IFR NAVAIR NAV-750 User manual

ME~

REV]

N

N

TECHNICAL

MANUAL

c~Jr,

2

I

INSTRUMENT

CALIBRATION

PROCEDURE

VOR/LOCICOMM

AND

G/S

BENCH

TEST SETS

IFR

INC.

NAV-750,

NAV-750A,

AND NAV-750B

DISTRIBUTION

WITHIN GIDEP

IS

AUTHORIZED

BY

NAVAL

WEAPONS

STATION,

SEAL

BEACH

LETTER,

SER

313/0994

DATED

14

MAY

1987

THIS

PUBLICATION

SUPERSEDES

NAVAIR

17—2OAX—737

DATED

1

JULY

1991

DISTRIBUTION

STATEMENT

C.

DISTRIBUTION

AUTHORIZED

TO

U.S.

GOVERNMENT

AGENCIES

AND

THEIR

CONTRACTORS

TO

PROTECT

PUBLICATIONS

REQUIRED

FOR

OFFICIAL

USE

OR

FOR

ADMINISTRATIVE

OROPERATIONAL

PURPOSES

ONLY.

OTHER

REQUESTS

FOR

THIS

DOCUMENT

SHALL

BE

REFERRED

TO

NAVY

MEASUREMENT

SCIENCEDIRECTORATE,

NAVAL

WARFARE

ASSESSMENT

DIVISION,

P0.

BOX

5000

CORONA.

CA

91718-5000

DESTRUCTION

NOTICE-

FORUNCLASSIFIED,

LIMITED

DOCUMENTS,

DESTROY

BY

ANY

METHOD

THAT

WILL

PREVENTDISCLOSURE

OF

CONTENTS

OR

“RECONSTRUCTION

OF

THE

DOCUMENT”

PUBLISHED

BY

DIRECTION OF

COMMANDER

NAVAL

AIR

SYSTEMS

COMMAND

1

AUGUST

1995

[BUL

This

document

has

been

modified

primarily

for

the

purpose

of

incorporating

changes

[SION

previously

identified

in

the

Metrology Bulletin

(METBUL)

as

unpublished

procedure

[‘ICE

changes.

NAVAIR

17-2OAX-737

Section

3

4

4.1

4.2

4.3

4.4

4.5

4.6

4.7

4.8

4.9

4.10

4.11

4.12

4.13

4.14

4.15

TABLE

OF CONTENTS

NAVAIR

17—2OAX—737

Page

1

4

6

7

7

8

9

10

11

14

15

18

18

19

20

20

22

24

27

29

1

Introduction

and

Description

Equipment

Requirements

Preliminary

Operations

Calibration

Process

Frequency

Accuracy

Tests

Attenuator

FrequencyResponse

Tests

Attenuator

Line

aritv

Tests

DEMOD

Tones

and DC

OFFSET

Tests

Tone

Frequency

Tests

Tone

Distortion

Tests

Percent

Amplitude

Modulation

ofTones and

ModulationMeter

Tests

RF

Level

Meter

Tests

VOR

Bearing

Tests

LOC

Centering

Test

GIS

Centering

Test

Spectral

Purity

Tests

(NAV—750

only)

Spectral

Purity

Tests

(NAV—750A

only)

Spectral

Purity

Tests

(NAV—750B

only)

Residual

FM

Tests

Navy

Calibration

Checklist

ILLUSTRATIONS

Page

FM

Deviation

Display

12

9960

Hz

Deviation

(Expanded)

13

TABLES

Page

Calibration

Description

Figure

1

2

Table

1

NAVAIR

17—2OAX—737

SECTION

1

INTRODUCTIONAND

DESCRIPTION

1.1

This

procedure

describes

the

calibration

of

IFR

Inc.

NAV—750,

NAV—750A,

NAV—750B

VOR/LOC/COMM

and

G/S

Bench

Test

Sets.

The

instrument

being

calibrated

is

referred

to

herein

as

the

TI (Test

Instrument).

1.2

This

procedure

wasderived

from

draft

prepared

by

NADEP

Cherry

Point.

