Translation of the original instructions

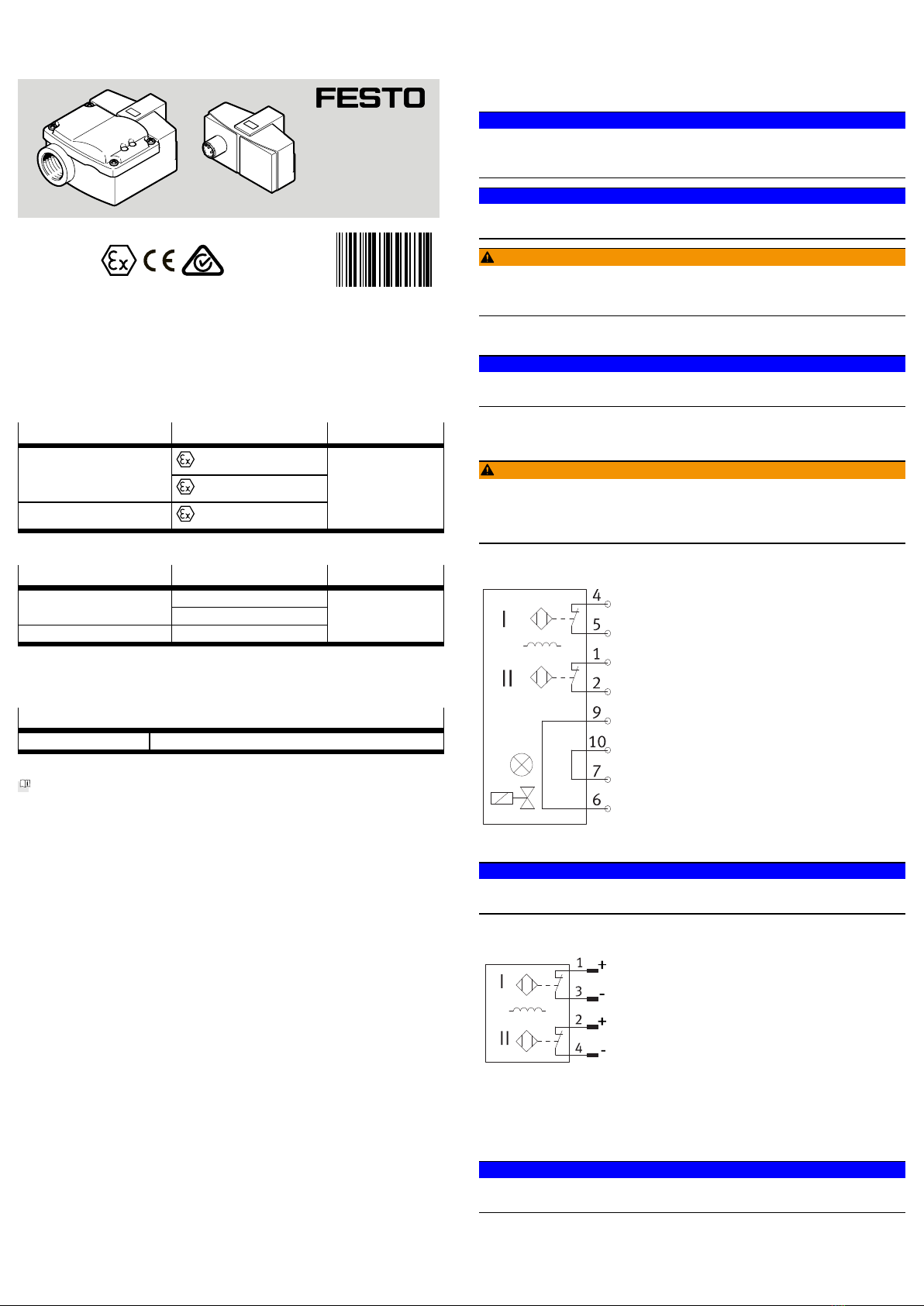

1 Identification EX

Type Identification ATEX Certificates

II 1G Ex ia IIC T6…T1 GaSRBG-C1-N-20N-ZC-M12-EX5

II 1D Ex ia IIIC T135°C Da

SRBG-C1-N-20N-ZC-C2-C2-EX5 II 1G Ex ia IIC T6…T1 Ga

TÜV 16 ATEX 174269X

Tab. 1

Type Identification IECEx Certificates

Ex ia IIC T6…T1 GaSRBG-C1-N-20N-ZC-M12-EX5

Ex ia IIIC T135°C Da

SRBG-C1-N-20N-ZC-C2-C2-EX5 Ex ia IIC T6…T1 Ga

IECEx TUN 18.0003X

Tab. 2

2 Further applicable documents

User documentation

Sensorbox, SRBG Instructions Operating

Tab. 3

All available documents for the product èwww.festo.com/pk.

