2

Contents

1 Preliminary note���������������������������������������������������������������������������������������������������4

1�1 Symbols used ������������������������������������������������������������������������������������������������4

2 Safety instructions �����������������������������������������������������������������������������������������������4

3 Items supplied������������������������������������������������������������������������������������������������������5

4 Functions and features ����������������������������������������������������������������������������������������5

4�1 Applications ���������������������������������������������������������������������������������������������������5

4�2 Restriction of the application area ����������������������������������������������������������������6

5 Getting started �����������������������������������������������������������������������������������������������������6

5�1 Example configuration �����������������������������������������������������������������������������������7

6 Function���������������������������������������������������������������������������������������������������������������8

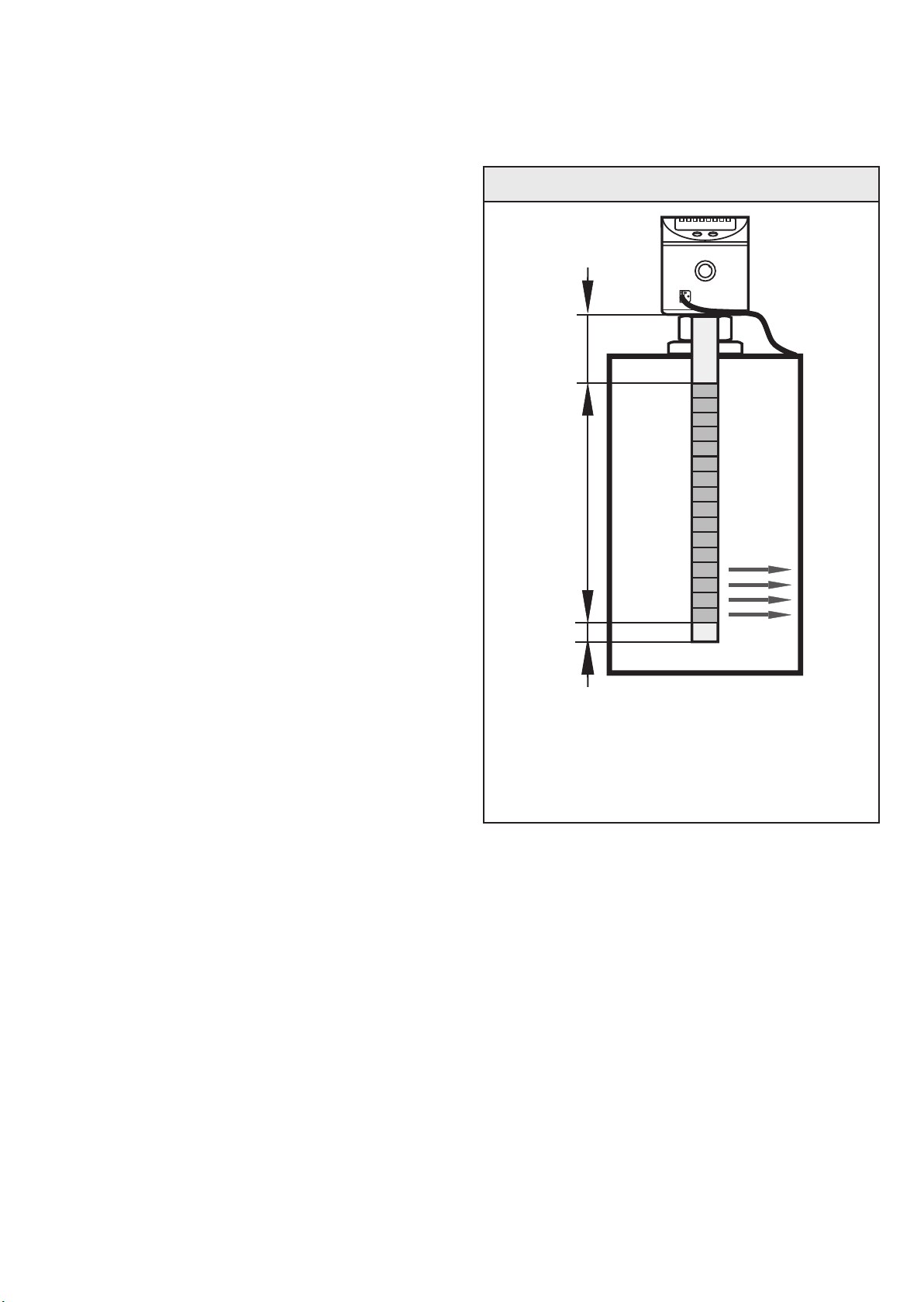

6�1 Measuring principle ���������������������������������������������������������������������������������������8

