T1000A OPERATOR MANUAL

viii

CONTENTS

DECLARATIONS............................................................................................................. i

ELECTROMAGNETIC COMPATIBILITY......................................................................ii

European Community Directive Conformance Statement.........................................ii

SAFETY......................................................................................................................... iii

WARNING...................................................................................................................iii

GROUNDING ..............................................................................................................iii

POWER SUPPLY........................................................................................................iv

T1000A OPERATION..................................................................................................iv

CAUTION.....................................................................................................................iv

Electrical Isolation..............................................................................................iv

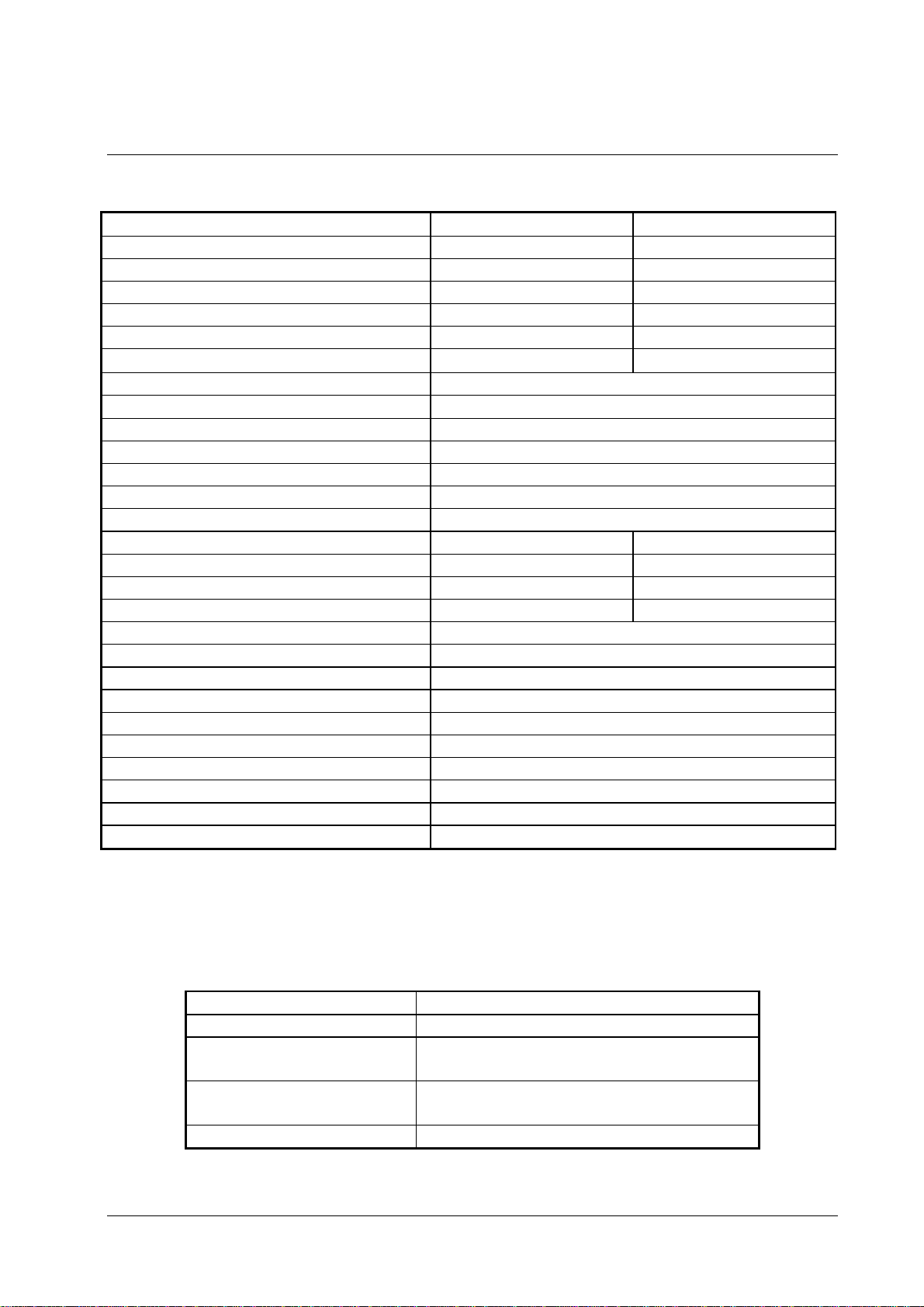

SPECIFICATIONS..........................................................................................................iv

ENVIRONMENTAL OPERATING CONDITIONS .........................................................v

ACCESSORIES...........................................................................................................vi

Standard Accessories...............................................................................................vi

SYMBOLS ...................................................................................................................vi

SECTION 1 – INTRODUCTION................................................................................... 1-1

THE T1000A FAULT LOCATOR.............................................................................. 1-1

1-1 Introduction to the T1000A.............................................................................. 1-1

1-2 Areas of application......................................................................................... 1-1

1-3 Analog Signature Analysis...............................................................................1-1

1-4 The T1000A transistor curve tracer.................................................................1-2

SECTION 2 – GENERAL DESCRIPTION................................................................... 2-1

PRINCIPLES OF OPERATION ................................................................................2-1

2-1 Controls, connectors and probes .................................................................... 2-1

The T1000A front panel..................................................................................2-1

CURVE TRACE section...............................................................................2-1

ASA section................................................................................................. 2-1

The T1000A rear panel...................................................................................2-1

2-2 Producing signatures....................................................................................... 2-2

2-3 Four-quadrant signatures................................................................................2-2

2-4 The T1000A equivalent circuit......................................................................... 2-3

2-5 Producing transistor curves............................................................................. 2-4

Bipolar junction transistors.............................................................................. 2-4

Field effect transistors..................................................................................... 2-4