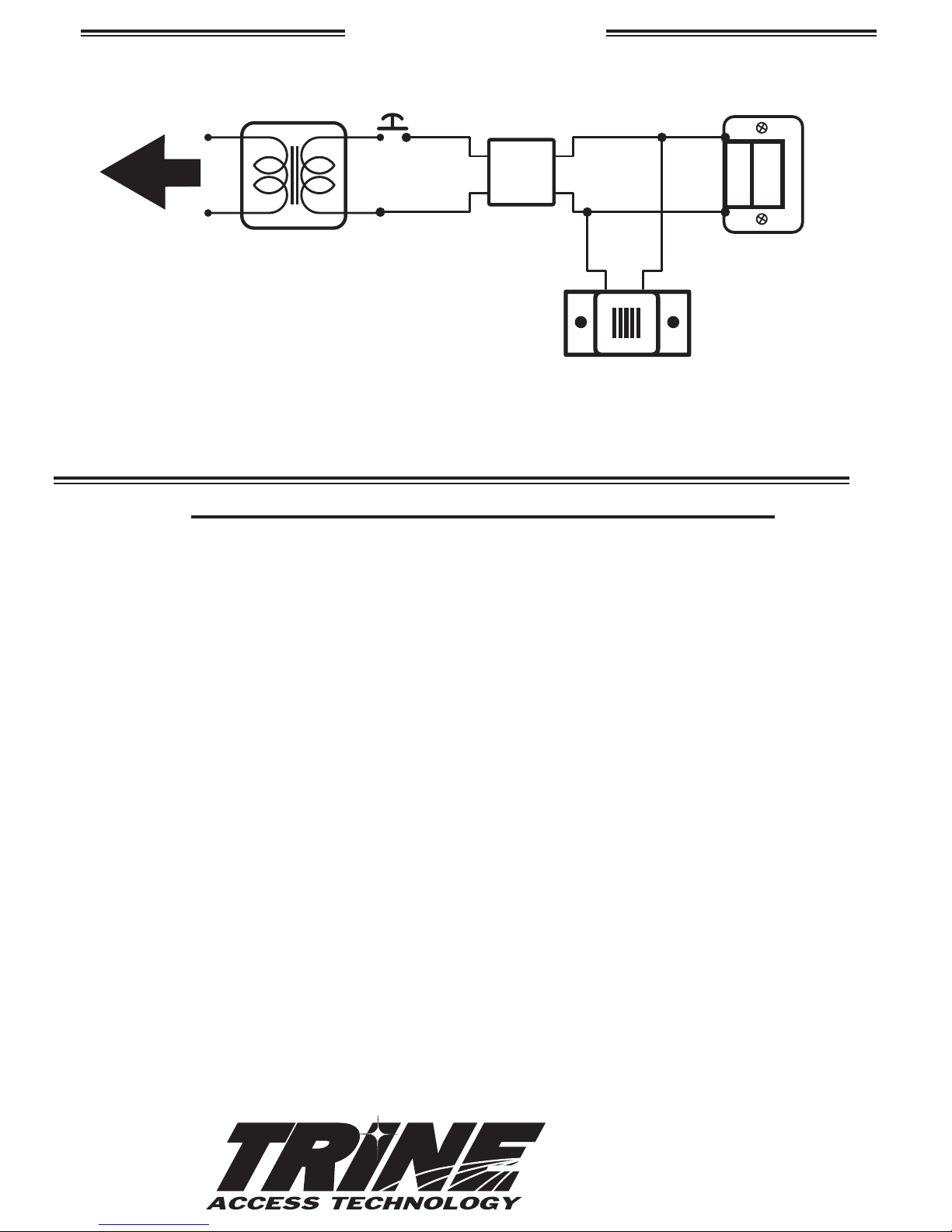

24V DC OR 12V DC

TRANSFORMER

TO 120V AC LINE

PUSH

BUTTON

NORMALLY

CLOSED

+

-

FAIL-SAFE

ELECTRIC STRIKE

USE THE PROPER

CONNECTOR 12VDC OR 24VDC

ASSEMBLY FOR

THE 4100 STRIKE

Cannot use AC in Fail Safe Configuration

24V DC OR 12V DC TRANSFORMER

TO 120V AC LINE

PUSH

BUTTON

NORMALLY OPEN

+

-

USE THE PROPER

CONNECTOR 12VDC OR 24VDC

ASSEMBLY FOR

THE 4100 STRIKE

For AC use the 12 VDC connectors

For 12 - 24 VAC use 50-60 Hz

FAIL-SECURE

ELECTRIC STRIKE

V. 14.0814

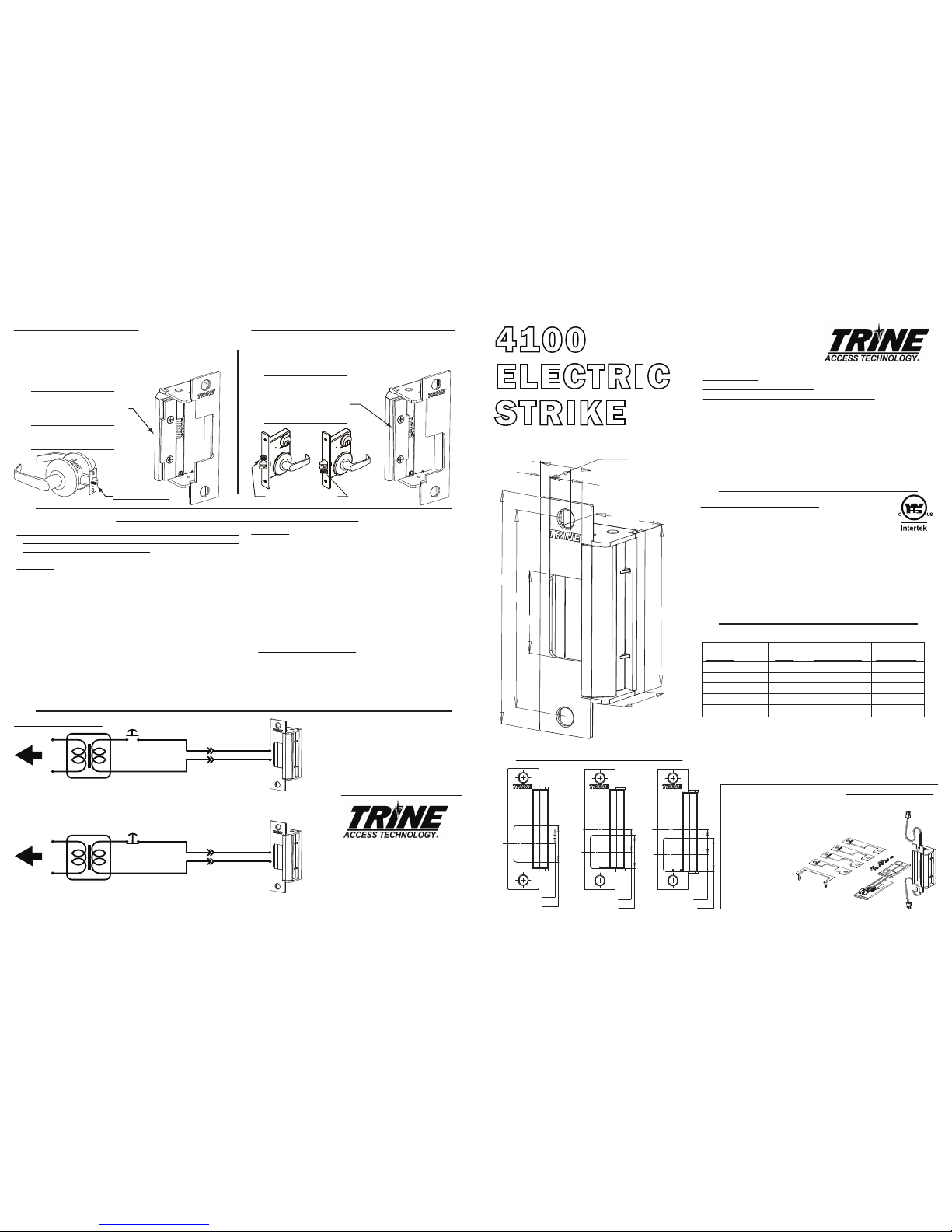

FACEPLATE AND OFFSET DIMENSIONS:

CAVITY

C

L

STRIKE

C

L

1 1/64"

1 11/32"

CAVITY

C

L

STRIKE

C

L

29/32"

1 11/32"

STRIKE

C

L

CAVITY

C

L

19/32"

1 15/32"

MHO MMO MLO

1 -(1) 4100 Electric

Strike Mechanism

2 -(4) Faceplates with Openings (CC, MHO, MMO, MLO)

3 -(2) #12-40 x 1 inch Philips Mounting Screws

4 -(2) #12-40 x 1 inch Torx®Security Mounting Screws

5 -(2) Quick Connect Socket &

Wire Assembly 12VDC

& 24VDC Version

6 -(2) Sealed Crimp

Connectors

7 -(2) Latch Spacer

Shims & (2) Mounting Screws

8 -(1) Frame Trim Skirt & (2) Screws

WHAT'S IN THE BOX:

4100 OPTIONS:

4100RS - FAIL SAFE CONFIGURATION

4100LB - LATCH BOLT MONITORING

4100RSLB -

FAIL SAFE/LATCH

BOLT MONITORING

BZ-12 - 12VDC Piezo Buzzer

BZ-24 - 24VDC Piezo Buzzer

INSTALLING THE4100 STRIKE:

NOTE: The 4100 electric strike has two terminal wires to supply power to

two separate solenoids.

USE THEBOTTOMWIRE LEADS ONLY.

1. Prepare door frame as shown on page 2 (based on frame type).

2. Pull the switched power wires to the door frame. (Caution: Connect the

power ONLY as the last step.)

RECOMMENDED PRE-INSTALLATION CHECK:

1. Determine that the door swings without interfering

with jamb or sill; the door must operate properly in

order for the system to providebest results.

2. The door must be equipped with a door closer and

the door closer "latch mode" must hold door in a

completely closed position in order to avoid the lock

latch from applying pressure against the releasing

latch portion of the electric strike.

3. Electrical wire connections must be completed and

ready to be terminated inside the frame.

4. Confirm that the power line in the frame is the

correct voltage and that the switch works properly.

5. Confirm proper clearance exists between the end of

the lock latch and jamb.

6. The faceplate opening used on the electric door

strike must be centered with lock latch centerline

when itisinstalled on the doorjamb.

7. For best installation results, the door frame must be

reasonably flat and straight. 3

COMPATIBLE LOCKSETS:

CC: Centered Cylindrical (Reference

HES®

J faceplate)

Cylindrical Locksets up to 3/4" throw and all locksets

center linedbolts: Corbin Russwin

®

Security Bolt, Weiserbolt

®

.

MHO: MortiseHighOffset (Reference

HES®

KM faceplate)

Accurate

®

,Arrow

®

, Best

®

, Corbin Russwin

®

, Falcon

®

(1992MSeries),

Sargent

®

(7800,8200 & 9200 Series), Yale

®

(8800).

MMO: Mortise Medium Offset (Reference HES®K faceplate)

Baldwin

®

, Marks

®

, PDQ

®

.

MLO: Mortise Low Offset (Reference HES

®

KD faceplate) Jackson

®

,

Sargent

®

(7700 & 8100), Schlage

®

(L Series), Yale

®

(8700).

Additional Faceplates:

CCRD - 4-7/8” x 1-1/4“Centered Cavity with Radiused Corners

CRD7 - 6-7/8” x 1-1/4“ Tall Centered Cavity with Radiused Corners

CRD8 - 7-15/16” x 1-7/16“ Tall Centered Cavity with Radiused Corners

CRD9 - 9” x 1-1/4“Tall Centered Cavity

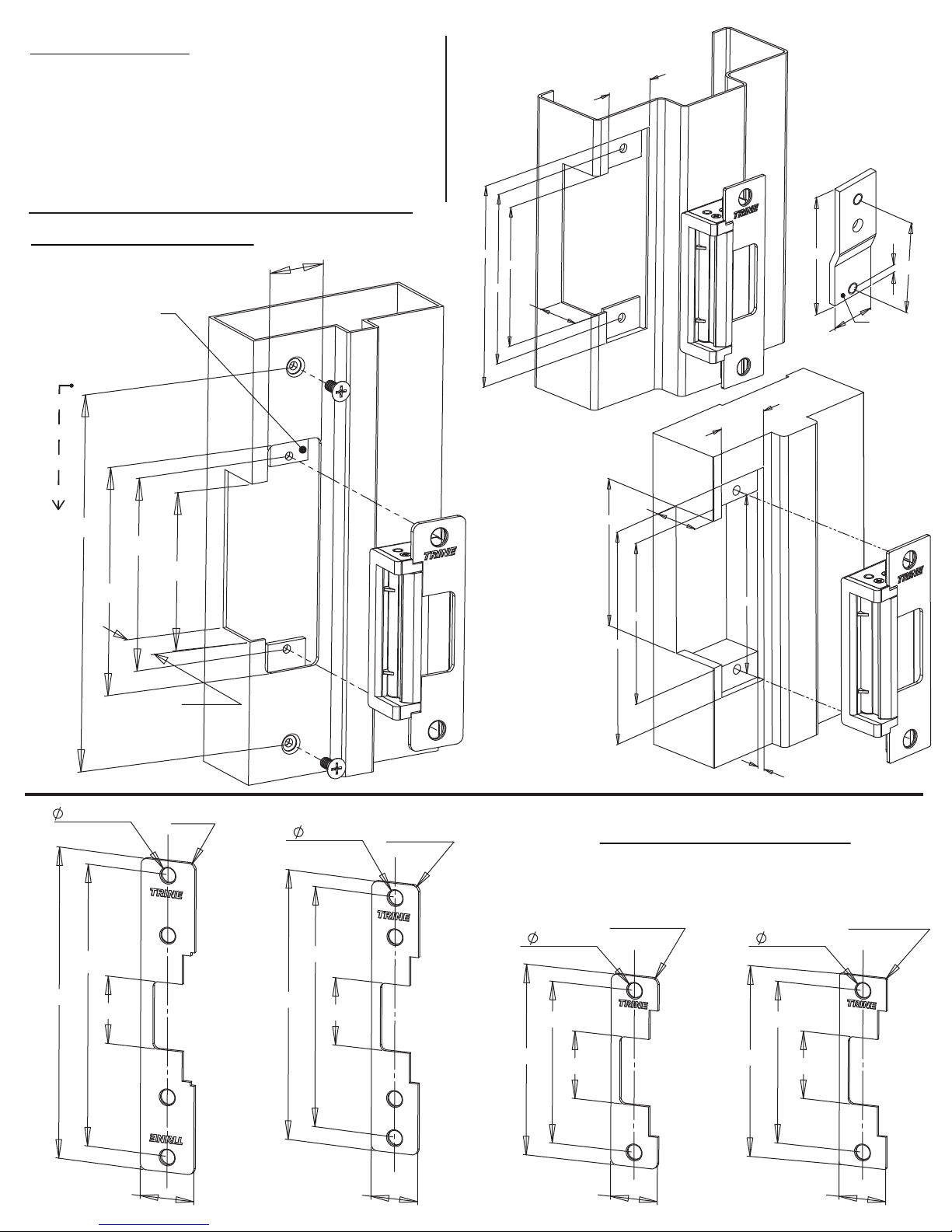

Plug the bottom

terminal of the strike

to the quick connect socket.

