IDT ZMID5201 User manual

ZMID520x User Guide for Getting Started

© 2018 Integrated Device Technology, Inc.

1

April 6, 2018

Contents

1. Introduction...................................................................................................................................................................................................3

2. Inductive Sensing Technology Introduction..................................................................................................................................................3

2.1 Device Block Diagram .........................................................................................................................................................................6

3. Getting Started .............................................................................................................................................................................................7

3.1 LC Tank –Tx Front-End Tuning ..........................................................................................................................................................7

3.2 Device Initialization..............................................................................................................................................................................8

3.2.1 Output Mode Selection .........................................................................................................................................................8

3.3 Offset Check for Rx Coils ....................................................................................................................................................................9

3.4 Gain Stage Setting ............................................................................................................................................................................11

3.5 Input Amplitude Offset Compensation...............................................................................................................................................12

3.6 Output Calibration..............................................................................................................................................................................13

3.7Output Linearization ..........................................................................................................................................................................14

4. Internal Memory..........................................................................................................................................................................................17

5. Programming the ZMID520x EEPROM......................................................................................................................................................19

6. Glossary .....................................................................................................................................................................................................19

7. Revision History..........................................................................................................................................................................................20

List of Figures

Figure 1. Tx Loop Magnetic Field .......................................................................................................................................................................3

Figure 2. Current Paths and Shapes for Coils –Example for Linear Position Sensing ......................................................................................4

Figure 3. Geometrical Illustration for Coils and Target –Example for Linear Position Sensing..........................................................................5

Figure 4. Main Internal Functional Block Diagram..............................................................................................................................................6

Figure 5. ZMID520x Transmitter LC Tank..........................................................................................................................................................7

Figure 6. TX Oscillation and LF-U 5 Probe.........................................................................................................................................................8

Figure 7. ZMID520x EEPROM Memory Values –ZMID5203 Example for the Linear Output Mode Settings ..................................................9

Figure 8. ZMID520x EEPROM Gain Stage Setting –Example using the ZMID5203........................................................................................9

Figure 9. Coil Offset Reading –Example using the ZMID5203........................................................................................................................10

Figure 10. Magnitude for Gain Selection –Example for the ZMID5203 .............................................................................................................11

Figure 11. ZMID520x Input Amplitude Offset Compensation –Example for the ZMID5203 ..............................................................................12

Figure 12. Output Calibration..............................................................................................................................................................................13

Figure 13. Output Calibration Verification...........................................................................................................................................................14

Figure 14. Correction Mode Selection ................................................................................................................................................................14

Figure 15. Measured Value Readings for 9 Linearization Points........................................................................................................................15

Figure 16. Input Fields for the 9 Linearization Points Measured Values.............................................................................................................16

Figure 17. ZMID520x Internal Memory ...............................................................................................................................................................17

ZMID520x User Guide for Getting Started

© 2018 Integrated Device Technology, Inc.

2

April 6, 2018

List of Tables

Table 1. EEPROM and Shadow RAM Contents..............................................................................................................................................17

ZMID520x User Guide for Getting Started

© 2018 Integrated Device Technology, Inc.

3

April 6, 2018

1. Introduction

This document describes the procedures for setting up the IDT ZMID520x internal memory and transmitter (Tx) front-end in order to start

measurements with the device in user applications. It describes the settings needed to prepare the device for operation and then gives an

internal memory overview.

The steps provided here are needed when configuring a new device in a user application. These procedures can also be applied to any of the

ZMID520x application modules provided by IDT; however this is typically not needed because the sensor has been fully configured before the

module is shipped.

Recommendation: Read the ZMID520x Datasheet before using this document for a better understanding of the ZMID520x:

https://www.idt.com/document/dst/zmid520x-datasheet

Information on the OWI interface can be found in the ZMID520x Technical Brief –One Wire Interface (OWI).

2. Inductive Sensing Technology Introduction

This section provides some basic principles for inductive position sensing using the ZMID520x family of products, and it covers how the required

magnetic fields are generated.

