iDM iPUMP A 2-7 User manual

iPUMP A 2-7

iPUMP A 3-11

WITH NAVIGATOR 2.0

iDM iPump A/T

THE ENERGYFAMILY

TECHNICAL DOCUMENTATION

INSTALLATION INSTRUCTIONS

HEAT PUMPS FROM AUSTRIA

www.idm-energie.at

812548 Rev.19 - Translation of original instruction

AIR HEAT PUMP WITH

INVERTER-TECHNOLOGY

(C) IDM ENERGIESYSTEME GMBH

2

.

Installation instructions iPump A 2-7, 3-11

2

Contents

1. GENERAL INFORMATION 4

1.1. Standards and directives 4

1.2. Safety instructions 4

1.3. Storage 4

1.4. Installation room 4

1.5. Sound emission 5

1.6. Ice-covering outdoor unit 5

1.7. Installing additional components 5

1.8. Construction drying and screed heating 5

1.9. Cleaning 5

1.10. Servicing and maintenance 5

1.11. Service 5

1.12. Warranty and guarantee 5

1.13. Disposal 5

2. ACOUSTIC EVALUATION 6

3. DESCRIPTION 8

3.1. Intended use 8

3.2. Scope of delivery 8

3.3. Dimensions indoor unit 9

3.4. Connections indoor unit 9

3.5. Dimensions Outdoor unit 10

3.6. Connections Outdoor unit 10

3.7. Technical data 11

3.8. Performance data iPump A 2-7 acc. to EN 14511 13

3.9. Cooling data detailed iPump A 2-7 14

3.10. Filling quantity refrigerant 17

3.11. Maximum heigth difference 17

3.12. Linits of use 18

3.13. Performance data iPump A 3-11 acc. to EN 14511 20

3.14. Cooling data detailed iPump A 3-11 21

3.15. Filling quantity refrigerant 24

3.16. Maximum heigth difference 24

3.17. Limits of use 25

4. TRANSPORT 27

5. DISASSAMBLE THE IPUMP 28

5.1. Connecting the control unit 33

6. ASSEMBLY AND HYDRAULIC INSTALLATION 34

6.1. Assembly of the indoor unit 34

6.2. Replacement of the motor of the switching valve „Heating - hot water“ 36

6.3. Drinking water connection 37

6.4. Assembly of the outdoor unit 37

6.5. Installation variant for the outdoor unit 38

6.6. Place of installation 38

(C) IDM ENERGIESYSTEME GMBH Installation instructions iPump A 2-7, 3-11 3

Contents

All rights reserved for modifications to the technology and design!

6.7. Assembling of the outdoor unit on the concrete base 39

6.8. Earthing of the heat pump system 39

6.9. Condensation run-off 40

6.10. Connection of the condensation run-off 40

6.11. Minimum distances 40

7. CONNECTION OF THE REFRIGERANT CIRCUIT 41

7.1. Connection lines of the refrigerant circuit 41

7.2. Connection of the outdoor unit on refrigerant side 41

7.3. Connection of the indoor unit on refrigerant side 42

7.4. Wall opening 43

7.5. Installation of the refrigerant connection pipes 43

7.6. Important information about the installation of the refrigerant pipes 43

8. ELECTRICAL ASSEMBLY 44

8.1. Electrical power supply 44

8.2. Electrical connection indoor unit 44

8.3. Electrical connection indoor unit 44

8.4. Electrical connection of the outdoor unit 45

8.5. Connection diagram of the electrical module 46

8.6. Connection of the central unit 47

9. COMMISSIONING 48

9.1. Notes for commissioning 48

9.2. Appliance and operation 48

9.3. Faults 48

10. MAGNESIUM PROTECTION ANODE 49

10.1. General 49

10.2. Testing the magnesium protection anode 49

10.3. Exchange of the magnesium protection anode 50

10.4. Installing an external current anode 51

11. HYDRAULIC DIAGRAMS 52

11.1. iPump A with direct circuit for heating and hot water circulation 52

11.2. iPump A with direct heating circuit, hot water circulation and one mixer heating circuit 53

12. HEATING SIDE INSTALLATION 54

13. DECLARATION OF CONFIRMITY, PRODUCT FICHE 55

14. TECHNICAL DOCUMENTATION 58

(C) IDM ENERGIESYSTEME GMBH

1

.

G

e

n

eral i

n

formatio

n

Installation instructions iPump A 2-7, 3-11

4

General information

By purchasing this system you have acquired a

modern and efficient heating system. Ongoing qua-

lity controls and improvements as well as functional

checks at the factory guarantee you technically per-

fect equipment.

Please read through this documentation carefully.

It contains important information for correct

installation and safe and economical operation of

the system.

1.1. Standards and directives

Note for the installation of the heatpump follow all

effective national and international piping- and ins-

tallation rules and the instructions of this Installation

instruction.

Amongst others comparing the following:

- the general effective rules for accident prevention

and safety regulations

- the regulations for environmental protection

- the provisions/regulations of the professional asso-

ciations

- the effective laws, standards, guidelines and regu-

lations e.g. DIN, EN, DVGW, VDI and VDE

- regulations of the local suppliers/supply company

1.2. Safety instructions

Installation and maintenance work can be hazardous

due to high system pressure, high temperatures and

live parts, and may only be carried out by specialist

staff.

Heat pumps may only be installed by competent spe-

cialist staffand commissioned by a customer service

company trained to do so by iDM-Energiesysteme

GmbH.

When working on the heat pump, the system must be

shut-offand secured against re-activation.

In addition, all safety instructions in the relevant do-

cumentation, stickers on the heat pump itself and all

other applicable safety regulations must be observed.

1. General information

1.3. Storage

Heat pump components may not be stored outdoors.

Heat pumps should not be stored in wet rooms or in

potentially dust rooms.

1.4. Installation room

The internal unit of the iPump A should be installed in

a frost-proof room. The Room temperature should be

between 5°C and 25°C.

To minimize vibrations and noises, the heat pump

must be isolate from the building structure. Basically,

the setting up of the heat pump on lightweight design

ceilings must be avoided. In case of a floating floor

screed the screed and the sound damping around the

heat pump have to be omitted.

The installation in wet rooms or in potentially dust or

explosion-endangered rooms is not allowed.

Gas from refrigerants in plant rooms must not escape

into vicinal rooms, stair rooms, courtyards, walks or

into the drainage system of the building. The gas has

to be channelled offsafely.

In case of danger, the plant room has to be evacuated

immediately.

In case a natural ventilation is not possible, a me-

chanical ventilation has to be provided. A mechanical

ventilation has to be equipped with an independent

emergency control outside of the machine room near

the door.

Heat pumps should not be installed in rooms with high

electromagentic influences from other installations.

If the minimum size of the installation room falls below

the required value, the room must be designed as an

machine room according to EN 378!

(C) IDM ENERGIESYSTEME GMBH Installation instructions iPump A 2-7, 3-11 5

Space for customer service telephone

number:_________________________

General instructions on installing the heat

pump.

general information

1.5. Sound emission

The iPump A outdoor unit is very quiet in operation

thanks to the design. It is however important that

the site of the heater is situated as far as possible

from noise-sensitive living areas. This also applies to

refrigerant connection lines between the outside- and

the indoor unit.

Also the boiler room where the indoor unit of the

iPump A is installed should be placed outside of the

noise sensitive living area. The boiler room should be

furnished with a good lockable door.

1.6. Ice-covering outdoor unit

Depending on the weather and outdoor humidity, it

may happen that there will be formed an icy covering

on the protective grids of the heat pump. This effect

is common occuring in nature. This covering must

be removed by the heat pump operator during this

weather periods.

1.7. Installing additional components

The installation of additional components which have

not been tested with the equipment may impair its

function. No liability is accepted and your guarantee

is void in the event of damage caused for this reason.

1.8. Construction drying and screed heating

The heat pump is not designed for the increased heat

requirements when drying out construction work or

heating plaster or screed. This must be covered by

equipment to be provided by the customer if required.

1.9. Cleaning

If necessary, the internal and the outdoor unit of the

iPump A can be cleaned with a damp cloth. The use

of cleaning agents is not recommended.

1.10. Servicing and maintenance

Regular maintenance control and servicing of all

system components guarantee its safe and econo-

mical operation in the long term. To achieve this, we

recommend a maintenance contract with the relevant

customer service company.

Only original spare parts which meet the requirements

of iDM may be used!

1.11. Service

For technical information please contact your relevant

iDM customer service department.

1.12. Warranty and guarantee

Warranty and guarantee conditions are included

in the purchased documents. For questions please

contact your relevant customer service department.

1.13. Disposal

Heatpumps are electrical equipment made from

high valuable materials, which are not allowed to be

disposed like normal household garbage, but have to

be disposed professional and proper according the

regulations of the local authorities.

