IET Labs, Inc. RLC Digibridge 1693 Troubleshooting guide

♦ PRECISION INSTRUMENTS FOR TEST AND MEASUREMENT ♦

TEL: (516) 334-5959 • (800) 899-8438 • FAX: (516) 334-5988

www.ietlabs.com

534 Main Street, Westbury, NY 11590

IET LABS, INC.

Copyright © 2012 IET Labs, Inc.

Visit www.ietlabs.com for manual revision updates

1693 im/September 2012

1693

RLC Digibridge

User and Service Manual

TEL: (516) 334-5959 • (800) 899-8438 • FAX: (516) 334-5988

534 Main Street, Westbury, NY 11590

IET LABS, INC.

www.ietlabs.com

Standards • Decades • Strobes • Sound Level Meters • Bridges

TEL: (516) 334-5959 • (800) 899-8438 • FAX: (516) 334-5988

534 Main Street, Westbury, NY 11590

IET LABS, INC.

www.ietlabs.com

Standards • Decades • Strobes • Sound Level Meters • Bridges

i

1693 RLC Digibridge

WARRANTY

We warrant that this product is free from defects in material and workmanship and, when properly used,

will perform in accordance with applicable IET speci cations. If within one year after original shipment,

it is found not to meet this standard, it will be repaired or, at the option of IET, replaced at no charge when

returned to IET. Changes in this product not approved by IET or application of voltages or currents greater

than those allowed by the speci cations shall void this warranty. IET shall not be liable for any indirect,

special, or consequential damages, even if notice has been given to the possibility of such damages.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED,

INCLUDING BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OF MERCHANTABILITY OR

FITNESS FOR ANY PARTICULAR PURPOSE.

ii

1693 RLC Digibridge

WARNING

OBSERVE ALL SAFETY RULES

WHEN WORKING WITH HIGH VOLTAGES OR LINE VOLTAGES.

Dangerous voltages may be present inside this instrument. Do not open the case

Refer servicing to quali ed personnel

HIGH VOLTAGES MAY BE PRESENT AT THE TERMINALS OF THIS INSTRUMENT

WHENEVER HAZARDOUS VOLTAGES (> 45 V) ARE USED, TAKE ALL MEASURES TO

AVOID ACCIDENTAL CONTACT WITH ANY LIVE COMPONENTS.

USE MAXIMUM INSULATION AND MINIMIZE THE USE OF BARE

CONDUCTORS WHEN USING THIS INSTRUMENT.

Use extreme caution when working with bare conductors or bus bars.

WHEN WORKING WITH HIGH VOLTAGES, POST WARNING SIGNS AND

KEEP UNREQUIRED PERSONNEL SAFELY AWAY.

CAUTION

DO NOT APPLY ANY VOLTAGES OR CURRENTS TO THE TERMINALS OF THIS

INSTRUMENT IN EXCESS OF THE MAXIMUM LIMITS INDICATED ON

THE FRONT PANEL OR THE OPERATING GUIDE LABEL.

iiiTable of Contents

1693 RLC Digibridge

Table of Contents

Safety Information

General safety information .................................................................................................................. xi

Abbreviated Specifications

Features ................................................................................................................................................ xiii

Applications ......................................................................................................................................... xiii

Specications ....................................................................................................................................... xiii

Condensed operating instructions ........................................................................................................ xx

Chapter 1 Introduction

1.1 Purpose ....................................................................................................................................... 1

1.2 General Description .................................................................................................................... 2

1.2.1 1693 RLC Digibridge Overview ...................................................................................... 2

1.2.2 References ........................................................................................................................ 2

1.3 Controls, Indicators, and Connectors ......................................................................................... 2

1.4 Accessories ................................................................................................................................. 6

1.4.1 Supplied accessories ......................................................................................................... 6

1.4.2 Optional Accessories ........................................................................................................ 6

Chapter 2 Installation

2.1 Unpacking and Inspection .......................................................................................................... 8

2.2 Dimensions ................................................................................................................................. 8

2.3 Power Line Connection .............................................................................................................. 8

2.4 Line-Voltage Regulation ............................................................................................................. 8

2.5 Test-Fixture Connections ............................................................................................................ 9

2.6 Bias Voltage for the DUT ........................................................................................................... 9

2.6.1 Internal Bias ..................................................................................................................... 9

2.6.2 External Bias .................................................................................................................... 9

2.7 IEEE-488 Interface ..................................................................................................................... 10

2.7.1 Description ....................................................................................................................... 10

2.7.2 Signal Identication ......................................................................................................... 10

2.7.3 Codes and addresses ......................................................................................................... 10

2.8 Environment ............................................................................................................................... 12

2.9 Rack Mount Option .................................................................................................................... 12

iv Table of Contents

1693 RLC Digibridge

Chapter 3 Operation

3.1 Basic Operation .......................................................................................................................... 13

3.1.1 Overview .......................................................................................................................... 13

3.1.2 Startup .............................................................................................................................. 13

3.1.3 Zeroing ............................................................................................................................. 14

3.1.4 Routine Measurement....................................................................................................... 17

3.2 Connecting the DUT ................................................................................................................... 18

3.2.1 Overview .......................................................................................................................... 18

3.2.2 The 1689-9600 Remote Test Fixture (with 1689-9602 BNC Cable) ............................... 18

3.2.3 Using the Test-Fixture Adaptors for Axial-Lead DUT ..................................................... 19

3.2.4 1657-9600 Banana Plug Extender Cable.......................................................................... 20

3.2.5 The 1689-9602 Extender Cable with bnc-to-Banana-Plug Adaptors ............................... 21

3.2.6 The Effects of Cable and Fixture Capacitances ............................................................... 21

3.2.7 7000-05 Tweezers ............................................................................................................. 22

3.2.8 1700-03 Kelvin Clip Cable............................................................................................... 23

3.2.9 7000-04 Alligator Clip Leads ........................................................................................... 24

3.2.10 Connection to HACS-Z High Accuracy Decade Capacitor ........................................... 25

3.2.11 Connection to 1482 Inductance Standard ....................................................................... 27

3.2.12 Connection to 1409 Capacitance Standards ................................................................... 28

3.2.13 Connection to 1404 Reference Standard Capacitor ....................................................... 29

3.2.14 Connection to 1417 Capacitance Standard ..................................................................... 30

3.2.15 Connection to the 1433 Decade Resistor ....................................................................... 31

3.3 Measurement Parameters, Result Displays, and Outputs ........................................................... 33

3.3.1 Parameters (R/Q,L/Q,

C/D,C/R,R/X,G/B,Z/ANG,Y/ANG) ............................................................................................ 33

3.3.2 Equivalent Circuits - Series, Parallel ................................................................................ 34

3.3.3 Results Displayed ............................................................................................................. 37

3.3.4 Units, Multipliers, and Blank Displays ............................................................................ 39

3.3.5 D, Q, ANG in PPM ........................................................................................................... 40

3.3.6 Ratio Displays, Virtual Range Extensions, and Conductance Measurements.................. 41

3.4 Principal Test Conditions ............................................................................................................ 42

3.4.1 Test Frequency.................................................................................................................. 42