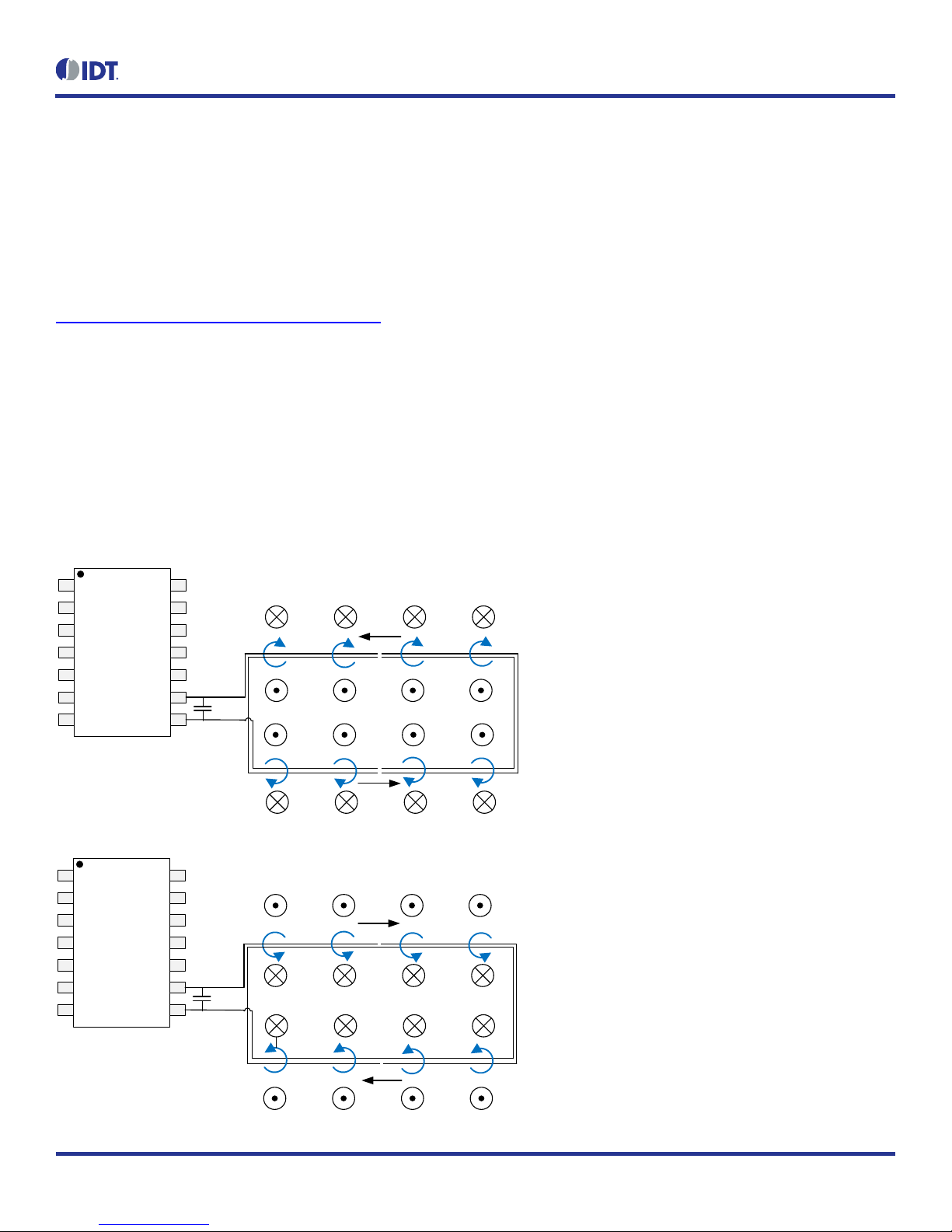

In the application, an LC oscillator generates a magnetic field in the transmit wire loop. The frequency of the oscillation is tuned by the

capacitance Ct. The polarity of the magnetic field depends on the direction of the current in the loop.

Figure 1. Tx Loop Magnetic Field

ZMID520x

1

2

14

13

12

11

10

9

8

3

4

5

6

7

R1P

R1N

R2P

R2N

VDDT

EP

EN

Test_D

Test-Ena

VDDD

SOUT

VDDA

VSSE

VDDE Tx

I

I

ZMID520x

1

2

14

13

12

11

10

9

8

3

4

5

6

7

R1P

R1N

R2P

R2N

VDDT

EP

EN

Test_D

Test-Ena

VDDD

SOUT

VDDA

VSSE

VDDE Tx

I

I

ZMID520x User Guide for Getting Started

© 2018 Integrated Device Technology, Inc.

4

April 6, 2018

The signal that is generated by the magnetic field of transmitter coil (Tx) is received by two receiver coils.

If a metallic target is placed over the coils, the transmitted energy below the target is dissipated as eddy currents in the target and does not

induce a secondary voltage in the receiver coils in that area.

The two receiver coils are designed with a 90phase shift, and the transmitter coil surrounds them. The target is placed on top of them and

moves over a plane parallel to the plane containing all the coils, as shown in Figure 2 below. Depending on the coil’s shape, movement can be

linear, arc, or rotary. The same physical principle is valid for different coils (and target) shapes.

The position of the target will be indicated through the differential phase and the amplitude of the signals measured on the Rx coils by the

ZMID520x

Figure 2. Current Paths and Shapes for Coils –Example for Linear Position Sensing

Metallic Target

RxCos

RxSin

Tx

Sin Loop 1

(cw)

Sin Loop 2

(ccw)

Sin Loop 3

(cw)

Tx Loop

Cos Loop 2

(ccw)

Cos Loop 1

(cw)

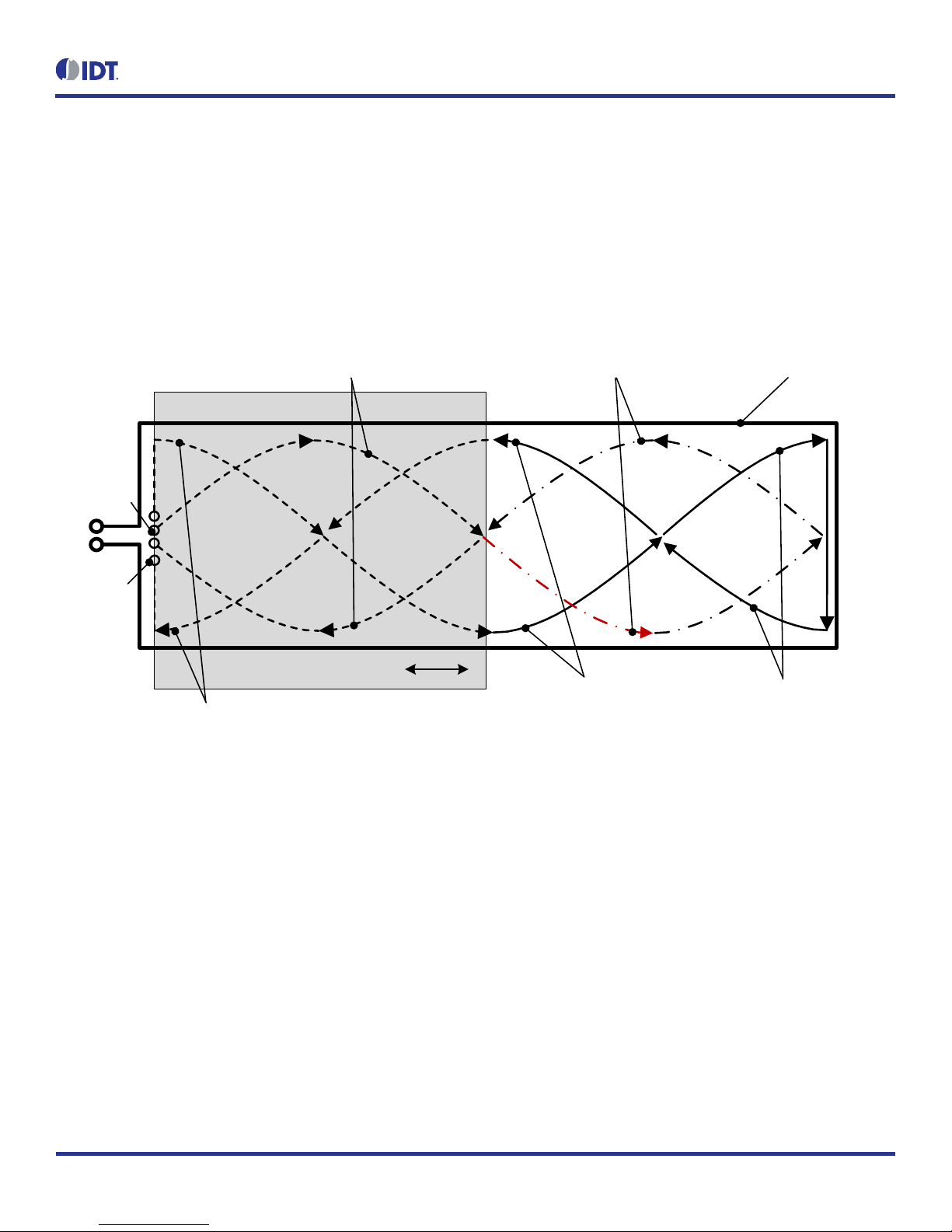

The key parameters influencing the proper operation of coils with the ZMID520x are the following: the length and width of the Tx and Rx coils,

the size of the target, and the airgap between the target and the printed circuit board (PCB) where the coils are integrated. Figure 3 provides

an illustration of the length and width of the coils for linear position sensing.

