AtoPro - atomac Sampling Valve

Ahaus GmbH

von-Braun-Straße 19a

D-48683 Ahaus

Postfach 1162 D-48661 Ahaus

Telefon: +49(0) 2561-686-100

Fax: +49(0) 2561-686-200

Register: 20

Page: 5

Date: 12.2009

Revision: 06.2020

AtoPro - atomac Sampling Valve

Ahaus GmbH

von-Braun-Straße 19a

D-48683 Ahaus

Postfach 1162 D-48661 Ahaus

Telefon: +49(0) 2561-686-100

Fax: +49(0) 2561-686-200

Register: 20

Page: 4

Date: 12.2009

Revision: 06.2020

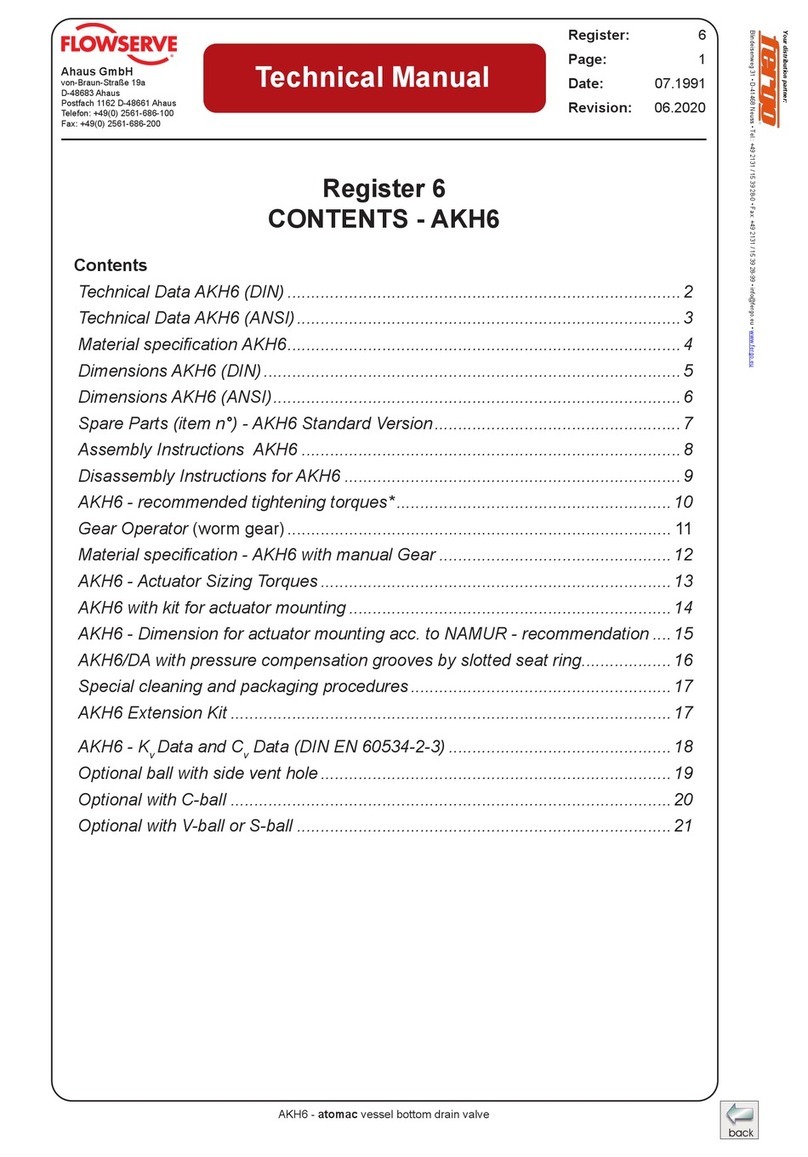

Technical ManualTechnical Manual

080

090

010

100

062

110

210 060

170

061

070

130

140

120

220

250

260

270

280

230

020

290

300

050

040

240

045

030

030

080

090

010

100

062

110

210 060

170

061

070

130

120

220

250

260

270

280

230

020

290

300

050

040

240

045

030

030

Assembly Instructions

AtoPro metallic

Disassembly Instructions

AtoPro metallic

The general installation and maintenance instructions must be observed.

1. Insert stem (040) and backup ring (045) from inside of the body (010) in

such a way that the ats of the stem are parallel to the body longitudinal

axis.

2. Insert chevron packing (100) and spacer (062).

3. Install belleville washers (110) in alternating arrangement on spacer.

4. Install top cap (060) and bushing (061) using the countersunk screws (120).

5. Install grounding device (170) also on gear or automated valves.

6. Install hand lever (070) on to stem (040) using the washer (130) and

hexagon screw (140).

7. Insert rst seat ring (030) into the body (010).

8. Insert ball (050) to the stem by pushing the ball in a downward motion

through valve body.

9. Turn hand lever to the 90° -position, longitudinal axis of body.

10. Place the second seat ring (030) on to ball (050).

11. Install the O-rings (290, 300) in the provided slots

of the ange (020).

12. The studs (080) are to be screwed into the ange

(020).

13. Install the ange (020) to the body (010).

14. Tighten the hexagon nuts (050) using the

recommended torques with the crisscross method.

15. Install the hexagon screws (230) with the washer

(240).

16. Install the stop (210) using the hexagon screw

(220).

17. Install the adapter (250) using the plate (260) and

the hexagon screws (270).

18. Screw the bottle (280) into the

adapter (250).

For all jobs which are to be carried out on an installed valve, the works safety

requirements and the general accident prevention instructions must be observed.

Moreover, the general installation and maintenance instructions for uorcarbon

resin-lined atomac valves must be considered.

1. Prior to disassembly, the valve must be cleaned from all uid according to

the above mentioned instructions. Remove the bottle (280). Particular care

must be taken that during the rinsing and draining of the piping, the valve

is opened and closed repeatedly. Only when following this procedure, it is

ensured that all remaining pressure inside the body is eliminated.

2. Put the valve on a work bench with a soft cover (rubber mat).

3. Remove the adapter (250) and plate (260) by unscrewing the hexagon bolts

(270) out of the ange (020).

4. Remove hexagon bolts (230) and washers (240).

5. Hexagon nuts (090) must be removed to get the ange (020) with the

O-rings (290, 300) disassembled from the body (010).

6. Remove rst seat ring (030) out of the ange (020).

7. The ball (050) in closed position can easily be

pushed out of the body (010).

8. The second seat ring (030) can be removed out of

the body (010).

9. Remove the hand lever (070).

10. Remove the grounding spring (170) from the top

cap (060).

11. Disassemble the stop (210)

12. Retighten the countersunk screws (120) and

remove the top cap (060) with the bushing (061), the

belleville washers (110) and spacer (062).

13. Remove the stem (040) with the backup ring

(045) by pushing it down through the

body (010).

14. The Chevron packing (100)

can easily be

removed.

Your distribution partner:

Blindeisenweg 31 • D-41468 Neuss • Tel.: +49 2131 / 15 39 28-0 • Fax: +49 2131 / 15 39 28-99 • info@fergo.eu • www.fergo.eu

Your distribution partner:

Blindeisenweg 31 • D-41468 Neuss • Tel.: +49 2131 / 15 39 28-0 • Fax: +49 2131 / 15 39 28-99 • info@fergo.eu • www.fergo.eu