Ier ES1S User manual

SU0072e.DOC 03/03 © IER Eberhard Henkel GmbH Subject to change without notice

Operating Instructions

ES1S

Electrode Controls

Safety Precautions

• The device may only be connected to supply voltage which is in

compliance with the technical data shown on the serial plate!

• Installation, initial start-up and maintenance may only be

performed by trained personnel!

Technical Data

Power Supply

230 V AC, +/-10%, 50-60 Hz

Optional: 24, 115 V AC or 24 V DC +/-10%

See serial plate on device.

Power Consumption

approx. 2 VA

Ambient Temperature

-15 to +45°C

Housing

22.5 x 75 x 100 mm, IP40

Quick mount to standard rail

DIN EN 50 022 (35 x 7.5 mm top-hat rail)

or 88 x 150 x 130 mm, IP55 for surface mounting

Terminals

IP20, screw terminals

Conductor cross-section: max. 2.5 square mm

Measuring Circuit

Electrically isolated

Alternating voltage < 6V / < 2 mA

Cable Length

max. 300 m (for highly conductive liquids)

See figure 1.

min. conductor cross-section: 0.5 square mm, shielded

Measuring Functions

MIN-MAX control,

MIN control or MAX control

Sensitivity

Two adjustable ranges

1 to 70 kΩ/ 5 to 150 kΩ

Can be selected / adjusted with DIP switch / potentiometer

(full left turn / anti clockwise = min. sensitivity)

Reset Hysteresis

approx. 20% of the selected sensitivity value

Relay Outputs

2 ea. floating changeover contacts

AC: max. 250 V, 5 A, 500 VA

DC: max. 125 V, 1 A, 40 W

Operating Principle

Working current / closed-circuit current

selectable with DIP switch

Delay

ON delay / OFF delay: 0.5 to 3 sec.

adjustable with potentiometer (full left = approx. 0,5 sec.)

Status Indication

1 ea. "on" LED, 1 ea. switching status LED

CE Mark of Approval

In accordance with low-voltage directive (73/23/EWG),

EMC directive (89/336/EWG) and

• EN 50 082-2:1995

• EN 55 011 (Class A): 1991

• EN 61010-1: 1993

Applications Limits

Conductive liquid-level controls are not suited for liquids which

contain oil or grease, or which may cause electrically insulating

deposits at the electrodes.

Functional Description

ES1S electrode controls function in accordance with the

conductive principle, i.e. the electrical conductivity of the liquid to

be monitored is used to establish an electrical connection between

the immersed electrodes.

Measuring Ranges

ES1S electrode controls can be used for liquids with a resistance

between the electrodes of less than 150 kΩ(observe maximum

cable length!).

Controls

Intermittent switching (minimum / maximum liquid level) with three

electrodes

Monitoring of a specific fill level (overflow / empty alarm) with two

electrodes. A metal container can be used as the reference

electrode.

Electrical Connections

MAX Electrode

MIN Electrode

Ref. Electrode

12

11

14

24

21

22

E0 E1 E2

L+ N-

Control Voltage

Filling Pump

Relay / Contactor

Filling pump relay/contactor pulls

in when MIN electrode is exposed,

... and is released when

MAX electrode is immersed.

ON

OFF

1

K

Power Supply

L1 N

+ -

Wiring Diagram 1: Filling the Container

MAX Electrode

MIN Electrode

Ref. Electrode

Power Supply

L1 N

+ -

12

11

14

24

21

22

E0 E1 E2

L+ N-

Control Voltage

Discharge Pump

Relay / Contactor

Discharge pump relay/contactor pulls

in when MAX electrode is immersed,

... and is released when

MIN electrode is exposed.

OFF

ON

1

K

Wiring Diagram 2: Draining the Container

Operating Instructions Electrode Reay ES1S

SU0072e.DOC 03/03 © IER Eberhard Henkel GmbH Subject to change without notice

Wiring Diagram 3: Empty Alarm

MAX Electrode

Ref. Electrode

E0 E1 E2

L+ N-

Control Voltage

Alarm Signal

22

21

24

14

11

12

Overflow Alarm (low signal):

Alarm signal relay K1 is released when MAX

electrode is immersed or if interference/power

f

occurs at electrode

tl

Overflow Alarm (high signal):

Alarm signal relay K1 is pulled in when MAX

electrode is immersed or if interference/power

f

occurs at electrode

tl

---> Connect relay K1 to terminal 12.

K1

ON

OFF

1

Power Supply

L1 N (AC)

+ - (DC)

Wiring Diagram 4: Overflow Alarm

Please observe instructions concerning EMC compliant installation,

wiring and operation of electronic measuring and control devices!

