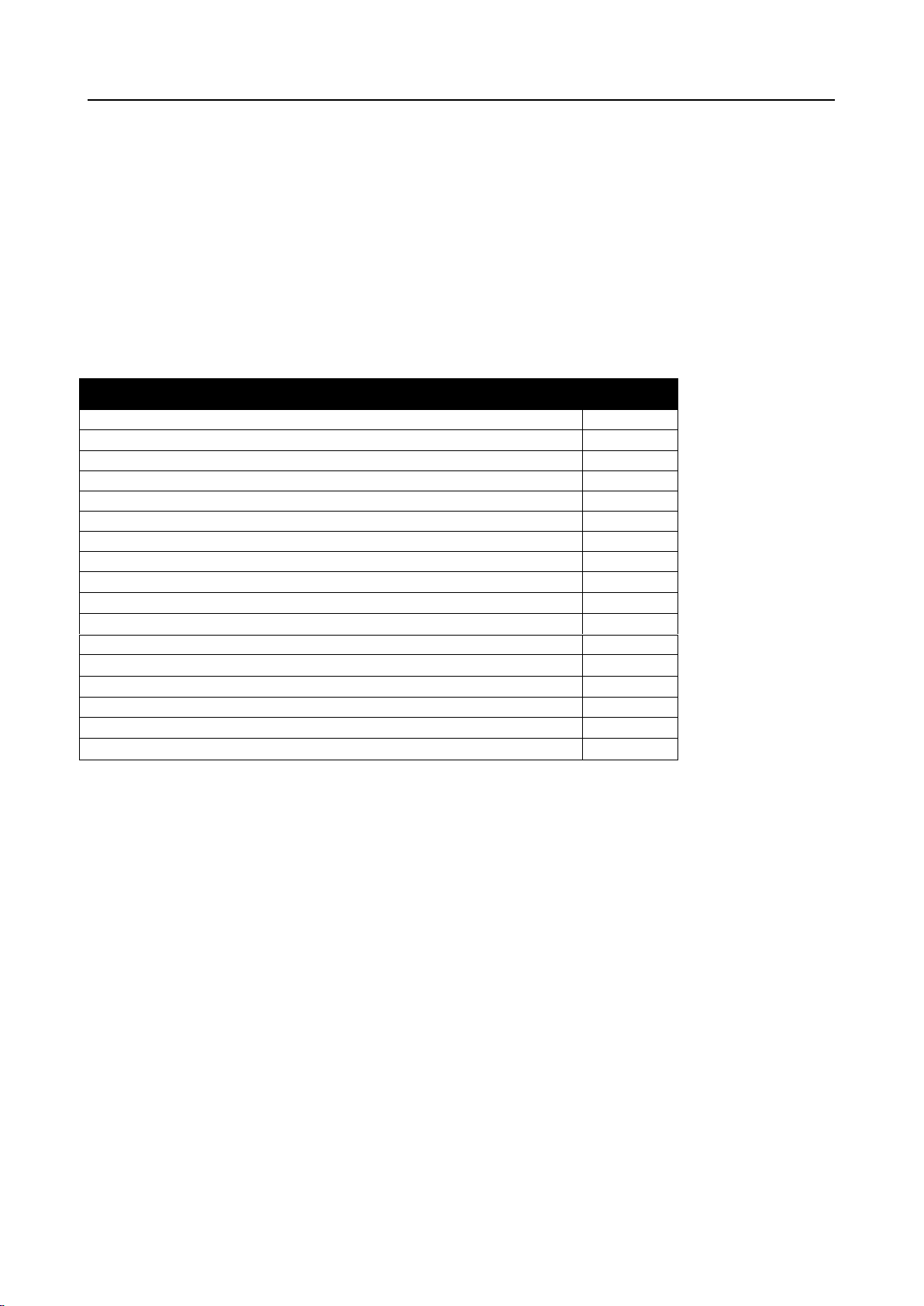

TABLE OF CONTENTS

1. Introduction............................................................................................................................2

1.1 Customer registration ......................................................................................................2

1.2 Declaration of conformity.................................................................................................3

1.3 Purpose of use.................................................................................................................4