All

comments

concerning

this

procedure

should

be

directed

to

Navy

Measurement

Science

Directorate,

Naval

Warfare

Assessment

Division,

P.O.

Box 5000,

Corona,

CA

91718—5000.

1.3

This

procedure

includes

tests

of

essentialperformance

parameters

only. Any

malfunctionnoticed

duringcalibration,

whether

specifically

tested

for

or not,

should

be

corrected.

DEMOD

tones

DC

offset

Frequency

range:

108.000

to

335.000

MI-Iz;

(70.000

to

79.000,

NAV—750B

only)

Tolerance:

±1

ppm

Range:

70.0

MHz

to

335.0

MHz

Tolerance:

±1.5

dB

@

—6

dBm

to

-50

dBm;

±2.5

dB

@

-51

dBm

to

—120

dBm

Range:

—6

to

—50

dBm

Tolerance:

±1.5

dB

Range:

—51

to

—120

dBm

Tolerance:

±2.5

dB

Tone

frequencies:

30, 90,

150,

1020,

and

9960

Hz

DC

offset: +40 mV

to

—40

mV dc

Tone

Frequencies:

400,

1300,

and

3000

Hz

DC

offset: +80 mV

to

—80

mV dc

Tone

frequencies:

30,

90,

150,

and

9960

Hz

Tolerance:

±0.02%

Tone

frequency:

1020

Hz

Tolerance:

±0.5%

Tone

frequencies:

400,

1300,

and

3000

Hz

Tolerance:

±0.7%

Tone

frequencies:

90

and

150

Hz

Tolerance:

±0.4%

Tone

frequencies:

30

and

1020

Hz

Tolerance:

±0.5%

Tone

frequencies:

400,

1300,

and

3000

Hz

Tolerance:

±0.7%

Measured

with

an

electronic

counter.

Attenuatoroutput

monitored

by

a

power

meter

while

the

frequency

is

verified.

Attenuatoroutput

measured

with

a

signal

analyzer.

Offset

measured

using

a

digital

multimeter.

Measured

with

an

electronic

counter.

Table

1.

Calibration

Description

TI

Characteristics

Performance

Specifications

Test

Method

Frequency

accuracy

Attenuator

frequency

response

Attenuator

linearity

Tone

frequency

Tone

distortion

Measured

with

a

signal

analyzer.

1

NAVAIR

11—2OAX—737

Harmonic

spurious

noise

VOR

30

Hz: 20% AM

Tolerance:

±1.2%

VOR

9960

Hz: 30% AM

Tolerance:

±1.2%

LOC

90

Hz: 20% AM

Tolerance:

±0.8%

LOC

150

Hz: 20% AM

Tolerance:

±0.8%

G/S

90

Hz: 40%

AM

Tolerance:

±1.6%

G/S

150

Hz: 40% AM

Tolerance:

±1.6%

Comm

1020

Hz: 30% AM

Tolerance:

±1.2%

Range:

0 to 30% AM

Tolerance:

@

20%,

±0.8%;

@

30%,

±1.2%

Range:

0

to

100%

AM

Tolerance:

@

40%,

±1.6%;

@

95%,

±3.0%

Frequency

range:

108.000

to

335.000

MHz;

(70.000

to

79.000

MHz,

NAV—750B

only)

Tolerance:

±1.5

needle widths

Bearing

range:

00 to

360°

Tolerance:

±0.05%

Tone

frequencies:

90

and

150

Hz

Tolerance:

±2.75

mV

>30 dBc

from

108.000

to

335.000

MHz;

(>20

dBc

from

70.000

to

79.000

MHz,

NAV—750B

only)

NAV—750

only

Frequency:

108.000

MHz

Tolerance:

>68 dB

below

carrier

@

±12.5

kHz, and ~71

dB

below

carrier

~

±25.0

kHz

in

300

Hz

resolution

bandwidth

Frequency:

334.700

MHz

Tolerance:

~63

dB

below

carrier

@

±12.5

kHz,

and

74

dB

below

carrier

@

±15.0

kHz

in

300

Hz

resolutionbandwidth

Modulation

meter

indication

is

compared

to

signal

generator

calibrator

indication.