The top terminal is not

used. Put electrical tape

over it, tuck it into the

hollow of the frame or

trim it off if there is no

room in the frame.

Quick Connect

Socket

Crimp

Connector

3. Carefully choose the quick connect socket to match the required

voltage. The quick connect sockets are labeled 12VDC (Blue Wire) or

24VDC(White Wire).

4. Use the crimp connectors to terminate the ends of the quick connect

socket to the power wires coming out of the frame.

5. Connect the strikes bottom terminal to the quick connect socket.

6. Tuck the wires inside the door frame.

7. Install the electric strike into the door frame

8. Connect the power supply and turn power on.

9. Test your system.

Figure #2b

2

3 3/8"

1 3/8"

4 7/8"

1 17/64"

3/16"

3 11/16"

4 1/8"

FRAME PREPARATION

CC, MHO, MMO

ON HOLLOW

METAL FRAME

MLO

ON HOLLOW

METAL FRAME

(note 7/8” top

dimension)

Use the

Premium Trim Skirt

to clean up your

cutline (see pg 4)

Use the

Premium Trim Skirt

to clean up your

cutline (see pg 4)

Dead Locking

Trigger Trapped

ON WOOD FRAME

3 3/8"

4 7/8"

4 1/8"

1 17/64"

1 3/8"

7/8"

1 3/8"

3 3/8"

4 7/8"

1 17/64"

4 1/8"

PREMIUMTRIMSKIRT FOR THE 4100

USING THETRIMSKIRT

The skirt can be used to clean up the cut line

of the frame face during installation. The

Trim Skirt comes with 2 screws for fastening

to the top and bottom of the 4100.

Available in 6 architectual finishes: US32D,

US32, US3, US4, US10, US10B to match the

finish of the electric strike and faceplates.

FLUSH TO FRAME

If the 4100 electric strike does not mount flush to the rabbet of the frame,

use the enclosed shims to correct this condition. There are two ways of

mounting the shim; 1) between the strike mechanism and the faceplate as

shown in figure #2 or 2) between the frame mounting tab and the strike

mechanism as shown on figure #3.

WITH SOME LOCKING MECHANISMS

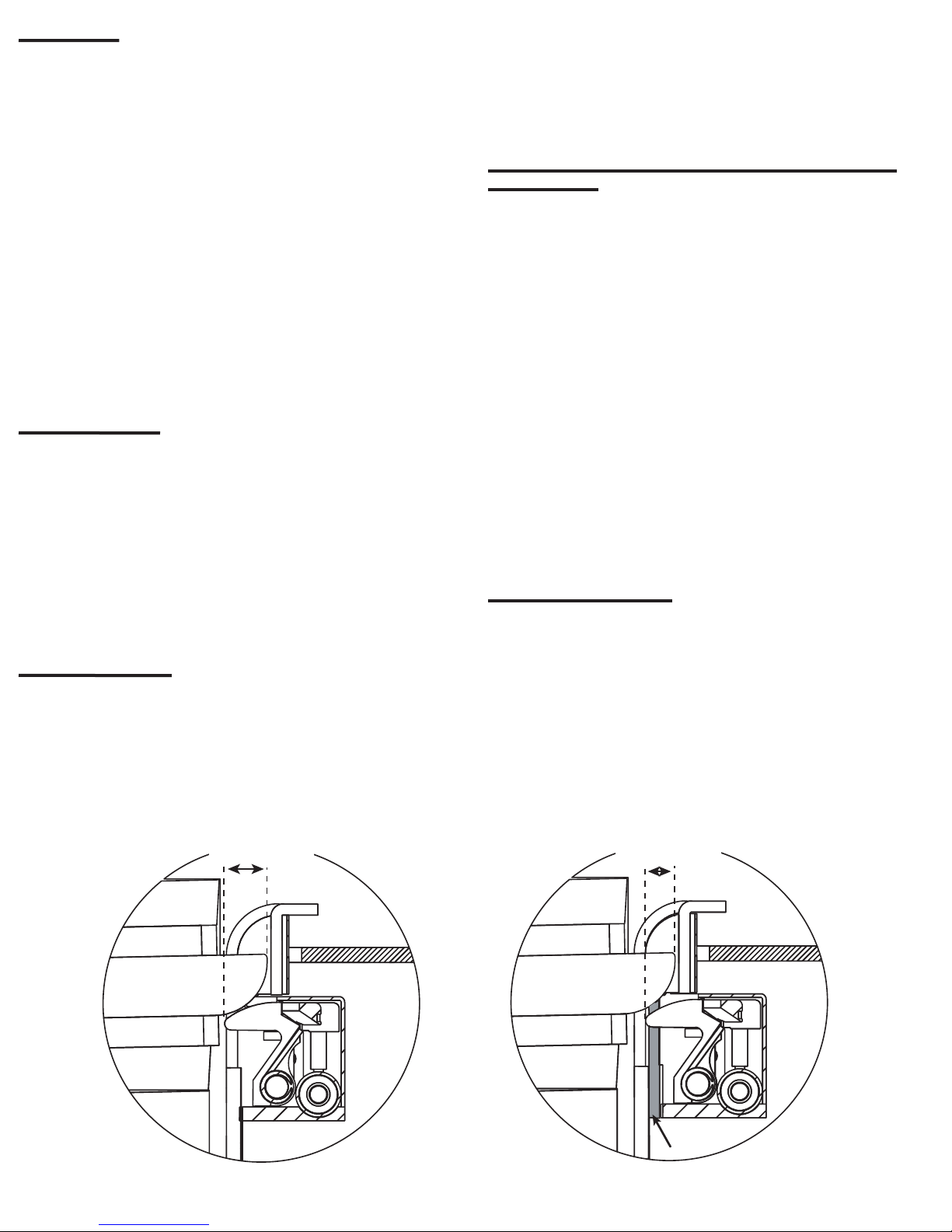

We have included different kinds of shims and trims to help fix problems

that are encountered in the field whileinstalling the 4100.

Here for example is a mortise lock with an anti-friction bolt and dead

locking trigger with sharp edges see Figure #1. Depending on the mounting

relationship of the strike and the lock, the dead locking trigger can wedge

between the faceplate and the latch keeper as shown on Figure #2a & 2b.

This can create a pre-load condition on the latch keeper which will prevent

the strike from unlocking.

Use the latch shim as shown on Figure #3a & 3b to prevent the dead

locking trigger from getting trapped between the latch keeper and the

strike faceplate. The faceplate must be notched to clear the latch

shim (see Figure #3a).

CCTS

If retrofitting for the electric strikes listed below, a separate Skirt

may be used to cover the gap left in the frame.Note: Specify the

finish of the CCTS so it matches the 4100 you have.

H.E.S.® 1006, Folger Adams® 712/732, Von Duprin® 6200 Series,

or Trine EN Series Strikes

Figure #2a

Figure #3bFigure #3a

Notch to

clear the

latch shim

Use the

latch shim

to fix the

problem.

Figure #1

Sharp Edges

Figure #1

Strike seats below

the rabbet of

the frame.

Figure #2

Strike

Mechanism

Shims

Faceplate

Figure #3

Strike

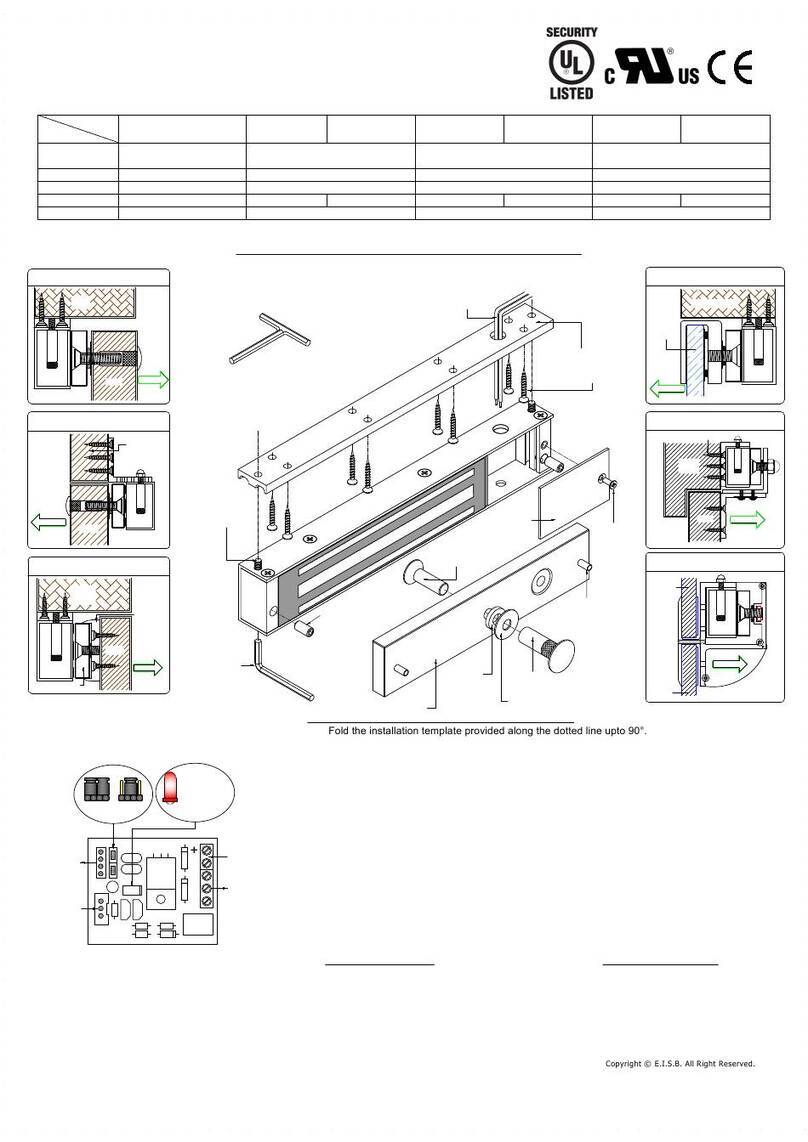

Mechanism

Shims

TRINE 4200

THE ONE BOX SOLUTION

FOR CYLINDRICAL LOCKS

AND DEADLATCHES

Congratulations on the purchase of this quality TRINE security

product. This product has been designed to install easily,

perform reliably, and provide years of trouble free security.

BEFORE proceeding

with your installation, please review the

following list of features. If you have any questions after reading this

document please call TRINE's TECHNICAL SUPPORT (718) 829-2332

EXT. 447, or visit the TRINE web site at www.trineonline.com

1440 Ferris Place l Bronx l New York l 10461

4200

ELECTRIC

STRIKE

INSTALLATION INSTRUCTIONS

TROUBLESHOOTING THE COMPLETED INSTALLATION:

WIRING DIAGRAMS

DO NOT APPLY A VOLTAGE OF MORE THAN 10% OVER THE

RATED OPERATING VOLTAGE OF THE STRIKE OR THE

SOLENOID WILL BE DAMAGED

SYMPTOM: Electric release is not actuating:

1. Verify proper voltage is present AT THE STRIKE. If voltage is

present, the strike may have been affected during the

installation, or dirt or debris may be preventing proper

operation. Ensure that all moving parts are clean. DO NOT

LUBRICATE THE SOLENOID.

2. If voltage IS NOT present:

· Verify Circuit breaker is on

· Verify voltage at the transformer/power supply output.

· Verify that there are no additional, external switches or

devices which may be interrupting your circuit.

· Check for damaged wiring or bad wire splices.

SYMPTOM: Door will not open but strike is working

· First, check to see if the electric strike works properly

while the door is open.

· Check for proper lock-latch engagement

· Check for pressure from the door on the electric strike

by following these steps:

Push the door from the outside, try and relieve the bolt

to latch pressure and actuate the 4200. While the

4200 is unlatched swing the door open. If the door

opens, then the bolt maybe applying pressure to the

latch. Adjust the position of the 4200 to relieve the

pressure.

Possible remedies include:

1. Re-adjust door closer.

2. Remove door silencers.

3. Remove, or trim, weather stripping around the door.

4. Adjust electric strike position if possible.

5. Correct excessive warping of door.

PHONE: (718) 829-2332

FAX: (718) 829-6405

1440 FERRIS PLACE

BRONX, NY 10461

email: customerser[email protected]

website: www.trineonline.com

4

Current Power

Voltage Draw Consumption Resistance

12DC .240 Amps 2.90 Watts 50 Ohms

24DC .114 Amps 2.74 Watts 210 Ohms

12AC

@ 50-60Hz

.210 Amps 2.50 Watts 50 Ohms

16AC

@ 50-60Hz

.281 Amps 4.48 Watts 50 Ohms

24AC

@ 50-60Hz

.420 Amps 10.08 Watts 50 Ohms

4200 ELECTRICAL CHARACTERISTICS:

Mount the shim with the step aligned

with the top of the latch as so.

This position will ensure that the cylindrical

lock's auxilliary trigger will function properly.

USING THE LATCH SPACER SHIM

The latch spacer shim is used to make an adjustment to

minimize the space between the door's inside face and the door

stop, or reduce door play. For cylindrical locks aligning to the

vertical center of the strike mount the shim as shown below.

