IEF Werner profiLINE 140 User manual

March 2019 Translation of the original instructions

MAN_EN_1039740_profiLINE140_R3d.docx profiLINE 140 Page 1 of 48

IEF-Werner GmbH

Wendelhofstraße 6

78120 Furtwangen - Germany

Phone: + 49 7723-925-0

Fax: + 49 7723-925-100

www.IEF-Werner.de

info@IEF-Werner.de

Translation of the original instructions

profiLINE 140

Edition: March 2019

Article no.: 1039740

Translation of the original instructions March 2019

Page 2 of 48 profiLINE 140 MAN_EN_1039740_profiLINE140_R3d.docx

Change History

Trademarks and trade names are used without any warranty of their free usability. Texts and

examples were created with great care. Nevertheless, errors cannot be excluded. IEF-Werner GmbH

does not assume legal responsibility nor any liability for missing or incorrect statements and their

consequences.

IEF-Werner GmbH reserves the right to modify or improve the software or hardware or parts of it, as

well as the supplied documentation or parts of it, without previous notice.

IEF-Werner GmbH expressly reserves all rights for replication and photomechanical reproduction,

including in extracts.

We are always grateful for suggestions for improvements and information about errors.

© March 2019, IEF-Werner GmbH

Document Code Date Revision

EN_profiLINE140_R3b.doc July 2005 Release of the English document.

MAN_EN_1039740_pofiLINE140_R3c.doc April 2013 Formal changes. Translation from German Document:

“MAN_DE_1039739_profiLINE140_R4d.doc”.

MAN_EN_1039740_pofiLINE140_R3d.docx 05.03.2019 Updating the document in relation to new EMC and low

voltage directive

March 2019 Translation of the original instructions

MAN_EN_1039740_profiLINE140_R3d.docx profiLINE 140 Page 3 of 48

Table of Contents

1Safety ...............................................................................................................................................5

1.1 Definition or warning notes .....................................................................................................5

1.2 General warning notes ...........................................................................................................5

1.3 Special hazard warnings ........................................................................................................6

2Intended use....................................................................................................................................7

2.1 Reasonably foreseeable misuse ............................................................................................7

3Assembly instructions ...................................................................................................................8

3.1 Installation position .................................................................................................................8

3.2 Motor installation ....................................................................................................................8

3.2.1 Axial motor installation...............................................................................................8

3.2.1.1 Pluggable coupling .....................................................................................9

3.2.2 Motor installation via offset gearbox flange .............................................................10

3.2.2.1 Overview of reduction ratios.....................................................................11

3.3 Transverse installation..........................................................................................................12

3.3.1 Mounting of basic body on carriage.........................................................................12

3.3.2 Mounting of carriage on carriage.............................................................................12

3.4 Attachment............................................................................................................................13

3.4.1 Installation of actuators............................................................................................14

3.4.2 Pinning .....................................................................................................................15

3.5 Wiring....................................................................................................................................16

3.5.1 Motors ......................................................................................................................16

3.5.2 Initiators ...................................................................................................................16

3.5.2.1 Technical data of initiators........................................................................16

3.5.2.2 Installation of initiators..............................................................................18

3.5.2.3 External installation of the initiators..........................................................19

3.5.2.4 Integrated installation of the initiators.......................................................20

3.5.3 Cable routing ...........................................................................................................21

3.6 Technical data ......................................................................................................................22

3.6.1 Tightening torques for screw connection.................................................................22

3.6.2 Standard strokes profiLINE140 ...............................................................................22

3.6.3 Type label ................................................................................................................22

3.6.4 Technical data of the linear module profiLINE 140 .................................................23

4Maintenance ..................................................................................................................................24

4.1 Guide rail system..................................................................................................................24

4.2 Ball screw spindle.................................................................................................................25

4.3 Sealing lip system.................................................................................................................25

5Troubleshooting............................................................................................................................26

6Parts lists and drawings ..............................................................................................................28

6.1Basic unit profiLINE 140 (TG 1000303) ...............................................................................28

Translation of the original instructions March 2019

Page 4 of 48 profiLINE 140 MAN_EN_1039740_profiLINE140_R3d.docx

6.2 Carriage unit profiLINE 140 (TG 1000900) ..........................................................................30

6.3 Parts list limit switch strip internal (TG 1000338) .................................................................32

6.4 Parts list limit switch strip external (TG 1000338) ................................................................32

6.5 Motor installation, axial (TG 1000315) .................................................................................34

6.6 Motor installation, gear flange (TG 1000308).......................................................................36

6.7 Motor installation variants.....................................................................................................38

6.7.1 Installation variant 0 profiLINE 140..........................................................................39

6.7.2 Installation variant 1 profiLINE 140..........................................................................40

6.7.3 Installation variant 2 profiLINE 140..........................................................................41

6.7.4 Installation variant 3 profiLINE 140..........................................................................42

6.7.5 Installation variant 4 profiLINE 140..........................................................................43

6.7.6 Installation variant 5 profiLINE 140..........................................................................44

6.8 Adapter plate (Part No.: 1010169) .......................................................................................45

6.9 Adapter plate (Part No.: 1016530) .......................................................................................46

6.10 Clamping rail M105 (Part No.: 1010173)..............................................................................47

7Declaration of incorporation........................................................................................................48

March 2019 Translation of the original instructions Safety

MAN_EN_1039740_profiLINE140_R3d.docx profiLINE 140 Page 5 of 48

1 Safety

1.1 Definition or warning notes

WARNING

Indicates potential danger. Non-observance of the safety provisions may

cause death or severe injury.

CAUTION

Indicates potential danger. Non-observance of the

safety provisions may cause property damage or injury.

NOTE Offers additional information.

1.2 General warning notes

The module must only be commissioned by specialists who received safety-technical

instruction and are able to assess potential dangers. Furthermore, all chapters of these

operating instructions must have been read and understood completely.

WARNING

The system must be powered down for all assembly, disassembly or

repair work. There is a high danger of injury.

WARNING OF HOT SURFACE

During operation, heating of the motor, in particular of stepper motors, can

cause burns of the skin when touching the motor. Install a protective device, if

possible! Do not touch the marked areas or wait for an adequate cooling time.

CAUTION

Motor connectors must not be inserted or disconnected when live. Risk of

burning of the contacts and risk of flying sparks.

Safety Translation of the original instructions March 2019

Page 6 of 48 profiLINE 140 MAN_EN_1039740_profiLINE140_R3d.docx

CAUTION

Linear modules always have to be operated in connection with suitable safety

devices (e.g., safety cell, protective room, protective housing,

light curtain).