Frequency

varied

and

meter

monitored

for

deflection.

Compared

to

a

bearing

standard.

Measured

with

a digital

multimeter.

Measured

with

a

spectrum

analyzer.

Measured

with

a

spectrum

analyzer.

TI

Characteristics

Performance

Specifications

Test

Method

Measured

with

a

signal

analyzer.

Tone

modulation

Modulation

meter

Meter

RF

level

Bearing

LOC-G/S

Harmonics

2

NAVAIR

17—2OAX—737

Frequency:

108.000

MHz

Tolerance:

75

dB

below

carrier

@

±12.5

kHz,

and

~83

dB

below

carrier

@

±25.0

kHz

in

300

Hz

resolutionbandwidth

NAV-750Aonly

Frequency:

334.700

MHz

Tolerance:

66

dB

below

carrier

@

±12.5

kHz,

and

77

dB

below

carrier

@

±25.0

kHz

in

300

Hz

resolutionbandwidth

NAV—750B

only

Frequency:

334.700

MHz

Tolerance:

>75

dB

below

carrier

@

±12.5

kHz,

and

~83 dB

below

carrier

@

±25.0

kHz

in

300

Hz

resolution

bandwidth

NAV—750

only

Frequency:

108.000

MHz

Tolerance:

14

dB

below

carrier

@

±20

kHz

in

300

Hz

resolutionbandwidth

Frequency:

334.700

MHz

Tolerance:

68

dB

below

carrier

@

±20

kHz

in

300

Hz

resolutionbandwidth

NAV-750A

and

NAV-750B

Frequency:

108.000

MHz

Tolerance:

~78 dB

below

carrier

@

±15

kHz

in

300

Hz

resolution

bandwidth

Frequency:

334.700

MHz

Tolerance:

>74

dB

below

carrier

@

±20

kHz

in

300

Hz

resolutionbandwidth

NAV-750Aonly

Frequency:

130.000

MHz

Tolerance:

.78

dB

below

carrier

@

±15

kHz

in

300

Hz

resolutionbandwidth

NAV-750and

NAV-750B

Frequency:

108.000

MHz

Tolerance:

~80

dB

below

carrier

@

±100

kHz

in

1

kHz

resolutionbandwidth

TI

Characteristics

Performance

Specifications

Test

Method

NAV-750A

and

NAV-750B

Single—sideband

noise

Broadband

noise

Measured

with

a

spectrum

analyzer.

Measured

with

a

spectrum

analyzer.

3

NAVAIR

17—2OAX—737

TI

Characteristics

Performance

Specifications

Test

Method

NAV-750

and

NAV-750B

Frequency:

334.000

MHz

Tolerance:

>80

dB

below

carrier

@

±100

kHz

in

1

kHz

resolutionbandwidth

NAV—750A

only

Frequency:

108.000

MHz

Tolerance:

>82dB

below

carrier

@

±100

kHz

in

1

kHz

resolutionbandwidth

Frequency:

334.000

MHz

Tolerance:

>82

dB

below

carrier

@

±100

kHz

in

1

kHz

resolutionbandwidth

Residual

FM

Frequency:

108.000

MHz

Residual

FM: ~200

Hz

Frequency:

334.700

MHz

Residual

FM:

~.400

Hz

Measured

with

a

signal

generator

RF

Type

N

Centerconnector

depthrange:

Measured

using

a

connector

connector

dimensions

0.197 inch

Tolerance:

±0.01

inch

(MIL—C—71B)

gage

kit

SECTION

2

EQUIPMENT

REQUIREMENTS

NOTE

Minimum

use

specifications

are

the

principal

parameters

requiredfor

performance

of

the

calibration,

and

are

included

to

assist

in the

selection

of

alternateequipment,

which maybe

used

at the

discretion

ofthe

using

laboratory. Satisfactory

performance

of

alternate

items

shall

be

verified

prior

to

use.

All

applicable

equipment

must

bear

evidence

of

current

calibration.