3.4.2 Test Voltage ...................................................................................................................... 43

3.4.3 Constant Voltage Source................................................................................................... 44

3.4.4 Constant Current Source .................................................................................................. 44

3.4.5 Other Conditions .............................................................................................................. 44

v

1693 RLC Digibridge

3.5 Measurement Time and Measurement Ranges ........................................................................... 45

3.5.1 General ............................................................................................................................. 45

3.5.2 Measure Rate Selection at Keyboard ............................................................................... 45

3.5.3 Settling Time or Programmed Delay, in Triggered Measure Mode ................................. 46

3.5.4 Measure Mode and Display Selection, Effects on Measurement Time ........................... 46

3.5.5 Integration-Time Factor (a Special Function) .................................................................. 46

3.5.6 Ranges and Range Changing ............................................................................................ 47

3.5.7 Range Holding .................................................................................................................. 48

3.5.8 Time Required for Obtaining Median Values and Averaging .......................................... 49

3.5.9 Time Required if IEEE-488 Output is Enabled ................................................................ 50

3.5.10 Effect of Selecting a Low Test Frequency on Measurement Time................................. 50

3.5.11 Measurement Time Summary......................................................................................... 51

3.6 Accuracy, The Limits of Errors .................................................................................................. 52

3.6.1 General ............................................................................................................................. 52

3.6.2 Accuracy for Some Typical Conditions ............................................................................ 53

3.6.3 Averaging to Improve Accuracy ....................................................................................... 54

3.6.4 Selection of Median Value for Better Accuracy ............................................................... 55

3.6.5 Accuracy Enhancement for Large or Small Impedances at Particular Frequencies ......... 55

3.6.6 Accuracy Enhancement by Special Attention to Short-Circuit Inductance ...................... 56

3.6.7 Cable-Related Errors and How to Correct for them ......................................................... 57

3.6.8 Use of Signal Reversing (Special Function) for Tests at Power Frequencies .................. 58

3.6.9 Accuracy When Holding a Non-Optimum Range ............................................................ 59

3.7 Bias for the DUT ........................................................................................................................ 59

3.7.1 Internal Bias ..................................................................................................................... 59

3.7.2 External Bias .................................................................................................................... 60

3.7.3 Suppression or Transients ................................................................................................. 62

3.8 Bin Sorting and Go/No-Go Results ............................................................................................ 62

3.8.1 Introduction to Binning (Sorting Based on Limit Comparisons) ..................................... 62

3.8.2 Sorting Methods ............................................................................................................... 62

3.8.3 Limit Entry Procedure ...................................................................................................... 63

3.8.4 Verication of Nominal and Limit Values ........................................................................ 64

3.8.5 Examples of Limit Entry .................................................................................................. 65

3.8.6 Notes on Limit Entries in General .................................................................................... 66

3.8.7 Go/No-Go and Bin Assignment Results ........................................................................... 67

3.8.8 Bin Sum Information ........................................................................................................ 67

3.8.9 Binning and Ratio Measurement Simultaneously ............................................................ 67

vi Table of Contents

1693 RLC Digibridge

3.9 Keyboard Lock, Function Map, and Summary of Integrations .................................................. 69

3.9.1 Keyboard Lock ................................................................................................................. 69

3.9.2 Function Map ................................................................................................................... 69

3.9.3 Summary of Interrogations ............................................................................................... 70

3.10 Special Functions ...................................................................................................................... 71

3.11 Data Output and Programming via IEEE 488 and RS-232 Interface ....................................... 72

3.11.1 Overview ........................................................................................................................ 72

3.11.2 Conguration .................................................................................................................. 72

3.11.3 Talk-Listen / Talk-Only Toggle Switch .......................................................................... 72

3.11.4 GPIB Address DIP Switch .............................................................................................. 73

3.11.5 Jumpers ........................................................................................................................... 73

3.11.6 RS-232 Serial Interface (Currently Not Implemented) .................................................. 73

3.11.7 Instrument Program Commands ..................................................................................... 74

3.11.8 Legacy Digibridge IEEE-488 Commands ...................................................................... 75

3.11.9 IEEE 488.2/SCPI Digibridge Command Summary ....................................................... 77

3.11.10 IEEE 488.2 / SCPI Digibridge Command Reference ................................................... 80

3.11.11 Example Programming ................................................................................................. 91

3.11.12 Talk-Only Use, for Data Output ................................................................................... 91

3.11.13 Talk/Listen Use, for Remote Programming and Data Transfers .................................. 94

3.11.14 Data Output in Compacted Binary Format ................................................................... 97

3.12 Sample IEEE Programs ............................................................................................................ 100

3.12.1 Programming Hints ........................................................................................................ 100

3.12.2 National Instruments GPIB-PCll Card With the PC ...................................................... 100

3.13 Self-checks and Failure Displays (Error codes) ....................................................................... 101

3.13.1 Power-up Self-Check ..................................................................................................... 101

3.13.2 Failure Display due to Signal Overload ......................................................................... 102

3.13.3 Failure Display due to Abnormal Measurement Cycle .................................................. 102

3.13.4 Failure Display due to LC Resonance ............................................................................ 102

Chapter 4 Theory

4.1 Introduction ................................................................................................................................ 104

4.1.1 General ............................................................................................................................. 104

4.1.2 Brief Description of the 1693 Digibridge......................................................................... 104

4.1.3 Block Diagram ................................................................................................................. 105

4.2 Principal Functions ..................................................................................................................... 107

4.2.1 Elementary Measurement Circuit ..................................................................................... 107

4.2.2 Frequency and Time Source ............................................................................................. 107

viiTable of Contents

1693 RLC Digibridge

4.2.3 Sine-Wave Generation ...................................................................................................... 107

4.2.4 The Dual-Slope Integrating Detector and Converter ....................................................... 109

Chapter 5 Service and Maintenance

5.1 Safety .......................................................................................................................................... 110

5.2 Customer Service ........................................................................................................................ 111

5.3 Instrument Return ....................................................................................................................... 111

5.3.1 Packaging ......................................................................................................................... 111

5.3.2 Repair and Replacement of Circuit Boards ...................................................................... 111

5.4 Performance Verication ............................................................................................................ 112

5.4.1 Overview .......................................................................................................................... 112

5.4.2 Performance Verication Procedure ................................................................................. 112

5.4.3 Measurement-Time Checkout .......................................................................................... 115

5.5 Disassembly and Access ............................................................................................................. 116

5.5.1 Relocation of bnc Connector Bracket .............................................................................. 119

5.5.2 Major internal components ............................................................................................... 120

5.5.3 Interface Options .............................................................................................................. 121

5.5.4 Removal of Multiple-Pin Packages .................................................................................. 122

5.6 Periodic Maintenance ................................................................................................................. 122

5.6.1 Care of Test Fixtures ........................................................................................................ 122

5.6.2 Care of the Display Panel ................................................................................................. 122

5.7 Trouble Analysis ......................................................................................................................... 123

5.7.1 Overview .......................................................................................................................... 123

5.7.2 Power-Up Self check and Certain Aborted Measurements .............................................. 124

5.7.3 Internal Fuse Replacement ............................................................................................... 127