OPERATING TEMP RANGE: -20°C TO +40°C

DO NOT APPLY A VOLTAGE OF MORE THAN 10% OVER THE RATED

OPERATING VOLTAGE OF THE STRIKE OR THE SOLENOID WILL BE DAMAGED

When removing the connector and using the wires direct; Blue Wire is Common,

Red Wire accepts 12DC & 12-16AC, Brown Wire accepts 24DC.

RS IS FAILSAFE ACTION (LOCKS WITH POWER) AND IS DC ONLY

24V DC OR 12V DC

TRANSFORMER

TO 120V AC LINE

PUSH

BUTTON

NORMALLY

CLOSED

+

-

FAIL-SAFE

ELECTRIC STRIKE

USE THE PROPER

CONNECTOR 12VDC OR 24VDC

ASSEMBLY FOR

THE 4200 STRIKE

Cannot use AC in Fail Safe Configuration

24V DC OR 12V DC TRANSFORMER

TO 120V AC LINE

PUSH

BUTTON

NORMALLY OPEN

+

-

USE THE PROPER

CONNECTOR 12VDC OR 24VDC

ASSEMBLY FOR

THE 4200 STRIKE

For AC use the 12 VDC connectors

For 12 - 24 VAC use 50-60 Hz

FAIL-SECURE

ELECTRIC STRIKE

V. 14.0218

C

L3 3/8"

4 7/8"

4 1/8"

1 1/4"

1/4"

1 3/4"

BACKSET

1 1/16"

1 5/8"

1/2”

CAVITY DEPTH

25/32"

32D (630) Satin Stainless

ALUM Aluminum Powder Coat

BLK Black Powder Coat

DKBZ

Dark Bronze Powder Coat

GRN Green Powder Coat

WHT White Powder Coat

AVAILABLE FINISHES

1 - (1) 4200 Electric Strike Mechanism

2 - (4) Faceplates as shown

3 - (6) #12-24 x 1/2 inch Philips Mounting Screws

4 - (2) #12-24 Lock Nut

5 - (2)

Quick Connect Socket & Wire Assembly 12VDC & 24VDC Version

6 - (2) Sealed Crimp Connectors

7 - (1) Latch Spacer Shims & (2) Mounting Screws

8 - (1) Frame Trim Skirt & (2) Screws

9 - (2) Mounting Tabs

WHAT'S IN THE BOX:

Auxilliary Trigger

PREMIUM TRIM SKIRT FOR THE 4200

USING THE TRIM SKIRT

The skirt can be used to clean up the

cut line of the frame face during

installation. The Trim Skirt comes

with 2 longer screws (included) for

fastening to the top and bottom of

the 4200.

Available in 5 powdercoat finishes:

Aluminum (ALUM), Black (BLK), Dark

Bronze (DKBZ), Green (GRN), and

White (WHT) which can match the

finish of the faceplate and Fascia’s.

RS IS FAILSAFE ACTION (LOCKS WITH POWER) AND IS DC ONLY

RECOMMENDED PRE-INSTALLATION CHECK:

1. Determine that the door swings without interfering with

jamb or sill; the door must operate properly in order for the

system to provide best results.

2. The door must be equipped with a door closer and the door

closer "latch mode" must hold door in a completely closed

position in order to avoid the lock latch from applying

pressure against the releasing latch portion of the electric

strike.

3. Electrical wire connections must be completed and ready

to be terminated inside the frame.

4. Confirm that the power line in the frame is the correct

voltage and that the switch works properly.

5. Confirm proper clearance exists between the end of the

lock latch and jamb.

6. The faceplate opening used on the electric door strike

must be centered with lock latch centerline when it is

installed on the doorjamb.

7. For best installation results, the door frame must be

reasonably flat and straight.

INSTALLING THE 4200 STRIKE:

NOTE: The 4200 electric strike has two terminal wires to

supply power to two separate solenoids.

1. Prepare door frame as shown on page 2 (based on frame

type).

3

4200 OPTIONS:

4200RS - FAIL SAFE CONFIGURATION

4200LB - LATCH BOLT MONITORING (coming soon)

4200RSLB -

FAIL SAFE/LATCH BOLT MONITORING

(coming soon)

BZ-12 - 12VDC Piezo Buzzer

BZ-24 - 24VDC Piezo Buzzer

Plug the

strike

terminal

in to the

quick

connect

socket.

Quick Connect

Socket

Crimp

Connector

2. Pull the switched power

wires to the door frame.

(Caution: Connect the

power ONLY as the last

step.)

3. Carefully choose the

quick connect socket to

match the required

voltage. The quick connect

sockets are labeled 12VDC

(Blue Wire) or 24VDC

(White Wire).

4. Use the crimp

connectors to terminate

the ends of the quick

connect socket to the

power wires coming out of

the frame.

5. Connect the strikes

bottom terminal to the

quick connect socket.

6. Tuck the wires inside

the door frame.

7. Install the electric strike

into the door frame

8. Connect the power

supply and turn power on.

9. Test your system.

The 4200 Fascia is designed to be replaceable and is available in 5 powder

coat finishes. Replacing the Fascia is easy, follow these steps:

1. Remove top and bottom assembly screws (see a.) from the electric strike,

these hold the Fascia (see b.) in place.

2. Fascia then slides away from the electric strike -- note two additional holes

(see c.) that provide stability to the Fascia.

3. New Fascia is aligned to the holes and pushed in until screw holes align.

4. Insert both the bottom and top assembly screws to secure the Fascia into

the electric strike body.

Longer Faceplates have

additional holes. 2 assembly

holes to mount the faceplate to

the electric strike. 2 holes for

mounting the assembled

faceplate/strike to the frame.

Available in 5 powdercoat finishes: Aluminum

(ALUM), Black (BLK), Dark Bronze (DKBZ), Green

(GRN), and White (WHT) which can match the finish

of the faceplate and trim skirts.

1 31/32"

7/8"

2 1/2"

5/32"

STRIKE SIDE

(Included)

FRAME PREPARATION

FACEPLATE DIMENSIONS

REMOVABLE FASCIA

(Match the Color of the Frame)

LONGER FACEPLATE

ASSEMBLY

Metal Frame

TAB

DIMENSIONS

Wood Frame

Use #12-24 x 1/2 inch

Philips Mounting Screws

for tab holes.

Aluminum

Frame

a.

a.

c.

c.

b.

MOUNTING TABS (2)

SUPPLIED

4 7/8"

1 17/64"

4 1/8"

3 3/8"

1 1/16"

8 1/16"

C

L

7 15/16"

1 7/16"

3/8" (4)

1 3/4"

7 3/16"

R5/32" (4)

C

L

6 7/8"

1 1/4"

3/8" (4)

1 3/4"

6 1/8"

R5/32" (4)

C

L

3/8" (2)

4 7/8"

1 1/4"

1 3/4"

4 1/8"

R5/32" (4)

C

L

3/8" (2)

4 7/8"

1 1/4"

1 3/4"

4 1/8"

R1/32" (4)

1 3/32"

1 1/4"

4 7/8"

3 3/8"

4 1/8"

4 7/8"

3 3/8"

1 1/4"

1 3/32"

3 11/16"

3/16"

4 1/8"

RECOMMENDED PRE-INSTALLATION CHECK:

1. Determine that the door swings without interfering with

jamb or sill; the door must operate properly in order for the

system to provide best results.

2. The door must be equipped with a door closer and the door

closer "latch mode" must hold door in a completely closed

position in order to avoid the lock latch from applying

pressure against the releasing latch portion of the electric

strike.

3. Electrical wire connections must be completed and ready

to be terminated inside the frame.

4. Confirm that the power line in the frame is the correct

voltage and that the switch works properly.

5. Confirm proper clearance exists between the end of the

lock latch and jamb.

6. The faceplate opening used on the electric door strike

must be centered with lock latch centerline when it is

installed on the doorjamb.

7. For best installation results, the door frame must be

reasonably flat and straight.

INSTALLING THE 4200 STRIKE:

NOTE: The 4200 electric strike has two terminal wires to

supply power to two separate solenoids.

1. Prepare door frame as shown on page 2 (based on frame

type).

3

4200 OPTIONS:

4200RS - FAIL SAFE CONFIGURATION

4200LB - LATCH BOLT MONITORING (coming soon)

4200RSLB -

FAIL SAFE/LATCH BOLT MONITORING

(coming soon)

BZ-12 - 12VDC Piezo Buzzer

BZ-24 - 24VDC Piezo Buzzer

Plug the

strike

terminal

in to the

quick

connect

socket.

Quick Connect

Socket

Crimp

Connector

2. Pull the switched power

wires to the door frame.

(Caution: Connect the

power ONLY as the last

step.)

3. Carefully choose the

quick connect socket to

match the required

voltage. The quick connect

sockets are labeled 12VDC

(Blue Wire) or 24VDC

(White Wire).

4. Use the crimp

connectors to terminate

the ends of the quick

connect socket to the

power wires coming out of

the frame.

5. Connect the strikes

bottom terminal to the

quick connect socket.

6. Tuck the wires inside

the door frame.

7. Install the electric strike

into the door frame

8. Connect the power

supply and turn power on.

9. Test your system.

The 4200 Fascia is designed to be replaceable and is available in 5 powder

coat finishes. Replacing the Fascia is easy, follow these steps:

1. Remove top and bottom assembly screws (see a.) from the electric strike,

these hold the Fascia (see b.) in place.

2. Fascia then slides away from the electric strike -- note two additional holes

(see c.) that provide stability to the Fascia.

3. New Fascia is aligned to the holes and pushed in until screw holes align.

4. Insert both the bottom and top assembly screws to secure the Fascia into

the electric strike body.

Longer Faceplates have

additional holes. 2 assembly

holes to mount the faceplate to

the electric strike. 2 holes for

mounting the assembled

faceplate/strike to the frame.

Available in 5 powdercoat finishes: Aluminum

(ALUM), Black (BLK), Dark Bronze (DKBZ), Green

(GRN), and White (WHT) which can match the finish

of the faceplate and trim skirts.

1 31/32"

7/8"

2 1/2"

5/32"

STRIKE SIDE

(Included)

FRAME PREPARATION

FACEPLATE DIMENSIONS

REMOVABLE FASCIA

(Match the Color of the Frame)

LONGER FACEPLATE

ASSEMBLY

Metal Frame

TAB

DIMENSIONS

Wood Frame

Use #12-24 x 1/2 inch

Philips Mounting Screws

for tab holes.

Aluminum

Frame

a.

a.

c.

c.

b.

MOUNTING TABS (2)

SUPPLIED

4 7/8"

1 17/64"

4 1/8"

3 3/8"

1 1/16"

8 1/16"

C

L

7 15/16"

1 7/16"

3/8" (4)

1 3/4"

7 3/16"

R5/32" (4)

C

L

6 7/8"

1 1/4"

3/8" (4)

1 3/4"

6 1/8"

R5/32" (4)

C

L

3/8" (2)

4 7/8"

1 1/4"

1 3/4"

4 1/8"

R5/32" (4)

C

L

3/8" (2)

4 7/8"

1 1/4"

1 3/4"

4 1/8"

R1/32" (4)

1 3/32"

1 1/4"

4 7/8"

3 3/8"

4 1/8"

4 7/8"

3 3/8"

1 1/4"

1 3/32"

3 11/16"

3/16"

4 1/8"

TRINE 4200

THE ONE BOX SOLUTION

FOR CYLINDRICAL LOCKS

AND DEADLATCHES

Congratulations on the purchase of this quality TRINE security

product. This product has been designed to install easily,

perform reliably, and provide years of trouble free security.

BEFORE proceeding

with your installation, please review the

following list of features. If you have any questions after reading this

document please call TRINE's TECHNICAL SUPPORT (718) 829-2332

EXT. 447, or visit the TRINE web site at www.trineonline.com

1440 Ferris Place l Bronx l New York l 10461

4200

ELECTRIC

STRIKE

INSTALLATION INSTRUCTIONS

TROUBLESHOOTING THE COMPLETED INSTALLATION:

WIRING DIAGRAMS

DO NOT APPLY A VOLTAGE OF MORE THAN 10% OVER THE

RATED OPERATING VOLTAGE OF THE STRIKE OR THE

SOLENOID WILL BE DAMAGED

SYMPTOM: Electric release is not actuating:

1. Verify proper voltage is present AT THE STRIKE. If voltage is

present, the strike may have been affected during the

installation, or dirt or debris may be preventing proper

operation. Ensure that all moving parts are clean. DO NOT

LUBRICATE THE SOLENOID.

2. If voltage IS NOT present:

· Verify Circuit breaker is on

· Verify voltage at the transformer/power supply output.

· Verify that there are no additional, external switches or

devices which may be interrupting your circuit.

· Check for damaged wiring or bad wire splices.

SYMPTOM: Door will not open but strike is working

· First, check to see if the electric strike works properly

while the door is open.

· Check for proper lock-latch engagement

· Check for pressure from the door on the electric strike

by following these steps:

Push the door from the outside, try and relieve the bolt

to latch pressure and actuate the 4200. While the

4200 is unlatched swing the door open. If the door

opens, then the bolt maybe applying pressure to the

latch. Adjust the position of the 4200 to relieve the

pressure.

Possible remedies include:

1. Re-adjust door closer.

2. Remove door silencers.

3. Remove, or trim, weather stripping around the door.

4. Adjust electric strike position if possible.

5. Correct excessive warping of door.

PHONE: (718) 829-2332

FAX: (718) 829-6405

1440 FERRIS PLACE

BRONX, NY 10461

email: customerser[email protected]

website: www.trineonline.com

4

Current Power

Voltage Draw Consumption Resistance

12DC .240 Amps 2.90 Watts 50 Ohms

24DC .114 Amps 2.74 Watts 210 Ohms

12AC

@ 50-60Hz

.210 Amps 2.50 Watts 50 Ohms

16AC

@ 50-60Hz

.281 Amps 4.48 Watts 50 Ohms

24AC

@ 50-60Hz

.420 Amps 10.08 Watts 50 Ohms

4200 ELECTRICAL CHARACTERISTICS:

Mount the shim with the step aligned

with the top of the latch as so.

This position will ensure that the cylindrical

lock's auxilliary trigger will function properly.

USING THE LATCH SPACER SHIM

The latch spacer shim is used to make an adjustment to

minimize the space between the door's inside face and the door

stop, or reduce door play. For cylindrical locks aligning to the

vertical center of the strike mount the shim as shown below.