A non-proper disposal can cause, apart from sanc-

tions for the violator, environmental damages and

harm for your health.

This device is characterized according to the euro-

pean directive 2012/19/EU on waste electrical and

electronic equipment (Waste electrical and electronic

equipment - WEEE). The guideline provides the

framework for an EU-wide return and recycling of old

equipment.

Dispose the device properly and do not damage the

pipes of the refrigerant circuit.

Important information on installing and

operating the heat pump. It is essential that

this information is observed!

General instructions on operating the heat

pump.

(C) IDM ENERGIESYSTEME GMBH

2

.

A

coustic e

v

aluatio

n

Installation instructions iPump A 2-7, 3-11

6

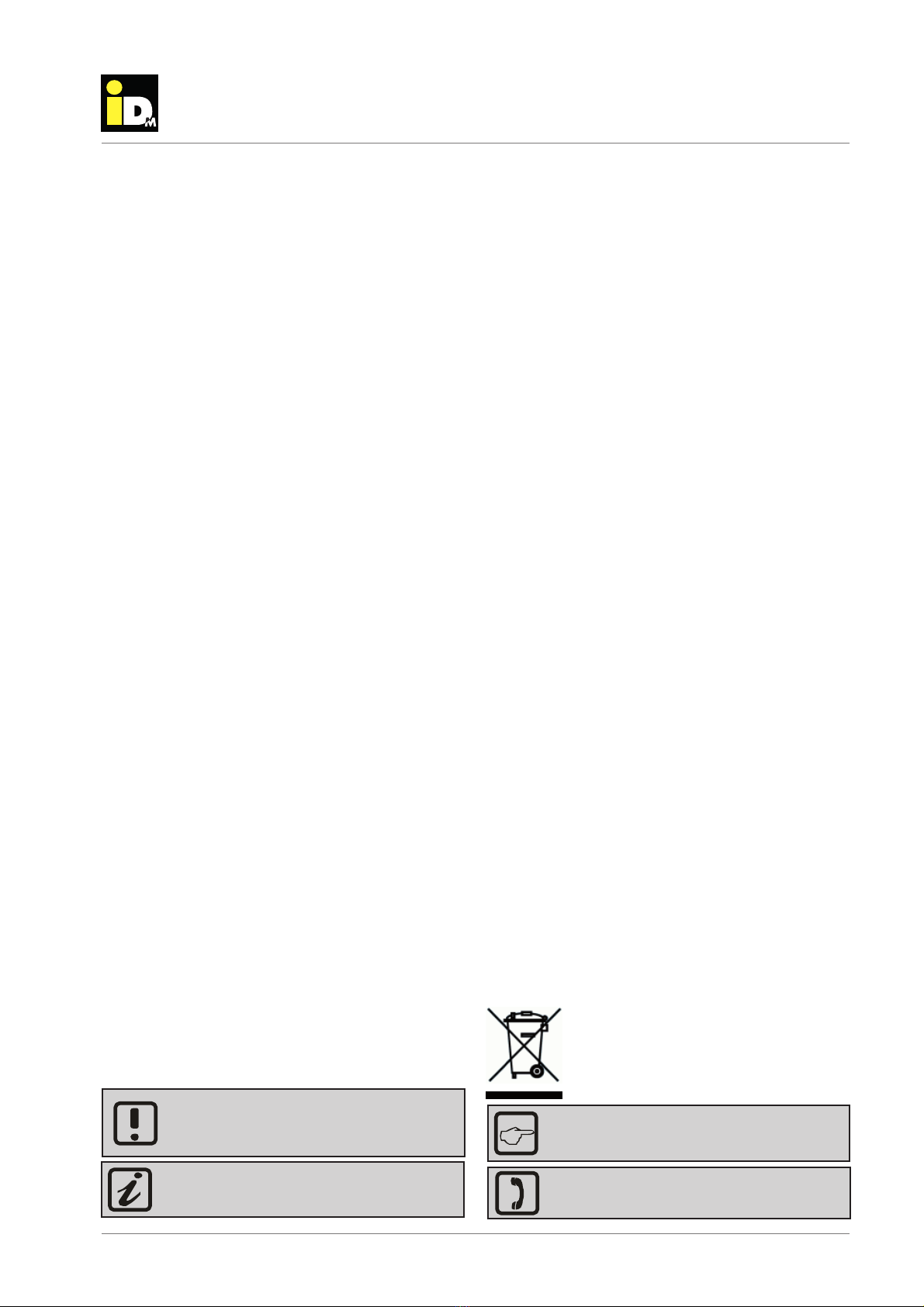

Version 1: Spherical spreading into 1/2 space (free

standing installation)

Version 2: Spherical spreading into 1/4 space

(installation next to facade)

Version 3: Spherical spreading into 1/8 space:

acoustic evaluation

2. Acoustic evaluation

Sound power level

The sound power is the sound energy per second

emitted of a noise source. The sound power level is

specific to the source of sound, independent of dis-

tance and direction and enables an easy comparison

of different sound emitting devices. The sound power

can only be determined via mathematical calculation

according to international standards of the series

ISO 3740 - based on sound pressure level measure-

ments - as well as ISO 9614, which is based on the

measurement of sound intensity. The sound power

level of the heat pumps can be found in the technical

specifications.

Sound pressure level

In contrast to the sound power level, the sound pres-

sure level, which is caused by a noise source can be

measured. The measured sound pressure is depen-

dent on the distance from the noise source and the

receiver location (geometrical divergence) as well as

the local conditions. As the sound pressure level is a

measure of the loudness of noise sensed by humans,

the legislation defines limit values, that must not be

exceeded.

Sound-propagation-outdoor

With increasing distance from a point noise source,

the sound power is distributed on an increasing area

due to spherical spreading. Therefore, the sound

pressure level is continuously decreasing with in-

creasing distance from the noise source to receiver

location. Doubling the distance leads to a reduction of

the sound pressure level of 6 dB(A). Besides the di-

stance from the installation site of the heat pump the

sound, the installation situation and local conditions

also have significant impact on the resulting sound

pressure level at the relevant place of immission.

Major factors of influence are:

- sound attenuation by massive barriers e.g. buil-

dings, walls or different terrain.

-reflection on acoustically hard ground e.g. glass

facade and stone surfaces

- attenuation due to sound absorbing porous sur-

faces e.g. grass, trees

- reinforcement/reduction of by wind speed/direction

Noise immission

The noise caused by an source at a certain place is

expressed as Immission, the corresponding sound

pressure level is called Immission level.The immissi-

on level at the relevant place of immission can either

be calculated with the iDM-sound calculator.

The calculation of the sound pressure level shall be

calculated by means of the following examples for

typical installation situations of the outdoor unit.

Source: bwp-Leitfaden-Schall

Source: bwp-Leitfaden-Schall

Source: bwp-Leitfaden-Schall

(C) IDM ENERGIESYSTEME GMBH Installation instructions iPump A 2-7, 3-11 7

acoustic evaluation

Relevant place of immission

The sound immission have to be determined 0.5 m

in the middle in front of the open window (outside the

building) of the most affected rooms, which need par-

ticular protection. According DIN 4109:1989 rooms

needing particular protection are:

- Living- and bed rooms

- Children rooms

- Work spaces / offices

- Classrooms / seminar rooms

Rating level Lr .

The rating level corresponds to an equivalent conti-

nuous sound pressure level associated with a specific

period. The rating level is determined for both rating

periods „day“ (6 am-10 pm) and „night“ (10 pm-6 am)

separately. The operation time of the heat pump has

particular impact on the resulting equivalent conti-

nuous sound pressure level. Reducing the operation

time from 16 h per day to 4 h per day the rating level

is reduced by 6 dB(A).

But the equivalent continuous sound pressure level

alone is not sufficient in order to determine the distur-

bing effect of noise. In general noise is perceived very

disruptive, if individual tones are clearly discernable

or the noise is irregular (impulsiveness). These noise

characteristics will be taken into account by applying

a surcharge. Additionally, daytimes with increased

sensitivity are taken into consideration. According the

„TA Lärm“ the following corrections are applied:

Information incorporation 3 or 6 dB(A)

Impulsiveness 0,3 or 6 dB(A)

Daytimes with increased

sensitivity 6 dB(A)

The rating level Lrshall be obtained by summing the

calculated immission level and the applied correc-

tions of the specific periods.

Finally, the determined rating level can be compared

with legal limit values (e.g. „TA Lärm“).