5.7.4 Power Supply and Regulator Board ................................................................................. 128

5.7.5 Sinewave Generator Checks ............................................................................................. 129

5.7.6 Front End Ampliers and Switches .................................................................................. 129

5.8 Accuracy Verication ................................................................................................................. 130

5.8.1 General ............................................................................................................................. 130

5.8.2 Capacitance Measurement Accuracy (Ranges 1-3) .......................................................... 131

5.8.3 Capacitance Measurement Accuracy................................................................................ 132

5.8.4 Resistance Measurement Accuracy .................................................................................. 134

5.8.5 Inductance Measurement Accuracy.................................................................................. 135

5.8.6 D Measurement Accuracy ................................................................................................ 137

5.8.7 Limit Comparison Bins .................................................................................................... 138

viii Table of Contents

1693 RLC Digibridge

Figures and Tables

Figure-A: Source Impedance Factors .........................................................................................................xv

Figure 1-1: 1693 RLC Digibridge, front view ...........................................................................................2

Figure 1-2: 1693 Front Display.................................................................................................................3

Figure 1-3: 1693 Keyboard .......................................................................................................................3

Figure 1-4: Rear controls and connectors on 1693 Digibridge ................................................................5

Figure 1-5: Typical operating guide attached to 1693 ..............................................................................7

Figure 2-1: Input power module with a drawer for the input fuse ............................................................8

Figure 2-2: IEEE-488 interface .................................................................................................................10

Figure 2-3: DIP switch set to Decimal Address 3 .....................................................................................11

Figure 3-1: Open and short measurements with banana plugs .................................................................14

Figure 3-2: Open and short measurements with Kelvin cables .................................................................15

Figure 3-3: Open and short measurements with bnc-to-bnc cables ..........................................................15

Figure 3-4: Open and short measurements with GR874 connectors.........................................................16

Figure 3-5: Chip component tweezers .......................................................................................................16

Figure 3-6: Open and short measurements in 1689-9600 .........................................................................17

Figure 3-7: Connecting remote test xture to RLC Digibrige ...................................................................18

Figure 3-8: 1689-9600 Remote Test Fixture ..............................................................................................19

Figure 3-9: 1689-9600 Remote Test Fixture with 1657-5995 Test Clips ...................................................19

Figure 3-10: Banana plugs on the 1657-9600 cable .................................................................................20

Figure 3-11: Connecting remote test xture and the Extender cable to RLC Digibrige ...........................20

Figure 3-12: 1689-9602 Extender Cable with bnc-to-banana-plug adapters ...........................................21

Figure 3-13: 7000-05 Chip Component Tweezers .....................................................................................22

Figure 3-14: 1700-03 Kelvin Cables .........................................................................................................23

Figure 3-15: 7000-04 Alligator Clip Leads ...............................................................................................24

Figure 3-16: Connecting alligator clips ...................................................................................................24

Figure 3-17: Connection to HACS-Z BP terminals with 1689-9602 cable and 1894 & 4684 adapters ...25

Figure 3-18: Connection to HACS-Z BP terminals with 1657-9600 Extender Cable

or 7000-04 cable (without alligator clips) ..........................................................................................25

Figure 3-19: Connection to HACS-Z bnc terminals with 1689-9602 cable with 6700 adapters ..............26

Figure 3-20: Connecting 1693 to 6-terminal 1482 ...................................................................................27

Figure 3-21: Direct connection of 1693 and 1482 ....................................................................................27

Figure 3-22: Connecting 1693 to a 3-terminal 1482 ................................................................................28

Figure 3-23: Connection to 1409 Standard Capacitor ..............................................................................28

Figure 3-24: Connecting 1693 to a 1404 ..................................................................................................29

Figure 3-25: Connecting to a 1417 ...........................................................................................................30

5.9 Recalibration ............................................................................................................................... 140

5.9.1 Preparation........................................................................................................................ 140

5.9.2 Zeroing and Selecting “DQ in PPM” ............................................................................... 141

5.9.3 Recalibration for Range 4................................................................................................. 141

5.9.4 Recalibration for Range 3................................................................................................. 142

5.9.5 Recalibration for Range 2................................................................................................. 142

5.9.6 Recalibration for Range 1................................................................................................. 143

5.9.7 Frequency Calibration ...................................................................................................... 143

5.9.8 Frequency Correction K Factor Procedure ....................................................................... 144

5.10 Internal Address Settings for IEEE-488 Interface .................................................................... 146

ixTable of Contents

1693 RLC Digibridge

Figure 3-26: Connection to 1433 via 7000-04 cable.................................................................................31

Figure 3-27: Connection to 1433 via 1657-9600 cable.............................................................................32

Figure 3-28: Phase relationships ..............................................................................................................37

Figure 3-29: Relationships of Measurement Time .....................................................................................51

Figure 3-30: General view of the tradeoffs between measurement time and accuracy ............................53

Figure 3-31: Approximate RLC Accuracy vs Test Frequency ....................................................................54

Figure 3-32: Recommended Wire Shapes for Zeroing ...............................................................................56

Figure 3-33: Nested limits for sorting .......................................................................................................63

Figure 3-34: Sequential limits for sorting .................................................................................................63

Figure 3-35: Keyboard Map ......................................................................................................................69

Figure 4-1: Block diagram of the 1693 RLC Digibridge ..........................................................................106

Figure 4-2: Elementary Measurement Circuit ...........................................................................................108

Figure 4-3: Frequency and timing source .................................................................................................108

Figure 4-4: Sine wave generator ...............................................................................................................108

Figure 5-1: Screws holding the interface assembly on the rear panel ......................................................117

Figure 5-2: Interior top view of 1693 Digibridge .....................................................................................118

Figure 5-3: Analog and Control Board Assembly (1689-4702) ................................................................120

Figure 5-4: Display Board Assembly (1689-4705) ....................................................................................120

Figure 5-5: Keyboard Assembly (1687-4200) ...........................................................................................121

Figure 5-6: Power Supply Assembly (700011) ..........................................................................................121

Figure 5-7: IEEE interface (1689-9640), front view .................................................................................121

Figure 5-8: IEEE interface (1689-9640), top view ....................................................................................121

Figure 5-9: Screws holding the interface assembly on the rear panel ......................................................122

Figure 5-10: Timing diagram of the power-up self check. ........................................................................124

Figure 5-11: Location of internal fuse .......................................................................................................127

Figure 5-12: Power Supply and Regulator Board Test Points ..................................................................128

Figure 5-13: Series connections of standards for D accuracy checks ......................................................137

Figure 5-14: Calculating the K factor .......................................................................................................145

Figure 5-15: IEEE-488 interface on the rear panel ..................................................................................146

x Table of Contents

1693 RLC Digibridge

This page is intentionally left blank.

xi

1693 RLC Digibridge

Safety Information

General safety information

Safety Summary

The following general safety precautions must be

observed during all phases of operation, service

and repair of this instrument. Failure to comply

with these precautions or specic WARNINGS

given elsewhere in this manual will violate safety

standards of the design, manufacturing, and

intended use of the instrument. IET Labs. assumes

no liability for the customer’s failure to comply with

these requirements.

Before Applying Power

Verify that the power is set to match the rated input

of this instrument.