Theinstruments

utilized

in this

procedure

were

selected

from those

known

to

be

available

at

Navy

calibration

facilities,

and

the listing

by

make

or

model

number

carries

no

implication

of

preference,

recommendation,

or

approvalfor

use

by

other

agencies.

It is

recognized

that

equivalentequipmentproduced

by

other

manufacturers

may be

capable

of

equally

satisfactory

performance

in this

procedure.

I

4

NAVAIR

17—2OAX—737

2.2

Electronic

counter

2.3

Digital

multimeter

(DMM)

2.4

Power

meter/power

sensor

2.5

Signal

generator

calibrator

2.7

Navigation

indicator

T/S

2.8

Spectrum

analyzer

2.9

Connector

gage

kit

*Non_NCE

equipment

Bandwidth:

50

MHz

Uncertainty:

±3%

timebase

Dualtrace

and

delayed

sweep

capability

Frequency

range:

25

Hz

to

335

MHz

Uncertainty:

±0.25

ppm

Resolution:

1

Hz

DC

voltage

range:

0

to

±80

mV dc

Uncertainty:

±1%

Powerrange:

—25

to

—35

dBm

Uncertainty:

±1.25%

Frequency

range:

70

to

335

MHz

Frequency

range:

108

to

118

MHz

Tuned

RF

level

rang:

e—6

to

—100

dBm

Uncertainty:

±0.35

dB

AM modulation

range:

15%

to

100% AM

Uncertainty:

±1%

AM

FM

modulation

range:

<200

Hz

to

400

Hz

FM

Uncertainty:

±2%

Capable

of

measuringdistortion

down

to

0.1%

with

0.01%

resolution

No

known

substitute

Range:

50

MHz

to

1.2

GHz

Resolution:

300

Hz

mm

Dynamic

range:

>85

dB

Range:

0

to

0.197 inch

Uncertainty:

±0.0025

inch

(MIL—C--71B)

Tektronix

7704AM0D

1

29GOPTO3,

7904AOPT03

or

7704AM0D129G

with

7A26

and

7B92A

plug—ins

Hewlett—Packard

5335A0PT010,

030,

040,

5345A0PT012,

or 5345A

Fluke

8SO6AAN,

8502AAT,

or

884OAAFOPTO5

Hewlett—Packard

436A0PT022,

436A, or

435A

with

8484A

Hewlett—Packard

8902A0PTE02

(consists

of:

H-P

8902A0PT002;

and

H—P

11722A) or

8902A0PTE04

(consists

of:

H—P8902A;

H—P

8672AOPT001,

008;

H—P

11792A0PT001,H04;

and

H—P

1

1793A0PTH04)

Sound

Technology

1700BOPTOO3, 005;

or

Hewlett—Packard

8903B0PT050,

907, 910,

or

8903BOPT907

Collins

478A—3

ZIFOR

111*

Hewlett—Packard

8562A0PTE50,

8569BOPT001,

or 8566B

Maury

Microwave

AOO7B,

AOO7A

2.1

Oscilloscope

Item

Minimum

Use

Specifications

Calibration

Equipment

2.6

Distortion

analyzer

5

NAVAIR

17—2OAX--737

SECTION

3

PRELIMINARY

OPERATIONS

3.1

Ensure

that

all

power

switches

are set

to

off,

and

set

all

auxiliary

equipment

controls

as

necessary

to

avoid

damage

to

the

equipment

and

so that

dangerous

voltages

will

not

be

present

on

output

terminals

when

the

power

switches

are

turned

on.

3.2

Connect

the

auxiliary

equipment,

and

theTI,

to

theappropriatepower

source.

3.3

Verify

that

the

TI

panel

meter

indicateszero.

If

the

TI

meter

does

not

indicate

zero,

adjustthe

TI

meter

mechanical

screw

adjustment

for

a

zero

scale indication. (Perform

adjustment

only

after

TI has

been

off for

at

least

30

minutes.)

