IDEM SAFETY SWITCHES ES-P User manual

Emergency Stop Switches

Standards:

IEC

60947

-

5

-

5 UL508

EN

ISO

13850

Case Material

Stainless Steel 316 or Plastic

Sa ety Contact type

IEC 60947

-

5

-

1 Double break Type Zb

Contact Material

Silver

Termination

Clamp up to 2.5 sq. mm conductors

Rating

Utilisation Ca

tegory : AC15

Operational Rating

AC15 A300 240V. 3A /120V 6A. ac

Thermal Current (Ith)

10A.

Rated Insulation Voltage (Ui)

500V.

Withstand Voltage (Uimp)

2500V.

Short Circuit Overload Protection

Fuse Externally 10A. (FF)

Operating

Temperature

-

25C / 80C.

Enclosure Protection

IP67 Plastic or IP69K Stainless Steel

(NEMA 6)

Optional Explosion Proof Contact Block:

Classi ication

Rated Voltage

Rated Current

Safety Classification and Reliability Data:

Mechanical Reliability B10d

ISO 13849-1

EN 62061

Sa ety Data - Annual Usage

PFHd

Proo Test Interval (Li e)

MTTFd

Ex d IIC T6 (-20C Ta 60C) Gb

Ex tb IIIC T85C (-20C Ta 60C) Db

250V ac/dc

2 pole 4A. 4 pole 2.5A.

1.5 x 106 operations at 100mA load

up to PLe depending upon system architecture

up to SIL3 depending upon system architecture

8 cycles per hour / 24 hours per day / 365 days

<1.0 x 10-7

21 years

214 years

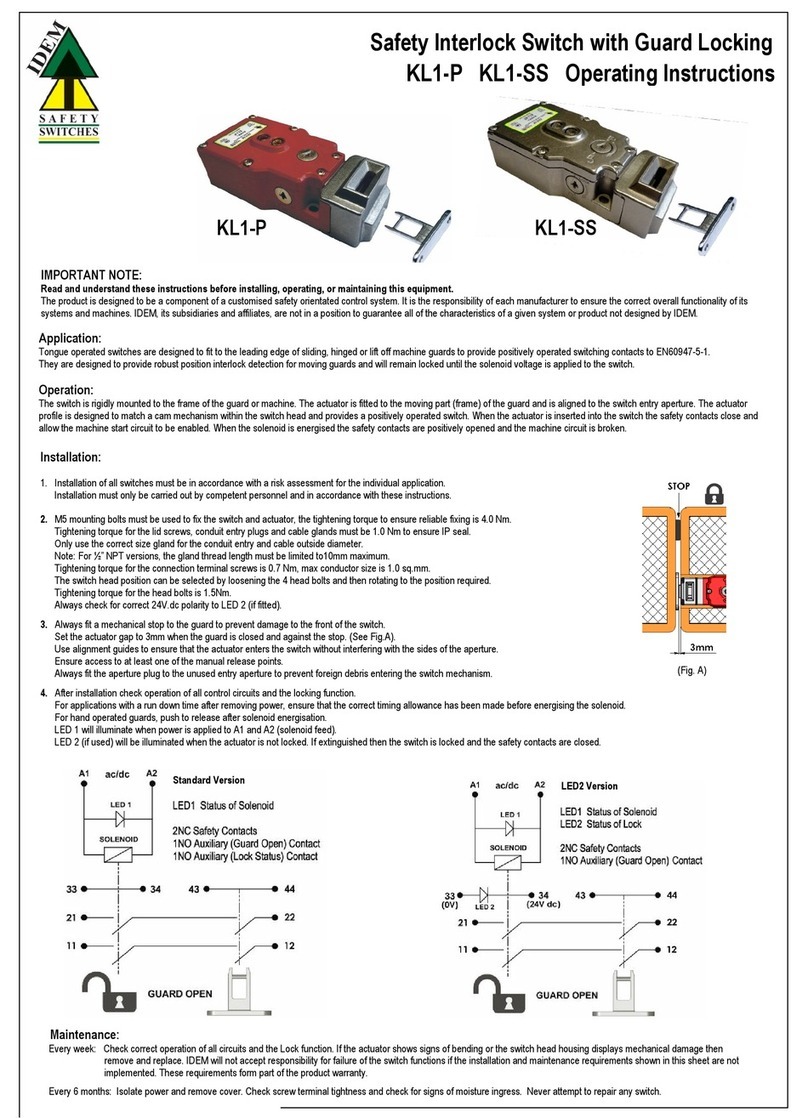

MPORTANT NOTE:

Read and understand these instructions before installing, operating, or maintaining this equipment.

