IDEM SAFETY SWITCHES KL1-P User manual

Safety Interlock Switch with Guard Locking

Application:

Tongue operated switches are designed to fit to the leading edge of sliding, hinged or lift off machine guards to provide positively operated switching contacts to EN60947- -1.

They are designed to provide robust position interlock detection for moving guards and will remain locked until the solenoid voltage is applied to the switch.

Operation:

The switch is rigidly mounted to the frame of the guard or machine. The actuator is fitted to the moving part (frame) of the guard and is aligned to the switch entry aperture. The actuator

profile is designed to match a cam mechanism within the switch head and provides a positively operated switch. When the actuator is inserted into the switch the safety contacts close and

allow the machine start circuit to be enabled. When the solenoid is energised the safety contacts are positively opened and the machine circuit is broken.

KL1

-

P KL1

-

SS

Operating Instructions

KL1

-

P

KL1

-

SS

I PORTANT NOTE:

Read and understand these instructions before installing, operating, or maintaining this equipment.

The product is designed to be a component of a customised safety orientated control system. It is the responsibility of each manufacturer to ensure the correct overall functionality of its

systems and machines. IDEM, its subsidiaries and affiliates, are not in a position to guarantee all of the characteristics of a given system or product not designed by IDEM.

Installation:

1. Installation of all switches must be in accordance with a risk assessment for the individual application.

Installation must only be carried out by competent personnel and in accordance with these instructions.

2. M mounting bolts must be used to fix the switch and actuator, the tightening torque to ensure reliable fixing is 4.0 Nm.

Tightening torque for the lid screws, conduit entry plugs and cable glands must be 1.0 Nm to ensure IP seal.

Only use the correct size gland for the conduit entry and cable outside diameter.

Note: For ½” NPT versions, the gland thread length must be limited to10mm maximum.

Tightening torque for the connection terminal screws is 0.7 Nm, max conductor size is 1.0 sq.mm.

The switch head position can be selected by loosening the 4 head bolts and then rotating to the position required.

Tightening torque for the head bolts is 1. Nm.

Always check for correct 24V.dc polarity to LED 2 (if fitted).

3. Always fit a mechanical stop to the guard to prevent damage to the front of the switch.

Set the actuator gap to 3mm when the guard is closed and against the stop. (See Fig.A).

Use alignment guides to ensure that the actuator enters the switch without interfering with the sides of the aperture.

Ensure access to at least one of the manual release points.

Always fit the aperture plug to the unused entry aperture to prevent foreign debris entering the switch mechanism.

4. After installation check operation of all control circuits and the locking function.

For applications with a run down time after removing power, ensure that the correct timing allowance has been made before energising the solenoid.

For hand operated guards, push to release after solenoid energisation.

LED 1 will illuminate when power is applied to A1 and A2 (solenoid feed).

LED 2 (if used) will be illuminated when the actuator is not locked. If extinguished then the switch is locked and the safety contacts are closed.