ZMID520x User Guide for Getting Started

© 2018 Integrated Device Technology, Inc.

5

April 6, 2018

Figure 3. Geometrical Illustration for Coils and Target –Example for Linear Position Sensing

Note: The following display was created by the ZMID520x Inductive Coil Design Tool Software.

IDT provides a software tool to support coil design as illustrated in Figure 3:

ZMID520x Inductive Coil Design Tool Software: https://www.idt.com/document/swr/zmid520x-inductive-coil-design-tool-software

ZMID520x User Guide –Inductive Coil Design Tool: https://www.idt.com/document/mas/zmid520x-user-guide-inductive-coil-design-tool

Reference designs for linear, arc and rotary position sensors are shown in the “Layout” section of the applicable Application Modules User

Manual available on the following application module product pages, which also provide relevant Gerber design files:

ZMID520xMLIN Application Module:

www.idt.com/products/sensor-products/position-sensors/zmid5201mlin-zmid5201-inductive-linear-application-module-analog-output

www.idt.com/products/sensor-products/position-sensors/zmid5202mlin-zmid5202-inductive-linear-application-module-pwm-output

www.idt.com/products/sensor-products/position-sensors/zmid5203mlin-zmid5203-inductive-linear-application-module-sent-output

ZMID520xMARC Application Module:

www.idt.com/products/sensor-products/position-sensors/zmid5201marc-zmid5201-inductive-arc-application-module-analog-output

www.idt.com/products/sensor-products/position-sensors/zmid5202marc-zmid5202-inductive-arc-application-module-pwm-output

www.idt.com/products/sensor-products/position-sensors/zmid5203marc-zmid5203-inductive-arc-application-module-sent-output

ZMID520xMROT Application Module:

www.idt.com/products/sensor-products/position-sensors/zmid5201mrot-zmid5201-inductive-rotary-application-module-analog-output

www.idt.com/products/sensor-products/position-sensors/zmid5202mrot-zmid5202-inductive-rotary-application-module-pwm-output

www.idt.com/products/sensor-products/position-sensors/zmid5203mrot-zmid5203-inductive-rotary-application-module-sent-output

ZMID520x User Guide for Getting Started

© 2018 Integrated Device Technology, Inc.

6

April 6, 2018

2.1 Device Block Diagram

Refer to the ZMID520x Datasheet for the latest block diagram information.

The main building blocks include the following:

Power management: power-on-reset (POR) circuit and low drop-out (LDO) regulators for internal supplies.

Oscillator: generation of the transmit coil signal.

Analog front-end: demodulator and gain control for the receive signals.

Analog-to-digital converter (ADC): conversion into digital domain.

Digital signal processing: offset correction; conversion of sine and cosine signals into angle and magnitude; angle range adjustment; and

linearization.

EEPROM: nonvolatile storage of factory and user-programmable settings.

One-wire interface (OWI): programming of the chip through the output pin.

Interface options:

Analog output for ZMID5201

PWM output for ZMID5202

SENT output for ZMID5203

Protection: overvoltage, reverse polarity, short circuit protection.

Figure 4. Main Internal Functional Block Diagram

ZMID520x User Guide for Getting Started

© 2018 Integrated Device Technology, Inc.

7

April 6, 2018

3. Getting Started

The following procedures require the ZMID520x EVK Application Software, which includes the graphical user interface (GUI) provided for the

ZMID520x Application Modules.

A complete description of the GUI is given in the ZMID520x Evaluation Kit User Manual, which is available on the IDT website via the following

link, and it includes instructions for downloading and installing the GUI: https://www.idt.com/document/man/zmid520x-evaluation-kit-user-

manual-application-modules.

3.1 LC Tank –Tx Front-End Tuning

The transmit circuitry for ZMID520x applications consists of an LC tank that is formed from the inductance of the transmitting coil and a capacitor

on the circuit board as shown in Figure 5.

Figure 5. ZMID520x Transmitter LC Tank

The objective of the Tx front-end tuning is to set the oscillation frequency in the range of operation specified in the ZMID520x Datasheet; a

typical value is approximately 3.5MHz.

The first step is to measure the inductance value of the Tx coil and verify that the value is within the limits specified in the ZMID520x Datasheet.

Once the inductor value is known, the capacitor value (Ct in Figure 5) can be calculated using Equation 1.

f = 1

2𝜋√ LC

Equation 1

Direct measurement of the frequency will confirm the exact value of the oscillation frequency.

If the measurement of the inductance of the printed circuit board coil (Lt in Figure 5) is not an option, a successive approximation approach can

be used; i.e., testing multiple Ct values until the resulting oscillation frequency is as close as possible to 3.5MHz. A capacitor value of 560pF is

generally a good starting point.

Recommendation: To ensure a good quality factor and low temperature drift for the LC tank circuit, use ceramic capacitors class C0G (C-zero-

G) ceramics also known as NP0 (negative-positive-zero). The capacitor must be placed close to the EP and EN pins on the ZMID520x.

ZMID520x User Guide for Getting Started

© 2018 Integrated Device Technology, Inc.

8

April 6, 2018

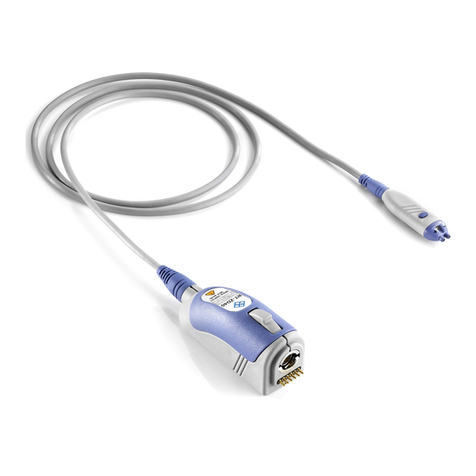

Figure 6 shows the TX pin oscillation detected with a LF-U 5 Near-Field Probe from Langer EMV-Technik.

Figure 6. TX Oscillation and LF-U 5 Probe

3.2 Device Initialization

3.2.1 Output Mode Selection

The ZMID allows selecting one of two output modes: Linear or Modulo 360.

Linear: The Linear Output Mode is a non-repeating output mode in which the sensor output signal is clamped at the mechanical end

points.

Modulo 360: The Modulo 360 Output (Sawtooth Output) Mode is a repeating output mode in which the sensor output signal is not

clamped at the mechanical end points, but it is switched back to its origin.