Standard Immission Values (SIV) - relevant place of

immission outside the building:

Territory SIV-day SIV-night

Industrial area 70 dB(A) 70 dB(A)

Business park,

commercial areas 65 dB(A) 50 dB(A)

Village areas and mixed

areas 60 dB(A 45 dB(A)

Settlement area 55 dB(A) 40 dB(A)

Residential area 50 dB(A) 35 dB(A)

Spa area, hospitals 45 dB(A) 35 dB(A)

In case of sound propagation inside buildings or

structure-borne sound transmission the Standard

Immission Values for the rating level of rooms nee-

ding particular protection are as following:

SIV-day: 35 dB(A)

SIV-night: 25 dB(A)

For the calculation of the rating level according „TA

Lärm“ a calculation tool is provided at the hom page:

http://www.idm-energie.com

Tips for installation of heat pumps

-

Sound reflections areas should be kept as low as

possible

- The installation on acoustically hard ground and

areas with depression in the terrain should be avo-

ided

- The distance from the heat pump and the relevant

place of immission should be as big as possible

- In case of outdoor installation the blow out of air

in direction to the neighbour or relevant receiver

location should be avoided

- The airflow should not be blown directly against

walls as sound reflections lead to increased sound

pressure levels accordingly

(C) IDM ENERGIESYSTEME GMBH

3

.

D

escriptio

n

Installation instructions iPump A 2-7, 3-11

8

Description

Montage Heizungsseitig

3. Description

iPump A are compact air-water heat pump with a sc-

roll capsule compressor with inverter technology and

400 V or 230 V power supply.

The Indoor unit of the iPump A includes the conden-

ser, a high efficiency loading pump, the switching

valve for heating-/domestic hot water, an immersion

heater, a 200 l DHW storage tank and a sensor set.

The outdoor unit includes the evaporator and the

axial ventilator.

The microprocessor controller NAVIGATOR 2.0 en-

sures efficient operation of the heat pump.

The heat pump system is controlled as needed and is

equipped with a variety of monitoring-, security- and

reporting functions.

By default, an unregulated and a regulated heating

circuit can be controlled.

The microprocessor controller NAVIGATOR 2.0 pro-

vides a variety of additional applications, e.g. Smart

Grid, remote control or operation via smartphones.

The heat meter is integrated by default.

A colored 7“ touch display simplifies the operation of

the heat pump. The display can be removed from the

housing of the iPump A and can be placed separately,

e.g. in the living room.

In order to simplify the transport into the heating

room, the iPump A can be split.

The connections for the refrigerating pipes are optio-

nal on the right or left side of the heat pump.

The connections for heating- and hot water lines are

at the top, as well as the LAN-connection, the cable

inlet for the sensors and the optional connection for

the circulation.

The lower the maximum flow temperature

is set, the higher is the efficiency of the

heat pump.

The electrical lines and refrigerant con-

nection pipes between the indoor and out-

door units are not in the scope of delivery.

The parts are available as accessories

and must be connected according to the

technical specifications.

3.1. Intended use

For monovalent heating and cooling of single- and

multiple dwellings with the heat source air. In this

case, the building should be equipped with a low tem-

perature heating systems (e.g. underfloor heating,

wall heating, low temperature radiator heating). The

heat pump may only be used for domestic and not for

purely commercial operation!

The iPump A is working with the safety refrigerant

R410A, that circulates in an closed circuit. When ins-

talled and commissioned properly, meaning that there

is no environmental impact.

3.2. Scope of delivery

Outdoor unit iPump A

- Housing in sheet metal covering, powder-coated

- Housing optional with cladding panels

- Fin evaporator

- Electronic expansion valve

- Axial ventilator with Flow-Grid

- Mounting kit for the installation of the outdoor unit-

consists of:

4 pcs. threaded bolt M12 x 210 mm

8 pcs. hexagonal nuts M12

8 pcs. washers M12

Indoor unit iPump A

- Heat pump with Scroll-compressor with inverter

technology

- Inverter with patented CIC-Technology

- Copper soldered stainless steel plate heat ex-

changer as condenser

- Refrigerant collector

- Refrigerant dryer

- Refrigerant inspection glass

- Electronic expansion valve

- Electronic high pressure and low-pressure limiter

- Switching valve heating/domestic hot water

- Integrated A-Label loading pump

- Colored 7“ Touch display with NAVIGATOR 2.0

- Stable base frame

- Cladding, insulated against heat and noise

- Sensor package

(C) IDM ENERGIESYSTEME GMBH Installation instructions iPump A 2-7, 3-11 9

description

Monta

g

e Heizun

g

sseiti

g

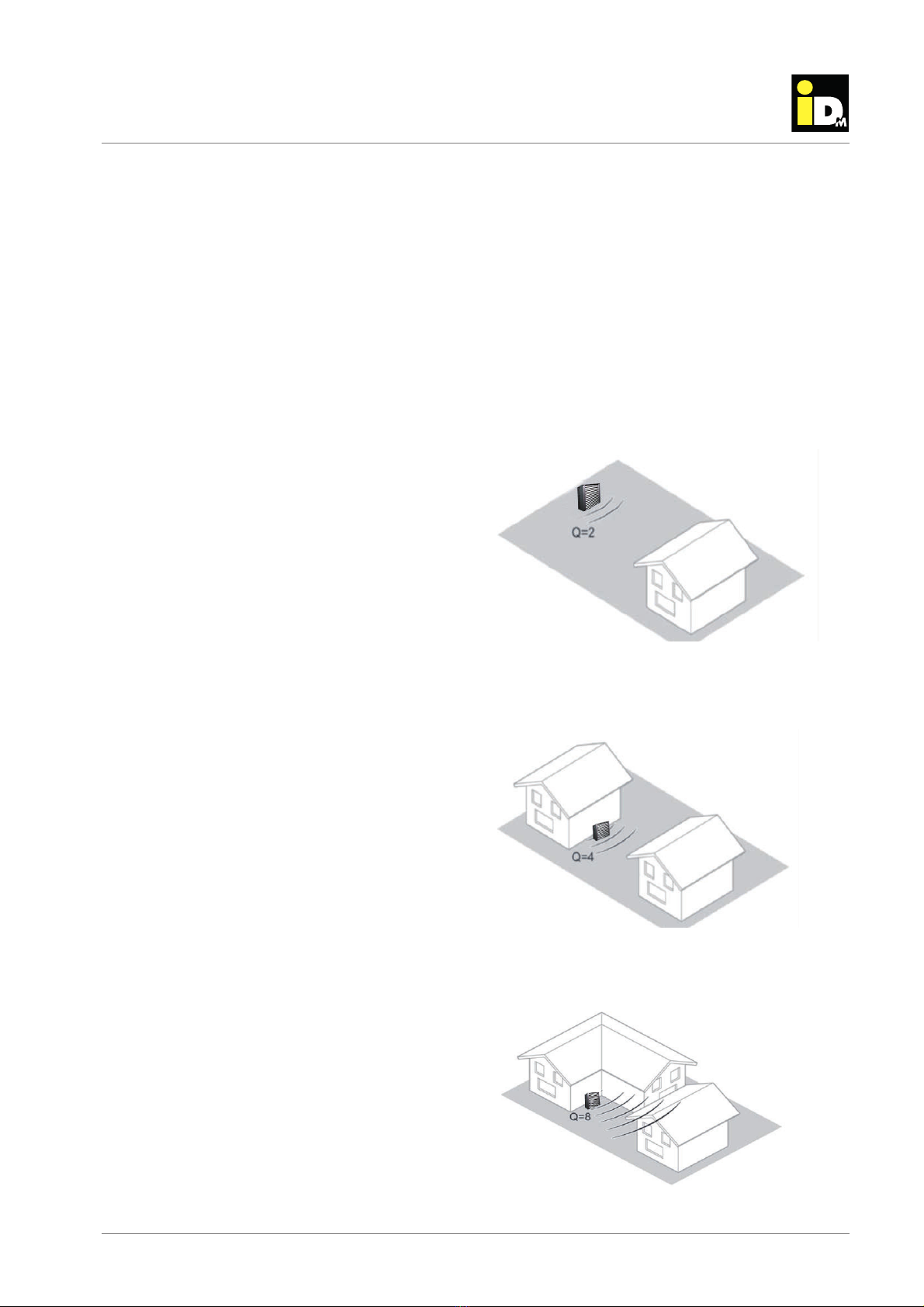

Bottom view

Side view / right Front view

Side view / left

3.3. Dimensions indoor unit

9

10

2

1

3

4

5

6

7

8

Bottom view

Front view

1 Heating supply 1“

2 Heating return 1“

3 Hot water connection 3/4“

4 Cold water connection 3/4“

5 Inlet cables of sensors

6 LAN-Connection

7 Circulation connection 3/4“

8 Cable inlet main current

9 Refrigerant pipe - liquid line 12 mm

10 Refrigerant pipe - hot gas line 16 mm

3.4. Connections indoor unit

(C) IDM ENERGIESYSTEME GMBH

3

.