3.4

Setthe

TI

controls

as

follows:

TO—FROM

bearing

switch

to

Meter

function

switch

to

MASTER

MOD

control

to

1020

Hz

indent

tone

MOD

control

to

9960

Hz

FM

tone

MOD

control

to

30

Hz

tone

MOD

control

to

.01—.05

degree

bearing

switch

to

LOC

DDM

switch

to

LOC

variable

DDM

control

to

LOC—GIS

frequency

switch

to

G/S

DDM

switch

to

G/S

variable

DDM

control

to

FREQUENCY

MHz

switches

to

Channeling

frequencyincrement

switch

to

AUTO-MANUAL

switch

to

CHANNELING

rate

control

to

~F

control

to

BEARING—FREQ

display

select

switch

to

Attenuator

control

to

FROM

0—100

or

OFF

CAL

(UNCAL

lamp

off)

CAL

(UNCAL

lamp

off)

CAL

(UNCAL

lamp

off)

CAL

(UNCAL

lamp

off)

.01

0

0

LOC

0

0

108.000

25

kHz

MANUAL

fully

ccw

fully

ccw

FREQ

-3OdBm

3.5

Turn

all

power

switches

on,

and

allow a

sufficient

warm—up

time

forthe

equipment

(the

TI

requires

a

1

hour

warm—up

time).

3.6

Using

connector

gage

kit

(item

2.9),

ensure

the

TI

RF

connector

complies

with

specifications

of

MIL—C—71B.

6

NAVAIR

17—2OAX—737

SECTION

4

CALIBRATION

PROCESS

NOTE

Unless

otherwise

specified,

verify

the

results

of

each

test

and

take

corrective

action

whenever

the

test

requirement

is

not

met,before

proceeding.

4.1

FREQUENCY

ACCURACY

TESTS

4.1.1

Set the TI

controls

as

follows:

FREQUENCY

MHz

switches

to

108.000

MASTER

MOD

control

to

UNCAL

[fully

ccw

(0)]

Output

attenuator

control

to

—20

dBm

4.1.2

Ensure

that

the

TI

0

LOCK

indicator

is

on.

4.1.3

Connect

the

electronic

counter

to

the

TI

RF

output

connector,and

set

the

electronic

counter

for

frequency

measurements,

as

necessary.

4.1.4

Adjust

the TI

output

attenuator

control,

if

necessary,

to

obtain

a

stable

electronic

counter

indication.

(Repeat

this

step,

if

necessary,

for

the

following

tests

of

the

TI

frequency

accuracy.)

4.1.5

Verify

that

the

electronic

counter

indicates

between

107.999892

and

108.000108

MHz.

4.1.6

Set

the TI

FREQUENCY

MHz

switches

to

130.000,

and

verify

that

the

electronic

counter

indicates

between

129.999870

and

130.000130

MHz.

4.1.7

Setthe

TI

FREQUENCY

MHz

switches

to

157.000,

and

verify

that

the

electronic

counter

indicates

between

156.999843

and

157.000157

MHz.

4.1.8

Set

the TI

FREQUENCY

MHz

switches

to

328.000,

and

verify

that

the

electronic

counter

indicates

between

327.999672

and

328.000328

MHz.

4.1.9

Set

the TI

FREQUENCY

MHz

switches

to

335.000,

and

verify

that

the

electronic

counter

indicates

between

334.999665

and

335.000335

MHz.

4.1.10

If

the

TI is a

NAV—750B,

proceed

with

step

4.1.11.

Otherwise,

if

the

TI is

not

a

NAV—750B,

skip

to

step

4.1.13.

4.1.11

Set

the TI

FREQUENCY

MHz

switches

to

070.000,

and

verify

that

the

electronic

counter

indicates

between

69.999930

and

70.000070

MHz.

4.1.12

Set

the TI

FREQUENCY

MHz

switches

to

079.000,

and

verify

that

the

electronic

counter

indicates

between

78.999921

and

79.000079 MHz.

4.1.13

Disconnect

the

electronic

counter

from

theTI.

7

NAVAIR

17—2OAX—737

4.2

ATI’ENUATOR

FREQUENCY

RESPONSE

TESTS

4.2.1

Connect

the

power

sensor

to

the

powermeter.

Zero

and

reference

calibrate

the

power

sensorand

powermeter.