NOTE Observe the Declaration of Incorporation (see section Declaration of

incorporation, page 48).

1.3 Special hazard warnings

In addition, this translation of Original User's Manual also contains the following special

hazard warning:

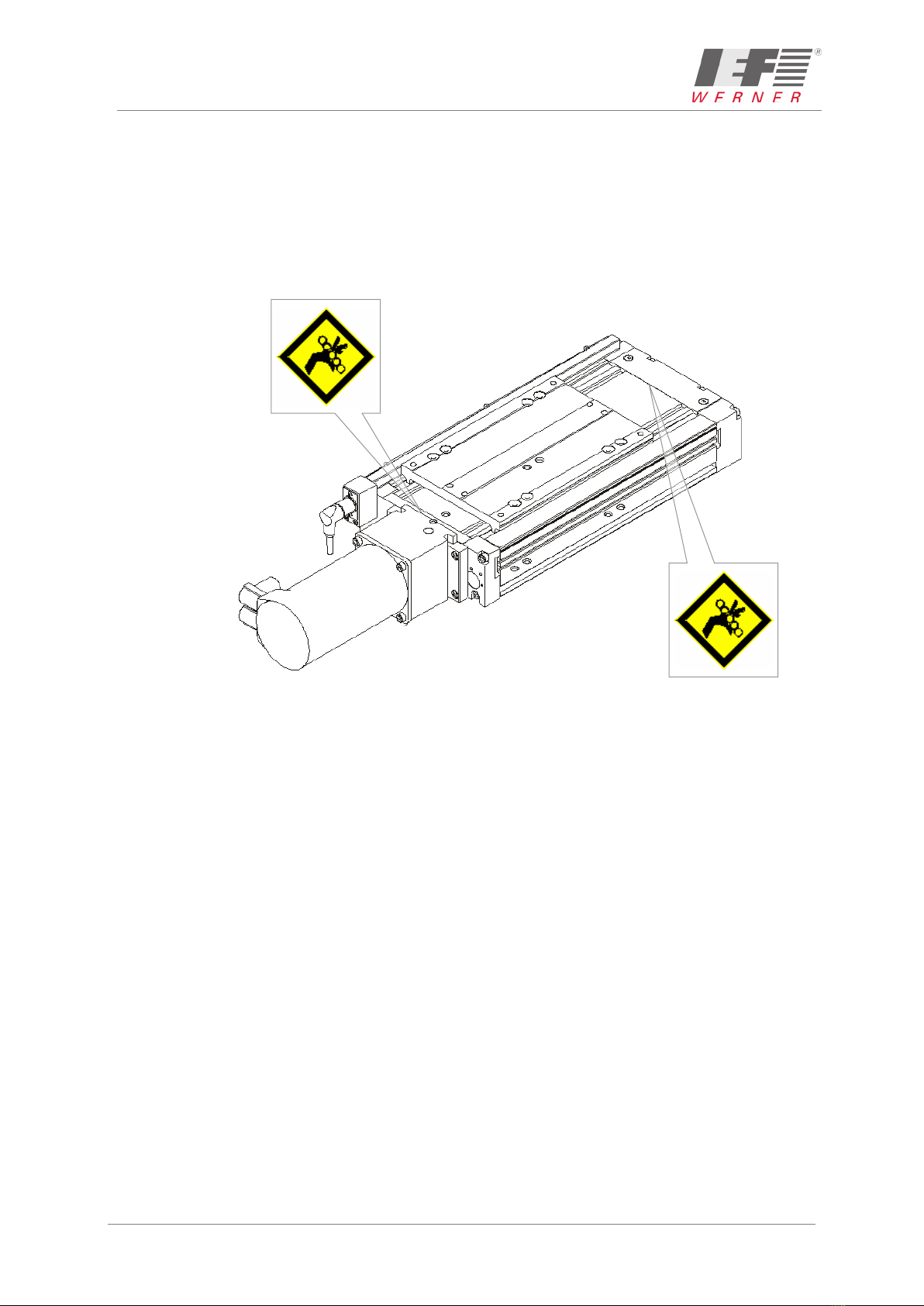

DANGER OF CRUSHING

These places of the components pose the danger of crushing limbs in

operation.

March 2019 Translation of the original instructions Intended use

MAN_EN_1039740_profiLINE140_R3d.docx profiLINE 140 Page 7 of 48

2 Intended use

The profiLINE 140 movement unit (see Figure 1) is a precise, linear adjustment unit with

spindle drive that is used in the commercial area as an attachment part in connection with

other components. In combination with many standardised assembly elements, as well as the

other movement units of IEF-Werner GmbH, it can be used to build complex multi-axis

positioning systems as well.

Figure 1: Module profiLINE 140

Area of application of the module profiLINE 140:

•Component insertion systems

•Palletising systems

•Loading and unloading stations

•Manipulators for the packaging industry

•etc.

2.1 Reasonably foreseeable misuse

The linear module profiLINE 140 is not to be used for certain applications such as the

transport of persons and animals or as a pressing/bending device for cold working of

metal.

Use of the linear module without additional measures is also not possible in special fields of

application, such as the chemical or food industry or in explosive atmospheres.

In case of doubt, consult the manufacturer.

Assembly instructions Translation of the original instructions March 2019

Page 8 of 48 profiLINE 140 MAN_EN_1039740_profiLINE140_R3d.docx

3 Assembly instructions

3.1 Installation position

The installation position is optional, i.e. the profiLINE 140 movement unit can be installed

horizontally as well as vertically.

CAUTION

With the vertical installation position, use only motors with spring-operated

brake to prevent the lowering of the drive in de-energized condition!

3.2 Motor installation

CAUTION

Wire the motors according to the motor data sheet.

When using customer-specific motors, inquire at the respective manufacturer

with which cable the motor has to be connected.