D

escriptio

n

Installation instructions iPump A 2-7, 3-11

10

Description

Montage Heizungsseitig

Front view Side view / left

Inlet side Outlet side

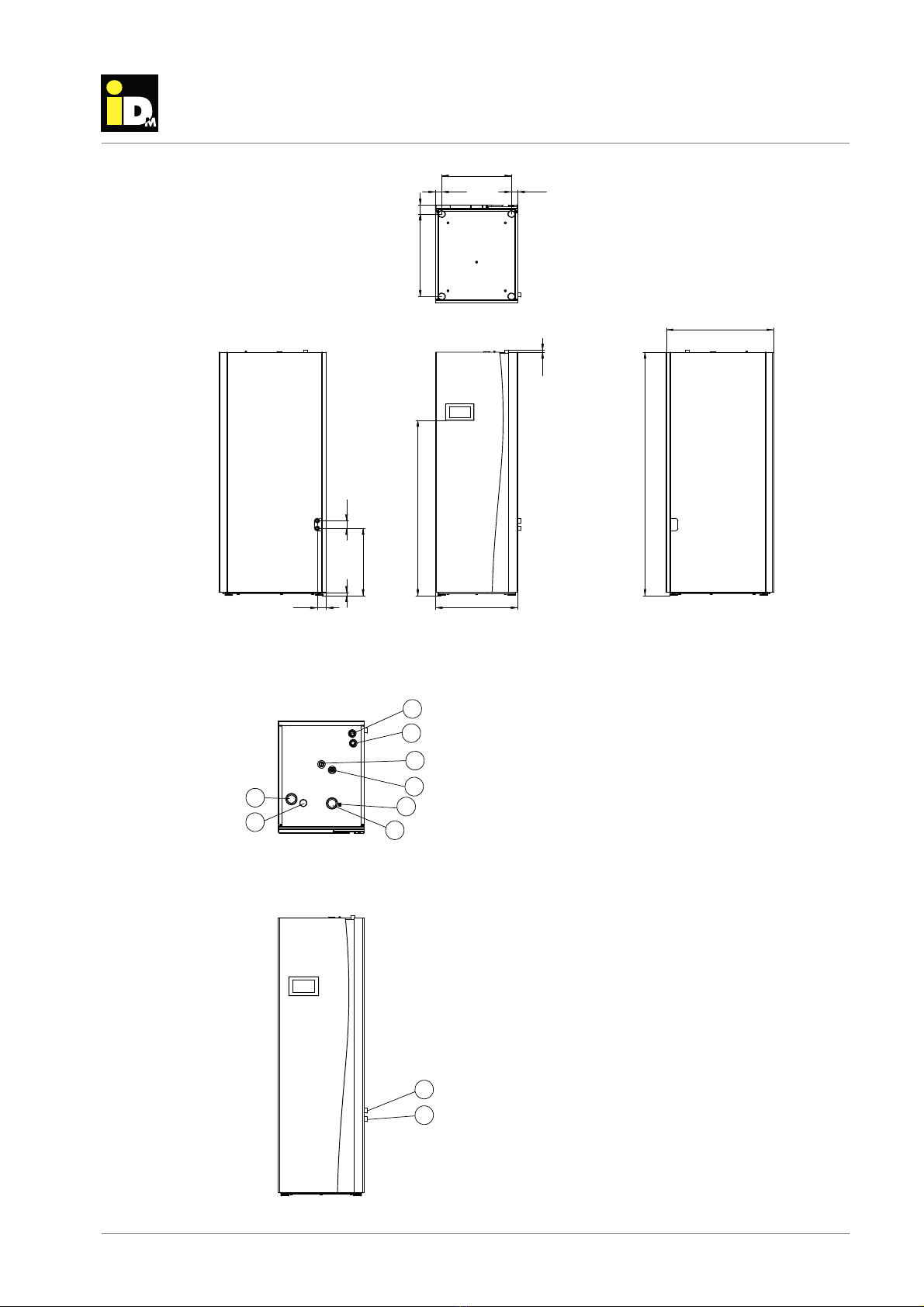

3.5. Dimensions Outdoor unit

Refrigerant pipe connections

Ø10 mm and Ø12 mm

resp. Ø12 mm und Ø16 mm

Condensation

drain 1“

Outlet side

Inlet side

3.6. Connections Outdoor unit (View from below)

(C) IDM ENERGIESYSTEME GMBH Installation instructions iPump A 2-7, 3-11 11

description

Monta

g

e Heizun

g

sseiti

g

Heat pump type iPump A 2-7 iPump A 3-11

Model 230 V 400 V

230 V

Space heating water energy efficiency class - 35°C 55°C 35°C 55°C

Energy efficiency class water heating -

Unit

Performance data acc. to EN 14511 at nominal speed

Heat output at A2°C/W35°C kW 3.90 5.92

Power consumption at A2°C/W35°C kW 0.88 1.35

COP at A2°C/W35°C - 4.42 4.37

Cooling capacity at A35°C/W18°C kW 4.95 7.80

Power consumption at A35°C/W18°C kW 1.03 1.81

EER at A35°C/W18°C - 4.80 4.32

Sound emission1

Sound power level nominal according to EN 12102 indoor unit dB(A) 42 45

Sound power level maximum according to EN 12102 indoor unit dB(A) 52 48

Sound power level nominal according to EN 12102 outdoor unit dB(A) 46 50

Sound power level maximum according to EN 12102 outdoor unit dB(A) 49 53

Sound reduced operation outdoor unit (reduced power) dB(A) 46 49

The sound pressure level can be calculated with

the iDM-sound calculation tool

Dimensions indoor unit

Height / Width / Depth mm 1950 / 600 / 786

Tilted height mm 2150 2150

Weight kg 251 270

Minimum size of installation room2(with standard filling) m³ 7.27 9.32

Dimensions outdoor unit

Height / Width / Depth mm 1180 / 1110 / 745

Weight kg 110 113

Hot water tank

Volume of hot water storage tank l 192

Maximum storage temperature °C 55

Maximum storage temperature with electrical heating unit °C 75

Max. single draw of hot water at 46°C tapping temp. - Heat pump3l 260

Max. single draw of hot water at 46°C tapping temp. - Electrical heater4l 356

Max. single draw of hot water at 40°C tapping temp. - Heat pump3l 315

Max. single draw of hot water at 40°C tapping temp. - Electrical heater4l 432

Max. operating pressure heating side bar 3

Max. operating pressure domestic hot water bar 10

Hot water connection R 3/4“

Cold water connection R 3/4“

3.7. Technical data

A+++ A++

A

A+++ A+++

A

(C) IDM ENERGIESYSTEME GMBH

3

.

D

escriptio

n

Installation instructions iPump A 2-7, 3-11

12

Description

Montage Heizungsseitig

Heat pump type iPump A 2-7 iPump A 3-11

Unit

Maximum heating supply temperature6°C 62

Regrigerant - R410A

Quantity of refrigerant (up to 6 m) kg 3.2 4.1

GWP51924

Compressor oil - FV50S EMKARATE

RL 32-3MAF

Quantity of compressor oil l 0.35 0.99

Compressor stages - 1-stage modulated

Air volume outdoor unit

(A7°C/W35°C at nominal speed6)m³/h 2500 3600

Integrated loading pump Wilo Yonos Para RS15/7.5

Nominal flow rate heating water (A7°C/W35°C nom. speed) m³/h 0.8 1.2

Free residual pressure loading pump (A7°C/W35°C max. speed*) kPa 65 66

Free residual pressure loading pump (A7°C/W35°C nom. speed*) kPa 36 40

Pressure loss heating side (A7°C/W35°C) at nominal output7kPa 9 9

Connection dimension

Heating supply / -return R1“

Refrigerant pipe - Hot gas line mm Ø12.7x0.8(1/2“) 16

Refrigerant pipe - Liquid line mm Ø9.53x0.8 (3/8“) 12

Maximum length of split-piping between indoor- and outdoor unit m 20 m /

max. height difference 10 m4

Electrical data

Electrical power supply compressor V / Hz 1~230 / 50 1~230 / 3~400

Electrical power supply heating unit V / Hz 3~400 / 50 3~400 / 50

Electrical power supply controller V / Hz 1~230 / 50 1~230/ 50

Maximum operating current of compressor A 15.8 9 / 24

Maximum operating current of ventilator A 0.24 0.5

Maximum power consumption ventilator W 56 113

Performance factor cos phi 1 0.98

Maximum power consumption heating unit A 26 13.04

Starting current A < 15.8 < 9

Performance factor 1~230 V cos phi 0.99 0.97/0.99

Fuse of main power supply A C/K 16 C/K 13 / 25

Fuse of control main supply A B/Z 13 B/Z 13

Fuse electrical heater A B/Z 13 B/Z 13

1Uncertainty of measurement ± 1,5 dB(A)

2If the size of the installation room is lower then the required minimum size, the room must be performed as an engine room according to EN 378

312°C cold water temperature / 58°C buffer temperature

412°C cold water temperature / 75°C buffer temperature

5According to the 5th IPPC Status Report

6The 62°C refers to the maximum heat pump flow temperature. The resulting lower hot water temperature must be checked in relation to compliance with the drinking water

ordinance.