(Info Sheet no.: SU0066. 1998)

Initial Start-Up

• Check for correct supply voltage! Observe data printed on the

serial plate!

• Make sure that

polarity is not

reversed if DC supply

power is used!

• Check electrode

connections!

Adjustments

The transparent front

panel can be pried out

with a screwdriver.

Sensitivity: Potentiometer P1 and DIP switch S2 are used to

adjust sensitivity to the conductivity of the liquid to be

monitored.

Procedure: The poorer the conductivity of the liquid, and the

greater the distance between the electrodes, the

higher the sensitivity must be adjusted.

Attention: Erroneous switching may occur if sensitivity is set too

high !

Working Current / Closed-Circuit Current: DIP switch S1

ON delay / OFF delay: Potentiometer P2

Flutter suppression is provided in order to prevent excessive

switching in the event of disturbances at the surface of the liquid.

Potentiometer Full Left Full Right

P1: Sensitivity min. max.

P2: Delay approx. 0.5 sec approx. 3 sec

DIP Switch ON OFF

1 working current closed-circuit current

2 high sensitivity

5 - 150 kΩ

low sensitivity

1 - 70 kΩ

Status Indication

Green LED lights up ready for operation

Yellow LED lights up output relay pulled in

Response when Supply Power is Switched On

Setting MIN

Immersed

MIN+MAX

Immersed

MIN+MAX

Exposed

Open-circuit current

+ no DT

0 0 0 -> 1

Working current + no DT 0 -> 1 0 -> 1 0

Open-circuit current + DT 1 ->DT->0 1 ->DT->0 0 -> 1

Working current + DT 0 ->DT->1 0 ->DT->1 0

0 = Relay released

1 = Relay pulled in

DT = Delay time

Mounting in electrical cubicles and boxes

cubicles with increased inner temperature:

notice the power loss -->

distances between the relays not less than 0,5 cm !

Operating Range

The capacitive resistance of long cables reduces the sensitivity of

the electrode controls.

A typical, shielded, 3 conductor PVC cable has a capacitance of

approx. 100 pF per metre. This results in an operating range which

is dependent upon cable length and the resistance of the liquid in

accordance with the following diagram:

0

20

40

60

80

100

120

140

160

50 100 150 200 250 300

Cable Length (m)

Resistance of Liquid (kΩ

Ω

Ω

Ω)

Operating Range

Operation is not possible

Figure 1: Operating Range

Maintenance

If the device is used for its intended purpose, no maintenance is

required.

Troubleshooting

Green LED does

not light up.

• No supply power

• Device is defective

Yellow LED

lights up, but the

relay does not

pull in. 1

• Measurement cable is interrupted

• Liquid is not conductive enough

• Contaminated electrodes (insulating layer)

• Device is defective

Yellow LED

lights up, but the

relay does not

release

• Short-circuited measurement cable

• Electrodes bridged with conductive

contamination

• Sensitivity is set too high

• Device is defective

1DIP switch 1 in "working current" position

IER Meß- und Regeltechnik

Eberhard Henkel GmbH

Innstrasse 2

68199 Mannheim

Tel. +49 (0)621 84224-0 z

zz

zFax: +49 (0)621 84224-90

zz

zInternet: www.IER.de

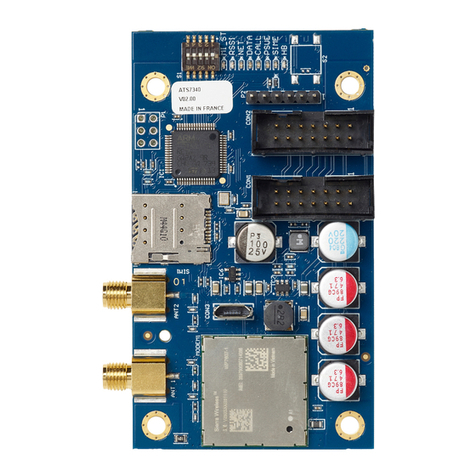

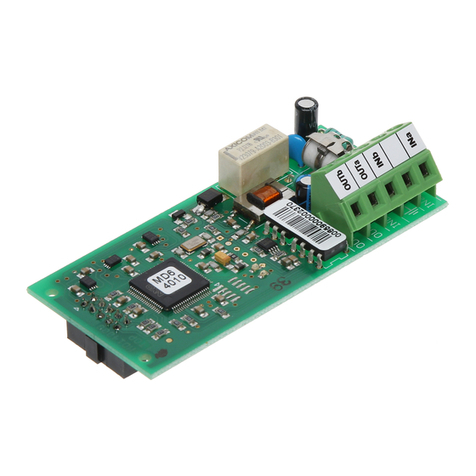

green LED

"Ready"

yellow LED

"Output Relay"