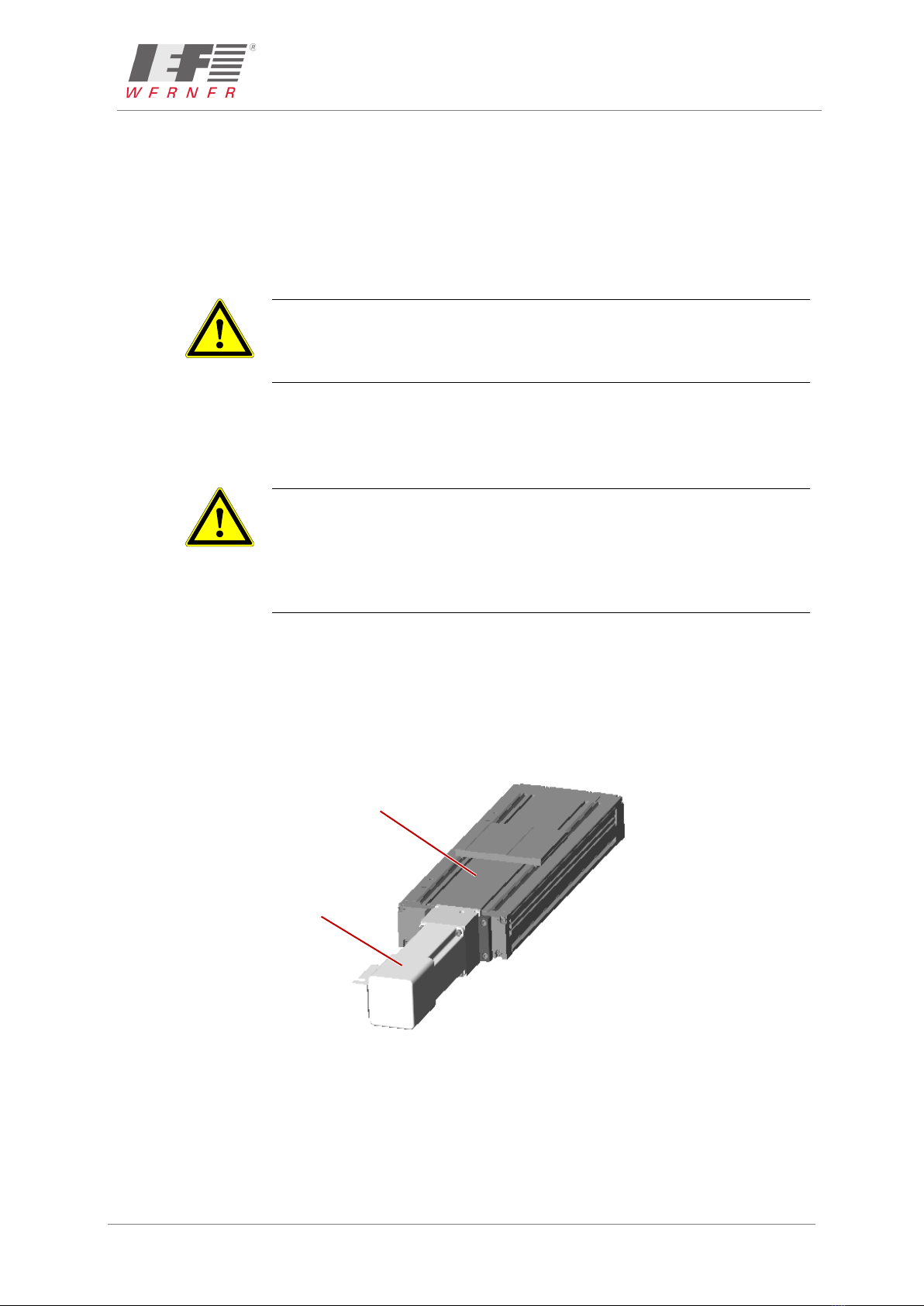

3.2.1 Axial motor installation

The carriage unit permits installation of the motor on the spindle extension via an axial motor

flange (adapter flange). The motor shaft is coupled with the spindle shaft by means of a

pluggable coupling. To centre the motor flange, the ball bearing of the floating spindle bearing

is used. Additional pinning of the motor flange with the end plate is not required.