Protective Ground

Make sure to connect the protective ground to

prevent an electric shock before turning on the

power.

Necessity of Protective Grounding

Never cut off the internal or external protective

ground wire, or disconnect the wiring of the

protective grounding terminal. Cutting the

protective ground could cause a potential shock

hazard and result in injury to a person.

Fuses

Only fuses with the required rated current, voltage

and specied type (normal blow, time delay, etc.)

should be used. Do not use repaired fuses or short-

circuited fuse holders. Using the wrong fuse could

cause a shock or re hazard.

Do not operate in an explosive atmosphere

Do not operate this instrument in the presence of

ammable gases or fumes.

Do not remove the cover of the instrument

Operating personnel must not remove the cover

of this instrument. Component replacements and

internal adjustments can be done only by qualied

service personnel. Dangerous voltages may be

present inside this instrument. Do not open the case

Refer servicing to qualied personnel.

Disposal

Do not dispose of electrical appliances as unsorted

municipal waste, use separate collection facilities.

Contact your local government for information

regarding the collection systems available. If

electrical appliances are disposed of in landlls

or dumps, hazardous substances can leak into the

groundwater and get into the food chain, damaging

your health and well-being. When replacing old

appliances with new one, the retailer is legally

obligated to take back your old appliances for

disposal.

SAFETY

INFORMATION

xii

1693 RLC Digibridge

Safety Information

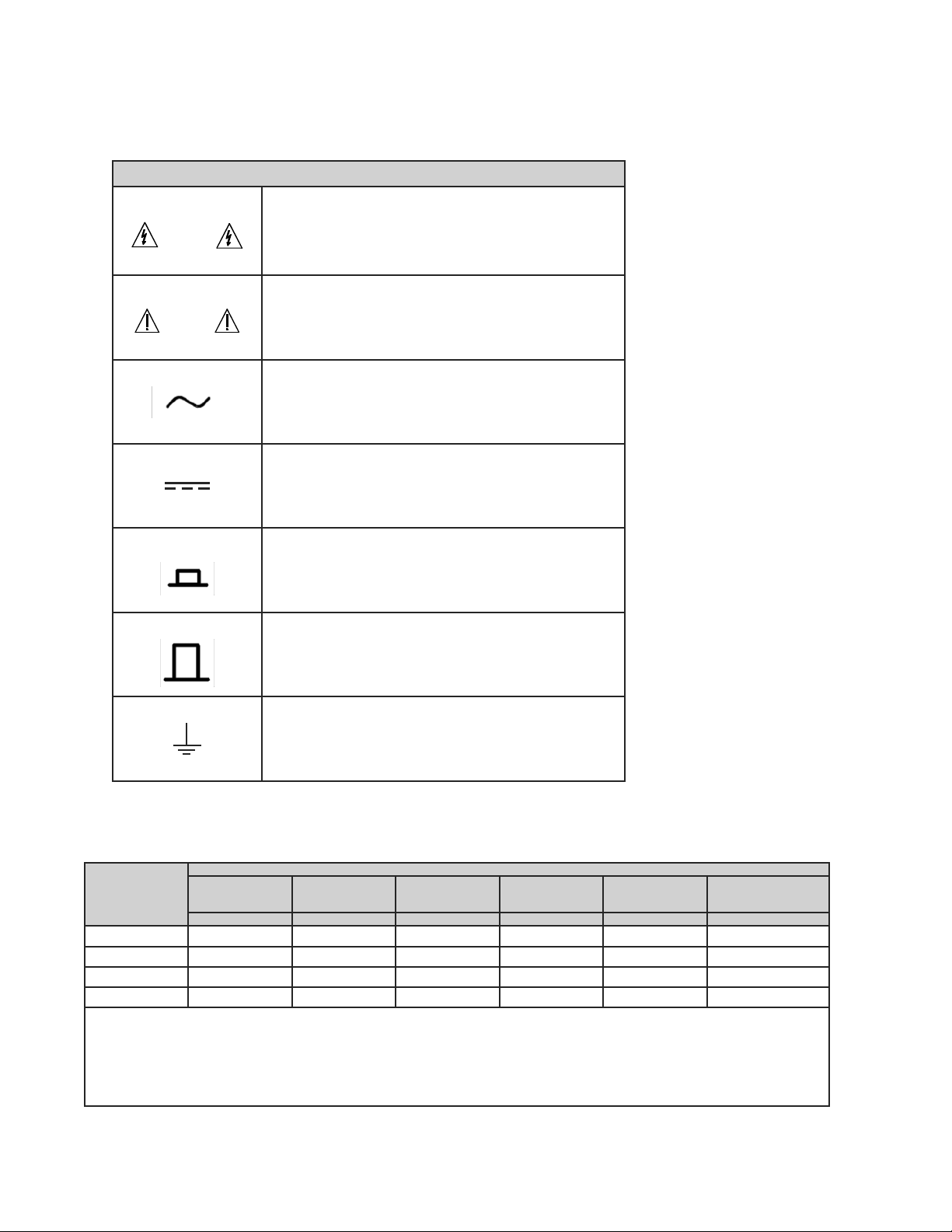

Safety Symbols

The product is marked with the following safety symbols.

Safety Symbols

WARNING

The WARNING sign denotes a hazard to the user. It calls attention

to a procedure, practice, or the like, which, if not correctly performed

or followed, could result in personal injury. Do not proceed beyond a

WARNING sign until the indicated conditions are fully understood and

met.

CAUTION

The CAUTION sign denotes a hazard to the equipment. It calls attention

to procedures, practices and conditions, which, if not observed, could

result in damage to the equipment or invalidating a procedure and/or test

results.

Alternating Current

Direct Current

I

On (Power Supply)

0

Off (Power Supply)

Protective grounding terminal: Protects against electrical shock in

case of a fault. This symbol indicates the terminal must be connected to

the ground wire before operating the equipment.