The product is designed to be a component o a customised sa ety orientated control system. It is the responsibility o each manu acturer to ensure the correct overall unctionality o its

systems and machines. IDEM, its subsidiaries and a iliates, are not in a position to guarantee all o the characteristics o a given system or product not designed by IDEM.

Application:

Emergency Stop Switches are mounted on machines and sections o plant conveyors that cannot be protected by guards.

In combination with any dual channel sa ety monitoring controllers these switches can be used as emergency stop devices and monitored or up to Category 4/PLe to ISO13849-1.

Operation:

All Emergency Stop Switches con orm to European Standard EN ISO 13850 and IEC 60947-5-5. They have a positive mechanical linkage between the switch contacts and the

E-Stop Button. The switches are mechanically latched and can then only be returned to the operational condition by a pressing the reset button as required by EN ISO 13850

and IEC 60947-5-5.

nstallation Guide:

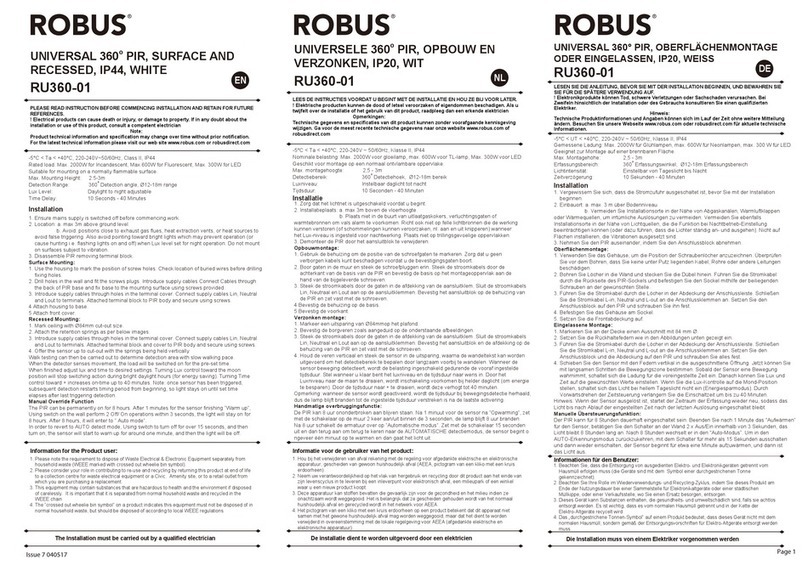

1. Installation o all switches must be in accordance with a risk assessment or the individual application and in accordance with local wiring regulations and EN60204-1.

Installation must only be carried out by competent personnel and in accordance with these instructions.

2. M4 mounting bolts must be used to ix the switches. Tightening torque or mounting bolts to ensure reliable ixing is 4 Nm. Tightening torque or the lid screws, conduit entry plugs and

cable glands must be 1.5 Nm to ensure IP seal. Only use the correct size gland or the conduit entry and cable outside diameter.

3. Check operation o all switches and the control circuits by activating the switch (depress the Red Button) and resetting each switch by twisting the Red Button. Ensure each time that

the switches latch o and require manual resetting.

4. For versions with the Protection Shroud ensure that the padlock size is suitable to prevent re-setting o the button.

Maintenance:

Every Week: Check correct operation o the control circuits and latching mechanism.

Inspect or damage to the E Stop button or casing.

Every 6 Months: Isolate power and remove cover. Check screw terminal tightness and

check or signs o moisture ingress. Never attempt to repair any switch.