DIP Switch 2

"Sensitivity"

Potentiometer

"Delay Time"

Potentiometer

"Sensitivity"

DIP Switch 1

"Work/<O-C. Current"

Table of contents

Popular Control Unit manuals by other brands

ABB

ABB Ability 800xA Series user manual

HumanTechnik

HumanTechnik MA-1 operating instructions

EnOcean

EnOcean STM 300U user manual

Altronic

Altronic AGV5 Series Service manual

Viessmann

Viessmann VITOTRONIC 100 Installation and service instructions

Scanivalve

Scanivalve ZOC 33/64Px Instruction and service manual

Conductix-Wampfler

Conductix-Wampfler 0815 Series installation instructions

National Instruments

National Instruments FieldPoint FP-1001 user manual

Quectel

Quectel EP06 manual

jablotron

jablotron JA-190X quick start guide

Fortinet

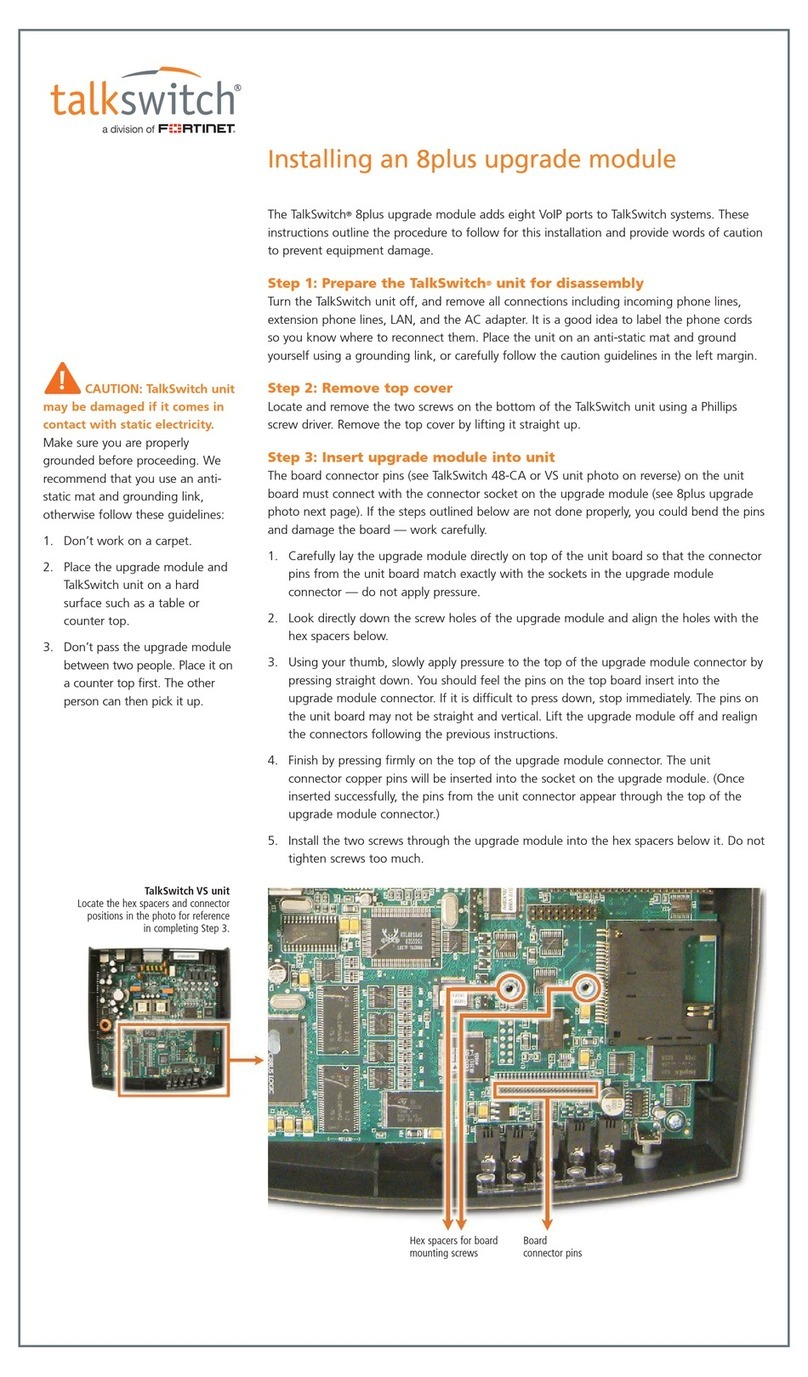

Fortinet TalkSwitch 8plus Installing guide

ABB

ABB SACE PR212/D-L instruction manual