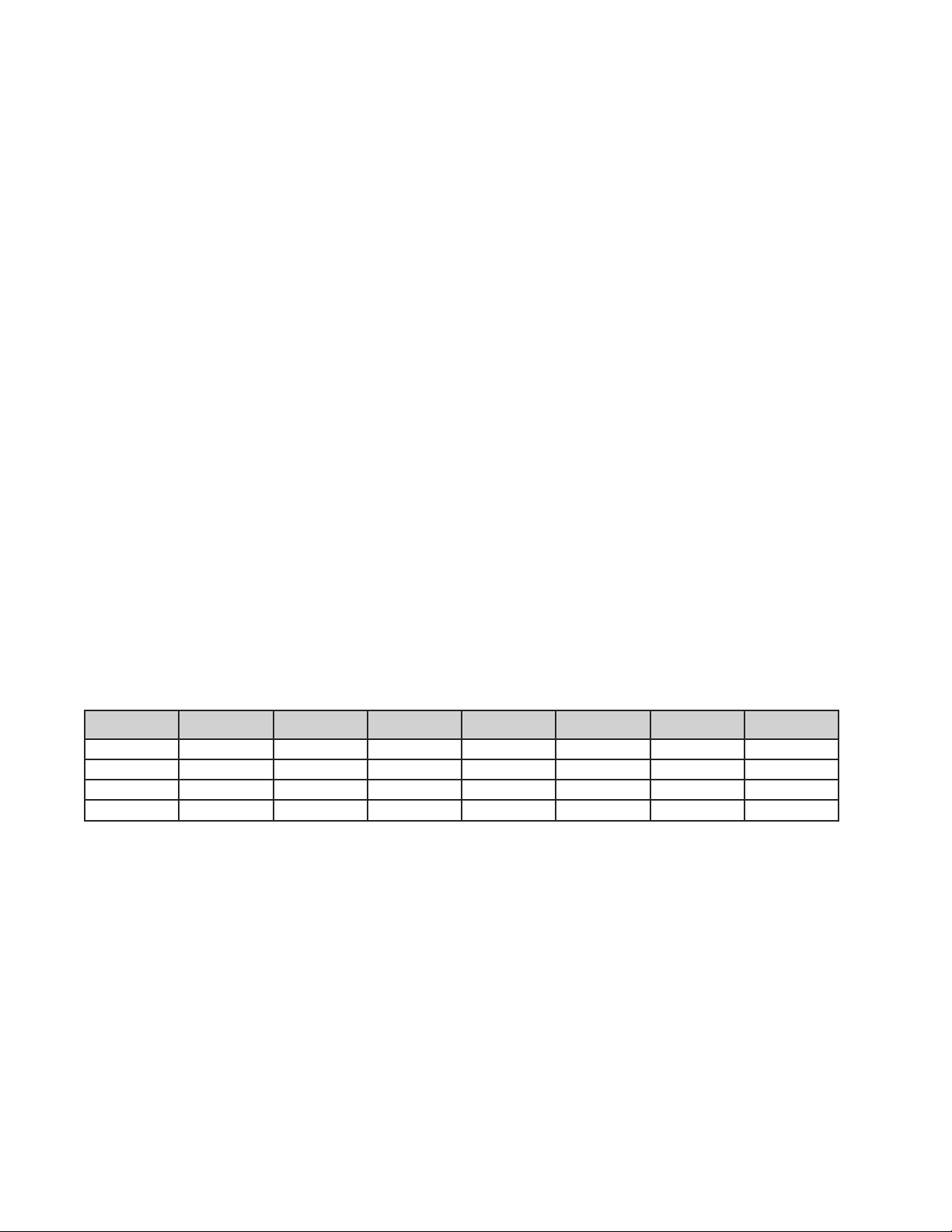

Material Contents Declaration

A regulatory requirement of The United States of America dened by specication SJ/T 11364-2006 mandates that

manufacturers provide a material contents declaration of electronic products. IET’s materials are listed below.

Part Name

Hazardous Substances

Lead Mercury Cadmium Hexavalent

Chromium

Polybrominated

Biphenyls

Polybromodiphenyl

Ethers

Pb Hg Cd Cr6+ PBB PBDE

PCBA X O O O O O

CHASSIS X O O O O O

ACCESSORY X O O O O O

PACKAGE O O O O O O

“O” indicates that the level of the specied chemical substance is less than the threshold level specied in the standards.

“X” indicates that the level of the specied chemical substance exceeds the threshold level specied in the standards.

IET Labs. has not fully transitioned to lead-free solder assembly at this moment; however, most of the components used are

RoHS compliant.

The environment-friendly usage period of the product is assumed under the operating environment specied in each product’s

specication.

xiii

1693 RLC Digibridge

Abbreviated Specifications

ABBREVIATED

SPECIFICATIONS

Features

• The world’s de facto standard for ac resistance,

low-frequency inductance, and capacitance

measurement

• 0.02% accuracy for R,L,C, G, Z, and Y

• 0.0001 accuracy for Dissipation and Q

• 11 Impedance Parameters

• Programmable test frequencies from 12 Hz to

200 kHz for testing versatility

• Programmable test voltages from 5 mV to

1.275 V

• Dual display featuring 5-digit readout for RLC

and 4-digit readout for D and Q

• Extremely reliable: over 30 years of history

• Optional IEEE-488 interface allows test proto-

cols and results to be stored in PC’s

Applications

• High-end metrology applications

• Measuring impedance (inductance, capaci-

tance, and resistance)

• Testing and sorting electrical components based

on 11 possible parameters

• Optional IEEE-488 interface allows test proto-

cols and results to be stored in PC’s

Specications

Measurement parameters:

Eight combinations of parameters are measured:

R and Q, C and D, L and Q, C and R, R and X, G

and B, Z(magnitude) and angle and Y (magnitude)

and angle as selected by the R/Q, C/D, L/Q, or C/R

keys, or the SHIFT key and the R/X, G/B, Z/ang/

or Y/ang keys. Either series or parallel equivalent

circuit values are measured for R, C, and L as

selected by the EQUIVALENT CIRCUIT key.

Series values are measured for R and X combination

and parallel values are measured for G and B.

Parameter selection is initially made automatically

based on the DDT being measuring. Automatic

selection is inhibited once a specic parameter

key has been selected by the operator (but may be

restored).

Display format:

Dual display featuring 5 full digit LED for

RLCGZY and full digit LED for DQRXBΘ

Automatically positioned decimal points and minus

signs where appropriate

Individual LED indicators for parameters, and

measurement units

MEASURE displays:

When the MEASURE function has been selected,

either VALUE, ∆RLC, ∆% or BIN NO. may be

displayed.

VALUE display:

The VALUE display provides ve digits for

measured primary parameter (rst quantity in each

pair given above) four digits for secondary quantity

xiv

1693 RLC Digibridge

Abbreviated Specifications

(second parameter in each pair) with automatically

positioned decimal points, units of measurement

and minus signs when appropriate.

The ∆RLC display:

The ∆RLC display indicates the difference between

the measured R, L or C and a nominal value entered

by the user with appropriate units (Ω, µF etc.). The

R, L,or C difference display has ve digits with a

simultaneous four digit direct reading display of

D, Q, or R with automatically positioned decimal

points and minus signs when appropriate.

The ∆% display:

The ∆% display indicates the % deviation of the

measured primary quantity and the stored nominal

value. The display is ve digits with a maximum

resolution of one part per million with minus sign

when appropriate. The resolution of the DQ and

angle displays may also be increased by using the

DQ in PPM key which gives D or Q in ppm or angle

in microdegrees.

The BIN NO. display:

The BIN NO. display provides a single digit bin

assignment number based on the measured value

and user entered bin limits.

Measurement modes and rates:

There are two test modes, CONTINUOUS and

TRIGGERED. The CONTINUOUS mode makes

successive measurements continually, updating

the display after each measurement. TRIGGERED

measurements are initiated by the START button or

remotely from the IEEE bus and the result held until

another measurement is started.

There are three measurement rates selected by

single keys; SLOW, MEDIUM and FAST whose

measurement times depend on the test frequency

(see table below for C and D, L and Q, or R and Q

speeds). Other measurement rates may be selected

by programming the integration time, AVERAGING

to 255 measurements or adding a programmed

DELAY of 1 to 99999 ms.

The measurement times in the following table

were obtained with the use of the high-speed

measurement option, continuous measurement

mode, bin number display, and without IEEE-Bus

data output. For other conditions refer to the notes

below the table.