Operating

nstructions

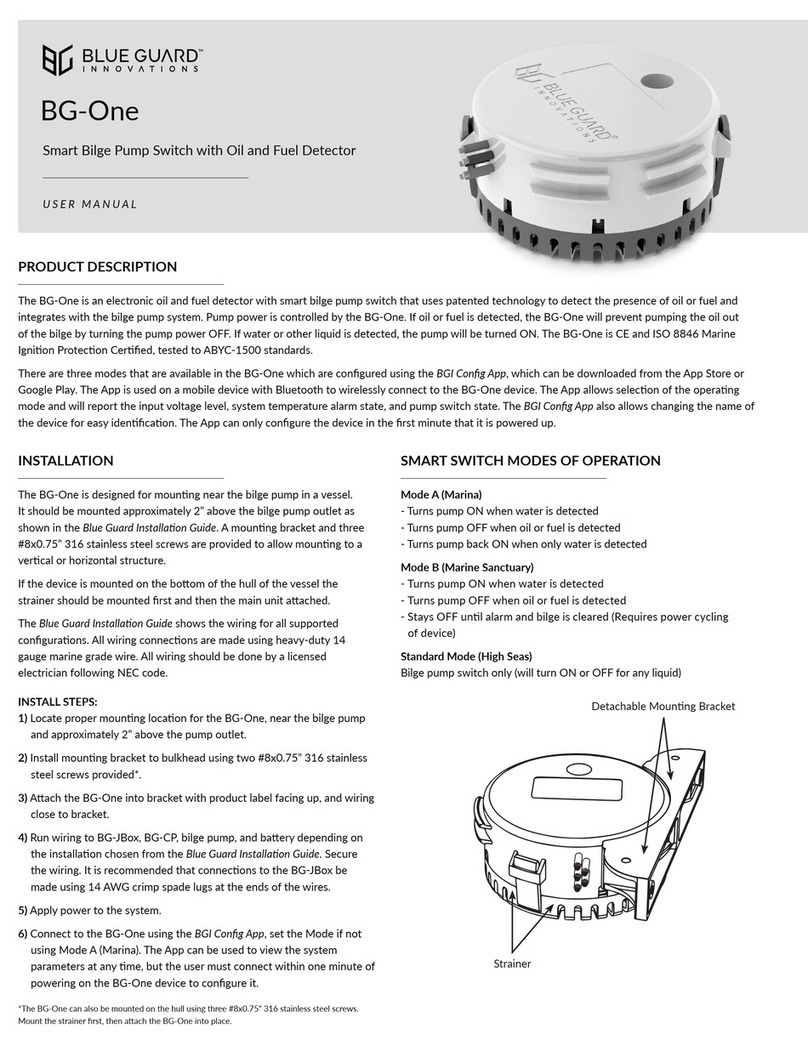

Type ES

-

P (Plastic)

Knock –out or

plastic version

Type ES

-

SS

(Stainless Steel)

Mirror Polished Finish

Type ES

-

SS(P)

(Stainless Steel)

With button protection

shroud with padlock

holes or lock o during

maintenance

Type ES

L

-

SS

(Stainless Steel)

Type ES

L

-

SS(P)

(Stainless Steel)

With button protection

shroud with padlock

holes or lock o during

maintenance

Type ES

L

-

SS(L)

(Stainless Steel)

With 2-colour LED

LED Wiring ex

amples (if fitted):

Black (or Terminal 2) is 0V (or Neutral or 110V and 230V ac versions).

When power is applied to the Red wire (or Terminal 1), the LED will illuminate Red.

When power is applied to the Green wire (or Terminal 3), the LED will illuminate Green.

LED has 2 colours

Recommended Colour Usage:

Flashing or Steady Red – Stopped

LED Steady Green - Run

Terminal 2 or Black

Terminal 1 or Red

Terminal 3 or Green

Wiring circuits for Explosion Proof Versions:

1 NC 1 NO

2 NC 2 NO

2 NC

NFORMAT ON W TH REGARD TO UL508:

Type 1 Enclosure

Contact Blocks A300 230V/3A 120V/6A

Wire range: 16AWG – 12AWG Copper Torque 7lb/in (0.8Nm)

LED powered by LVLC or Class 2 only.