OPERATING TEMP RANGE: -20°C TO +40°C

DO NOT APPLY A VOLTAGE OF MORE THAN 10% OVER THE RATED

OPERATING VOLTAGE OF THE STRIKE OR THE SOLENOID WILL BE DAMAGED

When removing the connector and using the wires direct; Blue Wire is Common,

Red Wire accepts 12DC & 12-16AC, Brown Wire accepts 24DC.

RS IS FAILSAFE ACTION (LOCKS WITH POWER) AND IS DC ONLY

24V DC OR 12V DC

TRANSFORMER

TO 120V AC LINE

PUSH

BUTTON

NORMALLY

CLOSED

+

-

FAIL-SAFE

ELECTRIC STRIKE

USE THE PROPER

CONNECTOR 12VDC OR 24VDC

ASSEMBLY FOR

THE 4200 STRIKE

Cannot use AC in Fail Safe Configuration

24V DC OR 12V DC TRANSFORMER

TO 120V AC LINE

PUSH

BUTTON

NORMALLY OPEN

+

-

USE THE PROPER

CONNECTOR 12VDC OR 24VDC

ASSEMBLY FOR

THE 4200 STRIKE

For AC use the 12 VDC connectors

For 12 - 24 VAC use 50-60 Hz

FAIL-SECURE

ELECTRIC STRIKE

V. 14.0218

C

L3 3/8"

4 7/8"

4 1/8"

1 1/4"

1/4"

1 3/4"

BACKSET

1 1/16"

1 5/8"

1/2”

CAVITY DEPTH

25/32"

32D (630) Satin Stainless

ALUM Aluminum Powder Coat

BLK Black Powder Coat

DKBZ

Dark Bronze Powder Coat

GRN Green Powder Coat

WHT White Powder Coat

AVAILABLE FINISHES

1 - (1) 4200 Electric Strike Mechanism

2 - (4) Faceplates as shown

3 - (6) #12-24 x 1/2 inch Philips Mounting Screws

4 - (2) #12-24 Lock Nut

5 - (2)

Quick Connect Socket & Wire Assembly 12VDC & 24VDC Version

6 - (2) Sealed Crimp Connectors

7 - (1) Latch Spacer Shims & (2) Mounting Screws

8 - (1) Frame Trim Skirt & (2) Screws

9 - (2) Mounting Tabs

WHAT'S IN THE BOX:

Auxilliary Trigger

PREMIUM TRIM SKIRT FOR THE 4200

USING THE TRIM SKIRT

The skirt can be used to clean up the

cut line of the frame face during

installation. The Trim Skirt comes

with 2 longer screws (included) for

fastening to the top and bottom of

the 4200.

Available in 5 powdercoat finishes:

Aluminum (ALUM), Black (BLK), Dark

Bronze (DKBZ), Green (GRN), and

White (WHT) which can match the

finish of the faceplate and Fascia’s.

RS IS FAILSAFE ACTION (LOCKS WITH POWER) AND IS DC ONLY

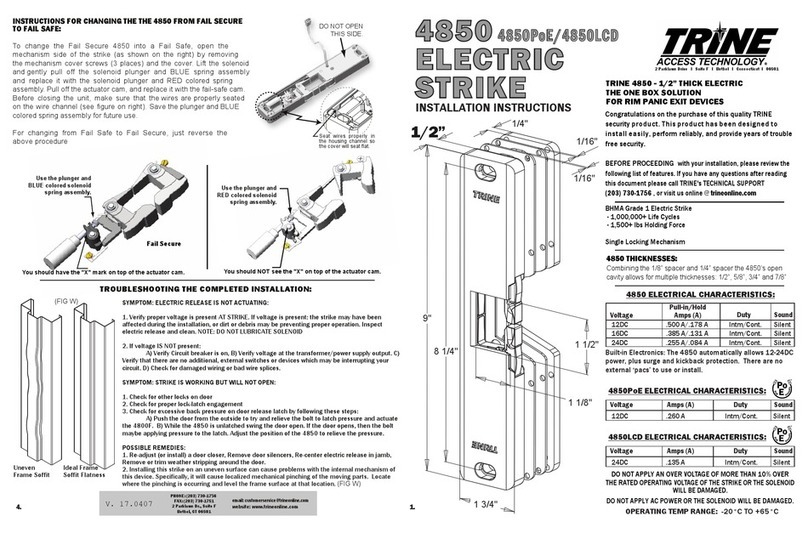

Fail Safe

(Fire Rating is void

when 4800F is fail-safe)

You should NOT see the "X" on top of the actuator cam.

Use the plunger and

RED colored solenoid

spring assembly.

Fail Secure

You should have the "X" mark on top of the actuator cam.

Use the plunger and

BLUE colored solenoid

spring assembly.

DO NOT OPEN

THIS SIDE.

TROUBLESHOOTING THE COMPLETED INSTALLATION:

.

Seat wires properly in

the housing channel so

the cover will seat flat.

INSTRUCTIONS FOR CHANGING THE THE 4800F FROM FAIL SECURE

TO FAIL SAFE:

To change the Fail Secure 4800F into a Fail Safe , open the

mechanism side of the strike (as shown on the right) by removing

the mechanism cover screws (3 places) and the cover. Lift the solenoid

and gently pull off the solenoid plunger and BLUE spring assembly

and replace it with the solenoid plunger and RED colored spring

assembly. Pull off the actuator cam, and replace it with the fail-safe cam.

Before closing the unit, make sure that the wires are properly seated

on the wire channel (see figure on right). Save the plunger and BLUE

colored spring assembly for future use.

For changing from Fail Safe to Fail Secure, just reverse the

above procedure

SYMPTOM: ELECTRIC RELEASE IS NOT ACTUATING:

1. Verify proper voltage is present AT STRIKE. If voltage is present: the strike may have been

affected during the installation, or dirt or debris may be preventing proper operation. Inspect

electric release and clean. NOTE: DO NOT LUBRICATE SOLENOID

2. If voltage IS NOT present:

A) Verify Circuit breaker is on, B) Verify voltage at the transformer/power supply output. C)

Verify that there are no additional, external switches or devices which may be interrupting your

circuit. D) Check for damaged wiring or bad wire splices.

SYMPTOM: STRIKE IS WORKING BUT WILL NOT OPEN:

1. Check for other locks on door

2. Check for proper lock-latch engagement

3. Check for excessive back pressure on door release latch by following these steps:

A) Push the door from the outside to try and relieve the bolt to latch pressure and actuate

the 4800F. B) While the 4800F is unlatched swing the door open. If the door opens, then the bolt

maybe applying pressure to the latch. Adjust the position of the 4800F to relieve the pressure.

POSSIBLE REMEDIES:

1. Re-adjust (or install) a door closer, Remove door silencers, Re-center electric release in jamb,

Remove or trim weather stripping around the door.

2. Installing this strike on an uneven surface can cause problems with the internal mechanism of

this device. Specifically, it will cause localized mechanical pinching of the moving parts. Locate

where the pinching is occurring and level the frame surface at that location. (FIG W)

4.

Uneven

Frame Soffit

Ideal Frame

Soffit Flatness

(FIG W)

PHONE: (203) 730-1756

FAX: (203) 730-1781

2 Parklawn Dr., Suite F

Bethel, CT 06801

email: customerservice@trineonline.com

website: www.trineonline.com

V. 16.0226

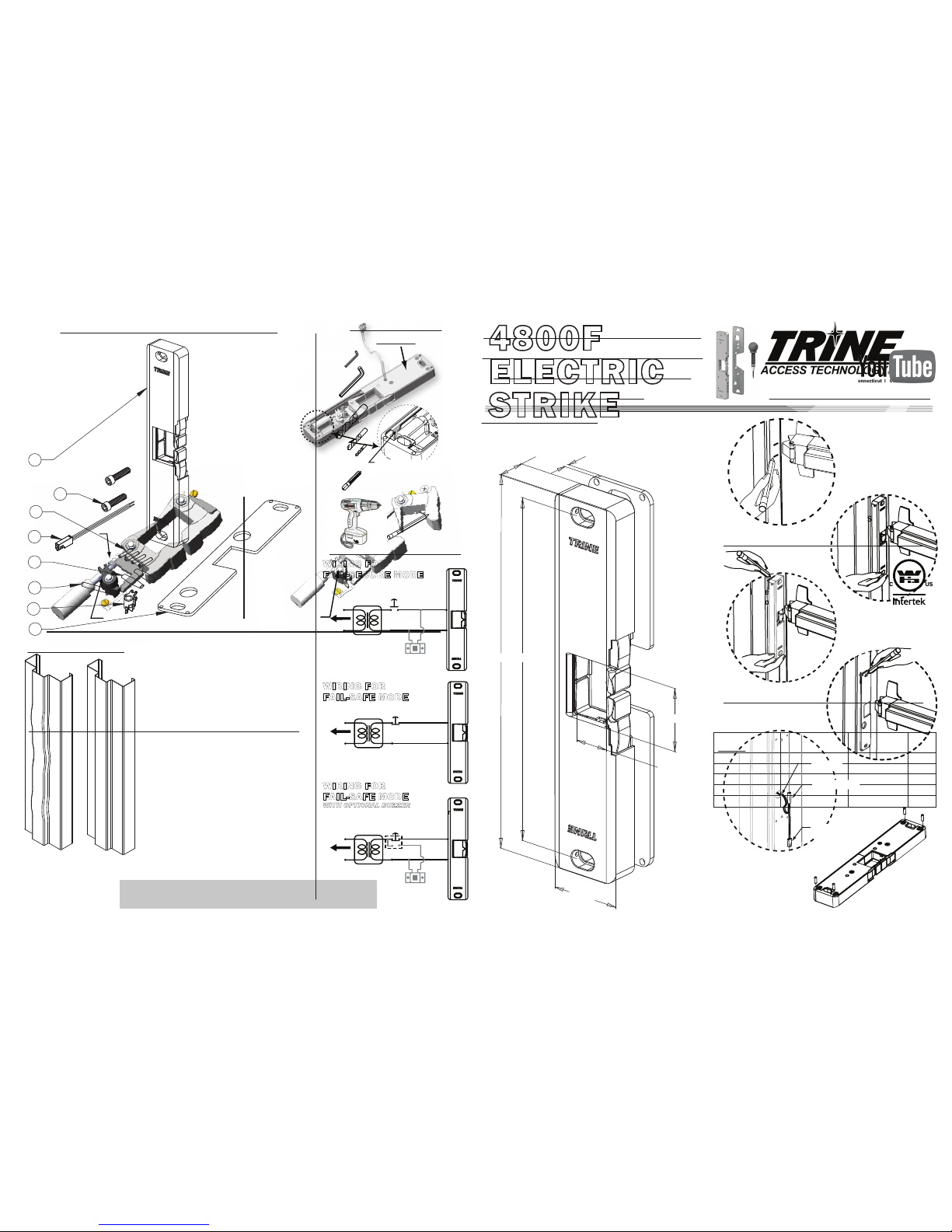

TRINE 4800F

THE FIRE RATED SOLUTION

FOR RIM PANIC EXIT DEVICES

4800F ELECTRICAL CHARACTERISTICS:

4800F

ELECTRIC

STRIKE

INSTALLATION INSTRUCTIONS Congratulations on the purchase of this quality TRINE

security product. This product has been designed to

install easily, perform reliably, and provide years of trouble

free security.

BEFORE PROCEEDING

with your installation, please review the

following list of features. If you have any questions after reading

this document please call TRINE's TECHNICAL SUPPORT

(203) 730-1756, or visit us online @ trineonline.com

Built-in Electronics: The 4800F automaticallys allows

12-24AC & DC power, plus surge and kickback protection.

There are no external ‘pacs’ to use or install.

The 4800F is WH recognized for:

Class A, 3 Hour Single door / frame configuration

- UL10C, Fire Tests of Door Assemblies

- UBC 7-2, Uniform building Code

- CAN4 S104,

Standard Method for Fire Tests of Door

Assemblies

NFPA 252

Issue: 1999/01/01 Standard Methods of Fire Tests of Door

Assemblies

NOTE: WH fire listing is void when using fail safe action.

BHMA Grade 1 Electric Strike

9"

1 3/4"

8 1/4"

1 1/2"

1/8"

3/4"

7/8"

Pull-in/Hold

Amps (A) Duty

Voltage Sound

12DC .566 A/.217 A Intm/Cont. Silent

24DC .253 A/.099 A Intm/Cont. Silent

12AC

@ 50-60Hz

.509 A/.181 A Intm/Cont. Silent

16AC

@ 50-60Hz

.405 A/.149 A Intm/Cont. Silent

24AC

@ 50-60Hz

.215 A/.087 A Intm/Cont. Silent

OPERATING TEMP RANGE: -20°C TO +65°C

DO NOT APPLY AN OVER VOLTAGE OF MORE THAN 10%

OVER THE RATED

OPERATING VOLTAGE OF THE

STRIKE OR THE SOLENOID WILL BE DAMAGED.

2 Parklawn Drive l Suite F l Bethel l Connecticut l 06801

TO 120V

AC LINE

USE 12V THRU 24V

AC OR DC

TRANSFORMER

WIRINGFOR

FAIL-SECURE MODE

SWITCH

NORMALLY

OPEN

FAIL-SECURE

CONFIGURED

STRIKE

OPTIONAL BUZZER

NOTE: MATCH THE VOLTAGE

OF THE TRANSFORMER

AND IF REQUIRED,

OBSERVE POLARITY

USE 12V THRU 24V

AC OR DC

TRANSFORMER

TO 120V

AC LINE

WIRINGFOR

FAIL-SAFE MODE

SWITCH

NORMALLY

CLOSED

FAIL-SAFE

CONFIGURED

STRIKE

USE 12V THRU 24V

AC OR DC

TRANSFORMER

TO 120V

AC LINE

WIRINGFOR

FAIL-SAFE MODE

WITH OPTIONAL BUZZER

SWITCH

SINGLE POLE

DOUBLE THROW

FAIL-SAFE

CONFIGURED

STRIKE

OPTIONAL BUZZER

NOTE: MATCH THE VOLTAGE

OF THE TRANSFORMER

AND IF REQUIRED,

OBSERVE POLARITY

RECOMMENDED PREINSTALLATION CHECK FOR THE 4800F SURFACE

MOUNT STRIKE:

1. Determine that door is properly adjusted; Door must operate properly in order for

system to provide best results.

2. Door must swing properly, without interfering with jamb or sill

3. The door should be equipped with a door closer and the door closer "latch

mode" must hold door in a completely closed position in order to avoid the lock

latch from applying pressure against the releasing latch portion of the electric

strike.