If the measurement mode is triggered, programmed

delay (settling time), if any, should be added.

Normal power up conditions include a programmed

delay of 7/f to 12/f ms depending upon

measurement rate. This delay can be programmed to

zero or any value up to 100 s.

Measurement

Rate 12 Hz 100 Hz 120 Hz 1 kHz 10 kHz 100 kHz 200 kHz

SLOW 899 ms 944 ms 944 ms 974 ms 944 ms 944 ms 944 ms

MEDIUM 694 ms 144 ms 194 ms 204 ms 194 ms 194 ms 194 ms

FAST 694 ms 129 ms 114 ms 89 ms 79 ms 79 ms 79 ms

MAXIMUM 672 ms 113 ms* 98 ms* 44 ms 34 ms 34 ms 34 ms

*These times can be shortened by 14ms by using the special quick acquisition routine.

Notes:

1. If the display is value, ∆%or ∆RLC, add 3 to 5 ms.

2. If data is output via the IEEE Bus, add 3 to 6 ms.

3. Speed in the table far e for C with D, L with Q or R with Q measurements.

Table-A: Measurement Rate

xv

1693 RLC Digibridge

Abbreviated Specifications

Test frequencies:

Over ve hundred test frequencies between 12 Hz

and 200 kHz may be selected by keyboard entry.

These are:

f = 200 kHz/n, where n = 1 to 13

f = 60 kHz/n, where n = 4 to 256

f= 3 kHz/n, where n = 13 to 250

For example frequencies that can be selected:

200 kHz/1 = 200 kHz

200 kHz/2 = 100 kHz

....

200 kHz/13 = 15.384.6 kHz

If the exact frequency selected is not available, the

nearest available frequency is used. The accuracy of

the test frequency is better than .01%.

Applied Voltages:

5 mV to 1.275 V (programmable in 5 mV steps).

The open circuit voltage accuracy is (5% + 2mV)

(1 + .001f2) where f is the frequency in kHz.

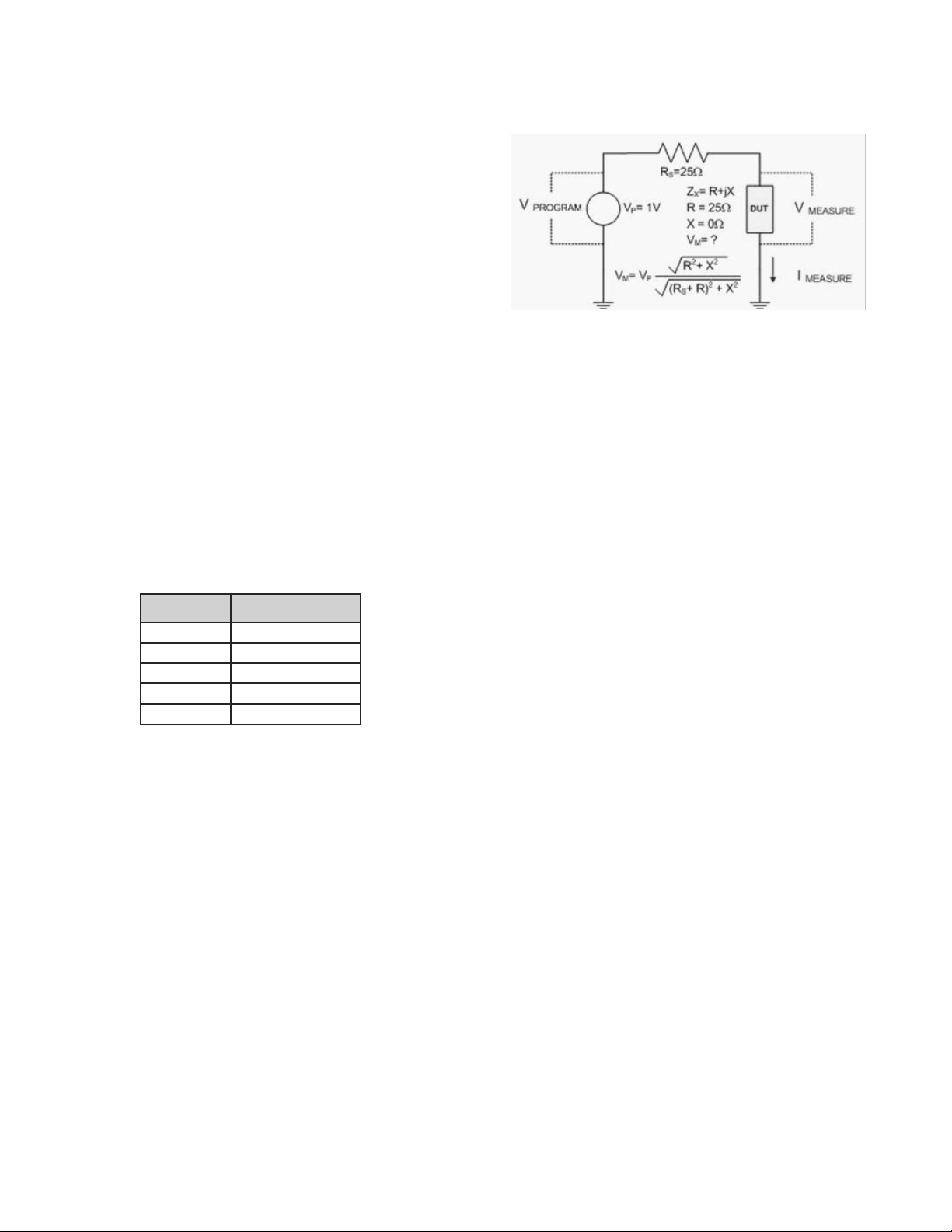

This voltage has a source impedance that depends

on the range. A CONSTANT VOLTAGE mode can

be selected which provides a low source impedance

(25 ohms) in order to maintain a constant ac test

level over a wider impedance range.

Range Source Resistance/

Impedance

1 97.4 kΩ

2 6.4 kΩ

3 400 Ω

4 25 Ω

Constant Voltage 25 Ω

Table-B: Range versus internal source

resistance

The programmed level is obtained under an open

circuit condition. The actually applied voltage can

be determined as follows.

A source resistance (Rs, internal to the meter) is

effectively connected in series with the AC output

and there is a voltage drop across this resistor. When

a test device is connected, the voltage applied to the

device depends on the value of the source resistor

(Rs) and the impedance value of the device. As an

example, where Range 4 is used which has a source

impedance Rs of 25 ohms and the programmed

voltage is 1 V but the voltage to the DUT is 0.5 V.

Figure-A: Source Impedance Factors

Internal dc bias is 2 V. External dc bias of up to

60 V may be applied.

Calibrations

An OPEN circuit zero calibration can be performed

to remove the effects of stray capacitance and

conductance shunting the internal test xture or any

other xture or cable connection . A similar SHORT

circuit zero calibration can be performed to remove

the effects of resistance and inductance in series in

the test connections . New zero calibrations should

be made to obtain best accuracy whenever the test

frequency or the xture geometry is changed. A

complete recalibration of the internal standards

for each measurement range may be performed by

using the optional 1689-9604 Calibration Kit and

either a 1689-9600 Test Fixture.