7at 80% pump capacity

*Adjustment min. speed loading pump 60%, max. 100%

(C) IDM ENERGIESYSTEME GMBH Installation instructions iPump A 2-7, 3-11 13

description

Monta

g

e Heizun

g

sseiti

g

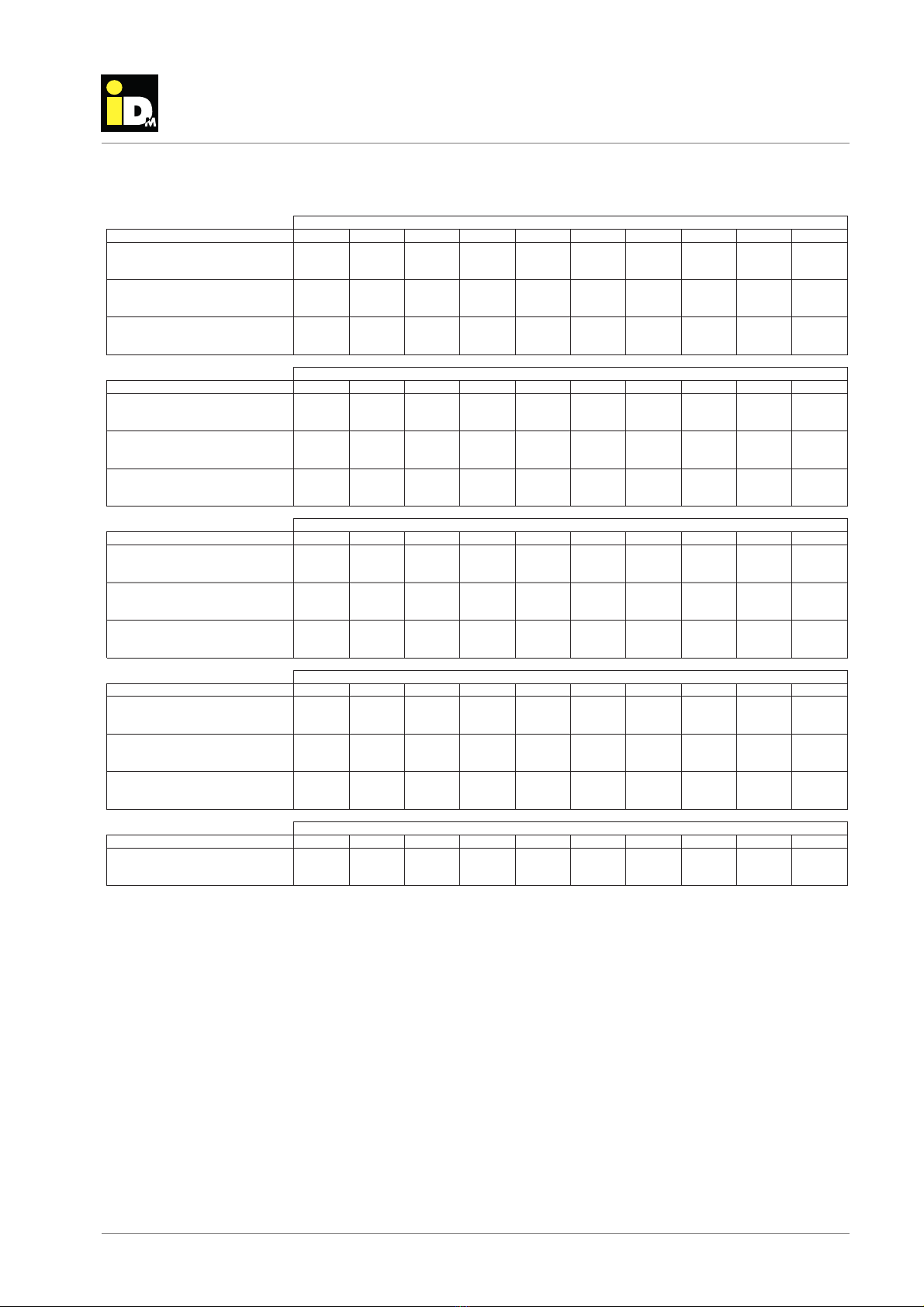

3.8. Performance data iPump A 2-7 acc. to EN 14511

20 15 12 10 7 2 -7 -10 -15 -18

4404675445967558739389879891005

205 205 206 204 202 200 187 184 173 171

258270295319378431459480482490

,ĞĂƚĐĂƉĂĐŝƚLJ [kW]

WŽǁĞƌĐŽŶƐƵŵƉƚŝŽŶ [kW]

COP

20322026129639045,4492506530540

083 083 083 087 0,87 088 087 083 081 079

256272313341442519566610636653

203200220200206223244260262270

041 040 040 041 043 047 060 070 075 079

256268312335438524591645

654

660

20 15 12 10 7 2 -7 -10 -15 -18

386415519570707833896941946963

248 246 247 244 241 216 219 213 214 210

389 384 381 367 346 327 260 244 194 184

200200241270362421459483487501

106 106 106 107 107 107 101 099 094 105

473 459 454 429 392 340 266 244 212 190

200199203200200200216231237254

053 053 054 054 055 067 079 086 094 105

190212235252297363400431443481

20 15 12 10 7 2 -7 -10 -15 -18

433426475518670791848908879905

295 294 297 285 280 271 248 250 251 281

306 299 306 297 282 247 209 190 170 154

200200228257346411445465471486

119 119 120 121 121 120 115 113 117 131

408 394 389 367 340 289 224 202 171 153

200182192173183202221239233243

059 058 058 058 059 064 079 095 108 131

153168201220286343383411405413

20 15 12 10 7 2 -7 -10 -15 -18

242299452509653795856900904926

283 282 283 280 276 243 258 254 251 247

327 320 318 306 288 269 197 178 119 098

200200215244329402430448

455472

129 128 129 131 128 125 118 116 129 142

367 354 348 329 313 263 206 185 155 141

200200200200

200200203210215231

070 069 069 071 075 083 103 108 129 142

141155185194242267285306313329

20 15 12 10 7 2 -7 -10 -15 -18

200200197226305389409424433452

143 141 142 145 138 132 122 120 146 157

316 307 299 282 282 231 185 164 137 127

MaxMIN MaxEKDMIN MINMaxMIN

KƵƚĚŽŽƌƚĞŵƉĞƌĂƚƵƌĞΣ

&ůŽǁƚĞŵƉĞƌĂƚƵƌĞtϯϱΣ

MAX

,ĞĂƚĐĂƉĂĐŝƚLJ [kW]

WŽǁĞƌĐŽŶƐƵŵƉƚŝŽŶ [kW]

COP

,ĞĂƚĐĂƉĂĐŝƚLJ [kW]

WŽǁĞƌĐŽŶƐƵŵƉƚŝŽŶ [kW]

COP

,ĞĂƚĐĂƉĂĐŝƚLJ [kW]

WŽǁĞƌĐŽŶƐƵŵƉƚŝŽŶ [kW]

COP

,ĞĂƚĐĂƉĂĐŝƚLJ [kW]

WŽǁĞƌĐŽŶƐƵŵƉƚŝŽŶ [kW]

COP

,ĞĂƚĐĂƉĂĐŝƚLJ [kW]

WŽǁĞƌĐŽŶƐƵŵƉƚŝŽŶ [kW]

COP

,ĞĂƚĐĂƉĂĐŝƚLJ [kW]

WŽǁĞƌĐŽŶƐƵŵƉƚŝŽŶ [kW]

COP

,ĞĂƚĐĂƉĂĐŝƚLJ [kW]

WŽǁĞƌĐŽŶƐƵŵƉƚŝŽŶ [kW]

COP

,ĞĂƚĐĂƉĂĐŝƚLJ [kW]

WŽǁĞƌĐŽŶƐƵŵƉƚŝŽŶ [kW]

COP

,ĞĂƚĐĂƉĂĐŝƚLJ [kW]

WŽǁĞƌĐŽŶƐƵŵƉƚŝŽŶ [kW]

COP

,ĞĂƚĐĂƉĂĐŝƚLJ [kW]

WŽǁĞƌĐŽŶƐƵŵƉƚŝŽŶ [kW]

COP

,ĞĂƚĐĂƉĂĐŝƚLJ [kW]

WŽǁĞƌĐŽŶƐƵŵƉƚŝŽŶ [kW]

COP

,ĞĂƚĐĂƉĂĐŝƚLJ [kW]

WŽǁĞƌĐŽŶƐƵŵƉƚŝŽŶ [kW]

COP

EKDEKD EKD

EKD

&ůŽǁƚĞŵƉĞƌĂƚƵƌĞtϰϱΣ

&ůŽǁƚĞŵƉĞƌĂƚƵƌĞtϱϬΣ

&ůŽǁƚĞŵƉĞƌĂƚƵƌĞtϱϱΣ

&ůŽǁƚĞŵƉĞƌĂƚƵƌĞtϲϮΣ

KƵƚĚŽŽƌƚĞŵƉĞƌĂƚƵƌĞΣ

KƵƚĚŽŽƌƚĞŵƉĞƌĂƚƵƌĞΣ

KƵƚĚŽŽƌƚĞŵƉĞƌĂƚƵƌĞΣ

KƵƚĚŽŽƌƚĞŵƉĞƌĂƚƵƌĞΣ

(C) IDM ENERGIESYSTEME GMBH

3

.