4. Electrical wire connections must be completed and ready to be terminated

inside the frame.

5. Confirm that the power line in the frame is the correct voltage, amperage, and

that the switch works properly.

6. Confirm proper clearance exists between the end of the lock latch and jamb.

7. The electric door strike must be aligned properly with lock latch when it is

installed on the doorjamb.

8. For best installation results, the door frame must be reasonably flat and straight.

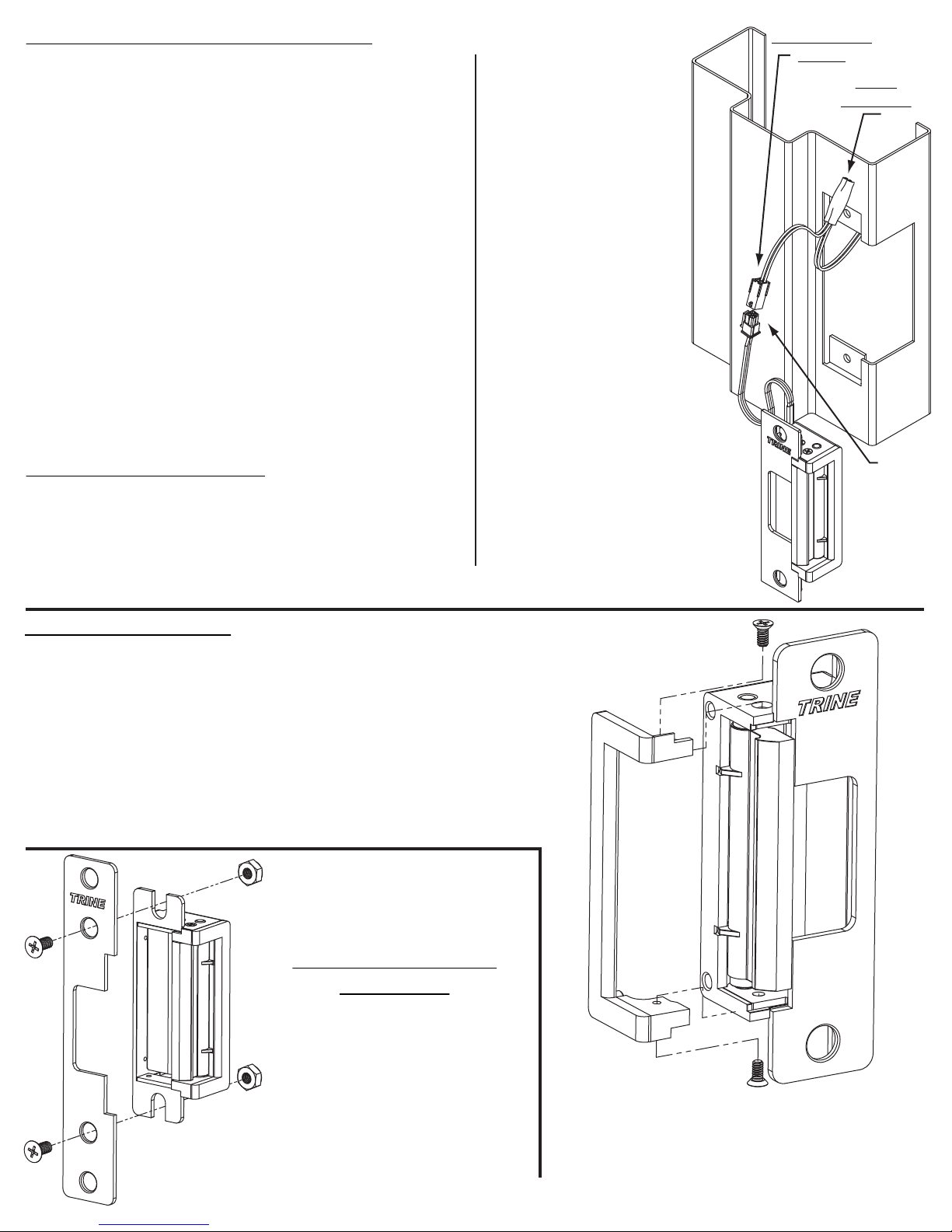

2. 3.

WHAT IS INCLUDED IN THE 4800F BOX:

INCLUDED IN THE BOX ARE:

1 - (1) 4800 OR 4801 SURFACE MOUNTED STRIKE

2 - (2) 1/4-20 x 1" UH CAP SOCKET MOUNTING SCREWS

3 - (4) ANCHOR SYSTEM PINS

4 - (1) QUICK CONNECT SOCKET AND WIRE ASSEMBLY

5 - (2) SEALED CRIMP CONNECTORS

6 - (1) FAIL SAFE SPRING (RED COLORED) & SOLENOID PLUNGER

7 - (1) FAIL SAFE CAM (NOTE: NOT FIRE RATED WHEN CONFIGURED FAIL-SAFE)

8 - (1) 1/8" THICK SPACER PLATE/ FRAME MOUNTING TEMPLATE

1

7

3

8

4

2

5

6

RECOMMENDED

TOOLS:

- 3/32 inch Allen Wrench

- 3/16 inch Allen Wrench

- 3/4 inch diameter Drill Bit

- #7 (0.201 inch

diameter) Drill Bit

- #30 (0.128 inch

diameter) Drill Bit

(for the optional Anchor Pins)

- 1/4-20 Tap

- Drill

- Marker

Figure 3

Figure 6

Figure 1

With the door closed,

mark the position of

the bolt on the frame.

Figure 2

Position the 4800F on

the frame and mark

the desire position.

Figure 4

Use the spacer as

template to mark the

holes you desire to use.

Push the anchor pins in

the back of any 4800F

series strike if you

desire to use this

Figure 5

Crimp the quick

connect socket

assembly to the

power wires.

Crimp Connectors

Quick Connect

Socket Assembly

Power Wire

1. Mark the end position of the exit devices latchbolt on the doorframe.

(Take off the original strike if present). See Figure 1.

2. Using the marks you just made as your guide, position the 4800F

over the mark on the frame. Make sure that the Auxiliary latch rides

up properly over the 4800's edge, and is engaged, and that the door

is in the fully closed position. See Figure 2

3. When you are confident with the position of the 4800F, mark two

perpendicular edges of the 4800F on the frame See Figure 3

4. Put the 4800F aside for a moment and place the spacer supplied

with the 4800F inside the marks you just made on the frame.

5. Using the spacer as a template; mark the two mounting holes and

the wire exit hole. If you are using the optional anchor pins, mark the

anchor pin positions using the spacer as a template. See Figure 4

6. Using a #7 bit, drill the two mounting holes and tap them ¼-20.

7. Using a ¾ inch diameter bit, drill the power wire exit hole

8. If you are utilizing the anchor pin system, use a #30 bit, drill the four

anchor pin holes.

9. Deburr any sharp edges around the holes after drilling, so that the

4800F will rest on a smooth clean surface and the wires will not be

accidentally cut or damaged while installing.

10. Pull the power wiring down the door frame and through the ¾ inch

diameter power wire hole.

11. Using the provided sealed crimp connectors, terminate the quick

connect socket assembly to the power wires. See Figure 5 (NOTE:

The 4800F is not polarized)

12.

If you intend to use the anchor pins system, insert them into the four

holes on the back side of the 4800F. See Figure 6. If you also intend to

use the 1/8" thick spacer plate, you can now slip the plate over the pins.

13. Snap together the power supply side connector coming off the

frame to the 4800 connector. Carefully push the wires and

connectors back into the frame.

14. Using the 2 mounting screws, mount the 4800F strike to the frame.

15. Adjust the strike to the desired position and tighten the mounting

screws using the 3/16 inch Allen wrench.

16. Using the 3/32 inch Allen wrench turn the two setscrews on the side

of the 4800F until they support the strike. DO NOT over tighten the

setscrews.

17. Turn the power ON and test your installation. Installation is now

complete.

INSTALLATION PROCEDURE:

CAUTION: TO AVOID ELECTRICAL SHOCK AND INJURIES,

BEFORE DOING YOUR WIRING, TURN OFF THE POWER FROM

THE CIRCUIT BREAKER.

CHECK OUT THE VIDEO ON

SEARCH

“4850ITL”

USE THE 4850ITL TO QUICKLY

MARK, TEST, ADJUST, CENTER

PUNCH AND SKIP MOST OF

THESE STEPS! more info @ trineonline.com/4850itl.php

Fail Safe

(Fire Rating is void

when 4800F is fail-safe)

You should NOT see the "X" on top of the actuator cam.

Use the plunger and

RED colored solenoid

spring assembly.

Fail Secure

You should have the "X" mark on top of the actuator cam.

Use the plunger and

BLUE colored solenoid

spring assembly.

DO NOT OPEN

THIS SIDE.

TROUBLESHOOTING THE COMPLETED INSTALLATION:

.

Seat wires properly in

the housing channel so

the cover will seat flat.

INSTRUCTIONS FOR CHANGING THE THE 4800F FROM FAIL SECURE

TO FAIL SAFE:

To change the Fail Secure 4800F into a Fail Safe , open the

mechanism side of the strike (as shown on the right) by removing

the mechanism cover screws (3 places) and the cover. Lift the solenoid

and gently pull off the solenoid plunger and BLUE spring assembly

and replace it with the solenoid plunger and RED colored spring

assembly. Pull off the actuator cam, and replace it with the fail-safe cam.

Before closing the unit, make sure that the wires are properly seated

on the wire channel (see figure on right). Save the plunger and BLUE

colored spring assembly for future use.

For changing from Fail Safe to Fail Secure, just reverse the

above procedure

SYMPTOM: ELECTRIC RELEASE IS NOT ACTUATING:

1. Verify proper voltage is present AT STRIKE. If voltage is present: the strike may have been

affected during the installation, or dirt or debris may be preventing proper operation. Inspect

electric release and clean. NOTE: DO NOT LUBRICATE SOLENOID

2. If voltage IS NOT present:

A) Verify Circuit breaker is on, B) Verify voltage at the transformer/power supply output. C)

Verify that there are no additional, external switches or devices which may be interrupting your

circuit. D) Check for damaged wiring or bad wire splices.

SYMPTOM: STRIKE IS WORKING BUT WILL NOT OPEN:

1. Check for other locks on door

2. Check for proper lock-latch engagement

3. Check for excessive back pressure on door release latch by following these steps:

A) Push the door from the outside to try and relieve the bolt to latch pressure and actuate

the 4800F. B) While the 4800F is unlatched swing the door open. If the door opens, then the bolt

maybe applying pressure to the latch. Adjust the position of the 4800F to relieve the pressure.

POSSIBLE REMEDIES:

1. Re-adjust (or install) a door closer, Remove door silencers, Re-center electric release in jamb,

Remove or trim weather stripping around the door.

2. Installing this strike on an uneven surface can cause problems with the internal mechanism of

this device. Specifically, it will cause localized mechanical pinching of the moving parts. Locate

where the pinching is occurring and level the frame surface at that location. (FIG W)

4.

Uneven

Frame Soffit

Ideal Frame

Soffit Flatness

(FIG W)

PHONE: (203) 730-1756

FAX: (203) 730-1781

2 Parklawn Dr., Suite F

Bethel, CT 06801

email: customerservice@trineonline.com

website: www.trineonline.com

V. 16.0226

TRINE 4800F

THE FIRE RATED SOLUTION

FOR RIM PANIC EXIT DEVICES

4800F ELECTRICAL CHARACTERISTICS:

4800F

ELECTRIC

STRIKE

INSTALLATION INSTRUCTIONS Congratulations on the purchase of this quality TRINE

security product. This product has been designed to

install easily, perform reliably, and provide years of trouble

free security.

BEFORE PROCEEDING

with your installation, please review the

following list of features. If you have any questions after reading

this document please call TRINE's TECHNICAL SUPPORT

(203) 730-1756, or visit us online @ trineonline.com

Built-in Electronics: The 4800F automaticallys allows

12-24AC & DC power, plus surge and kickback protection.

There are no external ‘pacs’ to use or install.

The 4800F is WH recognized for:

Class A, 3 Hour Single door / frame configuration

- UL10C, Fire Tests of Door Assemblies

- UBC 7-2, Uniform building Code

- CAN4 S104,

Standard Method for Fire Tests of Door

Assemblies

NFPA 252

Issue: 1999/01/01 Standard Methods of Fire Tests of Door

Assemblies

NOTE: WH fire listing is void when using fail safe action.

BHMA Grade 1 Electric Strike

9"

1 3/4"

8 1/4"

1 1/2"

1/8"

3/4"

7/8"

Pull-in/Hold

Amps (A) Duty

Voltage Sound

12DC .566 A/.217 A Intm/Cont. Silent

24DC .253 A/.099 A Intm/Cont. Silent

12AC

@ 50-60Hz

.509 A/.181 A Intm/Cont. Silent

16AC

@ 50-60Hz

.405 A/.149 A Intm/Cont. Silent

24AC

@ 50-60Hz

.215 A/.087 A Intm/Cont. Silent

OPERATING TEMP RANGE: -20°C TO +65°C

DO NOT APPLY AN OVER VOLTAGE OF MORE THAN 10%

OVER THE RATED

OPERATING VOLTAGE OF THE

STRIKE OR THE SOLENOID WILL BE DAMAGED.

2 Parklawn Drive l Suite F l Bethel l Connecticut l 06801

TO 120V

AC LINE

USE 12V THRU 24V

AC OR DC

TRANSFORMER

WIRINGFOR

FAIL-SECURE MODE

SWITCH

NORMALLY

OPEN

FAIL-SECURE

CONFIGURED

STRIKE

OPTIONAL BUZZER

NOTE: MATCH THE VOLTAGE

OF THE TRANSFORMER

AND IF REQUIRED,

OBSERVE POLARITY

USE 12V THRU 24V

AC OR DC

TRANSFORMER

TO 120V

AC LINE

WIRINGFOR

FAIL-SAFE MODE

SWITCH

NORMALLY

CLOSED

FAIL-SAFE

CONFIGURED

STRIKE

USE 12V THRU 24V

AC OR DC

TRANSFORMER

TO 120V

AC LINE

WIRINGFOR

FAIL-SAFE MODE

WITH OPTIONAL BUZZER

SWITCH

SINGLE POLE

DOUBLE THROW

FAIL-SAFE

CONFIGURED

STRIKE

OPTIONAL BUZZER

NOTE: MATCH THE VOLTAGE

OF THE TRANSFORMER

AND IF REQUIRED,

OBSERVE POLARITY

RECOMMENDED PREINSTALLATION CHECK FOR THE 4800F SURFACE

MOUNT STRIKE:

1. Determine that door is properly adjusted; Door must operate properly in order for

system to provide best results.