6�2 Operating principle / features of the unit��������������������������������������������������������9

6�2�1 Notes on the integrated overflow prevention ����������������������������������������9

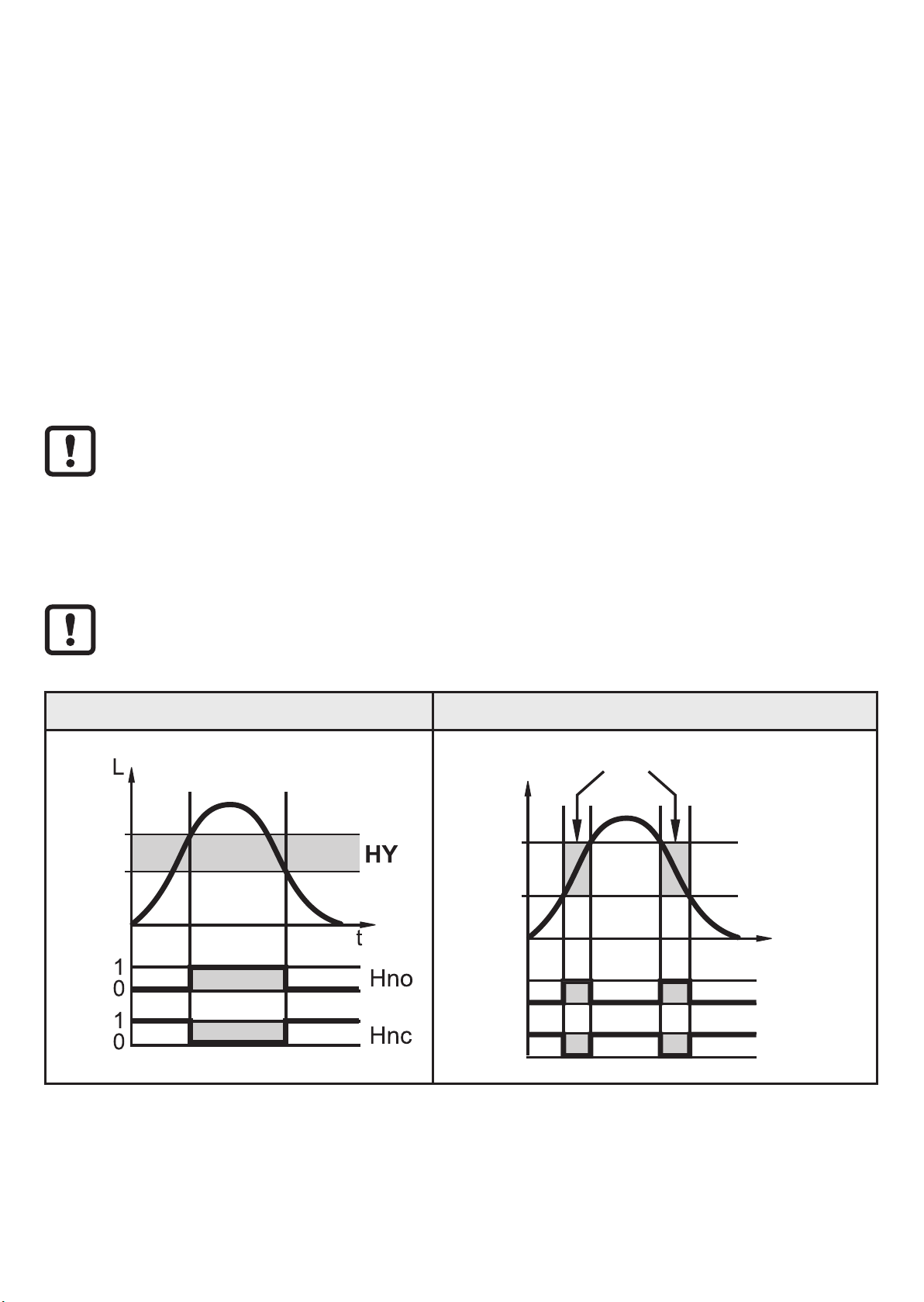

6�2�2 Display and switching functions����������������������������������������������������������10

6�2�3 Offset for indicating the real level in the tank�������������������������������������� 11

6�2�4 Defined state in case of a fault ����������������������������������������������������������� 11

6�2�5 IO-Link function ���������������������������������������������������������������������������������� 11

6�3 Password protection against inadvertent manipulation �������������������������������12