D

escriptio

n

Installation instructions iPump A 2-7, 3-11

14

Description

Montage Heizungsseitig

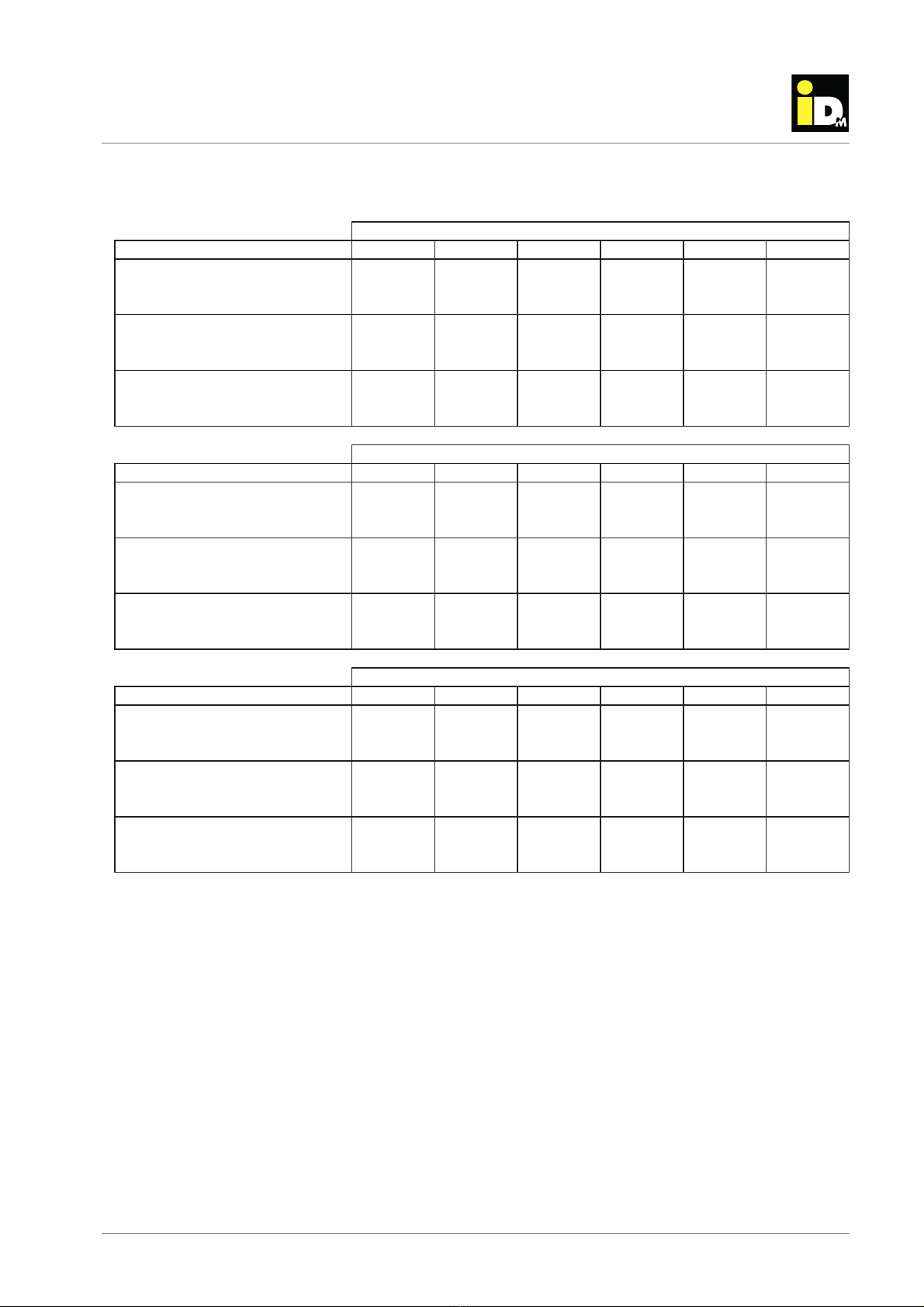

3.9. Cooling data detailed iPump A 2-7

To guarantee a correct cooling mode, when working with unregulated direct-heating circles (without cooling

buffer) following 3 requirements have to be fulfilled.

1. To ensure the minimum volume of heating site, appropriate zones have to remain open all the time.

Minimum volume 54 lt.

2. To ensure the minimum flow rate of heating site, appropriate zones have to remain open all the time.

Minimum flow rate 0.72 m³/h

3. To ensure the minimum cooling output rate of distribution system, appropriate zones have to remain open

all the time. The minimum cooling output rate is 70 % of the minimum cooling output power of the heat-

pump at A35°C/W18°C. Minimum cooling consumption 1.75 kW

All 3 requirements must be fulfilled independently. This is possible via the Navigator Pro. The entire distribution

system has to fulfill the 3 mentioned requirements. To ensure a large cooling demand, the cooling limit has to

be set as high as possible.

40 35 30 25 20 15

ϴϬϴ ϴϴϲ ϵϱϱ 1018 1079 ϭϭϮϲ

308 279 255 233 212 199

$PPMJOHDBQBDJUZ [kW]

1PXFSDPOTVNQUJPO [kW]

EER ϮϲϮ ϯϭϳ ϯϳϱ 436 508 567

459 495 563 611 651 685

106 103 086 076 064 052

$PPMJOHDBQBDJUZ [kW]

1PXFSDPOTVNQUJPO [kW]

EER 433 480 653 809 1016 1325

259 290 308 323 331 338

051 043 036 029 025 020

$PPMJOHDBQBDJUZ [kW]

1PXFSDPOTVNQUJPO [kW]

EER 506 679 861 1119 1348 1654

40 35 30 25 20 15

684 749 804 866 917 968

282 258 238 218 199 182

$PPMJOHDBQBDJUZ [kW]

1PXFSDPOTVNQUJPO[kW]

EER 243 290 337 397 461 531

403 431 475 512 533 571

113 103 090 080 068 057

$PPMJOHDBQBDJUZ [kW]

1PXFSDPOTVNQUJPO [kW]

EER 358 418 528 641 782 1007

220 230 247 263 279 283

057 045 039 032 026 021

$PPMJOHDBQBDJUZ [kW]

1PXFSDPOTVNQUJPO [kW]

EER 385 514 638 810 1055 1364

40 35 30 25 20 15

577 633 682 728 772 814

266 244 225 206 188 171

$PPMJOHDBQBDJUZ [kW]

1PXFSDPOTVNQUJPO [kW]

EER 217 260 303 353 411 475

337 376 400 425 451 471

114 101 090 080 070 060

$PPMJOHDBQBDJUZ [kW]

1PXFSDPOTVNQUJPO [kW]

EER 296 372 444 532 644 783

200 201 205 211 224 242

065 053 047 036 030 024

$PPMJOHDBQBDJUZ [kW]

1PXFSDPOTVNQUJPO[kW]

EER 306 379 440 593 753 1012

'MPXUFNQFSBUVSFBUW7¡$

MAX

N0.

MIN

0VUEPPStemperaturF[°C]

'MPXUFNQFSBUVSFBUW12¡$

MAX

N0.

MIN

0VUEPPStemperaturF[°C]

0VUEPPStemperaturF[°C]

'MPXUFNQFSBUVSFBUW18¡$

MAX

N0.