See the ZMID520x Datasheet and ZMID520x EVK User Manual for further details.

In most linear and arc applications, the Linear Output Mode is recommended. For rotary applications, the Modulo 360 Mode is recommended.

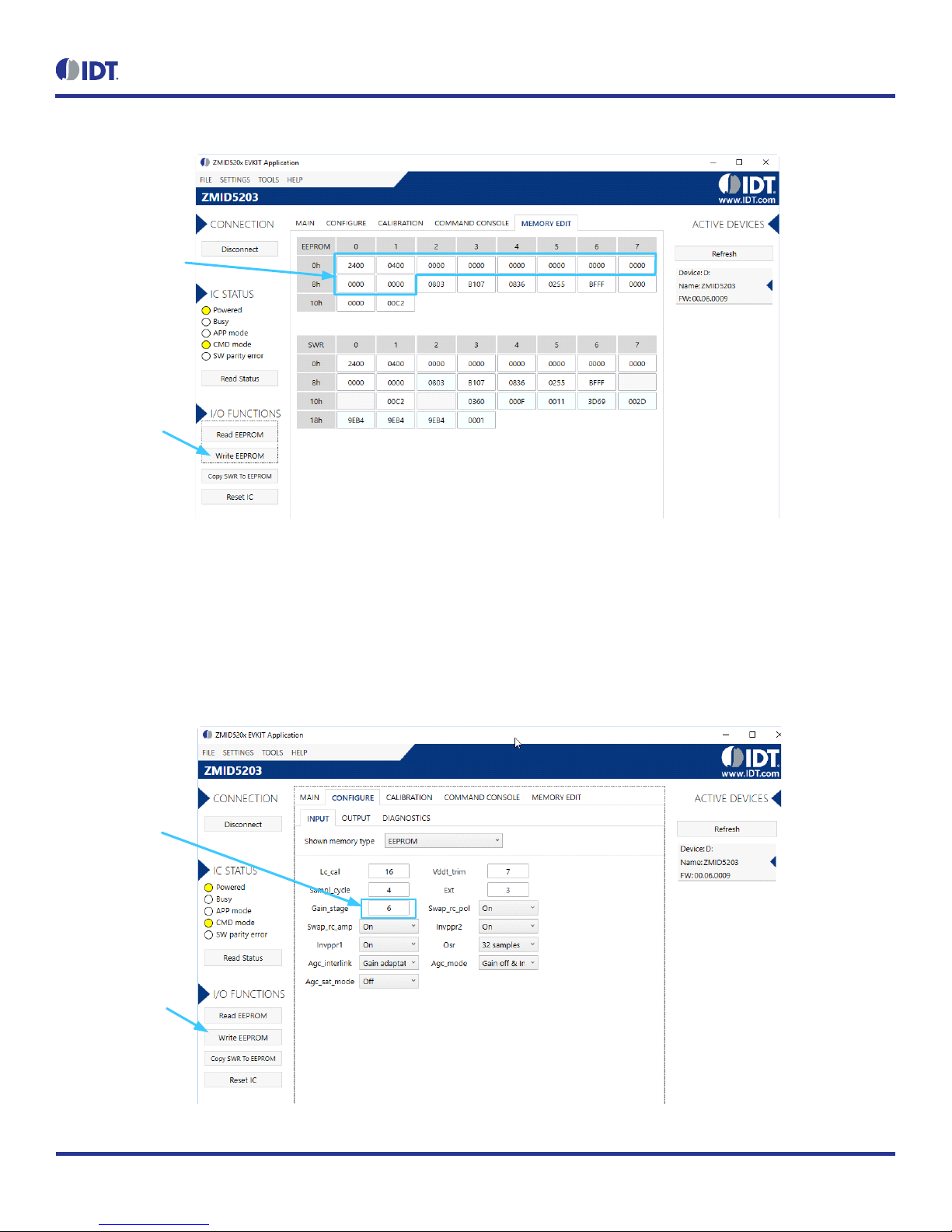

To ensure a smooth and successful procedure, use the GUI and the instructions in the ZMID520x EVK User Manual to set the ZMID520x

EEPROM registers from 00HEX to 09HEX to the following values. Note: Ensure that the new values are stored in EEPROM using the “Write

EEPROM” function.

If using the Linear Output Mode, set the following register values as shown in Figure 7: register 00HEX = 2400 HEX; register 01HEX = 0400HEX;

and registers 02HEX through 09HEX = 0000HEX.

If using the Modulo 360 Output Mode, set register 00HEX = 0000HEX, register 01HEX = 0400HEX, registers 02HEX through 08HEX = 0000HEX,

and register 09HEX = 1000HEX.

ZMID520x User Guide for Getting Started

© 2018 Integrated Device Technology, Inc.

9

April 6, 2018

Figure 7. ZMID520x EEPROM Memory Values –ZMID5203 Example for the Linear Output Mode Settings

Set these standard values

for registers 00HEX to 09HEX.

Remaining register values

might differ.

Write new values to the

ZMID520x EEPROM.

3.3 Offset Check for Rx Coils

The ZMID520x has a selectable input gain, which can be set via the GUI using the Gain_stage entry field found on the “INPUT” subtab under

the “CONFIGURE” tab as described in section 3.4. Before checking the offset of the Rx coils, set the Gain_stage value to a preliminary setting

of 6 using the entry field shown in the example for the ZMID5203 given in Figure 8, which is applicable to all ZMID520x ICs.

Save the new value in the ZMID520x EEPROM memory by clicking the “Write EEPROM” button,which updates register 0CHEX.

Figure 8. ZMID520x EEPROM Gain Stage Setting –Example using the ZMID5203

Set Gain_stage to 6.

Write new values to the

ZMID520x EEPROM.

ZMID520x User Guide for Getting Started

© 2018 Integrated Device Technology, Inc.