Figure 2: Carriage unit with axial motor installation

Carriage unit

Motor

March 2019 Translation of the original instructions Assembly instructions

MAN_EN_1039740_profiLINE140_R3d.docx profiLINE 140 Page 9 of 48

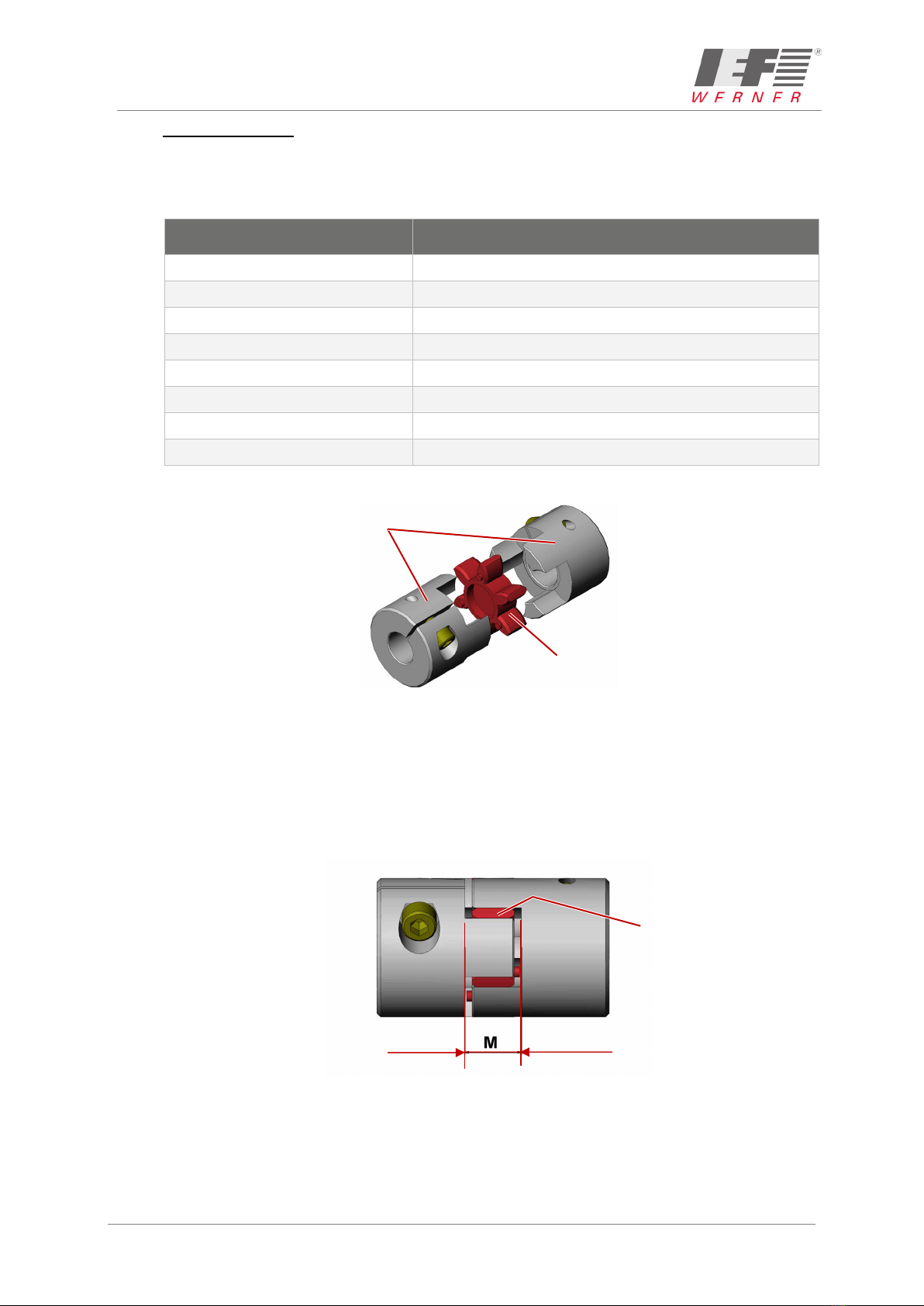

3.2.1.1 Pluggable coupling

The pluggable coupling system consists of the spindle coupling hub, the motor coupling hub

and an elastic ring gear.

The following hubs are available:

Motor shaft diameter Motor coupling hub article number

10 1064071

11 1064073

12 1064074

14 1064075

15 1064076

16 1064077

19 1064123

20 1064078

Different motor shaft diameters are available on request

Figure 3: Pluggable coupling

NOTE When installing the coupling, special care must be taken not to load the

elastic ring gear with axial pressure. It has to be ensured that the installation

dimension "M" =16 mm is observed in the installed condition. Light greasing

can reduce the axial installation force.

Figure 4: Coupling with installation dimension

Motor or

spindle coupling hub

Elastic ring gear

(E.g. No.: 1064079)

Elastic ring gear

M = 16 mm

Assembly instructions Translation of the original instructions March 2019

Page 10 of 48 profiLINE 140 MAN_EN_1039740_profiLINE140_R3d.docx

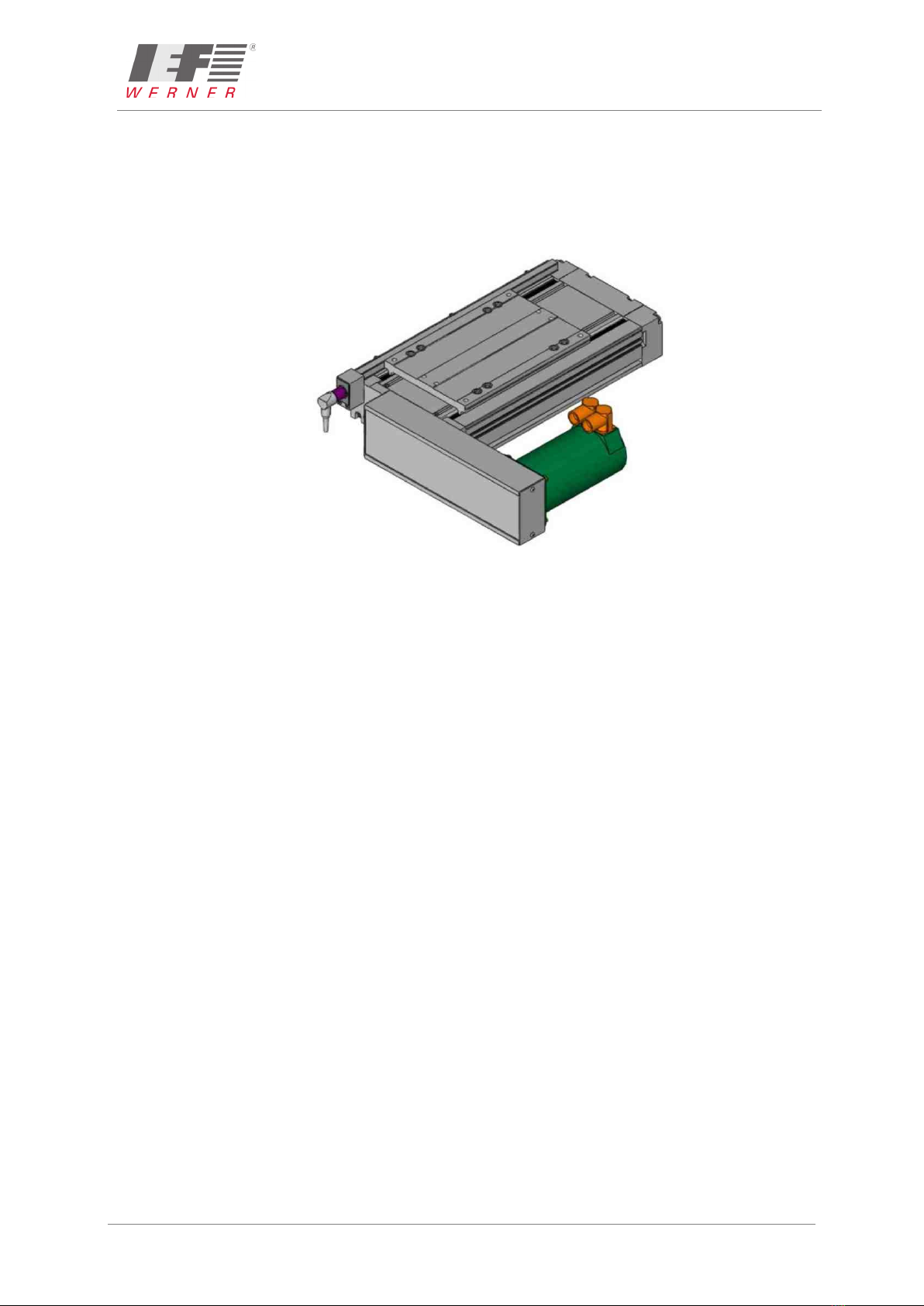

3.2.2 Motor installation via offset gearbox flange

The advantages of this installation variant are:

•Shorter overall length

•Gear reduction

•Adaptation to specific customer installation conditions with 4 possible installation variants

Figure 5: Motor installation via offset gearbox flange

NOTE For an overview of the different motor installation variants, see the section

Motor installation variants, Page 38.