4.2.2

Set the

TI

attenuator

to

—30

dBm.

and

the

TI

frequency

switches

to

108

MHz.

Connect

the power

sensor

input

to

the

TI

RF

output

connector.

4.2.3

Set

the

power

meter

controls

for

auto

ranging

or

—25

dBm

range,

as

applicable.

NOTE

For

that

following

tests,

set

the

power

meter

calibration

factor

switch

to the

appropriate

setting

corresponding

to the

power

sensor

cal

chart

at

the

test

frequency

(TI

FREQUENCY

MHz

switchessetting).

4.2.4

Verify

that

thepowermeter

indicates

between

—28.5

and—31.5

dBm.

4.2.5

Setthe

TI

FREQUENCY

MHz

switches

to

the

followingsettings.

At

each

setting,

verify

that

the

power

meter

indicates

within

the

tolerance

limits

listed.

TI

FREQUENCY

MHz

Switch

Setting

Power

Meter

Tolerance

Limits

(dBm)

115.000

125.000

135.000

145.000

157.000

—28.5

to

—31.5

“

“

“

“

4.2.6

Setthe

TI

FREQUENCY

MHz

switches

to

328.000.

4.2.7

Verify

that

the

TI

G/S

Mode

indicator

is

on,

and

that

thepowermeter

indicates

between

—28.5

and

—31.5

dBm.

4.2.8

Set

the

TI

FREQUENCY

MHz

switches

to the

following

settings.

At

each

setting,

verify

that

the

power

meter

indicates

within

the tolerance

limitslisted.

TI

FREQUENCY

MHz

Switch

Setting

Power

Meter

Tolerance

Limits

(dBm)

330.000

332.000

335.000

—28.5

to

—31.5

“

“

4.2.9

If

the

TI

is

a

NAV—750B

continue

with

step

4.2.10.

Otherwise,

if

the

TI

is

not

a

NAV—750B,

proceed

to step

4.2.13.

4.2.10

Set the

TI

FREQUENCY

MHz

switches

to

70.000.

4.2.11 Verify

that

thepowermeter

indicates

between

—28.5

to

—31.5

dBm.

8

NAVAIR

17—2OAX—737

4.2.12

Setthe

TI

FREQUENCY

MHz

switches

to

the

followingsettings.

At

each

setting,

verify

that

the

power meter

indicates

within

thetolerance

limits

listed.

TI

FREQUENCY

MHz

Switch

Setting

Power

Meter

Tolerance

Limits

(dBm)

072.000

074.000

076.000

079.000

—28.5

to

—31.5

“

“

“

4.2.13

Disconnect

thepower

sensor

from

the

TI.

4.3

ATTENUATOR

LINEARITY

TESTS

4.3.1

Set

the

TI

controls

as

follows:

FREQUENCY

MHz

switches

to

MASTER

MOD

control

to

108.000

MHz

UNCAL

[fully

ccw

(0)]

Output

attenuator

control

to

-6

dBm

4.3.2

Connect

the

signal

generator

calibratorsensor

module

input

to

the

TI

RF

output

connector.

4.3.3

Press the

signal

generator

calibratorINSTR

PRESET

key

(Blue

key,

AUTOMATIC

OPERATION

key),

and

ensure

that

the

signal

generator

calibrator

is in

the

FREQ

measurement

mode

and

tunes

to

the

TI

FREQUENCY

MHz

switches

setting.

Setthe

signal

generatorcalibrator

for

TUNED

RF

LEVEL

measurements

with

log

(dBm)

display,

enter

39.9

SPCL,

and

then

press

the

CALIBRATE

key.

4.3.4

Set

the

TI

outputattenuator

control

to

each

of

the

followingsettings.

At

each

setting,

verify

that

the

signal

generator

calibrator

indicates

within

thetolerance

limits

listed.

TI

Output

Attenuator

Control

Setting

Signal

Generator

Calibrator

Tolerance

Limits

(dBm)

—6

—4.5

to

—7.5

—10

—8.5

to

—11.5

—20

—18.5

to

—21.5

—30

—28.5

to

—31.5

—40

—38.5

to

—41.5

—50

—48.5

to

—51.5

—60

—57.5

to

—62.5

—70

—67.5

to

—72.5

—80

—77.5

to

—82.5

—90

—87.5

to

—92.5

—100

—97.5

to

—102.5

4.3.5

Disconnect

the

signal

generator

calibratorsensor

module

from

theTI.