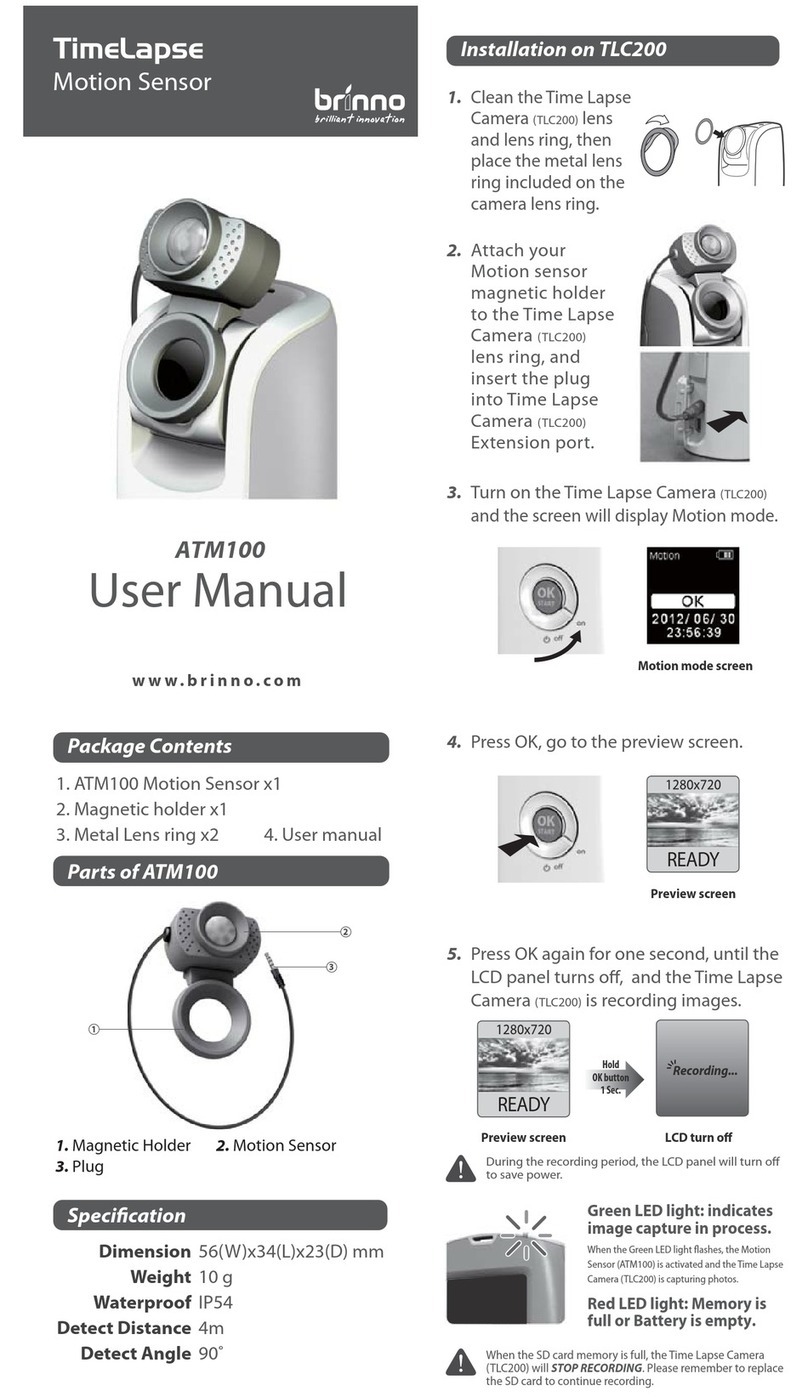

(Fig. A)

Standard Version

LED2 Version

aintenance

:

Every week: Check correct operation of all circuits and the Lock function. If the actuator shows signs of bending or the switch head housing displays mechanical damage then

remove and replace. IDEM will not accept responsibility for failure of the switch functions if the installation and maintenance requirements shown in this sheet are not

implemented. These requirements form part of the product warranty.

Every 6 months: Isolate power and remove cover. Check screw terminal tightness and check for signs of moisture ingress. Never attempt to repair any switch.

Safety Interlock Switch with Guard Locking

Conforming to Standard:

EN1088, IEC 60947

-

-

1, UL 08

Safety Classification and Reliability Data:

Mechanical Reliability B10d

ISO 13849-1

EN 62061

Safety Data - Annual Usage

PFHd

Proof Test Interval (Life)

MTTFd

2. x 10

6

operations at 100mA load

up to PLe / Cat.4 depending upon system architecture

up to SIL3 depending upon system architecture

8 cycles per hour / 24 hours per day / 36 days

3.44 x 10

-8

3 years

3 6 years

Solenoid Voltage (by part number)

24V ac/dc or 110V. ac or 230V. ac

+/

-

10% (12W.)

LED 2 Supply Voltage

24V dc +/

-

10%

Safety Contacts 11/12 21/22

Utilization Category

AC1 A300

3A.