March 2019 Translation of the original instructions Assembly instructions

MAN_EN_1039740_profiLINE140_R3d.docx profiLINE 140 Page 11 of 48

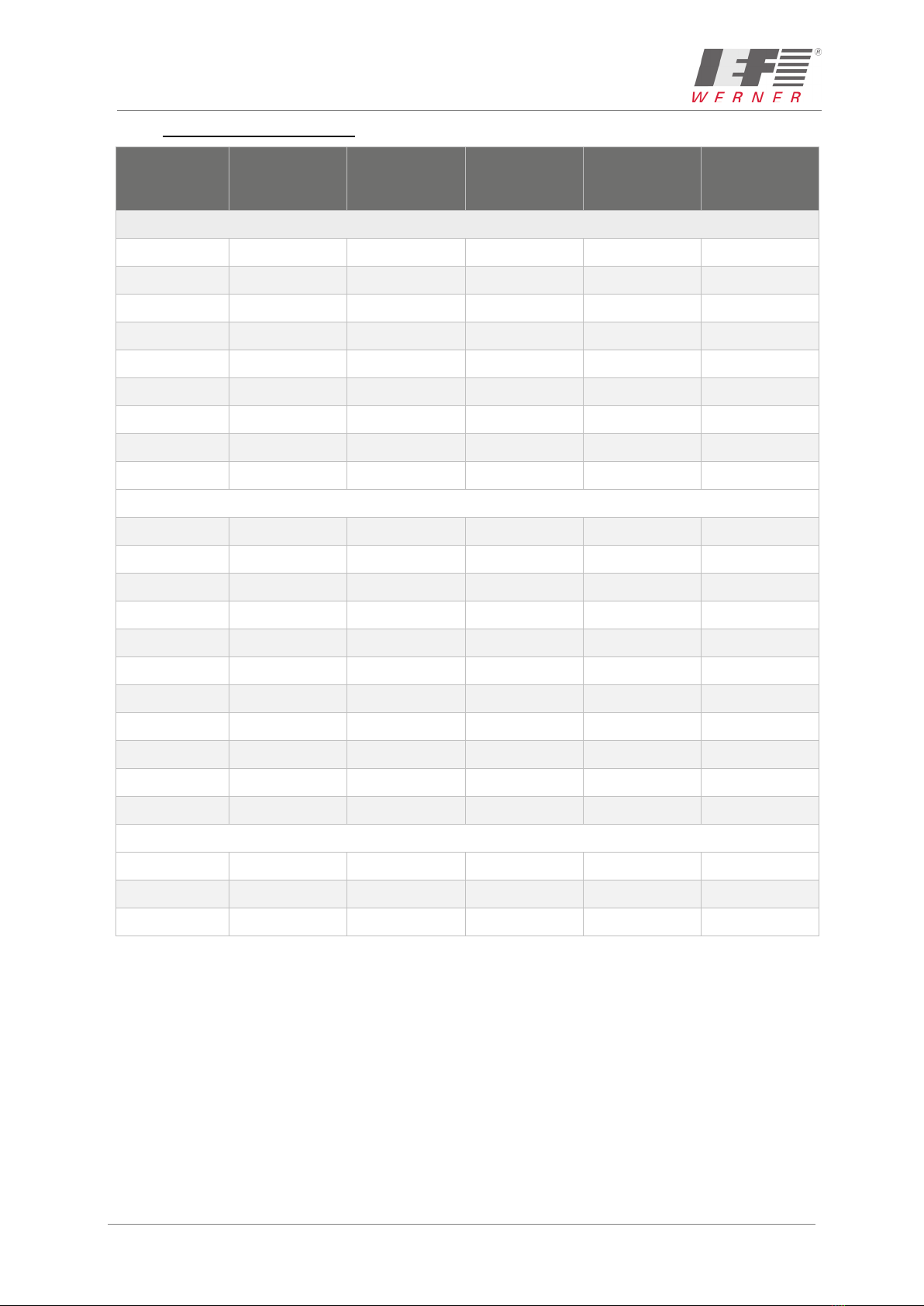

3.2.2.1 Overview of reduction ratios

Transmission

i =

Toothed disc

of motor

Toothed disc

of spindle

Max.

motor shaft*

Belt length

[mm]

Distance

between axes

[mm]

Preferred series

1 : 1 32 32 16 330 85

1 : 1 32 32 16 340 90

1 : 1 32 32 16 375 107.50

1 : 1 32 32 16 450 145

1 : 1 32 32 16 500 170

1 : 1 40 40 20 375 87.5

1 : 1 40 40 20 390 95

1 : 1 40 40 20 480 140

1 : 1 40 40 20 525 162.5

2:1 16 32 14 300 89.09

2:1 16 32 14 305 91.62

2:1 16 32 14 330 104.22

2:1 16 32 14 390 134.4

2:1 16 32 14 420 149.46

2:1 16 32 14 450 164.51

2:1 20 40 16 330 88.57

2:1 20 40 16 340 93.65

2:1 20 40 16 420 134.06

2:1 20 40 16 450 149.15

2:1 20 40 16 480 164.23

2,5:1 16 40 14 330 93.04

2,5:1 16 40 14 420 138.68

2,5:1 16 40 14 480 168.92

Different transmission ratios or distances between axes on request

* Plain motor shaft possible

Assembly instructions Translation of the original instructions March 2019

Page 12 of 48 profiLINE 140 MAN_EN_1039740_profiLINE140_R3d.docx

3.3 Transverse installation

Two methods are available for the transverse mounting of the profiLINE 140 movement units

(see the following sections).

3.3.1 Mounting of basic body on carriage

The transverse mounting is performed by means of two clamping rails, article No.: 1010173.

The overall height of the transverse mounting is 140 mm.

Figure 6: Basic body on carriage

3.3.2 Mounting of carriage on carriage

The transverse mounting is performed by means of an adapter plate, article No.: 1010169 as

well as two clamping rails article no.: 1010173. The overall height of the transverse mounting

is 155 mm (incl. adapter plate).