Impedance Ranges:

The direct reading display ranges for R, L. C, G,

|Z| and |Y| are given in Table A. These ranges may

be extended by using the RATIO mode which

multiplies or divides the measured result by an

entered number but does not display a unit. These

extended ranges are also shown. These ranges

exceed by far any practical values and the accuracy

capability of the instrument. The D and Q ranges are

not changed by the RATIO mode, nor is the range of

R when displayed with C, X with R or B with G.

xvi

1693 RLC Digibridge

Abbreviated Specifications

Parameter Direct Reading

Range Ratio and DQ in PPM

R and [Z] 0.00001 Ω to

99999 kΩ

0.00010 Ω to 9999.9 GΩ

L0.00001 mH to

99999 H

0.00010 nH to 9999.9 MH

C0.00001 pF to

99999 µF

0.00010 aF to 9999.9 F

G and [Y] 0.00001 µS to

99999 S

0.00010 pS to 9999.9 MS

R with C

0.0001 Ω to

9999 kΩ

not extended

X with R

0.0001 Ω to

9999 kΩ

not extended

B with G 0.0001 µS to

9999 S

not extended

D with C 0.0001 to 9999 1 to 9999 ppm

Q with R or L 0.0001 to 9999 1 to 9999 ppm

Angle ±0.0001° to 180° ±1 to 999 microdegrees

Table-C: Impedance ranges

Range selection:

Autoranging with manual hold

Basic accuracy*:

Basic RLCGZY: ±0.02%

Basic QD: ±0.0002 (±0.0001 in PPM mode)

Basic RXB: ±0.02%

Θ: ±0.01°

*See accuracy formulas below for actual accuracy based

upon instrument conguration and DUT.

Limit of error (accuracy):

The specied limit of error is given below for

all conditions (except constant voltage, for this

condition add 2 inside the brackets). Rx, Cx, Lx etc.

are the measured values, f is the frequency in kHz.

The range constants Rmax, Lmax, Cmin, Gmin etc

are given in Table-D. The constants Ks and Kfv

are given in Tables 0 and D. Note that for SLOW

measurements at 1kHz and 1 V with non constant

voltage these K constants are all zero and that f =1.

Accuracy of primary parameters (left readout):

To obtain accuracy, IET offers a convenient tool at: http://www.ietlabs.com/notes/digibridge_accuracy_

calculator. This tool is equivalent to the calculations shown for both primary and secondary parameters.

Note: This calculation tool is applicable for both 1689 and 1693 Digibridge modles.

Table A Direct Reading Display Ranges for R,L,C,G,|Z|, and |Y|

Insert from Datasheet: Ranges Table

Limit of Error (accuracy):

The specified limit of error is given below for all conditions (except constant voltage, for

this condition add 2 inside the brackets). Rx, Cx, Lx etc. are the measured values, f is

the frequency in kHz. The range constants Rmax, Lmax, Cmin, Gmin etc are given in

Table B. The constants Ks and Kfv are given in Tables 0 and D. Note that for SLOW

measurements at 1kHz and 1 V with non constant voltage these K constants are all

zero and that f =1.

Primary parameters (lefthand readout):

)

)

)

)

)

)

To obtain accuracy, IET offers a convenient tool at:

http://www.ietlabs.com/notes/digibridge_accuracy_calculator.

This tool is equivalent to the calculations shown for both primary and secondary

parameters.

xvii

1693 RLC Digibridge

Abbreviated Specifications

Accuracy of secondary parameters (right readout):

~ Remove this term of 0.0001, if DQ in PPM mode is used.

Secondary parameters (righthand readout)

)

)

)

)

)

~ Remove this term of 0.0001, if DQ in PPM mode is used.

Notes :

1. It is assumed that both that OPEN and SHORT zeroing calibrations

are made at the test frequency used.

2. Accuracy applies for measurements made using the 1689-9602 Extender

CabLewith or without the 1689-9600 or 1689-9605 Test Fixture.

Table B High-Impedance Range Constants vs Frequency

Constants 12Hz to 20kHz >20kHz to 200kHz

Rmax, Zmax, Xmax: 1 Mohm 60 kohm

Lmax 160 H 10 H

Cmin 160 pF 3 nF

Gmin, Ymin, Bmin 1 uS 15 uS

Table C Ks as a Function of Measurement Rate

Measurement

Rate

Slow

Medium

Fast

Maximum*

Ks

0

3

8

23

* = Maximum is FAST measurement mode with minimum integration time.

Notes :

1. It is assumed that both that OPEN and SHORT

zeroing calibrations are made at the test frequency

used.

2. Accuracy applies for measurements made using

the 1689-9602 Extender Cable with or without the

1689-9600 or 1689-9605 Test Fixture.

High-Impedance range constants vs frequency:

Constants 12 Hz to 20 kHz >20 kHz to 200 kHz

Rmax, Zmax, Xmax: 1 MΩ 60 kΩ

Lmax 160 H 10 H

Cmin 160 pF 3 nF

Gmin, Ymin, Bmin 1 µS 15 µS

Ks as a function of measurement rate:

Measurement Rate Ks

Slow 0

Medium 3

Fast 8

Maximum* 23

* = Maximum is FAST measurement mode with minimum

integration time.