Thermal Current (Ith) A

Auxiliary Contact 33/34 (selectable with LED2)

230V.ac/dc 0. A.

maximum.

Auxiliary Contact 43/44

230V.ac/dc 0. A. maximum.

Rated Insulation Voltage

600VAC

Rated Impulse Withstand Volt

2 00VAC

Travel for Positive Opening

10mm

Man. Actuation

Frequency

2 cycle/sec

Actuator entry minimum radius

17 mm Standard 100mm Flexible

Case Material

Glass Filled Polyester

or Stainless Steel 316

Actuator Material

Sta

inless S

teel

316

Enclosure Protection

IP67

(Plastic) IP69K (Stainless Steel)

Operating Temperature

-

2

°C to °C

Holding Force

14

00N. (Max.).

Vibration

IEC 68

-

2

-

6, 10

-

Hz+1Hz,

Excursion: 0.3 mm, 1 octave/min

Conduit Entry

Various (See Sales Part Numbers)

Fixing

4 x M

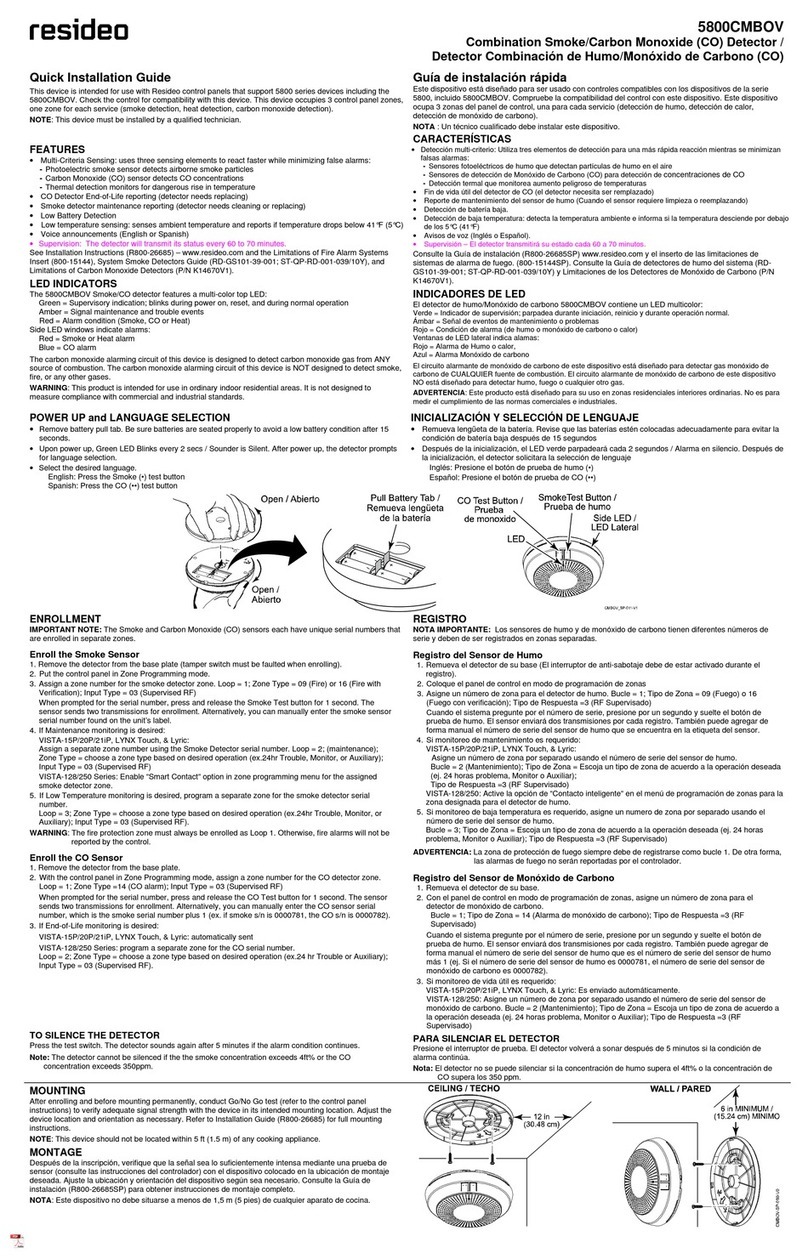

The guard is locked closed until the solenoid is energized. The solenoid can only

be energized when the

auxiliary contacts (A) of contactors K1 and K2 are closed.