2. Door must swing properly, without interfering with jamb or sill

3. The door should be equipped with a door closer and the door closer "latch

mode" must hold door in a completely closed position in order to avoid the lock

latch from applying pressure against the releasing latch portion of the electric

strike.

4. Electrical wire connections must be completed and ready to be terminated

inside the frame.

5. Confirm that the power line in the frame is the correct voltage, amperage, and

that the switch works properly.

6. Confirm proper clearance exists between the end of the lock latch and jamb.

7. The electric door strike must be aligned properly with lock latch when it is

installed on the doorjamb.

8. For best installation results, the door frame must be reasonably flat and straight.

2. 3.

WHAT IS INCLUDED IN THE 4800F BOX:

INCLUDED IN THE BOX ARE:

1 - (1) 4800 OR 4801 SURFACE MOUNTED STRIKE

2 - (2) 1/4-20 x 1" UH CAP SOCKET MOUNTING SCREWS

3 - (4) ANCHOR SYSTEM PINS

4 - (1) QUICK CONNECT SOCKET AND WIRE ASSEMBLY

5 - (2) SEALED CRIMP CONNECTORS

6 - (1) FAIL SAFE SPRING (RED COLORED) & SOLENOID PLUNGER

7 - (1) FAIL SAFE CAM (NOTE: NOT FIRE RATED WHEN CONFIGURED FAIL-SAFE)

8 - (1) 1/8" THICK SPACER PLATE/ FRAME MOUNTING TEMPLATE

1

7

3

8

4

2

5

6

RECOMMENDED

TOOLS:

- 3/32 inch Allen Wrench

- 3/16 inch Allen Wrench

- 3/4 inch diameter Drill Bit

- #7 (0.201 inch

diameter) Drill Bit

- #30 (0.128 inch

diameter) Drill Bit

(for the optional Anchor Pins)

- 1/4-20 Tap

- Drill

- Marker

Figure 3

Figure 6

Figure 1

With the door closed,

mark the position of

the bolt on the frame.

Figure 2

Position the 4800F on

the frame and mark

the desire position.

Figure 4

Use the spacer as

template to mark the

holes you desire to use.

Push the anchor pins in

the back of any 4800F

series strike if you

desire to use this

Figure 5

Crimp the quick

connect socket

assembly to the

power wires.

Crimp Connectors

Quick Connect

Socket Assembly

Power Wire

1. Mark the end position of the exit devices latchbolt on the doorframe.

(Take off the original strike if present). See Figure 1.

2. Using the marks you just made as your guide, position the 4800F

over the mark on the frame. Make sure that the Auxiliary latch rides

up properly over the 4800's edge, and is engaged, and that the door

is in the fully closed position. See Figure 2

3. When you are confident with the position of the 4800F, mark two

perpendicular edges of the 4800F on the frame See Figure 3

4. Put the 4800F aside for a moment and place the spacer supplied

with the 4800F inside the marks you just made on the frame.

5. Using the spacer as a template; mark the two mounting holes and

the wire exit hole. If you are using the optional anchor pins, mark the

anchor pin positions using the spacer as a template. See Figure 4

6. Using a #7 bit, drill the two mounting holes and tap them ¼-20.

7. Using a ¾ inch diameter bit, drill the power wire exit hole

8. If you are utilizing the anchor pin system, use a #30 bit, drill the four

anchor pin holes.

9. Deburr any sharp edges around the holes after drilling, so that the

4800F will rest on a smooth clean surface and the wires will not be

accidentally cut or damaged while installing.

10. Pull the power wiring down the door frame and through the ¾ inch

diameter power wire hole.

11. Using the provided sealed crimp connectors, terminate the quick

connect socket assembly to the power wires. See Figure 5 (NOTE:

The 4800F is not polarized)

12.

If you intend to use the anchor pins system, insert them into the four

holes on the back side of the 4800F. See Figure 6. If you also intend to

use the 1/8" thick spacer plate, you can now slip the plate over the pins.

13. Snap together the power supply side connector coming off the

frame to the 4800 connector. Carefully push the wires and

connectors back into the frame.

14. Using the 2 mounting screws, mount the 4800F strike to the frame.

15. Adjust the strike to the desired position and tighten the mounting

screws using the 3/16 inch Allen wrench.

16. Using the 3/32 inch Allen wrench turn the two setscrews on the side

of the 4800F until they support the strike. DO NOT over tighten the

setscrews.

17. Turn the power ON and test your installation. Installation is now

complete.

INSTALLATION PROCEDURE:

CAUTION: TO AVOID ELECTRICAL SHOCK AND INJURIES,

BEFORE DOING YOUR WIRING, TURN OFF THE POWER FROM

THE CIRCUIT BREAKER.

CHECK OUT THE VIDEO ON

SEARCH

“4850ITL”

USE THE 4850ITL TO QUICKLY

MARK, TEST, ADJUST, CENTER

PUNCH AND SKIP MOST OF

THESE STEPS! more info @ trineonline.com/4850itl.php

You should NOT see the "X" on top of the actuator cam.

Use the plunger and

RED colored solenoid

spring assembly.

Fail Secure

You should have the "X" mark on top of the actuator cam.

Use the plunger and

BLUE colored solenoid

spring assembly.

DO NOT OPEN

THIS SIDE.

TROUBLESHOOTING THE COMPLETED INSTALLATION:

.

Seat wires properly in

the housing channel so

the cover will seat flat.

INSTRUCTIONS FOR CHANGING THE THE 4850 FROM FAIL SECURE

TO FAIL SAFE:

To change the Fail Secure 4850 into a Fail Safe, open the

mechanism side of the strike (as shown on the right) by removing

the mechanism cover screws (3 places) and the cover. Lift the solenoid

and gently pull off the solenoid plunger and BLUE spring assembly

and replace it with the solenoid plunger and RED colored spring

assembly. Pull off the actuator cam, and replace it with the fail-safe cam.

Before closing the unit, make sure that the wires are properly seated

on the wire channel (see figure on right). Save the plunger and BLUE

colored spring assembly for future use.

For changing from Fail Safe to Fail Secure, just reverse the

above procedure

4850 THICKNESSES:

Combining the 1/8” spacer and 1/4” spacer the 4850’s open

cavity allows for multiple thicknesses: 1/2”, 5/8“, 3/4” and 7/8”

SYMPTOM: ELECTRIC RELEASE IS NOT ACTUATING:

1. Verify proper voltage is present AT STRIKE. If voltage is present: the strike may have been

affected during the installation, or dirt or debris may be preventing proper operation. Inspect

electric release and clean. NOTE: DO NOT LUBRICATE SOLENOID

2. If voltage IS NOT present:

A) Verify Circuit breaker is on, B) Verify voltage at the transformer/power supply output. C)

Verify that there are no additional, external switches or devices which may be interrupting your

circuit. D) Check for damaged wiring or bad wire splices.

SYMPTOM: STRIKE IS WORKING BUT WILL NOT OPEN:

1. Check for other locks on door

2. Check for proper lock-latch engagement

3. Check for excessive back pressure on door release latch by following these steps:

A) Push the door from the outside to try and relieve the bolt to latch pressure and actuate

the 4800F. B) While the 4850 is unlatched swing the door open. If the door opens, then the bolt

maybe applying pressure to the latch. Adjust the position of the 4850 to relieve the pressure.

POSSIBLE REMEDIES:

1. Re-adjust (or install) a door closer, Remove door silencers, Re-center electric release in jamb,

Remove or trim weather stripping around the door.

2. Installing this strike on an uneven surface can cause problems with the internal mechanism of

this device. Specifically, it will cause localized mechanical pinching of the moving parts. Locate

where the pinching is occurring and level the frame surface at that location. (FIG W)

4. 1.

PHONE: (203) 730-1756

FAX: (203) 730-1781

2 Parklawn Dr., Suite F

Bethel, CT 06801

email: customerservice@trineonline.com

website: www.trineonline.com

V. 17.0407

Uneven

Frame Soffit

Ideal Frame

Soffit Flatness

(FIG W)

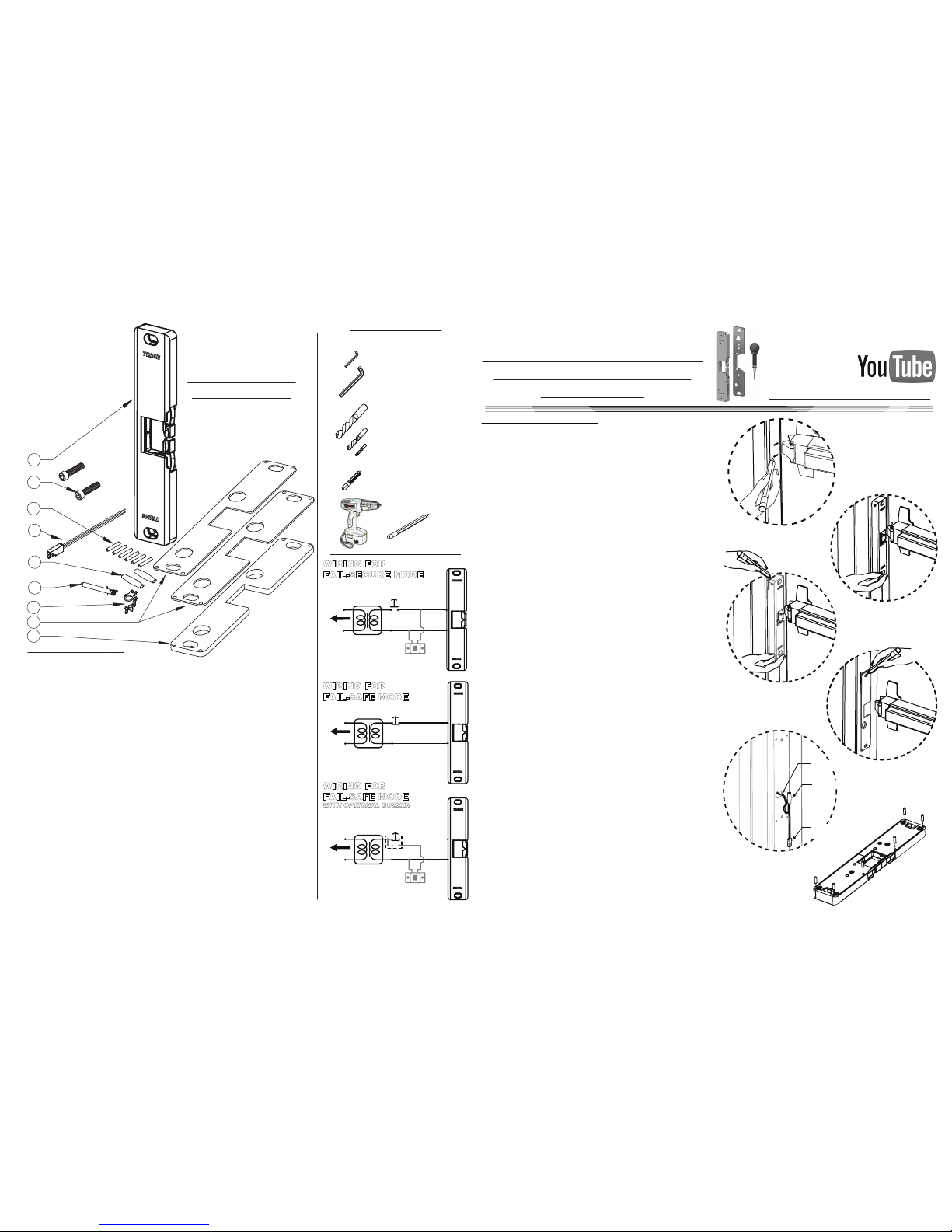

TRINE 4850 - 1/2” THICK ELECTRIC

THE ONE BOX SOLUTION

FOR RIM PANIC EXIT DEVICES

4850 ELECTRICAL CHARACTERISTICS:

4850

ELECTRIC

STRIKE

4850PoE/4850LCD

INSTALLATION INSTRUCTIONS Congratulations on the purchase of this quality TRINE

security product. This product has been designed to

install easily, perform reliably, and provide years of trouble

free security.

BEFORE PROCEEDING

with your installation, please review the

following list of features. If you have any questions after reading

this document please call TRINE's TECHNICAL SUPPORT

(203) 730-1756 , or visit us online @ trineonline.com

Built-in Electronics: The 4850 automatically allows 12-24DC

power, plus surge and kickback protection. There are no

external ‘pacs’ to use or install.

BHMA Grade 1 Electric Strike

- 1,000,000+ Life Cycles

- 1,500+ lbs Holding Force

Single Locking Mechanism

Pull-in/Hold

Amps (A) Duty

Voltage Sound

Sound

12DC .500 A/.178 A Intm/Cont. Silent

16DC .385 A/.131 A Intm/Cont. Silent

24DC .255 A/.084 A Intm/Cont. Silent

4850PoE ELECTRICAL CHARACTERISTICS:

Amps (A) DutyVoltage

12DC .260 A Intm/Cont. Silent

OPERATING TEMP RANGE: -20°C TO +65°C

2 Parklawn Drive l Suite F l Bethel l Connecticut l 06801

Sound

4850LCD ELECTRICAL CHARACTERISTICS:

Amps (A) DutyVoltage

24DC .135 A Intm/Cont. Silent

1/2”

DO NOT APPLY AN OVER VOLTAGE OF MORE THAN 10% OVER

THE RATED

OPERATING VOLTAGE OF THE STRIKE OR THE SOLENOID

WILL BE DAMAGED.

DO NOT APPLY AC POWER OR THE SOLENOID WILL BE DAMAGED.