Figure 7: Carriage on carriage

March 2019 Translation of the original instructions Assembly instructions

MAN_EN_1039740_profiLINE140_R3d.docx profiLINE 140 Page 13 of 48

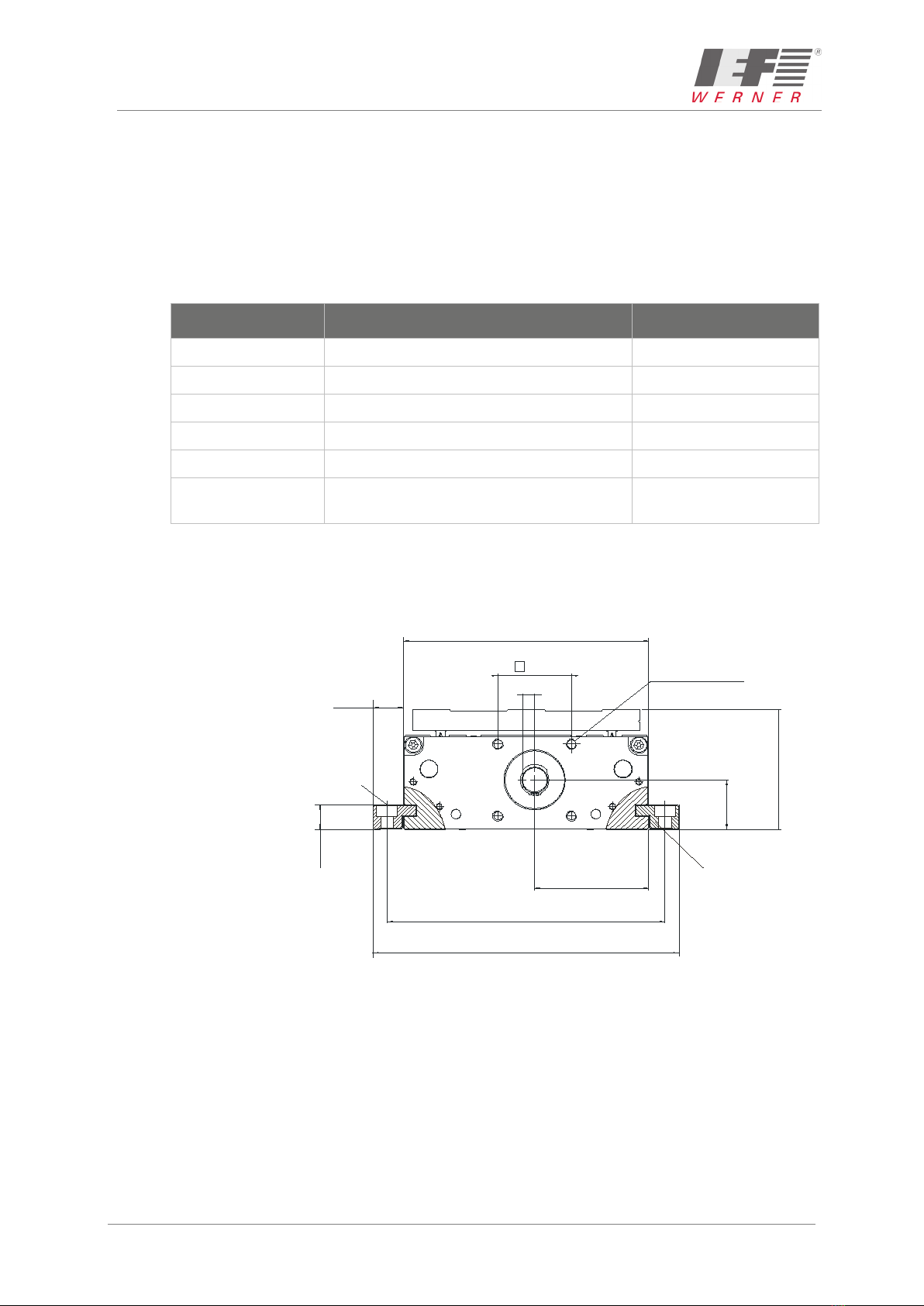

3.4 Attachment

The profiLINE 140 movement unit is attached to a level installation surface with clamping

profiles. We recommend using drilled attachment holes with a spacing of 80-120 mm. The

basic body has four mating holes to make possible a reproducible position.

If the attachment with clamping profiles is not possible, drilled attachment holes in the basic

body can also be made. Please contact us in this case.

The following clamping elements are available for attachment (see, e.g. Clamping rail M105

(Part No.: 1010173), page47):

Part No. Designation Length [mm]

220702 Type 16 clamping element 16

28674 Type 105 clamping element 105

220702 Type 140 clamping element 140

1010173 Clamping element (transverse mounting) 130

1019192 Clamping profile, yard goods Length of the basic unit

Clamping profiles according to customer

drawing

NOTE The installation area has to be a flat surface.

Any deviations from an ideal flat plane directly affect the processing

precision.

Figure 8: Attachment of profiLINE 140

159

70

29

140,0

65,2

42

54 x M6 x 10

Senkung DIN 74 - Km 6

Spannleiste

175

17,5

14,3

Countersink DIN 74 – Km 6

Clamping bar

Assembly instructions Translation of the original instructions March 2019

Page 14 of 48 profiLINE 140 MAN_EN_1039740_profiLINE140_R3d.docx

3.4.1 Installation of actuators

The actuators (cylinders, pick-up modules, etc.) that are to be installed on the profiLINE 140

movement unit can be attached via the drilling pattern on the carriage. Six drillings (M6) are

available for the attachment (see Figure 9).

Figure 9: Drilling pattern

CAUTION

During attachment, observe that the maximum screw-in depth of 9 mm is not

exceeded because this would lead to severe damage to the guide system.

March 2019 Translation of the original instructions Assembly instructions

MAN_EN_1039740_profiLINE140_R3d.docx profiLINE 140 Page 15 of 48

3.4.2 Pinning

The profiLINE 140 movement unit provides the possibility to pin a transverse mounting or a

customised installation without additional tools (drill, reamer) in a reproducible manner. For

this purpose, four hardened drill bushings are located in the short

carriage section.

Two drill bushings are firmly pressed in, two other drill bushings are inserted in a floating

manner in larger drillings. A fixed bearing and a floating bearing are arranged diagonally. The

part to be pinned requires a firmly defined drilling pattern for the mating holes that corresponds

to the drilling pattern in the short carriage section.

During installation and pinning, one of these floating drill bushings is embedded with special

two-component adhesive (article No.: 1027620) in the floating bearing. During installation of

the alignment pins, the drill bushing is optimally aligned with the alignment pins of the part to

be pinned. This type of pinning permits subsequent "fine adjustment" of the transverse

mounting within one hour. The adhesive hardens fully within 24 hours.

