(C) IDM Energiesysteme GmbH

.

e

eral descriptio

Installation instructions TERRA AL 60 Max

14

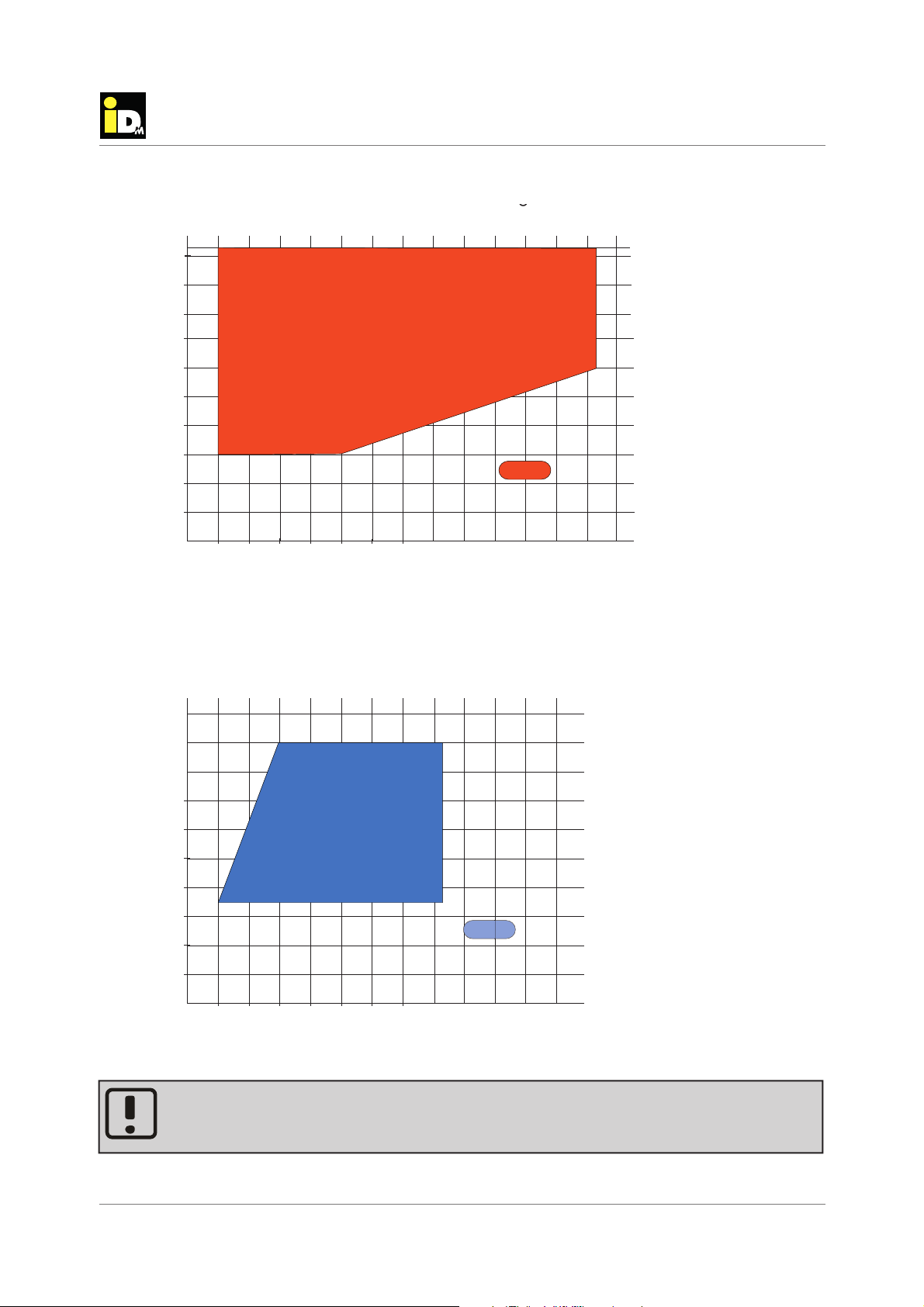

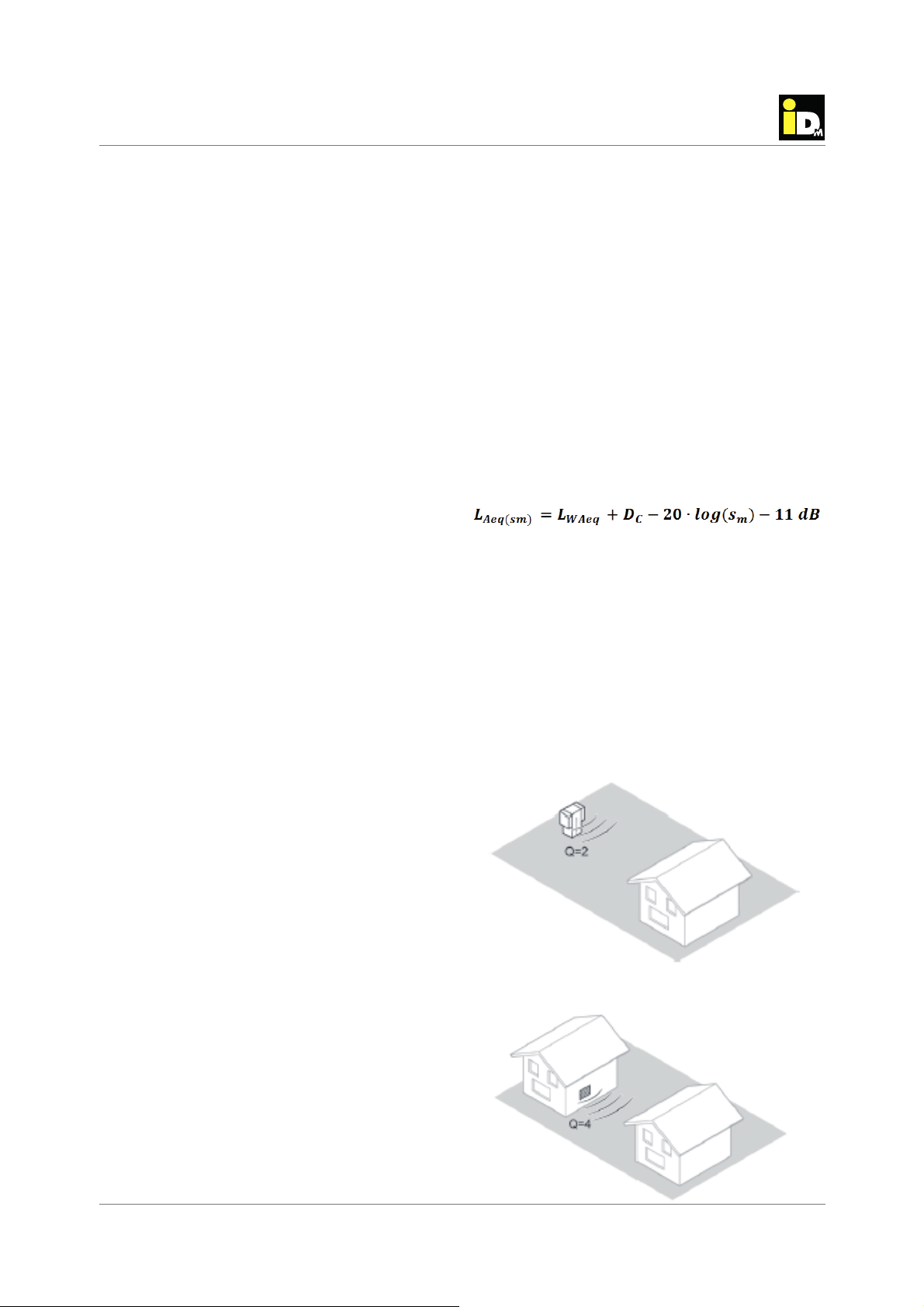

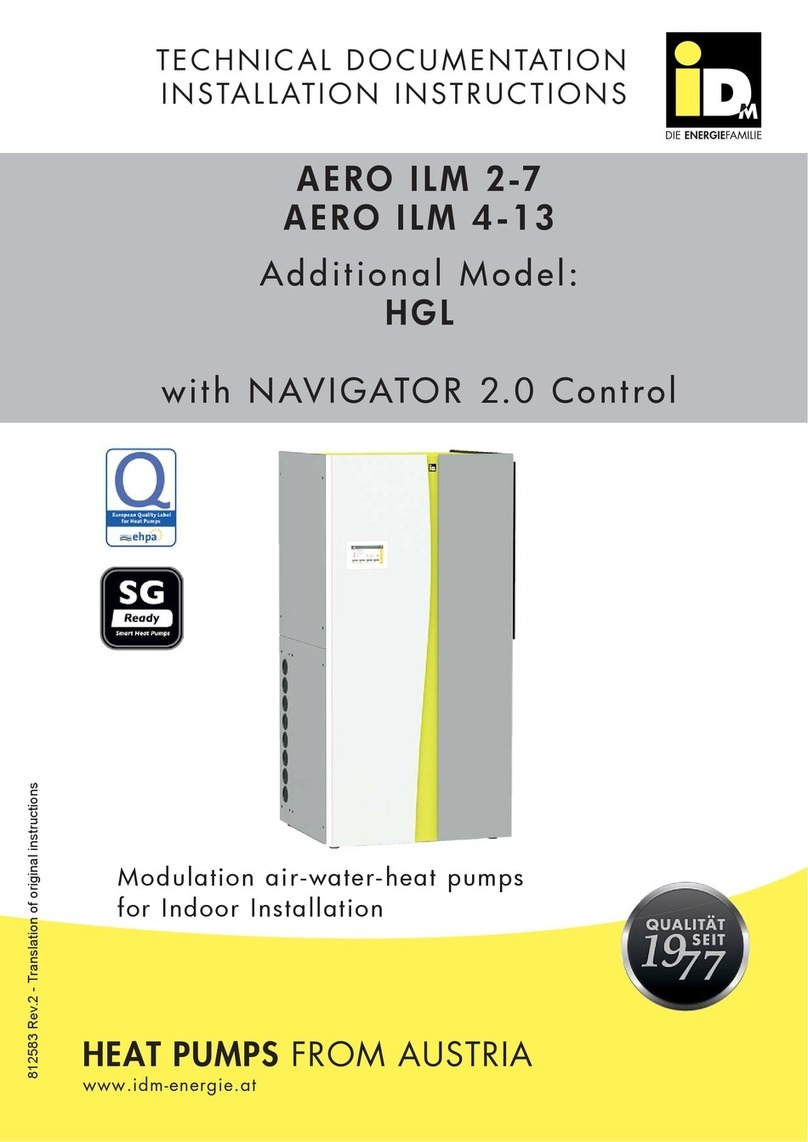

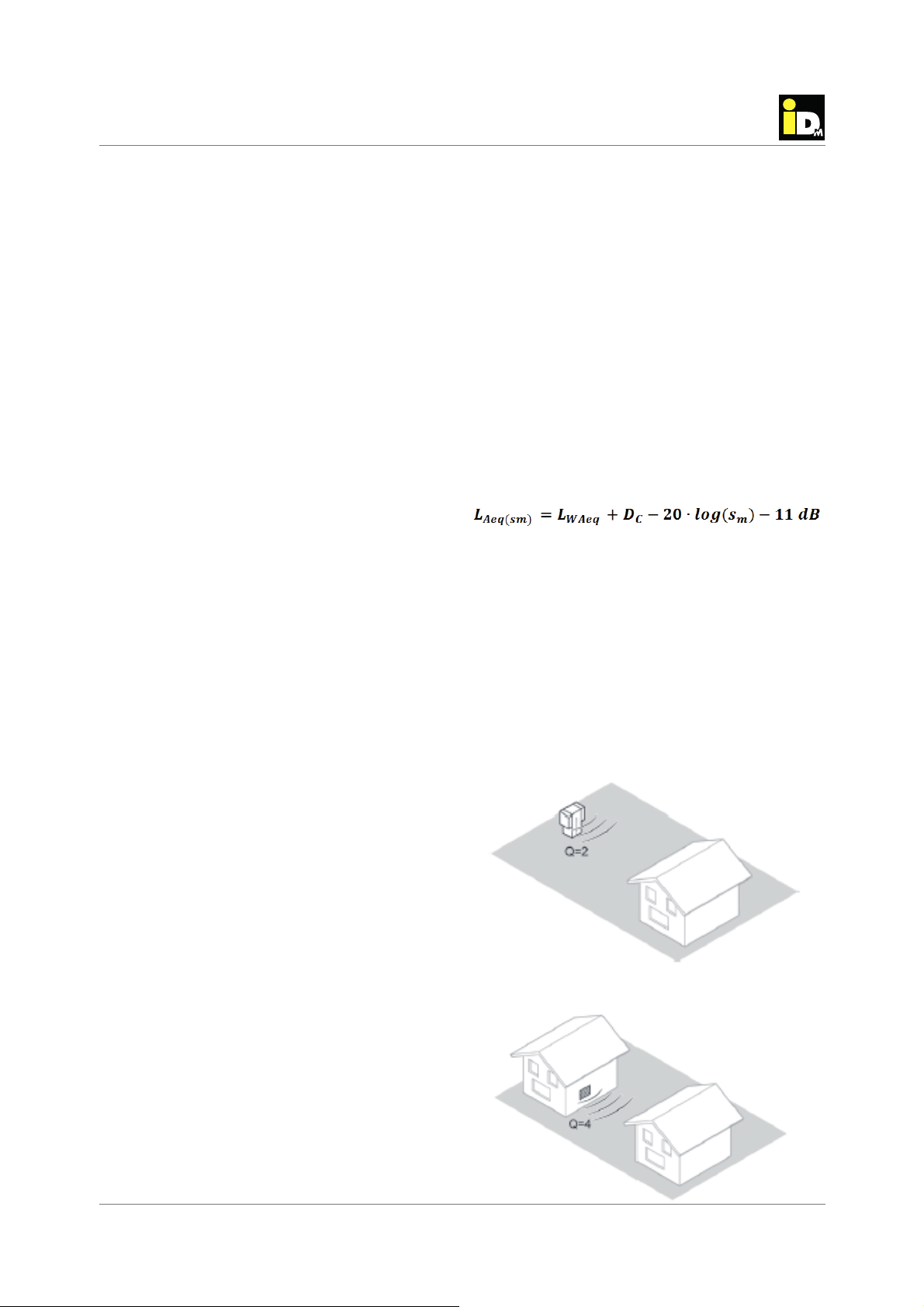

2: Spherical spreading into 1/4 space

(installation next to facade)

1: Spherical spreading into 1/2 space

(free standing installation)

Placement and Installation

4.6. Acoustic evaluation

Sound-power-level

The sound power is the sound energy per second

emitted of a noise source. The sound power level is

specific to the source of sound, independent of dis-

tance and direction and enables an easy comparison

of different sound emitting devices. The sound power

can only be determined via mathematical calculation

according to international standards of the series

ISO 3740 - based on sound pressure level measure-