10

April 6, 2018

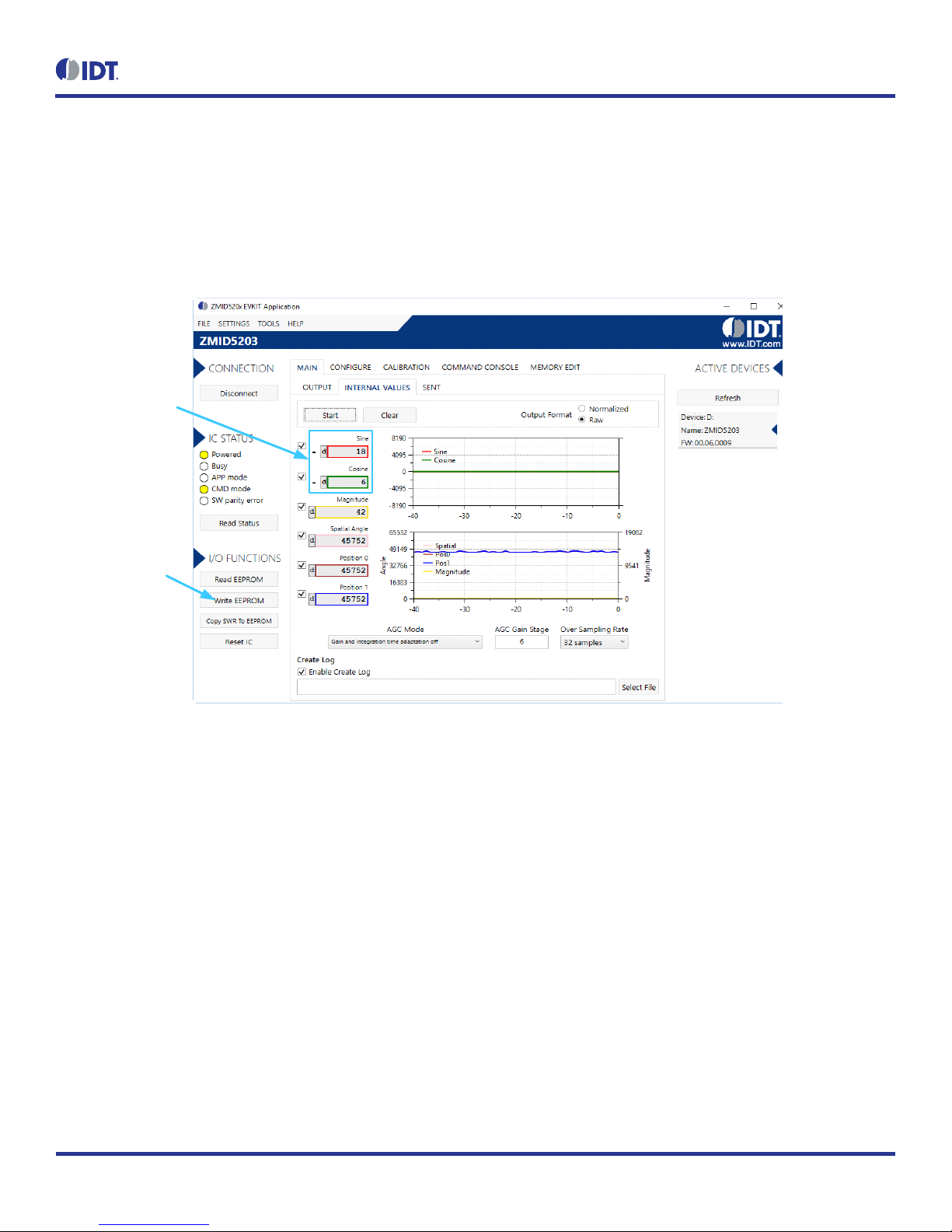

Next, remove the target from the sensor board (distance between the target and the Rx coils must be greater than 20mm). With this condition,

use the GUI to read the “Sine” and “Cosine” values on the “INTERNAL VALUES” subtab under the “MAIN” tab as shown in the ZMID5203

example given in Figure 9.

For properly designed coils, typical offset values are below 100DEC for “Sine” and “Cosine” values as shown in the example in Figure 9.

The coil design should meet the criteria of having a maximum symmetry for the two Rx coils. See section 2 for the links for software and

documentation for the ZMID520x Inductive Coil Design Tool Software provided by IDT for addressing this requirement.

Figure 9. Coil Offset Reading –Example using the ZMID5203

Check that offset values

are within requirements.

Write new values to the

ZMID520x EEPROM.

ZMID520x User Guide for Getting Started

© 2018 Integrated Device Technology, Inc.

11

April 6, 2018

3.4 Gain Stage Setting

Select the value of the Gain_stage setting so that the value of the “Magnitude” parameter is in the range of 6000DEC to 10000DEC when the

target is positioned at the nominal air gap over the sensor board. The GUI displays the “Magnitude” parameter tab on the “INTERNAL VALUES”

subtab under the “MAIN” tab for checking that this requirement has been met. In the ZMID5203 example given in Figure 10, Gain_stage has

been set to 8 DEC resulting in a “Magnitude” value within the required range.

For most applications, the automatic gain control (ACG) functionality can be disabled (see the “AGC Mode” setting in Figure 10).

Figure 10. Magnitude for Gain Selection –Example for the ZMID5203

ZMID520x User Guide for Getting Started

© 2018 Integrated Device Technology, Inc.