MIN

(C) IDM ENERGIESYSTEME GMBH Installation instructions iPump A 2-7, 3-11 15

description

Monta

g

e Heizun

g

sseiti

g

Heating output iPump A 2-7 at flow temperature 35°C

Heating output iPump A 2-7 at flow temperature 45°C

Ϭ

Ϯ

ϰ

ϲ

ϴ

ϭϬ

ϭϮ

ͲϮϬ Ͳϭϱ ͲϭϬ Ͳϱ Ϭ ϱ ϭϬ ϭϱ ϮϬ

HeDWFDSDFLW\ [kW]

2XWGRRUtemperaturH[°C]

Dy

EKD

D/E

Ϭ

Ϯ

ϰ

ϲ

ϴ

ϭϬ

ϭϮ

ͲϮϬ Ͳϭϱ ͲϭϬ Ͳϱ Ϭ ϱ ϭϬ ϭϱ ϮϬ

HeDWFDSDFLW\ [kW]

2XWGRRUtemperaturH[°C]

DĂdž

EKD

D/E

(C) IDM ENERGIESYSTEME GMBH

3

.

D

escriptio

n

Installation instructions iPump A 2-7, 3-11

16

Description

Montage Heizungsseitig

Heating output iPump A 2-7 at flow temperature 55°C

Heating output iPump A 2-7 at nominal speed

Ϭ

ϭ

Ϯ

ϯ

ϰ

ϱ

ϲ

ϳ

ϴ

ϵ

ϭϬ

ͲϮϬ Ͳϭϱ ͲϭϬ Ͳϱ Ϭ ϱ ϭϬ ϭϱ ϮϬ

HeDWFDSDFLW\ [kW]

2XWGRRUtemperaturH[°C]

DĂdž

EKD

D/E

ϭ

Ϯ

ϯ

ϰ

ϱ

ͲϮϬ Ͳϭϱ ͲϭϬ Ͳϱ Ϭ ϱ ϭϬ ϭϱ ϮϬ Ϯϱ

HeDWFDSDFLW\ [kW]

2XWGRRUtemperaturH[°C]

tϯϱ

tϰϱ

tϱϱ

tϱϬ

tϲϬ

(C) IDM ENERGIESYSTEME GMBH Installation instructions iPump A 2-7, 3-11 17

description

Monta

g

e Heizun

g

sseiti

g

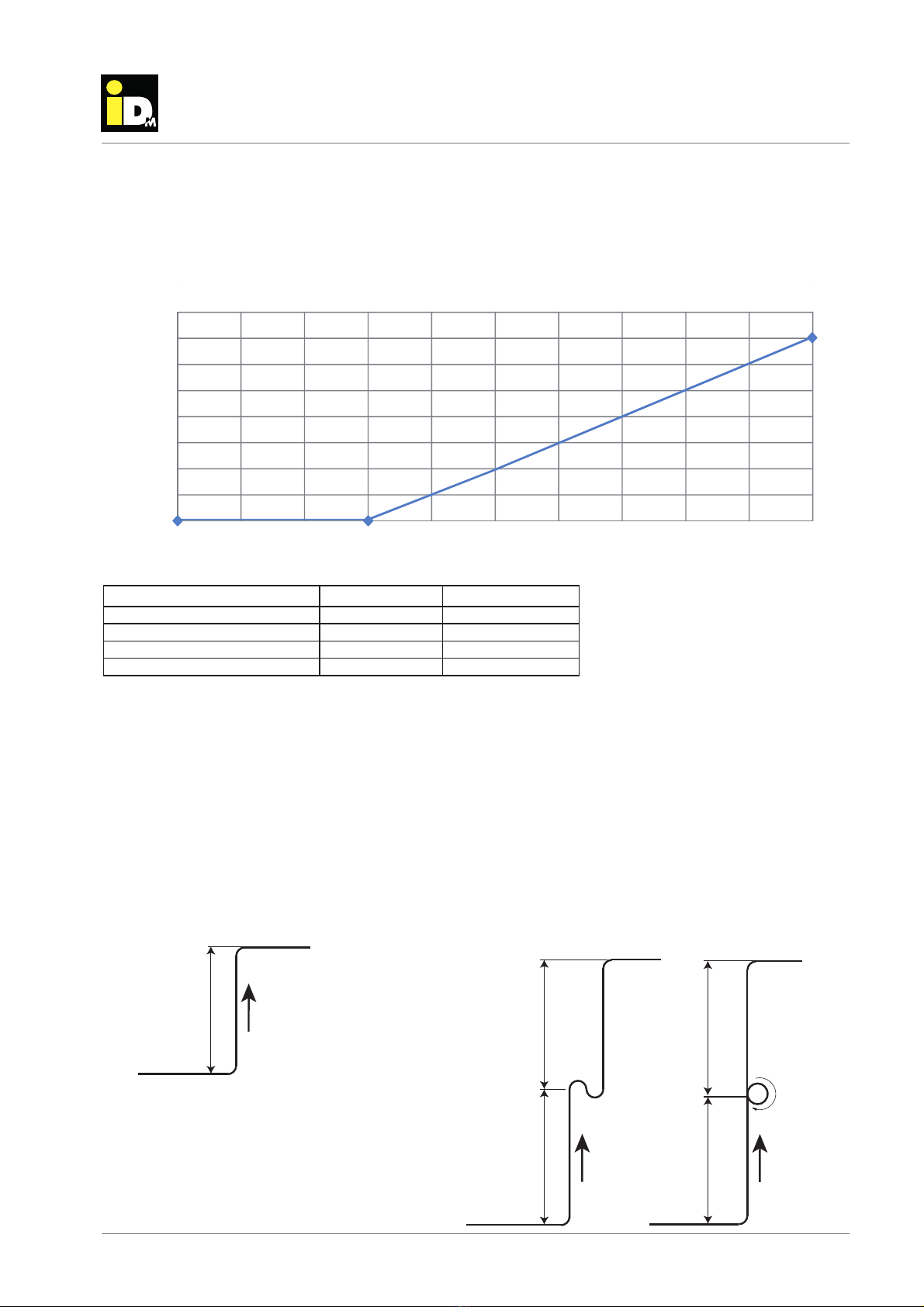

3.10. Filling quantity refrigerant

The iPump A 2-7 is pre-filled with refrigerant. Up to a distance of 6 m between indoor unit and outdoor unit no

refrigerant no additional needs to be refilled. For pipe length more than 6 m, the following refrigerant quantities

must be refilled.

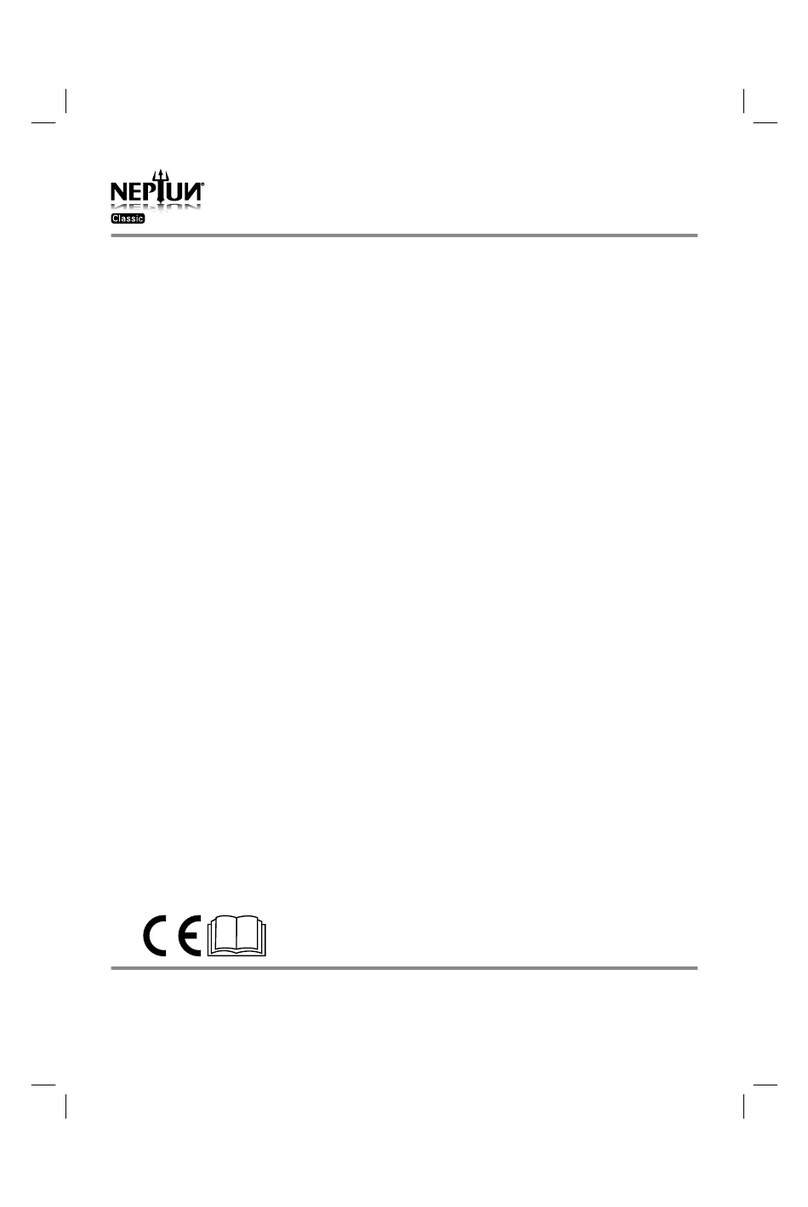

3.11. Maximum heigth difference

If the height difference between the indoor unit and outdoor unit is lower than 5 m no oil elevation arc must be

installed before the inclination. In case of a higher height difference the installation must be done after 5 m. The

oil elevation arc must be installed by a certificated service technician. Whether the indoor unit or the outdoor

unit is higher, does not matter. The maximum height difference between indoor unit and outdoor unit is 10 m.