1/16"

1/16"

9"

1 1/2"

1/4"

8 1/4"

1 3/4"

1 1/8"

TO 120V

AC LINE

USE 12V THRU 24V

DC TRANSFORMER

(Match voltage with

4850PoE and 4850LCD)

(Match voltage with

4850PoE and 4850LCD)

(Match voltage with

4850PoE and 4850LCD)

WIRINGFOR

FAIL-SECURE MODE

SWITCH

NORMALLY

OPEN

FAIL-SECURE

CONFIGURED

STRIKE

OPTIONAL BUZZER

NOTE: MATCH THE VOLTAGE

OF THE TRANSFORMER

AND IF REQUIRED,

OBSERVE POLARITY

USE 12V THRU 24V

DC TRANSFORMER

TO 120V

AC LINE

WIRINGFOR

FAIL-SAFE MODE

SWITCH

NORMALLY

CLOSED

FAIL-SAFE

CONFIGURED

STRIKE

USE 12V THRU 24V

DC TRANSFORMER

TO 120V

AC LINE

WIRINGFOR

FAIL-SAFE MODE

WITH OPTIONAL BUZZER

SWITCH

SINGLE POLE

DOUBLE THROW

FAIL-SAFE

CONFIGURED

STRIKE

OPTIONAL BUZZER

NOTE: MATCH THE VOLTAGE

OF THE TRANSFORMER

AND IF REQUIRED,

OBSERVE POLARITY

RECOMMENDED PREINSTALLATION CHECK FOR THE 4850 SURFACE

MOUNT STRIKE:

1. Determine that door is properly adjusted; Door must operate properly in order for

system to provide best results.

2. Door must swing properly, without interfering with jamb or sill

3. The door should be equipped with a door closer and the door closer "latch mode"

must hold door in a completely closed position in order to avoid the lock latch from

applying pressure against the releasing latch portion of the electric strike

.

4. Electrical wire connections must be completed and ready to be terminated

inside the frame.

5. Confirm that the power line in the frame is the correct voltage, amperage, and

that the switch works properly.

6. Confirm proper clearance exists between the end of the lock latch and jamb.

7. The electric door strike must be aligned properly with lock latch when it is

installed on the doorjamb.

8. For best installation results, the door frame must be reasonably flat and straight.

2. 3.

WHAT IS INCLUDED

IN THE 4850 BOX:

INCLUDED IN THE BOX ARE:

1 - (1) 4850 (OR 4850PoE/4850LCD) SURFACE MOUNTED STRIKE

2 - (2) 1/4-20 x 1" UH CAP SOCKET MOUNTING SCREWS

3 - (6) ANCHOR SYSTEM PINS

4 - (1) QUICK CONNECT SOCKET AND WIRE ASSEMBLY

5 - (2) SEALED CRIMP CONNECTORS

6 - (1) FAIL SAFE SPRING (RED COLORED) & SOLENOID PLUNGER

7 - (1) FAIL SAFE CAM

8 - (2) 1/16" THICK SPACER PLATES (replaces single 1/8” plate)

9 - (1) 1/4" THICK SPACER PLATE

1

7

3

8

9

4

2

5

6

RECOMMENDED

TOOLS:

- 3/32 inch Allen Wrench

- 3/16 inch Allen Wrench

- 3/4 inch diameter Drill Bit

- #7 (0.201 inch

diameter) Drill Bit

- #30 (0.128 inch

diameter) Drill Bit

(for the optional Anchor Pins)

- 1/4-20 Tap

- Drill

- Marker

Figure 3

Figure 1

With the door closed,

mark the position of

the bolt on the frame.

Figure 2

Position the 4850 on

the frame and mark

the desire position.

Figure 4

Use the spacer as

template to mark the

holes you desire to use.

Figure 6

Push the anchor pins in

the back of any 4850

series strike if you

desire to use this

Figure 5

Crimp the quick

connect socket

assembly to the

power wires.

Crimp Connectors

Quick Connect

Socket Assembly

Power Wire

1. Mark the end position of the exit devices latchbolt on the doorframe.

(Take off the original strike if present). See Figure 1.

2. Using the marks you just made as your guide, position the 4850 over

the mark on the frame. Make sure that the Auxiliary latch rides up

properly over the 4850's edge, and is engaged, and that the door is

in the fully closed position. See Figure 2

3. When you are confident with the position of the 4850, mark two

perpendicular edges of the 4850 on the frame See Figure 3

4. Put the 4850 aside for a moment and place the spacer supplied with

the 4850 inside the marks you just made on the frame.

5. Using the spacer as a template; mark the two mounting holes and

the wire exit hole. If you are using the optional anchor pins, mark the

anchor pin positions using the spacer as a template. See Figure 4

6. Using a #7 bit, drill the two mounting holes and tap them ¼-20.

7. Using a ¾ inch diameter bit, drill the power wire exit hole

8. If you are utilizing the anchor pin system, use a #30 bit, drill the four

anchor pin holes.

9. Deburr any sharp edges around the holes after drilling, so that the

4850 will rest on a smooth clean surface and the wires will not be

accidentally cut or damaged while installing.

10. Pull the power wiring down the door frame and through the ¾ inch

diameter power wire hole.

11. Using the provided sealed crimp connectors, terminate the quick

connect socket assembly to the power wires. See Figure 5 (NOTE:

The 4850 is not polarized)

12.

If you intend to use the anchor pins system, insert them into the 6 holes

on the back side of the 4850. See Figure 6. If you also intend to use the

1/8" thick spacer plate, you can now slip the plate over the pins.

13. Snap together the power supply side connector coming off the

frame to the 4850 connector. Carefully push the wires and

connectors back into the frame.

14. Using the 2 mounting screws, mount the 4850 strike to the frame.

15. Adjust the strike to the desired position and tighten the mounting

screws using the 3/16 inch Allen wrench.

16. Using the 3/32 inch Allen wrench turn the two setscrews on the side

of the 4850 until they support the strike. DO NOT over tighten the

setscrews.

17. Turn the power ON and test your installation. Installation is now

complete.

INSTALLATION PROCEDURE:

CAUTION: TO AVOID ELECTRICAL SHOCK AND INJURIES,

BEFORE DOING YOUR WIRING, TURN OFF THE POWER FROM

THE CIRCUIT BREAKER.

CHECK OUT THE VIDEO ON

SEARCH

“4850ITL”

USE THE 4850ITL TO QUICKLY

MARK, TEST, ADJUST, CENTER

PUNCH AND SKIP MOST OF

THESE STEPS! more info @ trineonline.com/4850itl.php

APPLICATION:

•Remote central station notification

•Local alarm monitoring

•Triggering video surveillance and

recording systems

•Active relay for trap door systems

•For Indoor applications ONLY.

TECHNICAL SPECIFICATIONS:

•SHARP®Infrared optical sensor

•Normally Open and Normally Closed

contact terminals

•Single pole, double throw, Form "C"

relay, rated at 1 Amp at 24 VAC or

24 VDC.

•Sensor Power - 12 through 30 VDC (ONLY)

FEATURES:

•Non-Mechanical operation

•Sensor is concealed within the unit

•Sensor does not require any adjustment

•Ignores ambient light, detecting radiant

Infrared reflections off the pullman latch

•Increase life and decrease in maintenance

due to electronic versus mechanical

operation

SENSOR WIRE

COLOR CODE

POWER LEADS:

Red - Positive

Black - Negative

RELAY LEADS:

Blue - Common

Yellow - Normally Open (NO)

White - Normally Closed (NC)

INFRARED

SENSOR

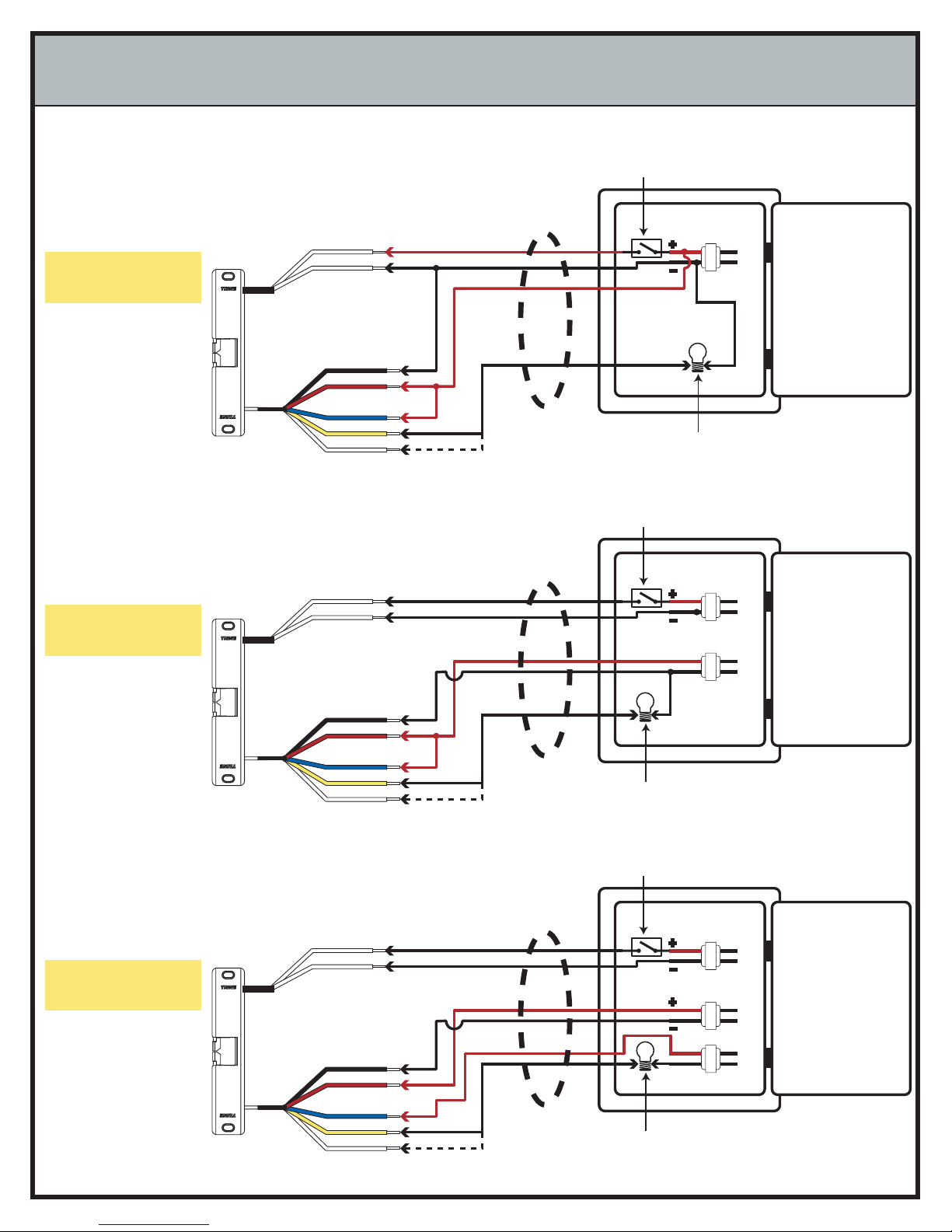

WIRING SCHEMATICS FOR TYPICAL APPLICATIONS

PREINSTALLATION CONSIDERATION:

When Mounting the 4800FLB, the pullman latch must be positioned as close

as possible to the vertical center of the latch cavity. Having the latch on

center will ensurethat the sensor will have enough surface to detect.

You can use the 1/8" and 1/4” spacer (included, 1/4” is for 4850LB only) to

move the 4850LB/4800FLB closer to the panic bar.

Spacer Plate

QUIESCENT TRIGGER

VOLTAGE CURRENT DRAW CURRENT DRAW

12VDC 13mA 23mA

24VDC 20mA 35mA

30VDC 22mA 39mA

WHITE - NORMALLY CLOSED (NC)

RED +

BLACK -

BLUE COMMON (COM)

YELLOW - NORMALLY OPEN (NO)

NOTE:

Please observe proper polarity for the LB sensor. The RED wire

terminal must be attached to the POSITIVE side and the BLACK wire

terminal must be attached to the NEGATIVE side.

TO TRANSFORMER

12V THROUGH 30V DC

RELAY TERMINALS

TO USER DEVICE OR

SENSORS.

LB SENSOR WIRE TERMINAL

COLOR CODING ASSIGNMENTS

RELAY

COMMON

NC

NO

TRANSFORMER

POWER

BUZZER OR

BELL

RELAY

COMMON

NC

NO

SECURITY SENSOR

For an alarm system a

Buzzer of Bell can be

wired to the NO terminal

such that when the door

is open the Buzzer or Bell

will sound.

For a security system

setup one side of the

circuit can be connected

to the common and the

other side to the NC

terminal so that when the

door is open, the system

senses the relay switch

as open

INSTRUCTION SHEET

SPECIFICATION AND

P: (203) 730-1756 -- F: (203) 730-1781

www.trineonline.com

4850LB/4800FLB

WHITE - NORMALLY CLOSED (NC)

BLACK -

RED +

BLUE COMMON (COM)

YELLOW - NORMALLY OPEN (NO)

120

VAC

12VDC

OUTPUT

CONTROL SWITCH

OR RELAY

PANEL INDICATOR

OR OTHER

SIGNALING DEVICE

POWER

SUPPLY

CONTROL

PANEL

PANEL SIDE

WIRING

FRAME SIDE

WIRING

Hook-up to either

Normally Open

or Normally

Closed Terminal

WHITE - NORMALLY CLOSED (NC)

BLACK -

RED +

BLUE COMMON (COM)

YELLOW - NORMALLY OPEN (NO)

120

VAC

120

VAC

12 - 24 VDC

OUTPUT

12 - 24 VDC

OUTPUT

CONTROL SWITCH

OR RELAY

PANEL INDICATOR

OR OTHER

SIGNALING DEVICE

POWER

SUPPLY 1

POWER

SUPPLY 2 CONTROL

PANEL

PANEL SIDE

WIRING

FRAME SIDE

WIRING

Hook-up to either

Normally Open

or Normally

Closed Terminal

WHITE - NORMALLY CLOSED (NC)

BLACK -

RED +

BLUE COMMON (COM)

YELLOW - NORMALLY OPEN (NO)

120

VAC

120

VAC

120

VAC

12 - 24 VDC

OUTPUT

12 - 24 VDC

OUTPUT

CONTROL SWITCH

OR RELAY

PANEL INDICATOR

OR OTHER

SIGNALING DEVICE

POWER

SUPPLY 1

POWER

SUPPLY 2

POWER

SUPPLY 3

CONTROL

PANEL

PANEL SIDE

WIRING

FRAME SIDE

WIRING

Hook-up to either

Normally Open

or Normally

Closed Terminal

WIRING SCHEMATICS FOR DIFFERENT APPLICATIONS

FOUR WIRE

SCHEMATIC UTILIZING

ONE TRANSFORMER

This wiring arrangement

uses the least amount of

conductors between the

Panel and the Frame.