12

April 6, 2018

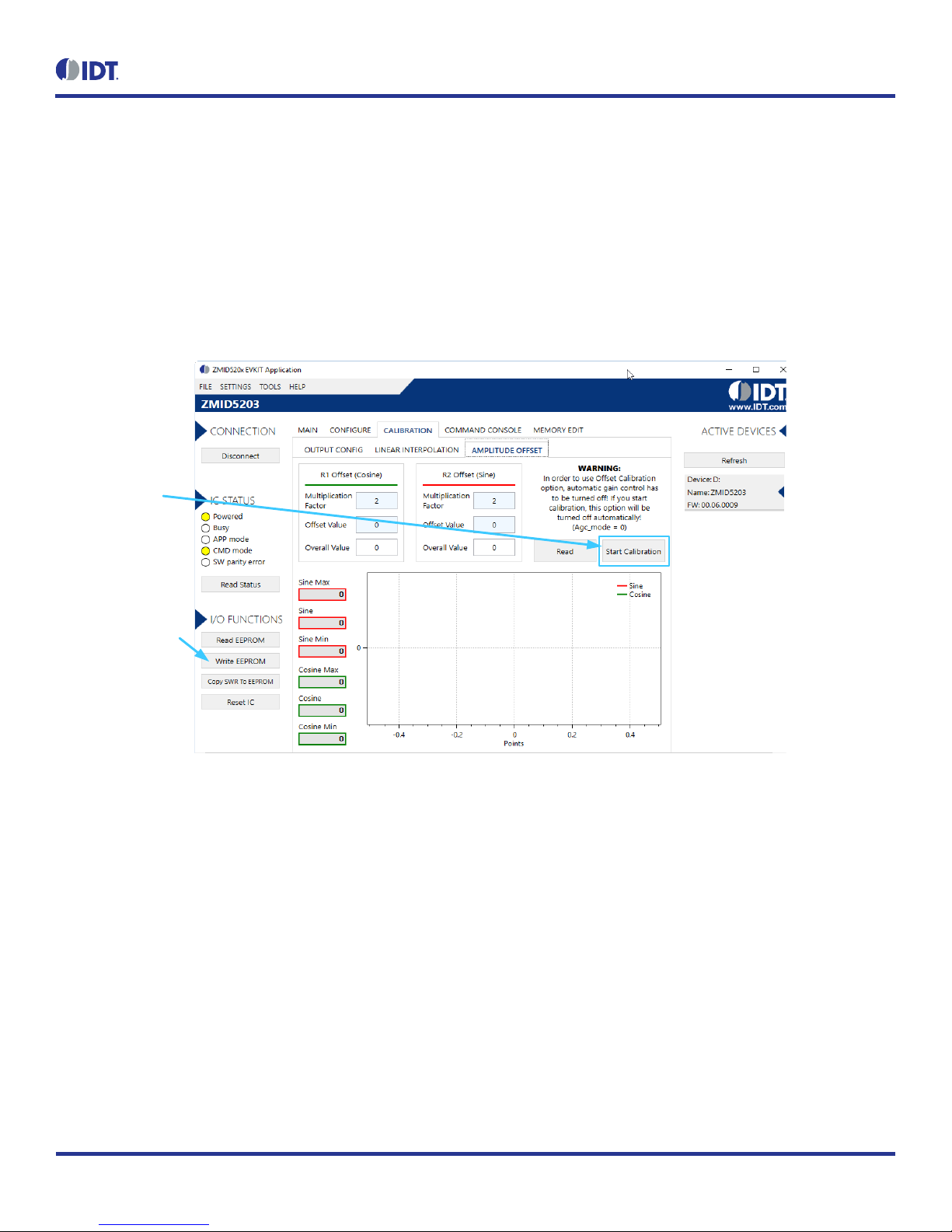

3.5 Input Amplitude Offset Compensation

The GUI offers an automated procedure for performing the input amplitude offset compensation with the target in place. For this procedure the

target must be positioned at the operational distance from the receiving coils (air gap).

1. Start the procedure by clicking the “Start Calibration” button located on the “AMPLITUDE OFFSET” subtab under the “CALIBRATION” tab

as shown in the ZMID5203 example given in Figure 11, which applies to all ZMID520x ICs. Follow instructions in the resulting dialog

windows to complete the calibration.

2. When the calibration is finished, click the “Write to EEPROM” button before moving to the next steps. This procedure modifies the contents

of register 08HEX.

Figure 11. ZMID520x Input Amplitude Offset Compensation –Example for the ZMID5203

Click here to start the

automatic calibration.

When the automatic

calibration is completed,

write the new values to

the ZMID520x EEPROM.

ZMID520x User Guide for Getting Started

© 2018 Integrated Device Technology, Inc.

13

April 6, 2018

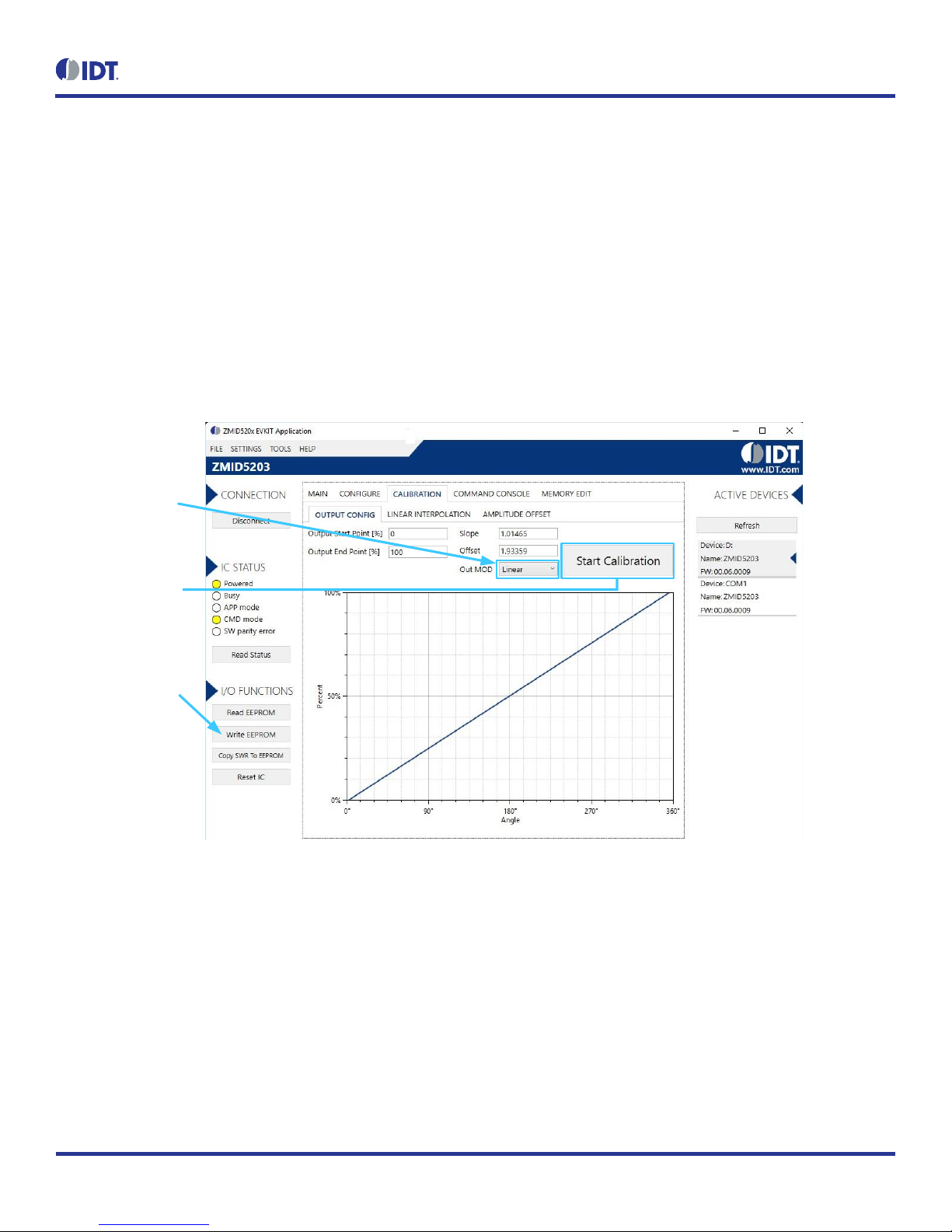

3.6 Output Calibration

The GUI offers an automated procedure for performing output calibration with the target in place at the operational distance from the receiving

coils (air gap).

1. Select the “Out MODE” setting as described in section 3.2.1.

2. Start the procedure by clicking the “Start Calibration” button on the “OUTPUT CONFIG” subtab under the “CALIBRATION” tab as shown

in the ZMID5203 example given in Figure 12.