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0 2 4 6 8 10 12 14 16 18 20

ZĞͲĨŝůůƋƵĂŶƚŝƚLJ in [kg]

Wŝ

Ɖ

ĞůĞŶ

Ő

ƚŚŝŶŽŶĞĚŝƌĞĐƚŝŽŶ

[

m

]

ZĞĨƌŝŐĞƌĂŶƚƌĞͲĨŝůůƋƵĂŶƚŝƚLJ iPump A 2-7

WŝƉĞůĞŶŐƚŚŝŶŽŶĞĚŝƌĞĐƚŝŽŶ[m] ZĞĨƌŝŐĞƌĂŶƚƋƵĂŶƚŝƚLJ[kg] ZĞͲĨŝůůƋƵĂŶƚŝƚLJ [kg]

032Ϭ6

02Ϭ34Ϭ

01

04536551

07Ϭ39Ϭ02

max 5 m

<5 m max 5 m

max 5 m max 5 m

Height difference lower than 5 m Height difference more than 5 m

Version 2Version 1

(C) IDM ENERGIESYSTEME GMBH

3

.

D

escriptio

n

Installation instructions iPump A 2-7, 3-11

18

Description

Montage Heizungsseitig

3.12. Linits of use

The heating of other fluids as heating water is not permitted with the iPump A 2-7 (for heating water quality,

see page 51). Heat pumps are by nature subjects to limits of use regarding of pressure and temperature (see

diagram). It is not permissible to operate the iPump A 2-7 outside these limits.

Note:

The following safety devices are included to protect the heat pump against faults:

- High pressure presostat

- Maximum flow temperature limitation with automatic reset via the NAVIGATOR control

- Starting current limiter via inverter technology and performance adjustment

-20 -10 0 5 10 20 30 35 40

30

40

50

60

20

[°C]

[°C]

R410A

62

42

Outdoor temperature

Flow temperature

iPump A 2-7 - Heating

Heating

The maximum heat pump flow temperature is the highest temperature that the heat pump can

produce (depending on the heat source temperature) and is then switched off at this value. Due to

the hydraulic spread over the heat pump and the control-related switching hysteresis, it is not pos-

sible to reach this temperature in the heating circuit or in the water heater. The maximum possible

management temperature depends on the hydraulic design and the configuration, and is at least 5

K below the maximum heat pump flow temperature.

(C) IDM ENERGIESYSTEME GMBH Installation instructions iPump A 2-7, 3-11 19

description

Monta

g

e Heizun

g

sseiti

g

10 15 20 25 30 35

10

15

20

25

30

5

[°C]

R410A

[°C]

40 45

0

Flow temperature

Outdoor temperature

iPump A 2-7 - Cooling

Cooling

The minimum heat pump flow temperature is the lowest temperature that the heat pump can produce

(depending on the heat source temperature) and is then switched off at this value. Due to the hydrau-

lic spread across the heat pump, the control-related switching hysteresis and the humidity-dependent

dew point, it is not possible to reach this temperature in the cooling circuit. The lowest possible

management temperature depends on the hydraulic design, the configuration and the actual dew

point on site and is at least 5 K above the minimum heat pump flow temperature.

The maximum power of the iPump A can be limited with the NAVIGATOR 2.0 controller.

(C) IDM ENERGIESYSTEME GMBH

3

.

D

escriptio

n

Installation instructions iPump A 2-7, 3-11

20

Description

Montage Heizungsseitig

3.13. Performance data iPump A 3-11 acc. to EN 14511

20 15 12 10 7 2 -7 -10 -15 -18

Heat output 08.670.813.900.0102.0105.2108.2108.2108.2108.21]Wk[

Power intake 34.306.386.327.304.351.379.258.295.203.2]Wk[

89.1

42.235.296.200.379.313.405.459.465.5POC

Heat output 02.314.300.424.429.597.692.708.703.809.8]Wk[

Power intake 43.103.163.153.1

53.133.153.153.114.114.1]Wk[

83.226.259.282.373.401.505.587.509.503.6POC

Heat output 08.208.208.208.208.209.202.34

5.340.406.4]Wk[

Power intake 42.141.110.149.097.036.056.096.027.047.0]

Wk[

52.254.277.279.265.336.409.431.506.502.6P

OC

20 15 12 10 7 2 -7 -10 -15 -18

Heat output 06.608.767.817.998.902.2104.2106.2107.2107.21]Wk[

Power intake 89.349.320.411.421.400.448.365.371.307.2]Wk[

COP 4.70 4.01 3.54 3.23 3.05 2.40 2.36 2.18 1.98 1.66

Heat output 11.3

92.368.362.405.534.670.773.758.704.8]Wk[

Power intake 65.165.106.116.146.136.106.106.195.155.1]Wk[

COP 5.41 4.95 4.61 4.41 3.95 3.36 2.64 2.41 2.11 1.99

Heizleistung 08.208.208.208

.208.208.208.212.308.324.4]Wk[

Power intake 42.239.165.193.180.167.086.017.087.038.0]Wk[

52.1

54.108.110.206.207.311

.405.458.403.5POC

20 15 12 10 7 2 -7 -10 -15 -18

Heat output 10.311.337.321.413.552.628.611.785.712.8]Wk[

Power intake 66.156.117.107.157.177.167.147.117.107.1]Wk[

COP 4.84 4.42 4.08 3.88 3.53 3.04 2.42 2.18 1.89 1.81

20 15 12 10 7 2 -7 -10 -15 -18

Heat output 84.803.907.910.2101.2153.2106.2106.21]Wk[ --

Power intake 02.493.438.426.404.414.400.423.3]Wk[ --

COP 3.80 3.15 2.80 2.75 2.60 2.01 2.12 2.02 --

Heat output 06.389.311.570.66

5.658.613.710.8]Wk[ --

Power intake 28.118.198.169.169.139.188.188.1]Wk[ --

COP 4.26 3.89 3.55 3.34 3.10 2.71 2.20 1.98 --

Heat output 08.208.208.208.208.209.205.308.3]Wk[ --

Power intake 62

.251.211.150.109.038.058.008.0]Wk[ --

42.103.135.276.221.315.301.447.4POC --

20 15 12 10 7 2 -7 -10 -15 -18

Heat output 08.456.523.616.620.767

.

7]Wk[ ----

Power intake 62.263.214.263.212.291,2]Wk[ ----

COP 3,55 3.18 2.80 2.62 2.39 2.12 ----

&ůŽǁƚĞŵƉĞƌĂƚƵƌĞW45Σ

NOMINAL

&ůŽǁƚĞŵƉĞƌĂƚƵƌĞW55Σ

&ůŽǁƚĞŵƉĞƌĂƚƵƌĞW50Σ

NOMINAL MAXMINNOMINAL MAX

KƵƚĚŽŽƌtemperature [°C]

KƵƚĚŽŽƌtemperature [°C]

&ůŽǁƚĞŵƉĞƌĂƚƵƌĞW35Σ

MAXNOMINALMIN

KƵƚĚŽŽƌtemperature[°C]

MIN

&ůŽǁƚĞŵƉĞƌĂƚƵƌĞW62Σ

NOMINAL

KƵƚĚŽŽƌtemperature ŝŶ[°C]

KƵƚĚŽŽƌtemperature [°C]

This manual suits for next models

1

Table of contents

Popular Water Pump manuals by other brands

Seaflo

Seaflo 51 Series manual

Kamoer

Kamoer X1 PRO T quick start guide

Grundfos

Grundfos Unilift AP12 Installation and operating instructions

DIVERSITECH

DIVERSITECH CP-16 Installation and safety instructions

Neptun

Neptun NCSP-E 35 Original operating instructions

Grundfos

Grundfos CRE Series Installation and operating instruction