Figure 10: Drill bushings of profiLINE 140

Scaled drawing for

alignment pins Tolerance Drilled hole Article no. of drill bushing

102 x 102 ±0,01 6 H7 627122

Drill bushings

Alignment pin

Assembly instructions Translation of the original instructions March 2019

Page 16 of 48 profiLINE 140 MAN_EN_1039740_profiLINE140_R3d.docx

3.5 Wiring

3.5.1 Motors

CAUTION

The electrical connection of the motors is performed according to the motor

data sheet. For customer-specific motors, the data sheet must be requested

from the respective manufacturer and the motor connected accordingly.

3.5.2 Initiators

Inductive proximity switches (PNP normally closed contacts, green switch operating point)

are used as standard stroke limit switches

CAUTION

These stroke limit switches are not safety limit switches according to

EN60204-1.

Optionally, an additional reference point switch (PNP normally open contact, red switch

operating point) can be used. An LED is available for detection of the switch status. Initiators

and cables are installed in an aluminium profile and routed centrally to a plug. The aluminium

profile can be built into the carriage or be externally attached.

3.5.2.1 Technical data of initiators

Parameter Value

Operating voltage (10...30) VDC

Operating voltage residual ripple < 10 %

Current load capacity I

a

≤150 mA

Voltage drop at I

a

max. ≤3.5 V

Switching frequency ≤1 kHz

Own current consumption ≤10 mA

Nominal switching distance on steel 2 mm

Switching hysteresis (H) (3...15) %

Reproducibility (Rmax) ±3%

Operating temperature (-25 ... +70) °C

Protection class IP 67

Short-circuit proof

(response value for short-circuit protection 160mA) Yes

Protected against polarity reversal Yes

Switch dampened LED off

Switch not dampened LED lit

March 2019 Translation of the original instructions Assembly instructions

MAN_EN_1039740_profiLINE140_R3d.docx profiLINE 140 Page 17 of 48

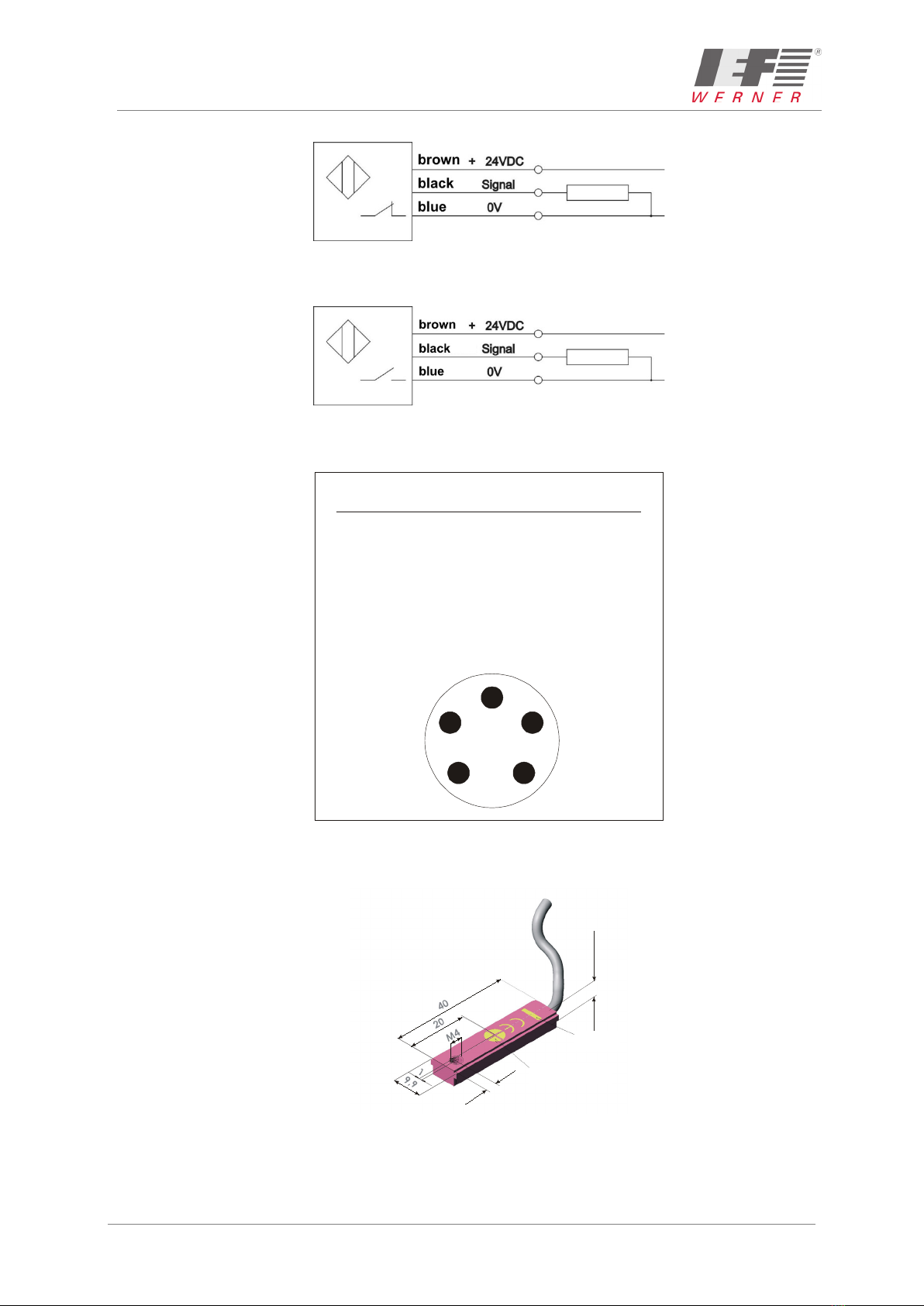

Figure 11: Electrical connection of PNP normally closed contact

Figure 12: Electrical connection of PNP normally open contact

1

2

3

5

4

Pin-no.