3. Click the “Write to EEPROM” button before moving to the next steps. This procedure modifies the contents of registers 00HEX, 01HEX, and

09HEX.

4. Verify that the calibration was successful by checking the “Position 1”field on the “INTERNAL VALUES” subtab under the “MAIN” tab at

the start and end positions of the measurement range via the “INTERNAL VALUES” subtab under the “MAIN” tab as shown in the ZMID5203

example given in Figure 13, which applies to all ZMID520x ICs.

Figure 12. Output Calibration

Then click here to start

the automatic calibration.

When the automatic

calibration is completed,

write the new values to

the ZMID520x EEPROM.

Select the output mode:

Linearfor arc and

linear applications

Modulus 360for

rotary applications

ZMID520x User Guide for Getting Started

© 2018 Integrated Device Technology, Inc.

14

April 6, 2018

Figure 13. Output Calibration Verification

End point = ~65535

Click Startand then

move target.

Start point = 0

3.7 Output Linearization

This section provides a basic output linearization procedure for the ZMID520x. Using a target positioning system for these procedures is strongly

recommended.

For additional information on calibration and linearization, refer to the ZMID520x Evaluation Kit User Manual. For the ZMID5201, also see the

ZMID5201 Manual for Calibration and Linearization Using the Analog Output available on the ZMID5201 product web page.

www.idt.com/document/man/zmid5201-manual-calibration-and-linearization-using-analog-output

1. Set the “Correction Mode" drop-down menu to “Post-calibration” on the “LINEAR INTERPOLATION” subtab under the “CALIBRATION”

tab (see Figure 14). This modifies register 09HEX.

2. Set the value for the “Motion Range” entry field according to the receiver coil shape.

Figure 14. Correction Mode Selection

Set Correction Mode

to Post-calibration.

Set Motion Rangevalue

according to the application.

ZMID520x User Guide for Getting Started

© 2018 Integrated Device Technology, Inc.

15

April 6, 2018

3. Select the “Raw” mode via the radio buttons above the fields for “Spatial Angle,” “Position 0,”and “Position 1” as shown in Figure 15.

4. Click the “Start Reading” button to start reading position values via the ZMID520x. The button changes to “Stop,” and the adjacent readings

should update to show the position readings.

5. Move the actual target position until the value in the “Position 0” field is 0000HEX. Note: The points identified by “Position 0” = 0000HEX and

“Position 0” = FFFFHEX are the start and end points identified with the calibration procedure.

6. Then physically measure the actual position or read the measured value from the positioning system (in mm or degrees) and enter the

value in the first column in the “Measured Value” row in the matrix on the “LINEAR INTERPOLATION” tab. Figure 15 shows an example

of the matrix for a 360 rotary position sensing application for the ZMID5203.

Figure 15. Measured Value Readings for 9 Linearization Points

Enter the physical

measurement in mm

or degrees; e.g. from

the positioning system.

Click Start Reading

to start reading the

measured values

from the ZMID520x.

Select RawMode.

7. Move the target again (e.g., with the positioning system) until the value in the “Position 0” field is 1FFFHEX. Then physically measure the

new actual position or read the measured value from the positioning system and enter the value in the second column in the “Measured

Value” row in the matrix.

8. Repeat the previous step for “Position 0” = (1FFF x n) + n –1 where n = 2 to 8 to obtain actual measurements for the remaining positions

in the matrix so that all 9 linearization points identified in Figure 16 have measured values entered in the “Measured Value” row.

The software immediately calculates the correction values, and the resulting values are displayed below the applicable “Measured Values”

entry.

9. Click on “Write EEPROM” to save the new values in registers 03HEX to 07HEX.

The linearization procedure is completed. The values in the Pos1 register will differ from those in Pos0 register, reflecting the linearization

correction performed (see Table 1). The device is ready for operation in the application environment.

ZMID520x User Guide for Getting Started

© 2018 Integrated Device Technology, Inc.

16

April 6, 2018

Figure 16. Input Fields for the 9 Linearization Points Measured Values

Advance the target and

enter actual measured

position values (e.g.,

from the positioning

system) in each column.

Click here to stop

reading measured

values.

ZMID520x User Guide for Getting Started

© 2018 Integrated Device Technology, Inc.

17

April 6, 2018

4. Internal Memory

Figure 17 shows the internal memory structure of the ZMID520x products, which is divided into a nonvolatile EEPROM and a volatile shadow

RAM (SWR) section. After the ZMID520x start up, the EEPROM content is copied into the SWR. During ZMID520x operation in OWI mode,

changes in the SWR will take immediate effect; whereas changes in the EEPROM require a memory WRITE command or a ZMID520x power

cycle (power off / power on).

Figure 17. ZMID520x Internal Memory

Memory

EEPROM Shadow Register

(SWR)

Communication IF

One Wire Interface (OWI)

1FHEX

00HEX

1FHEX

00HEX

PPU

Output

Traceability

Others

Table 1. EEPROM and Shadow RAM Contents

Address

Type

Location

Function

00HEX

R/W

EEPROM/SWR

This register value is the 14-bit zero-angle offset of output signal, which is used for device

calibration and sets the offset value of the output transfer function.

01HEX

R/W

EEPROM/SWR

This register value is the 13-bit slope value of output signal, which is used for device

calibration and sets the slope value of the output transfer function.

02HEX

R/W

EEPROM/SWR

This register value is used with the analog and PWM output protocols in order to clamp the

upper and lower output levels of the transfer function respectively below 95% and above 5%.

03HEX

R/W

EEPROM/SWR

This register value is used in linearization. The position transfer function can be modified by a

correction curve over the whole position range. The correction curve is defined by 9

linearization points. This register contains the correction factor for points n°2 and n°1. Bits

[15:8] are the correction factor for the position at 12.5% (45°), and bits [7:0] are the correction

factor for the position at 0% (0°).

04HEX

R/W

EEPROM/SWR

This register value is used in linearization (see register 03HEX for description). This register

contains the correction factor for points n°4 and n°3.

Bits [15:8] are the correction factor for the position at 37.5% (135°), and bits [7:0] are the

correction factor for the position at 25% (90°).

ZMID520x User Guide for Getting Started

© 2018 Integrated Device Technology, Inc.

18

April 6, 2018

Address

Type

Location

Function

05HEX

R/W

EEPROM/SWR

This register value is used in linearization (see register 03HEXfor description). This register

contains the correction factor for points n°6 and n°5.

Bits [15:8] are the correction factor for the position at 62.5% (225°), and bits [7:0] are the

correction factor for the position at 50% (180°).