9

NAVAIR

17—2OAX—737

4.4

DEMOD

TONES

AND

DC

OFFSET

TESTS

4.4.1

Set the

TI

controls

as

follows:

BEARING-FREQ

switch

to

FREQ

MASTER

MOD

control

to CAL

(UNCAL

lamp off)

1020

Hz

indent

tone

MOD

control

to

CAL

(UNCAL

lamp off)

9960

Hz

FM

tone

MOD

control

to

CAL

(UNCAL

lamp

off)

30

Hz

tone

MOD

control

to

CAL

(UNCAL

lamp

off)

LOC

DDM

switch

to

0

G/S

DDM

switch

to

0

4.4.2

Connect

the

oscilloscope

vertical

amplifierinput

to

the

TI

rear

panel

DEMOD

jack.

Connect

the

DMM

voltage

input

to

the

TI

rear

panel

TONES

jack.

4.4.3

Set

the TI

oscilloscope

and

DMM

controls

as

necessary

to

measure

the

TI

signals

in the following

steps:

4.4.3.1

Setthe

TI

FREQUENCY

MHz

switches

to

108.100

MHz.

Ensure

that

the

TI

frequency

display

indicates

108.100,

and

the

LOC

mode

indicator

is on.

4.4.3.2

Set

the

TI

G/S

DDM

switch

to

90

Hz,

and

ensure

that

the

150

Hz

tone

offindicator

ison.

4.4.3.3 Verify

that

the

oscilloscope

displays

a

90

Hz

tone,

and

that

the

DMM

indicates

between

—40.0

and

+40.0

mV

dc.

4.4.3.4

Set

the

TI

LOC—G/S

frequency

switch

to

G/S.

4.4.3.5

Ensure

that

the

TI

frequency

display

indicates

334.700,

and

the G/S

mode

indicator

is

on.

4.4.3.6

Verify

that

the

oscilloscope

displays

a

90

Hz

tone,

and

that

the

DMM

indicates

between

—40.0

and

+40.0

mV dc.

4.4.3.7

Set the TI G/S

DDM

switch

to

150

Hz,

and

then

ensure

that

the

90

Hz

tone

offindicator

is

on.

4.4.3.8 Verify

that

the

oscilloscope

displays

a

150

Hz

tone,

and

that

the

DMM

indicates

between

—40

to

÷4OmVdc.

4.4.3.9

Set

the

TI

LOC—G/S

frequency

switch

to

LOC.

4.4.3.10

Ensure

that

the

TI

frequency

display

indicates

108.100,

the

90Hz

tone

offindicator

is on, and the

LOC

mode

indicator

is on.

4.4.3.11

Verify

that

the

oscilloscope

displays

a

150

Hz

tone,

and

that

the

DMM

indicates

between

—40

to

+4OmVdc.

4.4.3.12 Set the

TI

G/S

DDM

switch

to 0, and

the FREQUENCY

MHz

switches

to

108.000.

4.4.3.13

Ensure

that

the

TI

VOR

mode

indicator

is

on.

4.4.3.14

Verify

that

the

oscilloscope

displays a

9960

Hz

tone,

and

that

the

tone

is

both

frequency

and

amplitudemodulated

with

a

30

Hz

tone.

10

NAVAIR

17—2OAX—737

4.4.3.15

Verify

that

the

DMM

indicates

between

—40.0

and

+

40.0 mV dc.

4.4.3.16

Adjust

the

TI

9960

FM

tone modulation

controltoUNCAL

[fully

ccw

(0)].

4.4.3.17

Verify

that

the

oscilloscope

displays a

30

Hz

tone,

and

that

the

DMM

indicates

between

—40.0

and

+40.0

mV dc.