Type ES

L

-

SS(LP)

(Stainless Steel)

With 2-colour LED and

button protection

shroud with padlock

holes or lock o during

maintenance

Emergency Stop Switches

SPEC AL NOTE:

Where required by local regulations

please a ix the supplied yellow

“EMERGENCY STOP” sticker as

shown in the image.

SPEC AL NOTE:

Where the Risk Assessment identi ies that inadvertent operation o the E-Stop button

may occur during use or breakage and loss o the button unction is oreseen, it may

be pre erable to speci y the protection shroud version. I the Risk Assessment or the

particular application allows use o the protection shroud, it is recommended

consideration be given to the conditions o operation o the button during spontaneous

operation as the shroud is not suitable or traditional E-Stop palm actuation o the

button. The Risk Assessment must clearly identi y any restrictions to the proper use o

the button including any training or the requirement to place any restriction notices at

the E-Stop location (e.g. “FINGER OPERATION REQUIRED”).

Doc: 102531

Jan. 2016

DEM SAFETY SW TCHES Ltd., 2 Ormside Close, Hindley ndustrial Estate, Hindley Green, Wigan, WN2 4HR UK. Tel: +44 (0)194

2 257070 Fax.: +44 (0)1942 257076

DEM (USA)

4416 Technology Drive

, Fremont, CA 94538 Tel:510

-

445

-

0751 Fax:1866

-

431

-

7064

email:

Web:

www.idemsafety.com

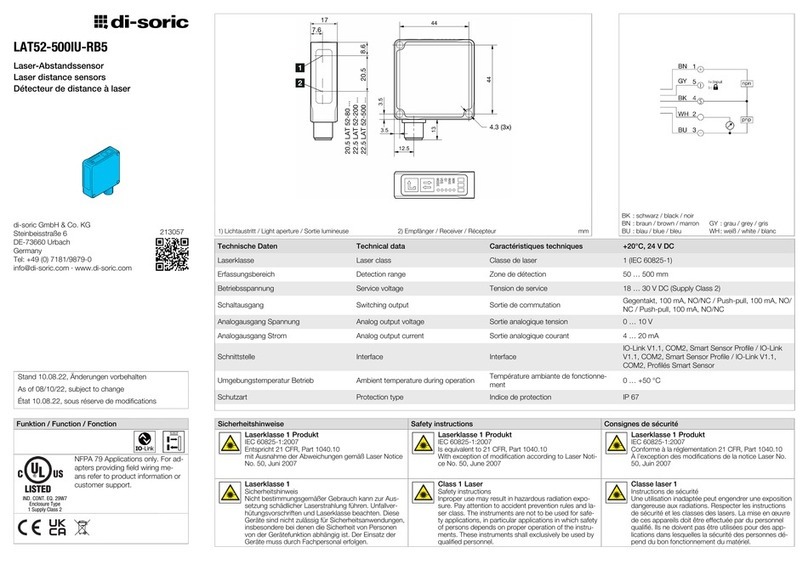

D MENS ONS: ES-P

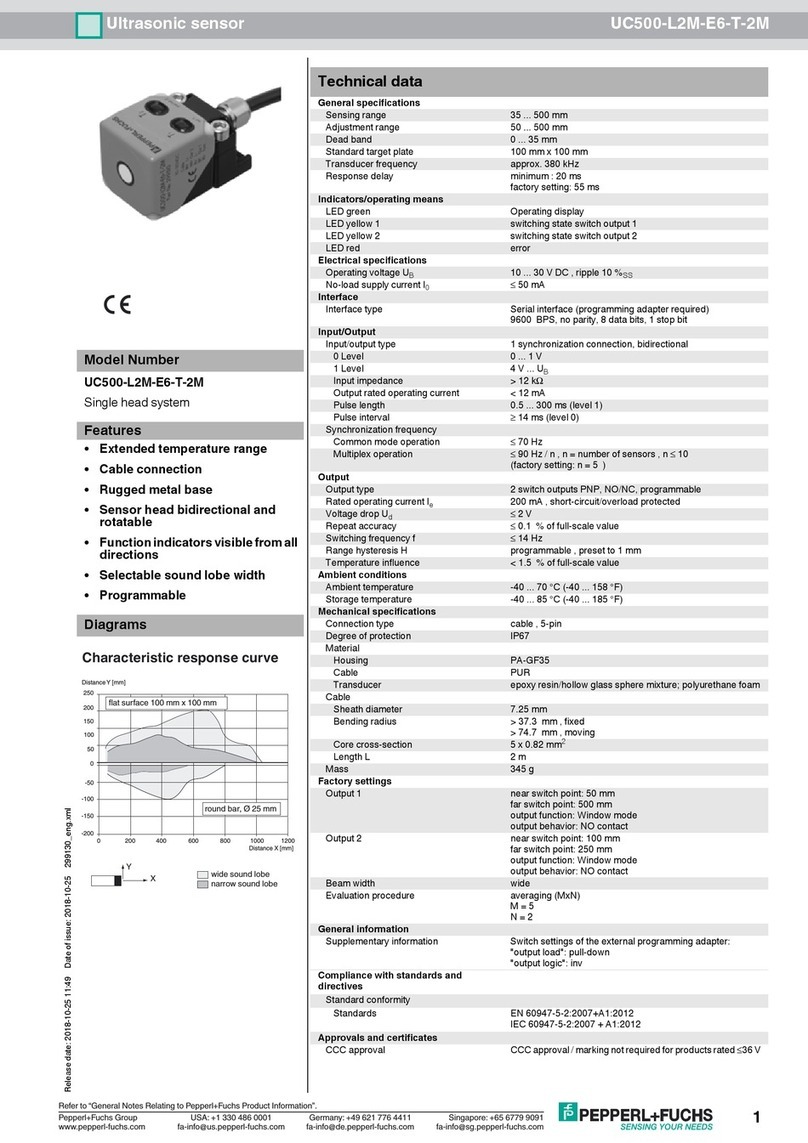

D MENS ONS:

ES

-

SS

ES-SS(P)