06HEX

R/W

EEPROM/SWR

This register value is used in linearization (see register 03HEXfor description). This register

contains the correction factor for points n°8 and n°7.

Bits [15:8] are the correction factor for the position at 87.5% (315°), and bits [7:0] are the

correction factor for the position at 75% (270°).

07HEX

R/W

EEPROM/SWR

This register value is used in linearization (see register 03HEXfor description). This register

contains the correction factor for point n°9.

Bits [15:8] are not used, and bits [7:0] are the correction factor for the position at 100% (360°).

08HEX

R/W

EEPROM/SWR

This register value is the signal offset correction of the demodulated input signals sin and cos

(R1and R2). It is used for input amplitude offset correction; the defined register offset values

are added/subtracted to/from the amplitude values of the receiver coil values.

09HEX

R/W

EEPROM/SWR

This register contains the control bits for selecting the output mode of the sensor (Linear

Output Mode or Modulo 360 Output Mode), the type of linearization (pre or post-calibration),

the angle offset for linearity correction (0° or -22.5°), the option to reverse the polarity of the

receiver coils, and the option to invert the phase polarity of the receiver coils.

0AHEX

R/W

EEPROM/SWR

This register value is used to define the type of communication interface (SENT, analog, or

PWM). It is used for configuration of the output SENT CRC, SENT pause; PWM slope current,

PWM frequency, and analog diagnostic level.

0BHEX

R/W

EEPROM/SWR

This register value is used to control the voltage of the internal VDDT voltage regulator, the

current of the Tx excitation coil, the oversampling rate of the ADC, and the PWM output slope

time.

0CHEX

R/W

EEPROM/SWR

This register value is used to set the gain stage value, the adjustment of the integration cycle

in relation to the Tx coil period, and the integration time in terms of the ADC sample periods

vs. the oversampling rate.

0DHEX

R/W

EEPROM/SWR

This register value is used to set the CORDIC magnitude upper and lower levels, the upper

and lower limits for the Tx coil frequency, the gain and integration time adaptation combined

settings, and mixed operation modes.

0EHEX

R/W

EEPROM/SWR

This register value is used to mask diagnostic register bits to prevent a diagnostic flag setting

the output in the diagnostic status.

0FHEX

R/W

EEPROM

Internal use only.

10HEX

R/W

EEPROM

Internal use only.

11HEX

R/W

EEPROM/SWR

This register value is used to the trigger actions for the shadow register, diagnostic register, Tx

coil alarm, Rx coils alarm, double-error detection for the EEPROM memory, parity error

detection on the SWR memory, ADC overflow, AGC offset saturation, Tx coil alarm, and a set

of parameters used in test mode only.

13HEX

R

SWR

This register value is used for analog front-end / automatic gain regulation; polarity of R1 and

R2 ADC gain; and number of integration cycles for the AGC.

14HEX

R

SWR

This register value is the 13-bit CORDIC raw input signal for Xsine.

15HEX

R

SWR

This register value is the 13-bit CORDIC raw input signal for Ycosine.

16HEX

R

SWR

This register value is the 15-bit CORDIC output angle (0° to 90°).

ZMID520x User Guide for Getting Started

© 2018 Integrated Device Technology, Inc.

19

April 6, 2018

Address

Type

Location

Function

17HEX

R

SWR

This register value is the 15-bit CORDIC output magnitude.

18HEX

R

SWR

This register value is the 16-bit output spatial angle (0° to 360°) before output calibration and

linear error correction.

19HEX

R

SWR

This register value is Position 0, which is the 16-bit output angle (0° to 360°) after output

calibration. If linearization is done before the output calibration, this value = Position 1. If

linearization is done after the output calibration, this value is not the same value as Position 1.

1AHEX

R

SWR

This register value is Position 1, which is the 16-bit output angle (0° to 360°) after output

calibration and linearization. This value is always affected by linearization.

1BHEX

R

SWR

Internal use only.

Complete information about registers map is available upon request. Contact: https://www.idt.com/support

5. Programming the ZMID520x EEPROM

The ZMID520x EEPROM can be programmed using the ZMID-COMBOARD USB Communication and Programming Board for ZMID Application

Modules in conjunction with the ZMID520x EVK Application Software. Instructions for using the software to program the EEPROM are given in

the ZMID520x Evaluation Kit User Manual. See section 2.1 for details for obtaining the software and the kit manual.

Additional information and documentation for the ZMID-COMBOARD are provided on the following IDT web page:

https://www.idt.com/products/sensor-products/position-sensors/zmid-comboard-usb-communication-and-programming-board-zmid-

application-modules

6. Glossary

Acronym

Definition

ADC

Analog Digital Converter

AGC

Automatic Gain Control

EEPROM

Electrically Erasable Programmable Read Only Memory

LSB

Least Significant Bit

MSB

Most Significant Bit

OWI

One-Wire Interface

OSR

Over-Sampling Rate

SWR

Shadow Word Register Bank

ZMID520x User Guide for Getting Started

© 2018 Integrated Device Technology, Inc.

20

April 6, 2018

7. Revision History

Revision Date

Description of Change

April 6, 2018

Initial release

Corporate Headquarters

6024 Silver Creek Valley Road

San Jose, CA 95138

www.IDT.com

Sales

1-800-345-7015 or 408-284-8200

Fax: 408-284-2775

www.IDT.com/go/sales

Tech Support

www.IDT.com/go/support

DISCLAIMER Integrated Device Technology, Inc. (IDT) and its affiliated companies (herein referred to as “IDT”) reserve the right to modify the products and/or specificatio ns described herein at any time,

without notice, at IDT's sole discretion. Performance specifications and operating parameters of the described products are determined in an independent state and are not guaranteed to perform the same

way when installed in customer products. The information contained herein is provided without representation or warranty of a ny kind, whether express or implied, including, but not limited to, the suitability

of IDT's products for any particular purpose, an implied warranty of merchantability, or non-infringement of the intellectual property rights of others. This document is presented only as a guide and does not

convey any license under intellectual property rights of IDT or any third parties.

IDT's products are not intended for use in applications involving extreme environmental conditions or in life support systems or similar devices where the failure or malfunction of an IDT product can be

reasonably expected to significantly affect the health or safety of users. Anyone using an IDT product in such a manner does so at their own risk, absent an express, written agreement by IDT.

Integrated Device Technology, IDT and the IDT logo are trademarks or registered trademarks of IDT and its subsidiaries in the United States and oth er countries. Other trademarks used herein are the

property of IDT or their respective third party owners. For datasheet type definitions and a glossary of common terms, visit www.idt.com/go/glossary. All contents of this document are copyright of Integrated

Device Technology, Inc. All rights reserved.

This manual suits for next models

2

Table of contents

Other IDT Accessories manuals