FIVE WIRE SCHEMATIC

UTILIZING TWO

TRANSFORMERS

If the Signaling Device or

Panel Indicator requires a

different voltage, this

wiring scheme can be

used.

SIX WIRE SCHEMATIC

UTILIZING THREE

TRANSFORMERS

This wiring arrangement

is used to isolate the

strike operation, from the

LB sensor power board

and finally the Panel

Indicator or Signaling

Device.

STRIKE POWER

WIRE LEADS

LB SENSOR POWER

WIRE LEADS

LB SENSOR SIGNAL

WIRE LEADS

STRIKE POWER

WIRE LEADS

LB SENSOR POWER

WIRE LEADS

LB SENSOR SIGNAL

WIRE LEADS

STRIKE POWER

WIRE LEADS

LB SENSOR POWER

WIRE LEADS

LB SENSOR SIGNAL

WIRE LEADS

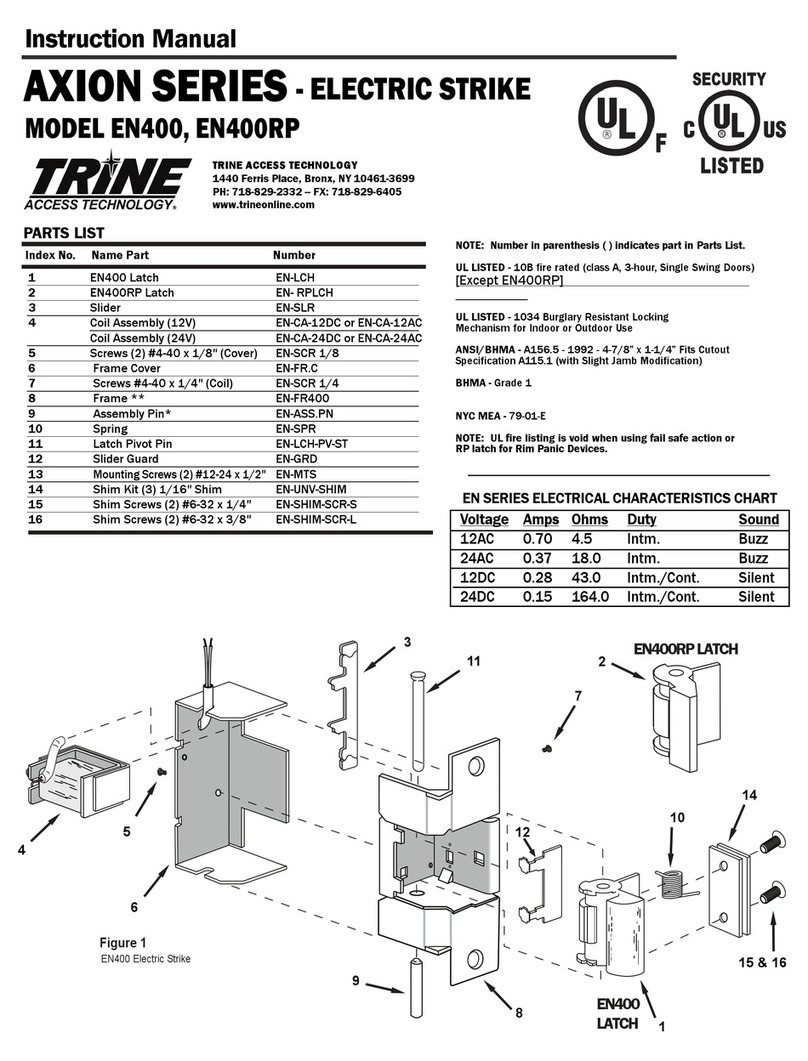

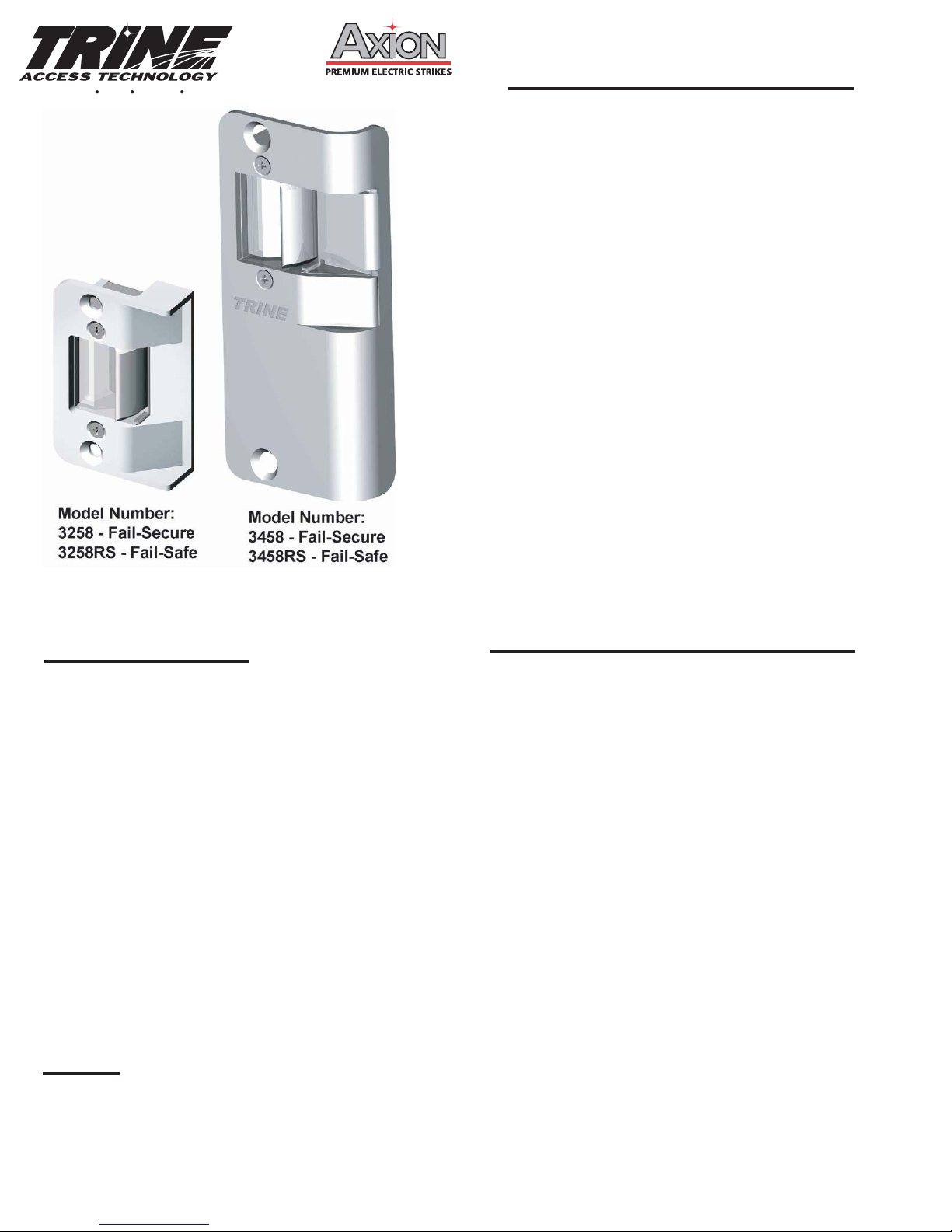

Model Number:

3478 - Fail Secure

3478RS - Fail Safe

Model Number:

3234W - Fail Secure

3234WRS - Fail Safe

Model Number:

3234 - Fail Secure

3234RS - Fail Safe

1440 Ferris Place · Bronx · New York· 10461-3699

TRINE 3000 SERIES ELECTRIC RELEASES

Congratulations on the purchase of this quality TRINE

security product.

This product has been designed to install easily, perform

reliably, and provide years of trouble free security.

In order for this product to fulfill its objectives, certain

steps must be performed by the installer, and certain site

conditions must be satisfied.

Before proceeding with your installation, please review

the following list of items. If you have any questions first

please finish reading this document to see if the

information you require is contained in this document,

otherwise please call:

TRINE TECH SUPPORT (718) 829-2332 EXT. 425,

or visit the TRINE Website www.TrineOnline.com.

The TRINE Model #3234, #3234W & Model #3478 are

designed for new installation or retrofitting into metal,

wood and aluminum door frames. Be sure that you have

ordered the correct TRINE strike for your application.

FINISHES

3234 3234W 3478

US3 (Polished Brass)

US4 (Satin Brass)

US10B (Dark Bronze)

US26 (Bright Chrome)

US26D (Satin Chrome)

US32D (Satin Stainless Steel)

STANDARD FEATURES

Face Plate - 3234, 2-3/4" x 1-1/8"

3234W, 3-3/4" x 1-1/4"

3478, 4-7/8" x 1-1/4"

Mortise Type - 1" backset (Smallest in the Industry)

Durability - 500,000 Life Cycles

Holding Force - 1,200 Pounds (Static Force)

- 70 ft-lb (Dynamic Force)

All stainless steel locking parts

Solid Cast Latch - Stainless Steel

Cavity: Width 5/8", Height 1-1/8", Depth 1/2"

Non-handed

Heavy-duty latch spring

Silent Operation

Intermittent Duty with the Standard versions

Intermittent and Continuous Duty with the LC versions

Micro Solenoid assembly

Fail-Secure:(standard action) unlocks with power

Fail-Safe: RS (reverse action) unlocks when power is off

RECOMMENDED INSTALLATION SEQUENCE:

1. Verify strike is proper for the door into which it is to be

installed.

2. Verify that you have all parts required to complete the

installation.

3. Verify that the new electric release operates with the

existing power supply/control circuit (retrofit

applications); or verify that the new power supply/

control circuit operates the new electric release (new

installations).

4. Locate and clearly mark the circuit breaker which

provides ac power to your transformer/ power supply

or that supplies power to the receptacle into which you

will plug your transformer/power supply. This will

enable you to safely cut power during installation, and

permit troubleshooting if required.

5. Verify that the receptacle or circuit providing power to

the electric release is not controlled by a wall switch,

time clock, or other external device.

6. Verify that the circuit/receptacle used for the locking

system is not powering any other equipment.

Remember that interruption of power to your locking

system could prevent access into the protected area,

or jeopardize the security/safety of the site's

occupants.

7. Verify that the door and associated components are in

good working order.

8. Install electric release as per attached guidelines.

9. Wire electric release as per attached guidelines.

10. Perform final test of completed installation.

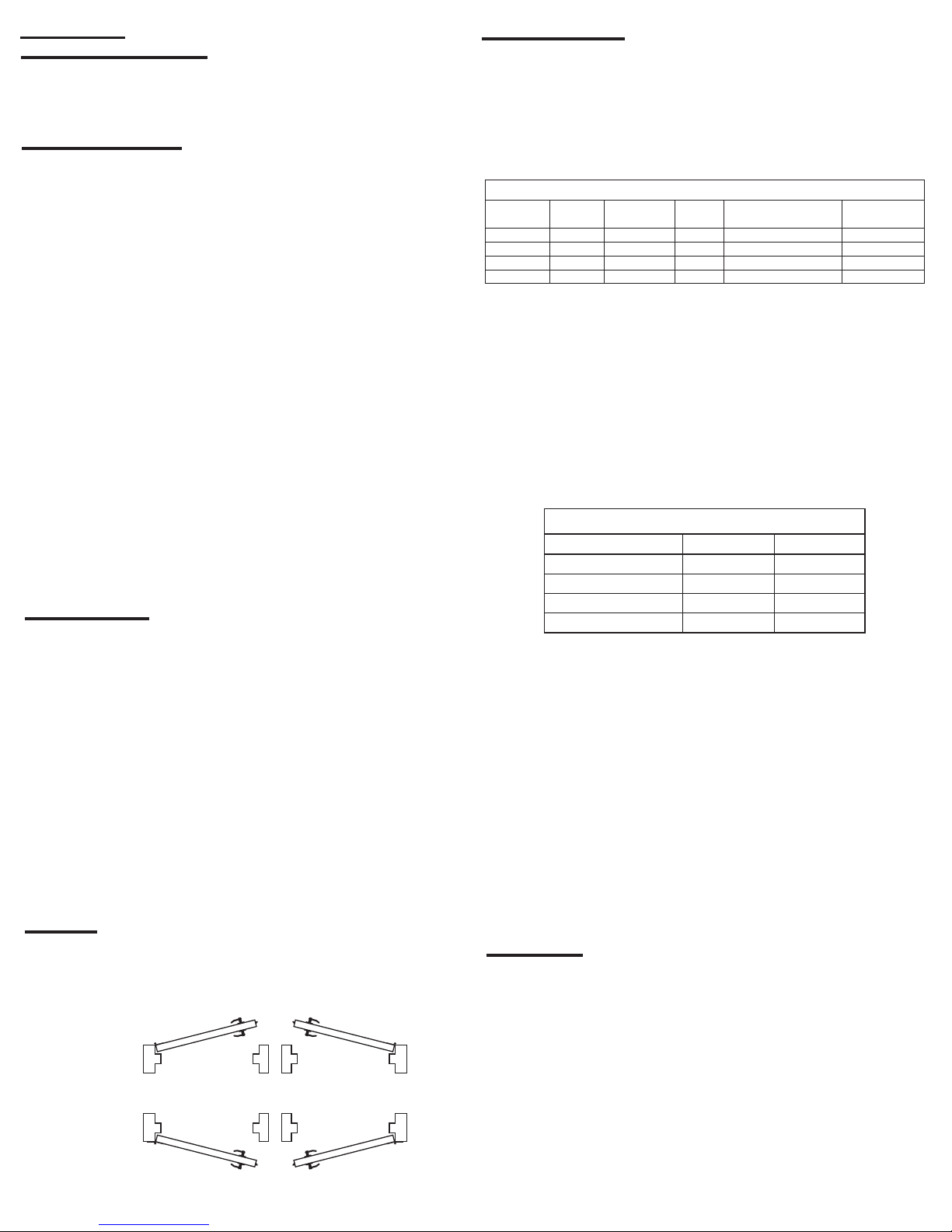

LEFT HAND

(LH)

LEFT HAND

REVERSE BEVEL

(LRB)

RIGHT HAND

(RH)

RIGHT HAND