Nibe SPLIT AMS 10 User manual

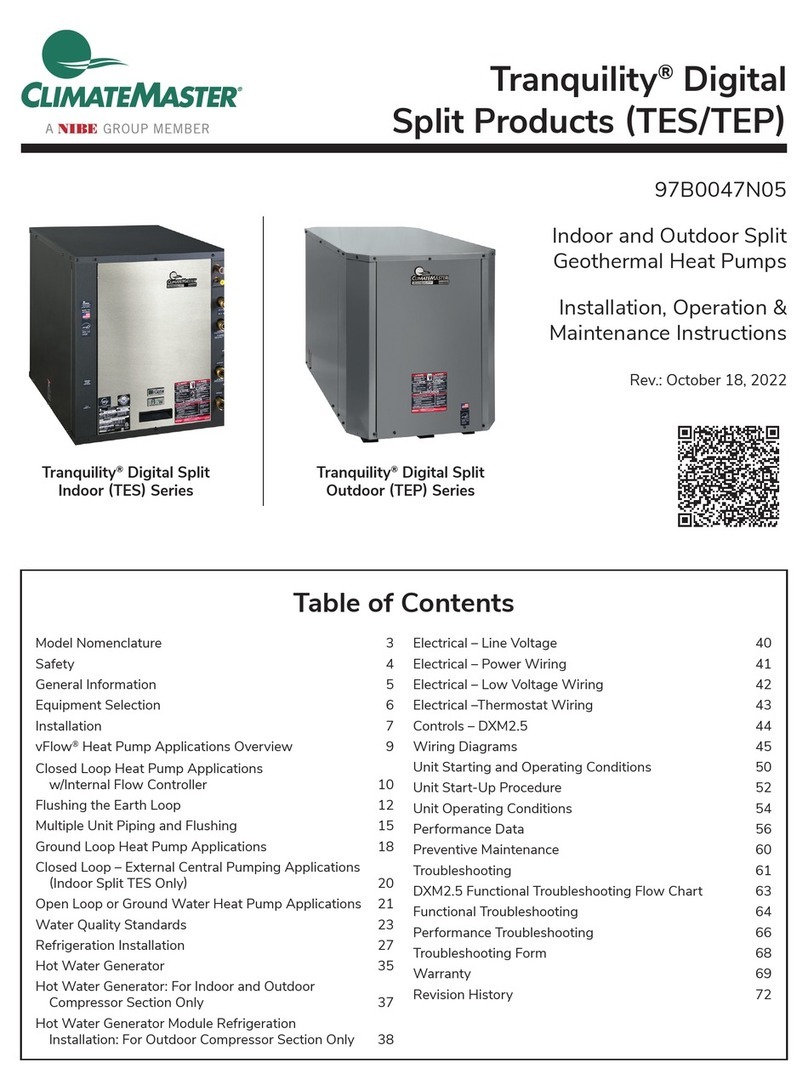

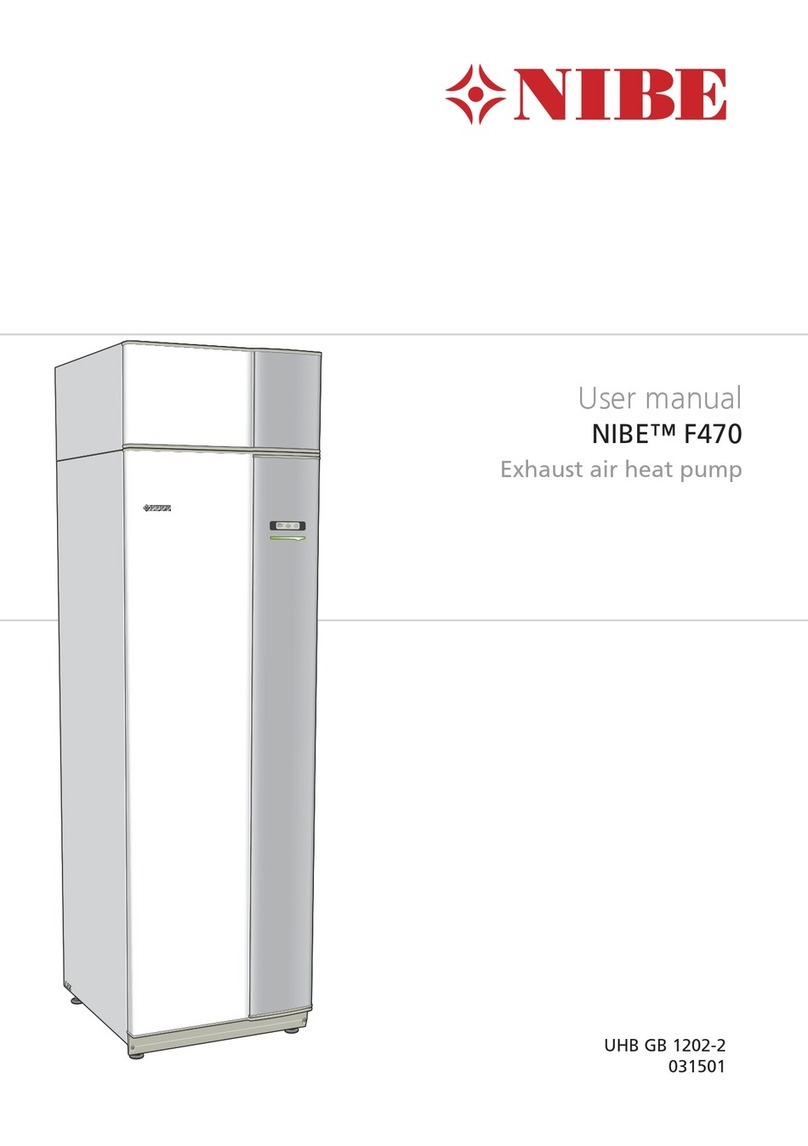

Other Nibe Heat Pump manuals

Popular Heat Pump manuals by other brands

Mitsubishi Electric

Mitsubishi Electric PUZ-SWM60VAA Service manual

Dimplex

Dimplex LI 16I-TUR Installation and operating instruction

Carrier

Carrier WSHP Open v3 Integration guide

TGM

TGM CTV14CN018A Technical manual

Carrier

Carrier 38MGQ Series installation instructions

Kokido

Kokido K2O K880BX/EU Owner's manual & installation guide

Viessmann

Viessmann VITOCAL 300-G PRO Type BW 2150 Installation and service instructions

Carrier

Carrier 48EZN installation instructions

Viessmann

Viessmann KWT Vitocal 350-G Pro Series Installation and service instructions for contractors

Ariston

Ariston NIMBUS user manual

Weishaupt

Weishaupt WWP L 7 Installation and operating instruction

GE

GE Zoneline AZ85H09EAC datasheet