xviii

1693 RLC Digibridge

Abbreviated Specifications

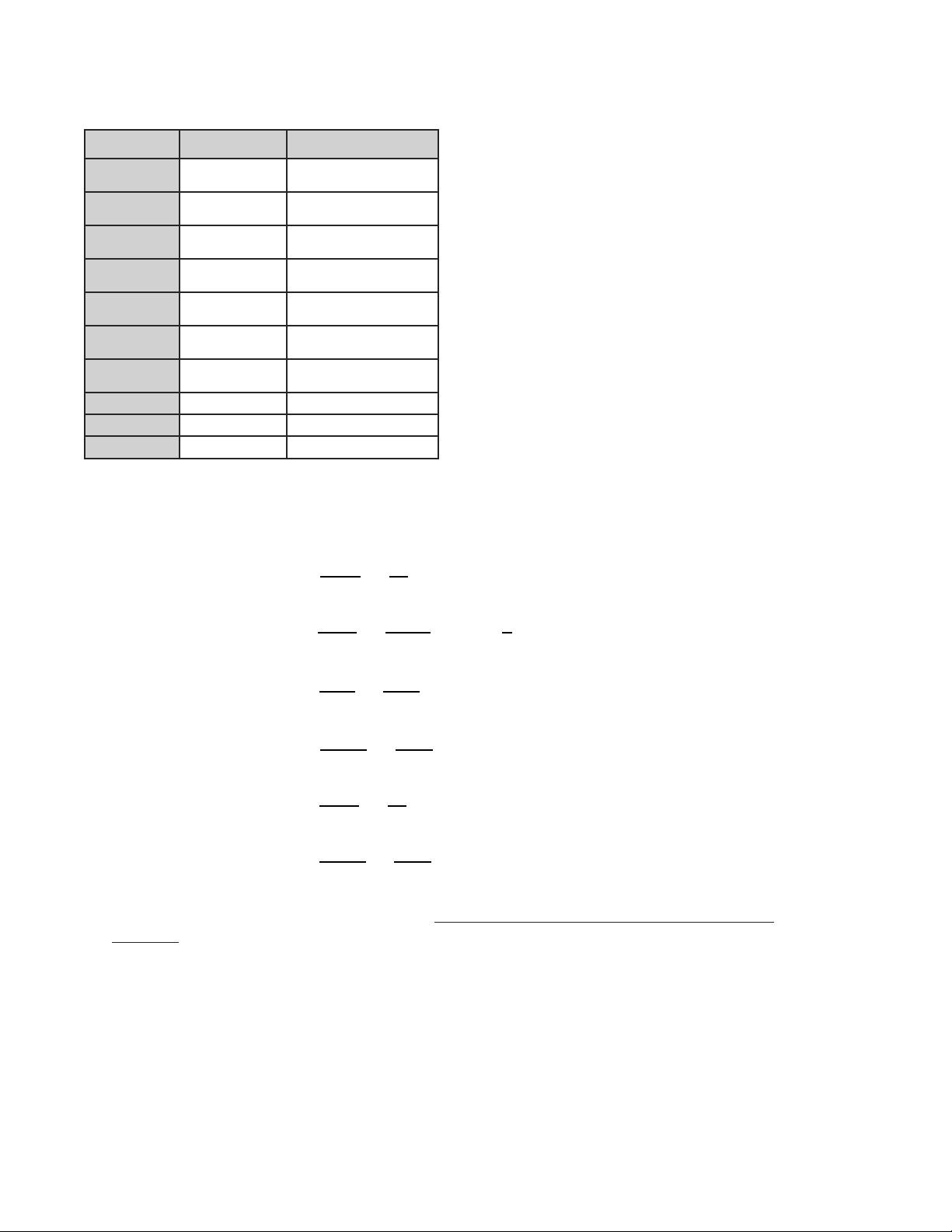

Kfv as a Function of Frequency and RMS Voltage:

Frequency

12 Hz to

<30 Hz

30 Hz to

<100 Hz

100 Hz to

<250 Hz

250 Hz to

<1 kHz 1 kHz >1 kHz to

3 kHz

>3 kHz to

6 kHz*

>6 kHz to

10 kHz*

>10 kHz to

20 kHz*

>20 kHz to

50 kHz*

>20 kHz

to 50 kHz* 200 kHz

1 V to 1.275 V AC Applied Voltage

5 3 2 1 0 1 1* 3* 5* 8 18 70

0.25 V to < 1 V AC Applied Voltage

8 5 3 2 1 2 2* 4* 6* 12 25 80

0.1 V to < 0.25 V AC Applied Voltage

12 8 6 5 4 5 6* 8* 10* 20 50 100

0.03 V to < 0.1 V AC Applied Voltage

35 30 25 20 14 15 15* 20* 25* 40 100 **

0.01 V to < 0.03 V AC Applied Voltage

90 80 70 60 50 50 50* 50* 60* 70 ** **

* Multiply Kfv values by 5 from 3kHz to 20kHz for Range 1 (Z > 25 kohms)

** Not Specied

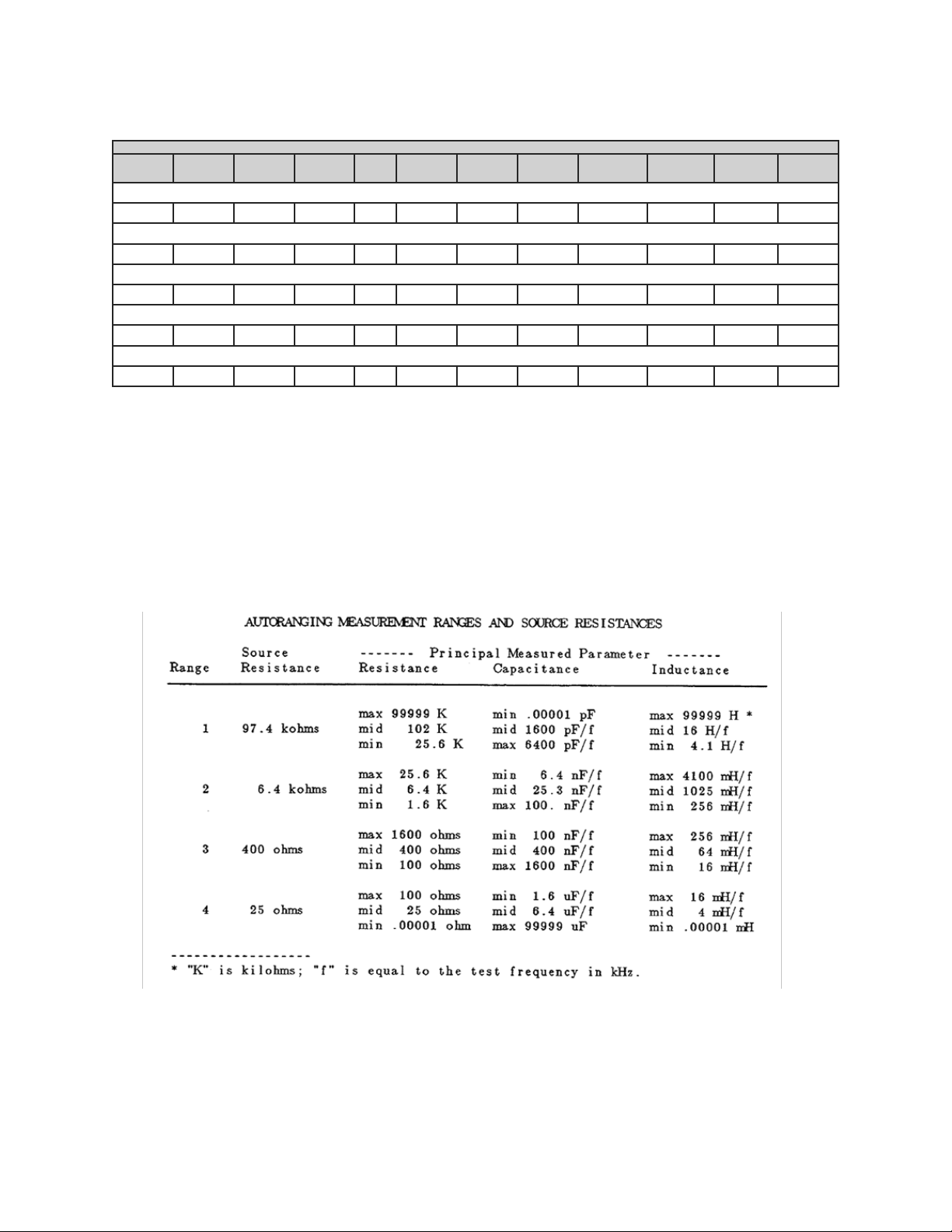

Measurement ranges and source impedance/

resistance:

The 1693 has 4 measurement ranges, Range 1 to

Range 4, that have specic source resistance. The

Ranges can be automatically or manually selected.

The source resistance does reduce the AC signal

applied to the DUT.

Table of contents