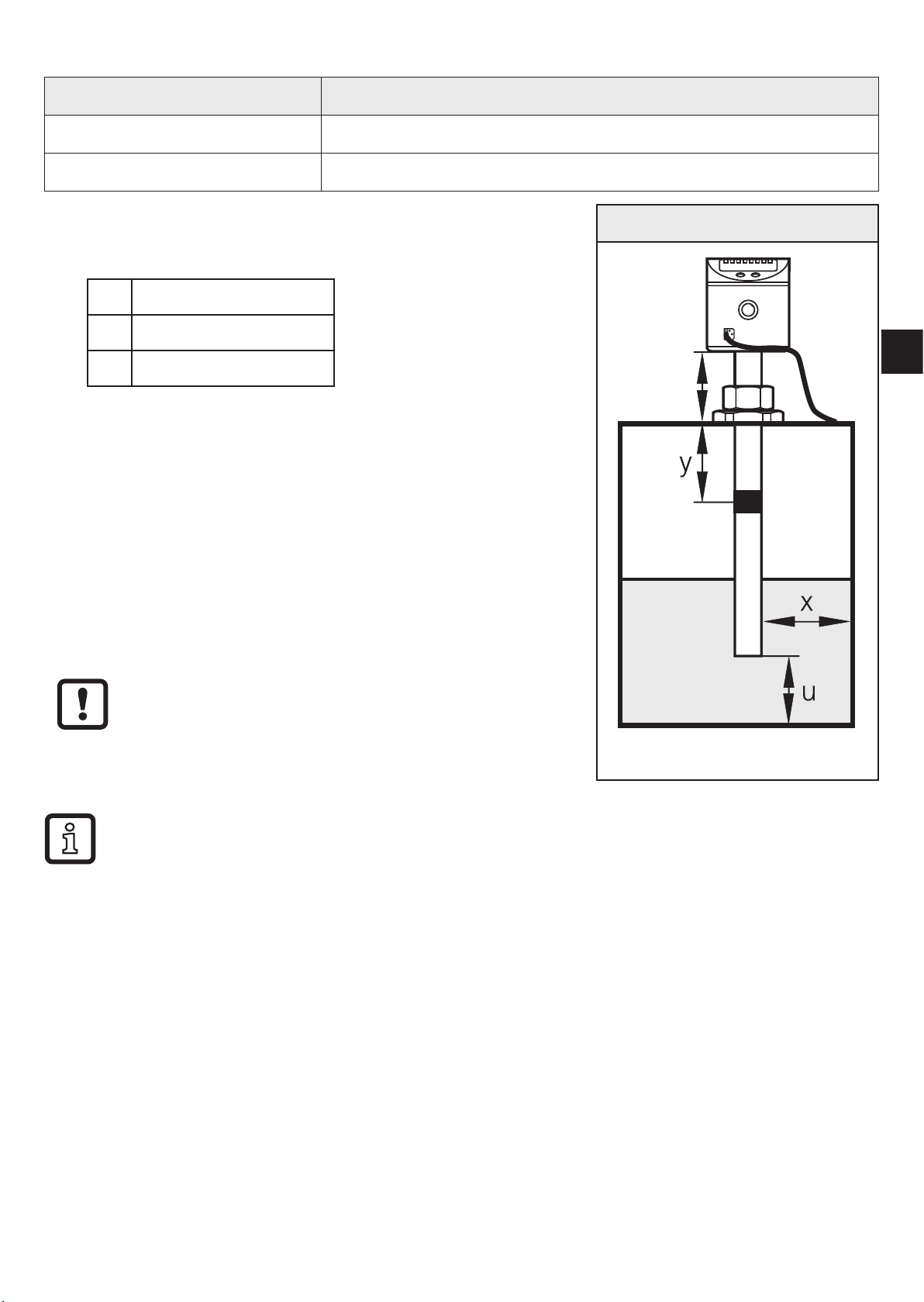

7 Installation����������������������������������������������������������������������������������������������������������12

7�1 Other installation notes��������������������������������������������������������������������������������14

7�1�1 Marking of the installation height �������������������������������������������������������14

8 Electrical connection������������������������������������������������������������������������������������������15

9 Operating and display elements ������������������������������������������������������������������������16

10 Menu����������������������������������������������������������������������������������������������������������������17

10�1 Menu structure�������������������������������������������������������������������������������������������17

10�2 Password protection ����������������������������������������������������������������������������������18

11 Parameter setting���������������������������������������������������������������������������������������������18

11�1 Parameter setting in general����������������������������������������������������������������������18

11�2 Basic settings ��������������������������������������������������������������������������������������������19

11�2�1 Set unit of measurement [uni]�����������������������������������������������������������19

11�2�2 Set offset [OFS] ��������������������������������������������������������������������������������19