1

2

3

4

5

assignment

+ 24 V

limit switch -movement

0 V

limit switch +movement

Reference switch

IEF-cable

brown

green

white

yellow

grey

Figure 13: Plug assignment, view of pins

4

5

LED

active area

Figure 14: Initiator

Assembly instructions Translation of the original instructions March 2019

Page 18 of 48 profiLINE 140 MAN_EN_1039740_profiLINE140_R3d.docx

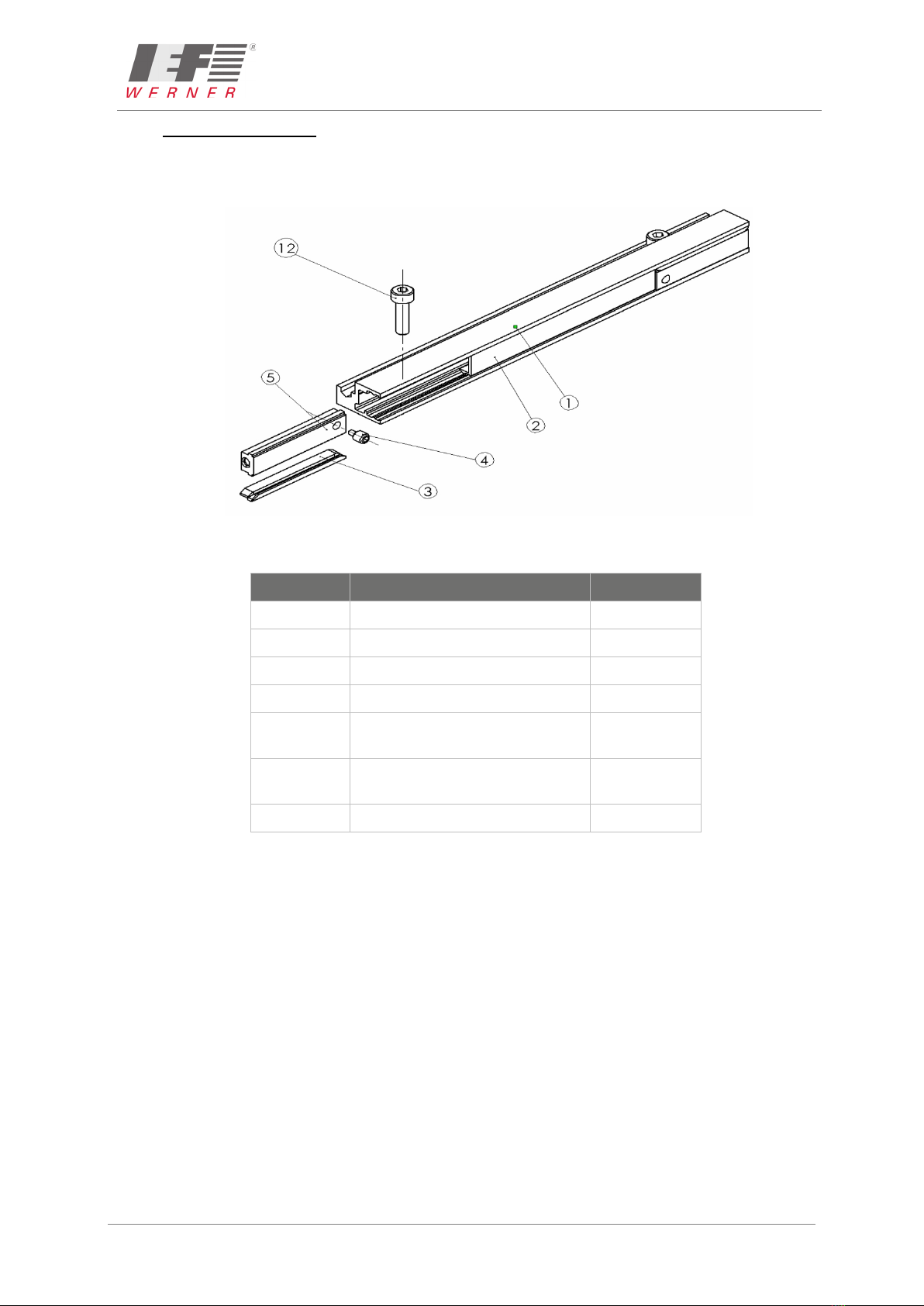

3.5.2.2 Installation of initiators

Initiators and cables are installed in an aluminium profile and routed centrally to a plug. The

aluminium profile can be built into the carriage or be externally attached.

Figure 15: Installation of initiators

No. Designation Article no.

1 Aluminium strip 1003692

2 Clip strip 028668

3 Limit switch holder 028585

4 Threaded pin M4 030887

5 Initiator PNP normally closed

contact

025165

5 Initiator PNP normally open

contact

726744

12 Screw M4 x 14 DIN 7984 1016016

March 2019 Translation of the original instructions Assembly instructions

MAN_EN_1039740_profiLINE140_R3d.docx profiLINE 140 Page 19 of 48

3.5.2.3 External installation of the initiators

External installation of the initiators is possible on both sides of the movement unit

(see Figure 16).

Figure 16: External installation of the initiators (Zn; 1010438)

No. Designation Article no.

1 Aluminium strip 1003692

7 Holder 1008967

8 Adapter piece 1006140

9 Cover 1006139

10 Connector 725163

11 Retaining plate 025626

12 Screw M4 x 16 DIN 7984 626061

13 Screw M4 x 30 DIN 912 626485

14 Screw M3 x 6 DIN 7380 626164

101 Screw M4 x 12 DIN 912 656836

102 Holder 1008969

103 Nut M4 DIN 439 626953

Assembly instructions Translation of the original instructions March 2019

Page 20 of 48 profiLINE 140 MAN_EN_1039740_profiLINE140_R3d.docx

3.5.2.4 Integrated installation of the initiators

In case of integrated installation, the initiators are within the movement unit and are protected

against contamination or mechanical influences (see Figure 17).

9

8

11

10

13

1

12

Figure 17: Integrated installation of the initiators

No. Designation Article no.

1 Aluminium strip 1003692

8 Adapter piece 1006140

9 Cover 1006139

10 Connector 725163

11 Retaining plate 25626

12 Screw M4 x 14 DIN 7984 1016016

13 Screw M4 x 30 DIN 912 626485

NOTE At integrated installation of the initiators, particularly observe that only screws

according to DIN 7984 (flat-head) are used, because the guide carriages

would otherwise be damaged.

This manual suits for next models

1

Table of contents

Popular DC Drive manuals by other brands

SEW-Eurodrive

SEW-Eurodrive MOVITRAC B System manual

Lenze

Lenze L-force 8400 Series Mounting instructions

Danfoss

Danfoss VLT AQUA Drive FC 202 Design guide

Danaher Motion

Danaher Motion Superior SLO-SYN SS2000MD4-M installation instructions

Automationdirect.com

Automationdirect.com DURApulse GS10 quick start guide

EACON

EACON EC6000 Series quick guide