3 Safety

3.1 Safety instructions

– The sensor box SRBG-C1-N-20N-ZC-M12-EX5 can be used in zone 0 of poten-

tially explosive gas atmospheres and in zone 20 of potentially explosive dust

atmospheres.

– The sensor box SRBG-C1-N-20N-ZC-C2-C2-EX5 can be used in zone 0 of poten-

tially explosive gas atmospheres.

– Carry out all work outside potentially explosive areas.

3.2 Intended use

Inductive dual sensors are intended for recording and display of the position of

process valves.

3.3 Identification X: Special conditions

– Ambient temperatureè 9 Technical data.

– Refer to the relevant certificate to see the relationship between the connected

circuit type, the maximum permitted ambient temperature, the effective inner

reactances, and if applicable the surface temperature or the temperature

class.

– Protect the device from impact effects if it is used in the temperature range

between the minimum permissible ambient temperature and -20 °C.

– Avoid electrostatic charges which could result in electrostatic discharges

while installing, operating, or maintaining the device.

– Avoid in admissibly high electrostatic charge of the metal housing compon-

ents on the device. Include the metal housing components in the equipoten-

tial bonding.

– Protect cables and cable glands from tensile load and torsional stress or use

certified cable glands.

– The sensor circuits for SRBG-C1-N-20N-ZC-M12-EX5 have to be considered

galvanically connected to each other, in safety technical point of view for

Group III. Verification of intrinsic safety must include the possibility of the

interconnection of these intrinsically safe circuits. The functional galvanically

separation remains unaffected.

– Mount the device with at least a degree of protection of IP20 according to

IEC/EN 60529.

– Mount the device in such a way that the bare casting resin surface is not

exposed to mechanical hazards.

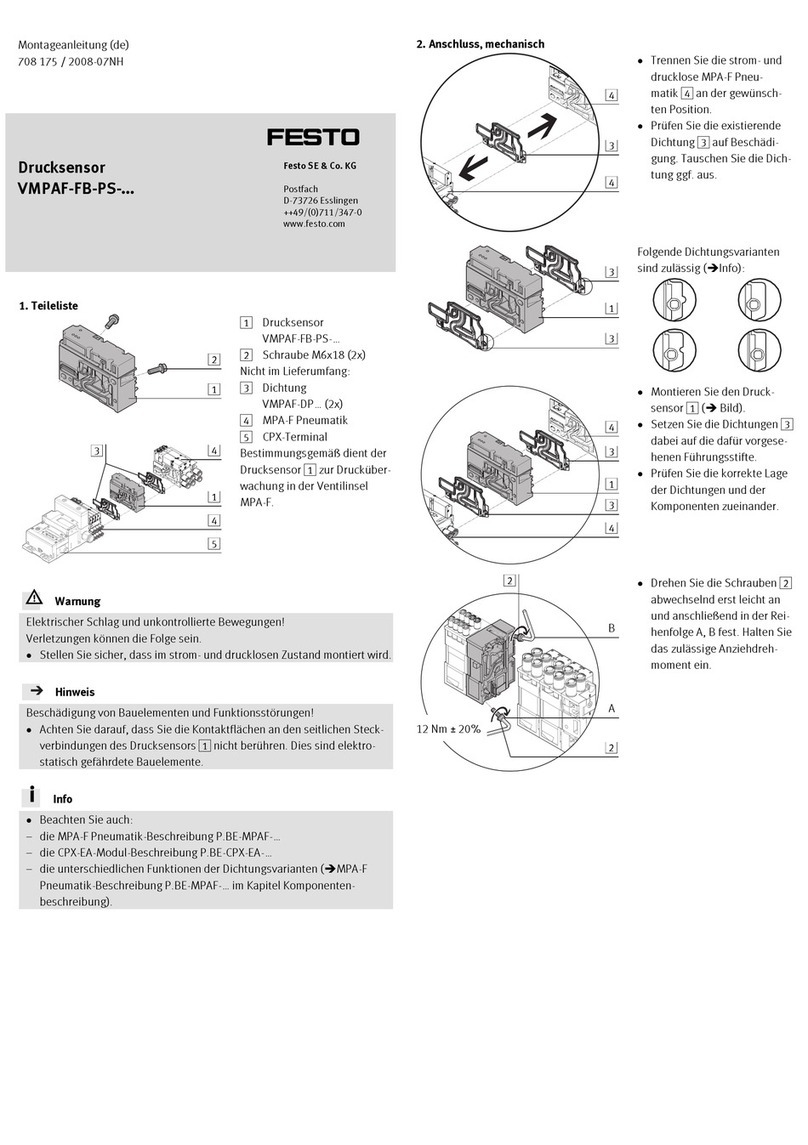

4 Installation

NOTICE!