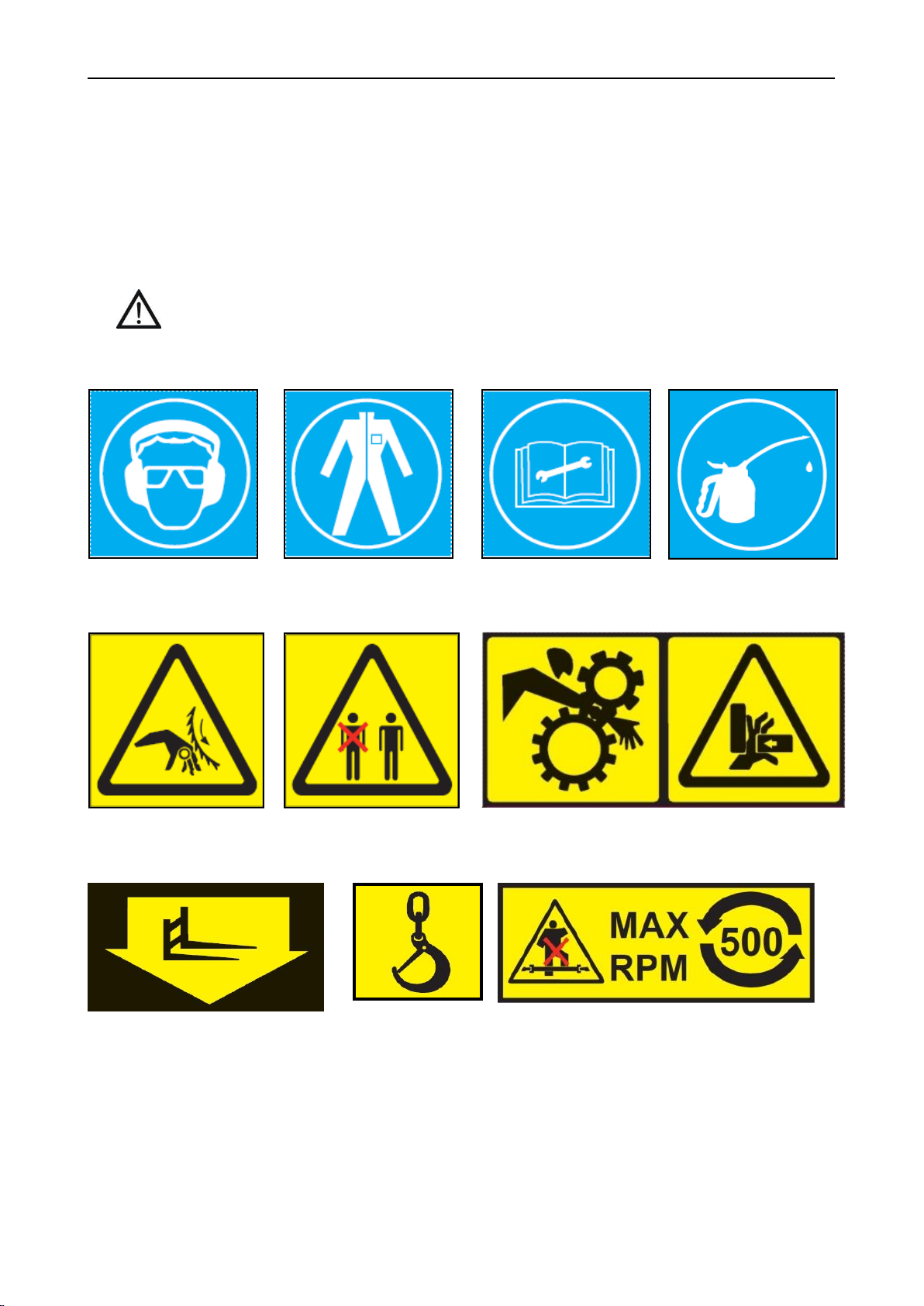

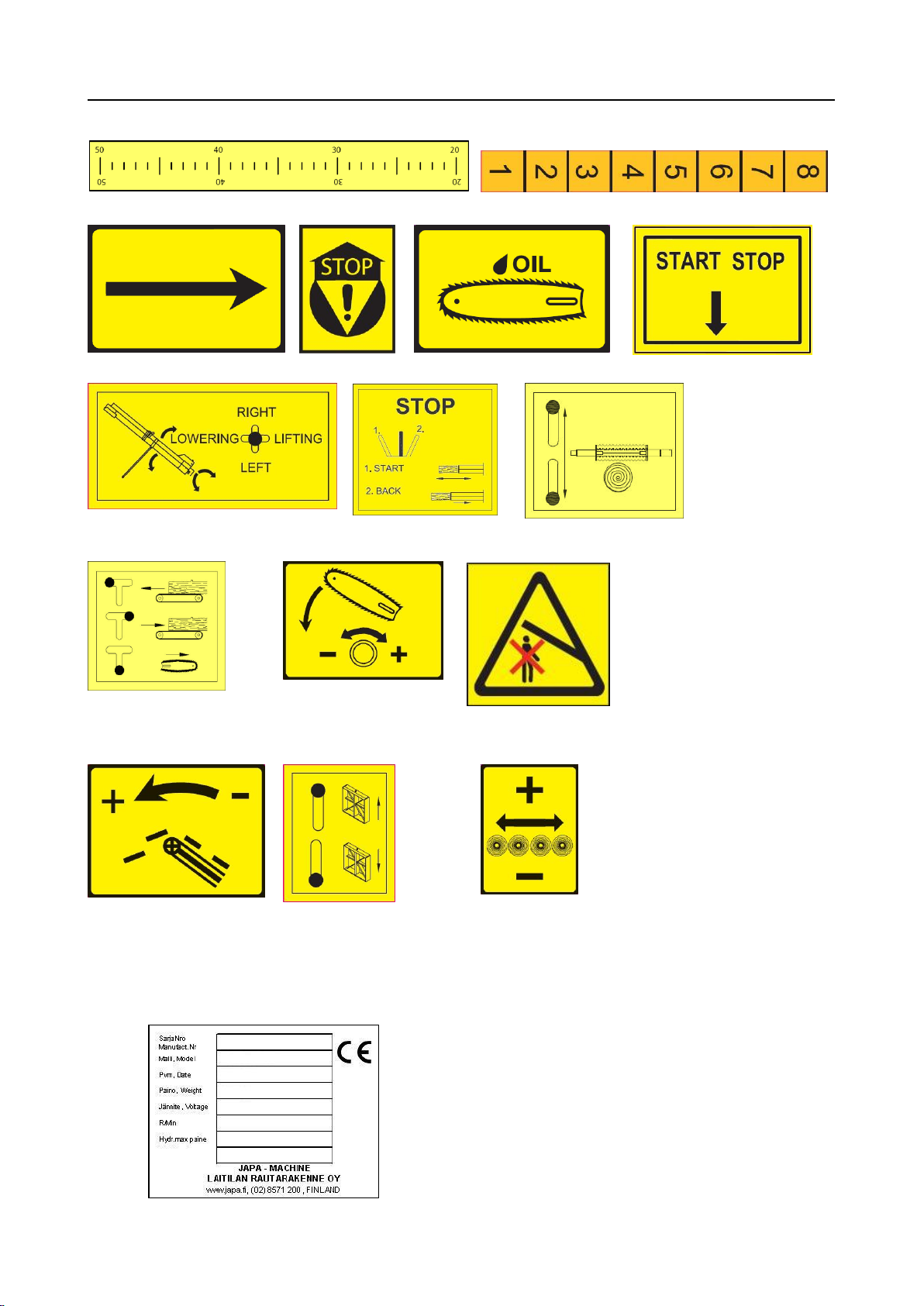

1.4 Instruction and warning labels on the machine ...............................................................4

1.5 The machine’s type plate.................................................................................................5

1.6 Machine models...............................................................................................................6

1.7 Safety instructions............................................................................................................7

1.8 Noise level and vibration..................................................................................................8

1.9 Guarantee terms..............................................................................................................9

2. Installation of the machine .................................................................................................10

2.1 Delivery inspection.........................................................................................................10

2.2 Main components of the machine..................................................................................10

2.3 Lifting and transporting the machine..............................................................................11

2.4 Working position ............................................................................................................12

2.5 Connecting the power source........................................................................................13

2.6 Transport position..........................................................................................................13

2.7 Connections...................................................................................................................14

3. Operating the machine........................................................................................................15

3.1 Acknowledging the hazards and responsibilities involved.............................................15

3.2 Before use......................................................................................................................15

3.3 Safety mechanism .........................................................................................................15

3.4 Control panel..................................................................................................................16

3.5 Cutting device................................................................................................................17

3.6 Blade lubrication ............................................................................................................18

3.7 Splitting device...............................................................................................................19

3.8 Replacing the splitting knife...........................................................................................20

4. Accessories..........................................................................................................................21

4.1 Splitting knives...............................................................................................................21

4.2 Dust extractor.................................................................................................................21

4.3 Hydraulic timber deck ....................................................................................................21

4.4 Cleaning drum................................................................................................................22

4.5 Sacking rack ..................................................................................................................22

5. Maintenance and troubleshooting.....................................................................................23

5.1 Maintenance table..........................................................................................................23

5.2 First maintenance ..........................................................................................................24

5.3 Daily maintenance (10 hrs)............................................................................................24

5.3.1 Maintaining the cutting blade ........................................................................................25

5.3.2 Maintaining the splitting knife........................................................................................26

5.4 Monthly maintenance (200 hrs).....................................................................................26

5.4.1 Adjustments of the cutting device .................................................................................28