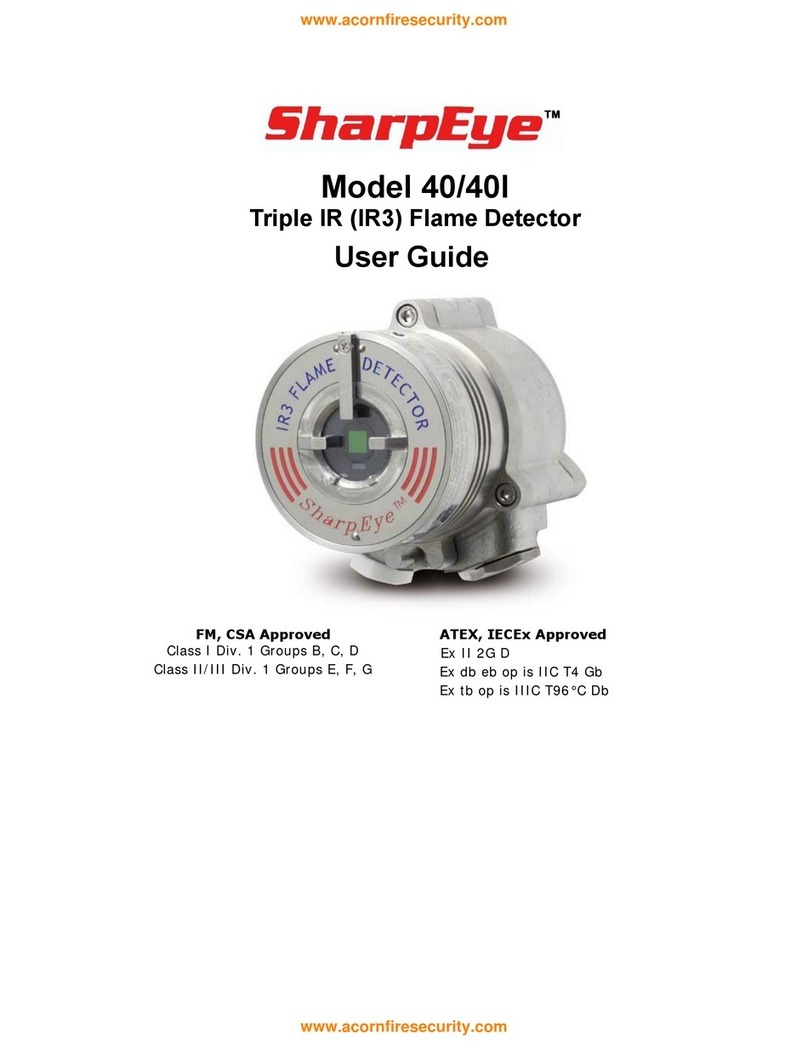

D MENS ONS:

ESL

-

SS

ESL-SS(P)

ESL-SS(L)

ESL-SS(LP)

This manual suits for next models

6

Other IDEM SAFETY SWITCHES Security Sensor manuals

Popular Security Sensor manuals by other brands

Techly

Techly I-LIGHT-SNR11TY quick start guide

Dräger

Dräger X-plore 5500 Instructions for use

Busch-Jaeger

Busch-Jaeger WaveLINE 6721 Installation and operating instructions

ESYLUX

ESYLUX MD 120 User instructions

Infinite

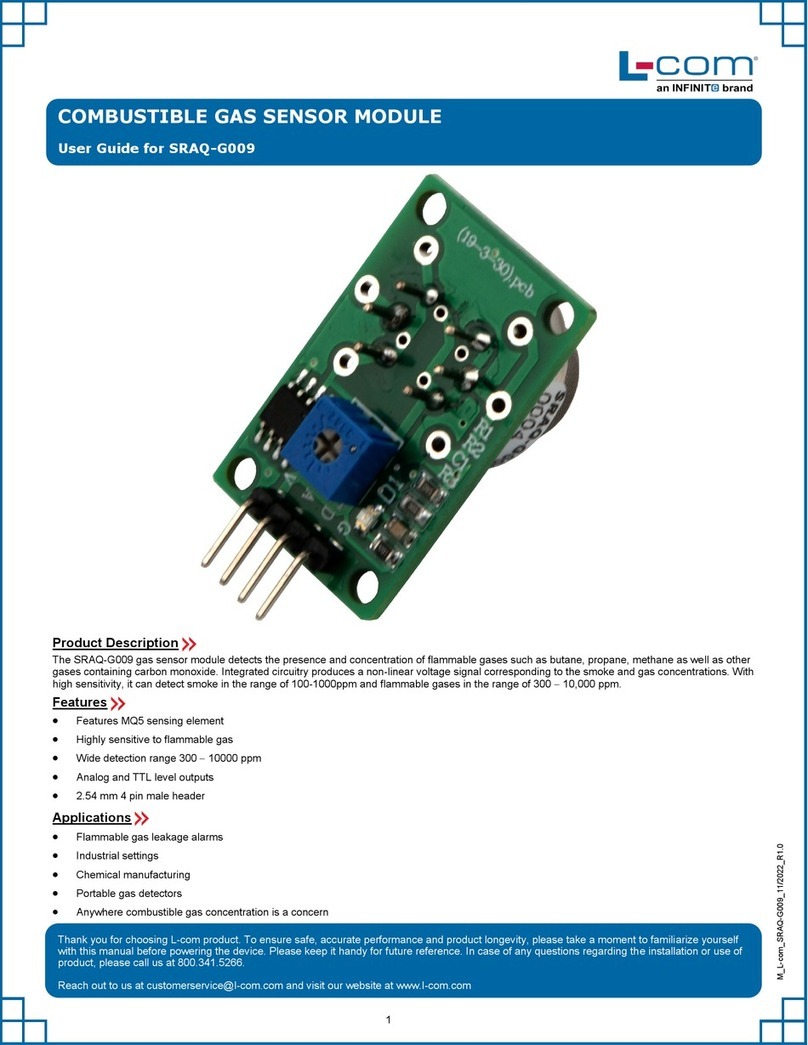

Infinite L-COM SRAQ-G009 user guide

jablotron

jablotron CA-550 Installation & operation manual