During commissioning, maintenance and installation of the sensor, make sure

that the regulations in accordance with EN 60079-14 and EN 60079-25 are com-

plied with.

NOTICE!

Installation and commissioning may only be performed in accordance with the

operating instructions and by qualified personnel.

WARNING!

The discharge of electrostatically charged parts can lead to sparks which can

cause an explosion. Prevent electrostatic discharges by means of suitable install-

ation and cleaning measures.

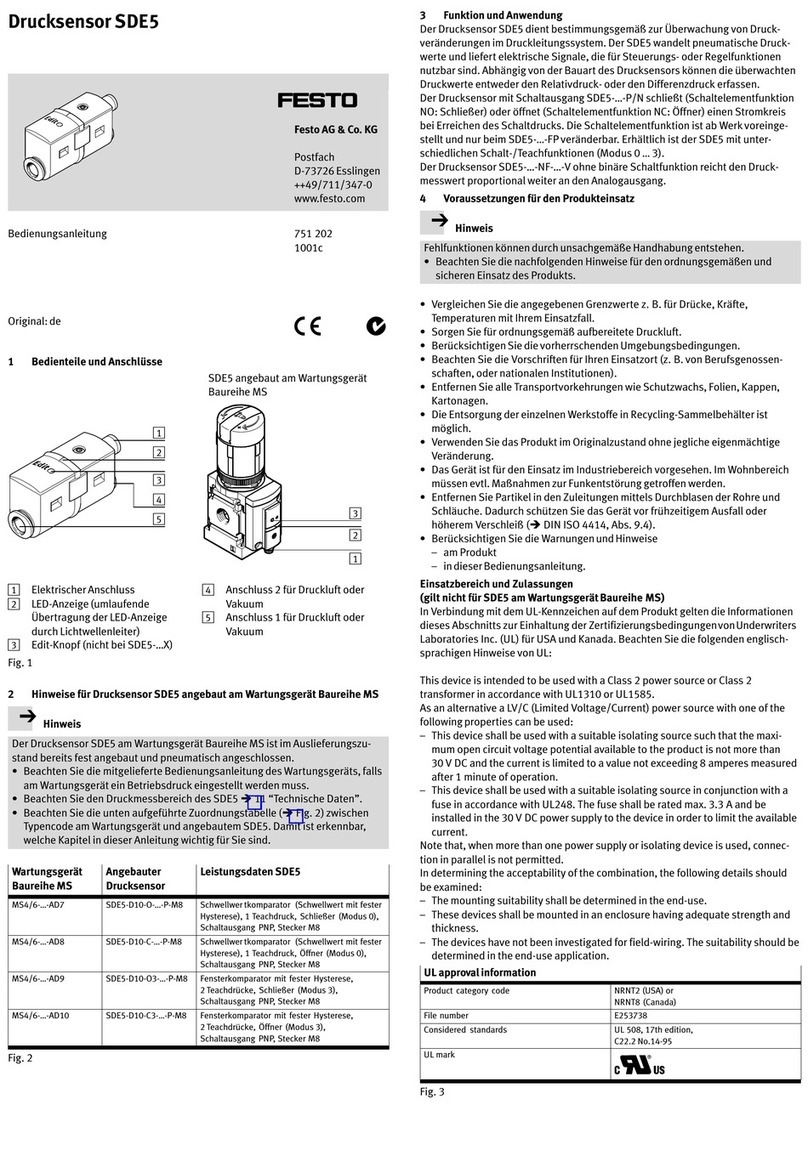

5 Electrical connection

NOTICE!

Electrical specifications and operating conditions in accordance with the product

label.

Connection is dependent on the sensor box.

– SRBG-C1-N-20N-ZC-C2-C2-EX5: Terminal box with spring-loaded terminal

– SRBG-C1-N-20N-ZC-M12-EX5: M12x1 plug connector

WARNING!

Avoid ignition of explosive atmosphere.

For SRBG-C1-N-20N-ZC-C2-C2-EX5:

• Tighten cover firmly.