ments - as well as ISO 9614, which is based on the

measurement of sound intensity. The sound power

level of the heat pumps can be found in the technical

specifications.

Sound-pressure-level

In contrast to the sound power level, the sound pres-

sure level, which is caused by a noise source can be

measured. The measured sound pressure is depen-

dent on the distance from the noise source and the

receiver location (geometrical divergence) as well as

the local conditions. As the sound pressure level is a

measure of the loudness of noise sensed by humans,

the legislation defines limit values, that must not be

exceeded.

Sound-propagation-outdoor

With increasing distance from a point noise source,

the sound power is distributed on an increasing area

due to spherical spreading. Therefore, the sound

pressure level is continuously decreasing with in-

creasing distance from the noise source to receiver

location. Doubling the distance leads to a reduction of

the sound pressure level of 6 dB(A). Besides the di-

stance from the installation site of the heat pump the

sound, the installation situation and local conditions

also have significant impact on the resulting sound

pressure level at the relevant place of immission.

Major factors of influence are:

• sound attenuation by massive barriers e.g. buil-

dings, walls or different terrain.

• reflection on acoustically hard ground e.g. glass

facade and stone surfaces

• attenuation due to sound absorbing porous sur-

faces e.g. grass, trees

• reinforcement/reduction of by wind speed/direction

Noise-Immission

The noise caused by an source at a certain place is

expressed as Immission, the corresponding sound

pressure level is called Immission level.The immissi-

on level at the relevant place of immission can either

be determined by measurements or calculation e.g.

forecasting method according „TA Lärm“ (German

Noise Prevention Code) especially, which is espe-

cially useful at the stage of planning. According to this

method of calculation, the expected sound pressure

level is calculated on the basis of the sound power

level of the heat pump, the distance of the heat pump

to the receiver location and the installation situation

(directivity correction Dc) of the relevant place of

immission according the following formula:

LWAeq = mean A-weighted sound pressure level [dB]

DC= directionality correction [-]

Sm= distance from noise source to receiver

location [m]

The following figures show the different installation

situations of heat pumps and the corresponding di-

rectivity correction.