When the lock release button is pushed the locking mechanism is released and the switch contacts 11-12 and

21-22 are opened. These contacts are in series with contactor coils of K1 and K2 and will prevent re-start whilst

the guard is open.

If after pressing the Stop button either contactor K1 or K2 stays closed the motor will stop but the solenoid

cannot be energized or the guard opened.

LED 1 provides visual indication of solenoid power applied.

LED 2 provides visual indication of guard locked and machine able to start.

System is shown with machine stopped, guard closed and locked, and the solenoid able to be energised.

Application Example: Dual Channel non monitored.

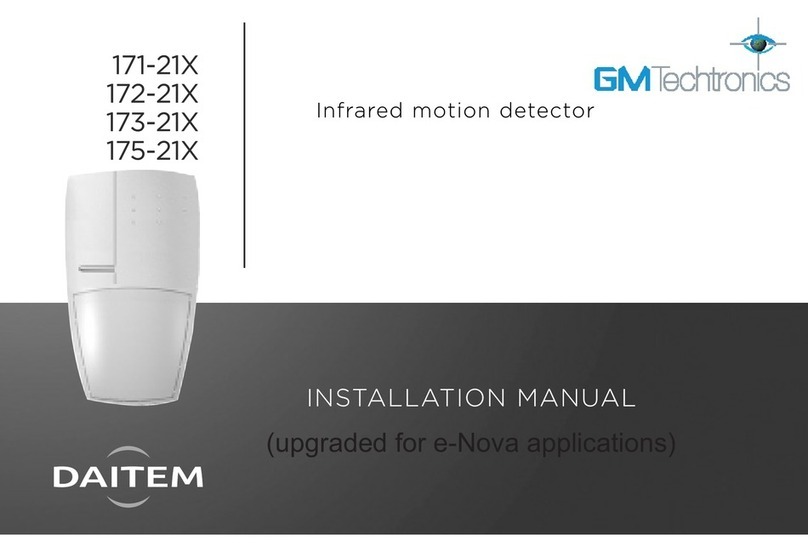

The above system can be enhanced by alternatively connecting the switch

circuits 11-12 and 21-22 to an SCR-3 Safety Relay to monitor for wiring short

circuits.

This provides Dual Channel monitoring and a check of the contactor feedback

circuits through the auxiliary contacts (A) of K1 and K2.

The SCR-3 monitors the switch and the contactors K1 and K2 and provides it’s

own self-monitoring via force guided internal relays.

System is shown with machine stopped, guard closed and locked, and the

solenoid able to be energised.

Application Example:

Dual Channel monitored.

IDE SAFETY SWITCHES Ltd., 2 Ormside Close, Hindley Industrial

Estate, Hindley Green, Wigan, WN2 4HR UK. Tel: +44 (0)1942 257070 Fax.: +44 (0)1942 257076

IDE (USA)

4416 Technology Drive,

Fremont, CA 94538 Tel:510

-

445

-

0751 Fax:1866

-

431

-

7064 email:

sales@idems

afety.com

Web:

www.idemsafety.com

Doc: 102 47

Oc

t.

201

3

Information with regard to UL 508:

Type 1 Enclosures.

Intended for same polarity use and

one polymeric conduit connection.

Electrical Rating: A300. 48W .

Max. Switching Current / Volt / Amp:

120V. 6A. (720VA break) PF 0.38

240V. 3A. (720VA break) PF 0.38

This manual suits for next models

1

Other IDEM SAFETY SWITCHES Security Sensor manuals