– Tightening torque: 1Nm

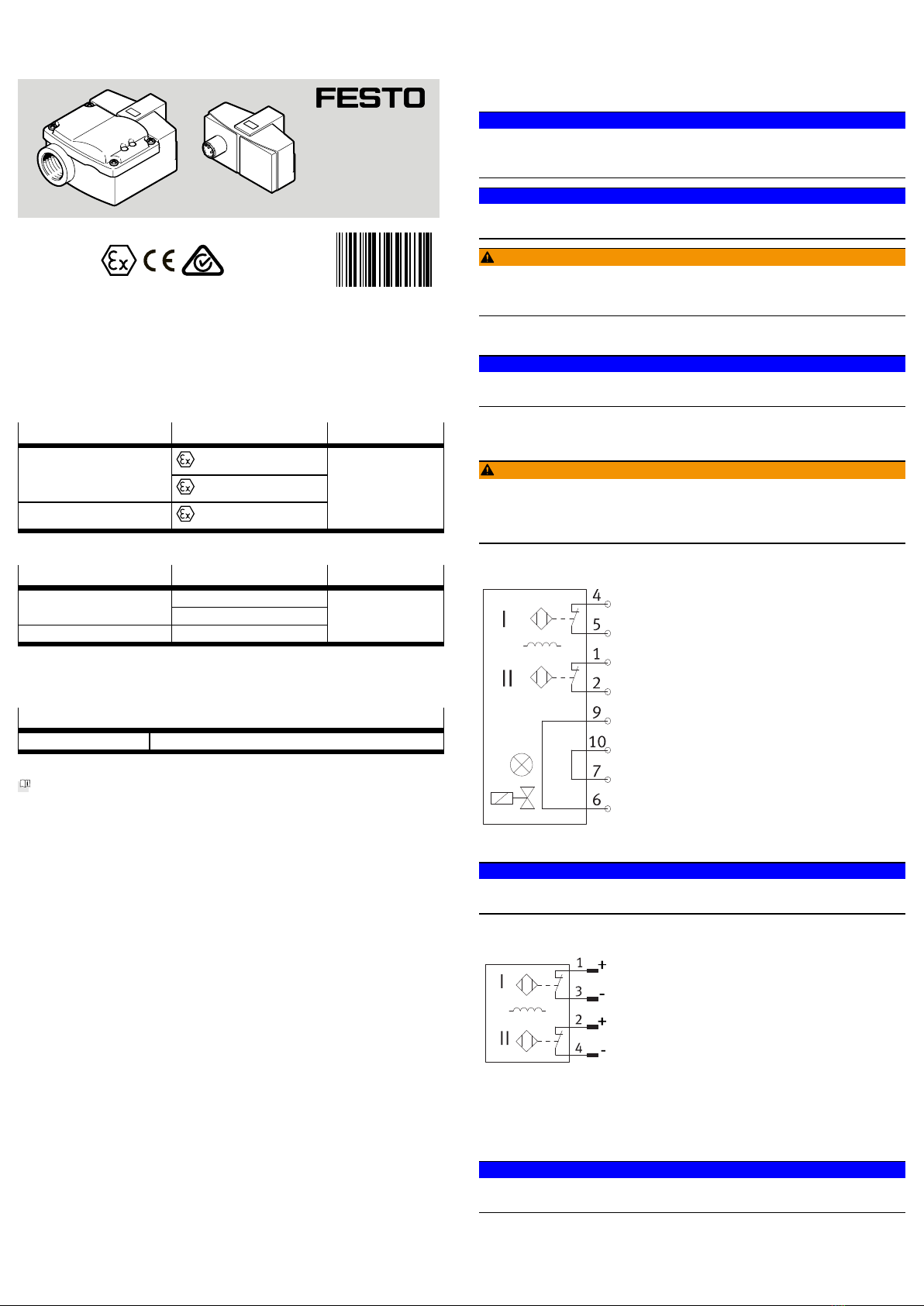

SRBG-C1-N-20N-ZC-C2-C2-EX5

Fig. 1

NOTICE!

If the polarity of the solenoid valve circuit connections are reversed, the valve

status indicator will not function. Low energy valves can thus be connected.

SRBG-C1-N-20N-ZC-M12-EX5

Fig. 2

6 Operation

If the equipment is not used under atmospheric conditions, a reduction of the per-

missible minimum ignition energy must be taken into consideration.

NOTICE!

The intrinsic safety is only assured in connection with corresponding equipment

and according to the proof of intrinsic safety.

– Cable connectors and blanking plugs must be approved for use in explosion

protection areas.

8079486

SRBG-C1-N-20N-ZC-…-EX5

Sensorbox

8079486

2017-10a

[8079488]

Operating conditions|EX

Festo AG & Co. KG

Ruiter Straße 82

73734 Esslingen

Germany

+49 711 347-0

www.festo.com