4.4.3.18 Set the

TI

9960

Hz

tone modulation

control

to the

CAL

(UNCAL

lamp

off)

position,

and

set the

FREQUENCY

MHz

switches

to

118.000.

4.4.3.19

Verify

that

the

oscilloscope

displays

a

1020

Hz

tone,

and

that

the

DMM

indicates

—40.0

to

+40.0

mV dc.

4.4.3.20

If

the

TI

is

a

NAV—750B

continue

with step

4.4.3.21.

Otherwise,

if

the

TI

is

not

a

NAV—750B,

proceed

to

step

4.4.3.27.

4.4.3.2

1

Set

the

TI

meter

function

and

toneselector

switch

to

400

Hz.

4.4.3.22

Verify

that

the

oscilloscope

displays

a

400

Hz

tone,

and

that

the

DMM

indicates

between

—80.0

to

+

80.0

mV dc.

4.4.3.23

Set

the

TI

meter

function

and

tone selector

switch

to

1300

Hz.

4.4.3.24

Verify

that

the

oscilloscope

displays a

1300

Hz

tone,

and

that

the

DMM

indicates

between

—80.0

and

+

80.0 mV dc.

4.4.3.25

Set

the

TI

meter

function

and

tone selector

switch

to

3000

Hz.

4.4.3.26

Verify

that

the

oscilloscope

displays

a

3000

Hz

tone,

and

that

the

DMM

indicates

between

—80.0

to

+80.0

mV dc.

4.4.3.27

Disconnect

the

oscilloscope

and

the

digital

multimeter

from

the

TI.

4.5

TONE

FREQUENCY

TESTS

4.5.1

Setthe

TI

controls

as

follows:

FREQUENCY

MHz

switches

to

108.000

LOC—G/S

frequency

switch

to

LOC

BEARING-FREQ

switch

to

FREQ

MASTER

MOD

control

to

CAL

(UNCAL

lamp

off)

1020

Hz

indent

tone

MOD

control

to

CAL

(UNCAL

lamp

off)

9960

Hz

FM

tone

MOD

control

to

CAL

(UNCAL

lamp

off)

30

Hz

tone

MOD

control

to CAL

(UNCAL

lamp

off)

LOC

DDM

switch

to

0

G/S

DDM

switch

to

0

4.5.2

Connect

the

electronic

counter,

set

for

a

30

Hz

measurementandAC

coupled,

input

to

the

TI

rear

panel

30

Hz

REF

jack.

11

NAVAIR

17—2OAX—737

4.5.3

Verify

that

the

electronic

counter

indicates

between

29.994

and

30.006 Hz.

4.5.4

Set

the TI

FREQUENCY

MHz

switches

to

108.100,

and

the G/S

DDM

switch

to

90

Hz.

4.5.5

Disconnect

the

electronic

counter

from

the

TI

30

Hz

REF

jack,

and

connect

it

to

the

TI

rear

panel

DEMOD

jack.

4.5.6

Verify

that

the

electronic

counter

indicates

between

89.982

and

90.018

Hz.

4.5.7

Set

the

TI

LOC—G/S

frequency

switch

to

G/S.

Ensure

that

the TI

frequency

display

indicates

334.700.

4.5.8

Verify

that

the

electronic

counter

indicates

between

89.982

and

90.018 Hz.

4.5.9

Set

the TI G/S

DDM

switch

to

150

Hz.

4.5.10 Verify

that

the

electronic

counter

indicates

between

149.97

and

150.03

Hz.

4.5.11

Set

the

TI

LOC—G/S

frequency

switch

to

LOC.

4.5.12 Verify

that

the

electronic

counter

indicates

between

149.97

and

150.03

Hz.

4.5.13

Set

the TI

FREQUENCY

MHz

switches to

108.000.

4.5.14

Adjust

the TI

30

Hz

tone modulation

control

to

UNCAL

[fully

ccw

(0)].

4.5.15

Connect

the

oscilloscope

vertical

amplifier

input

to

the

TI

rear

panel

TONES

jack.

4.5.16

Set

the

oscilloscope

controls

for

500

mV

vertical

sensitivity,

100

i.ts/div

sweep

time,

and

the

trigger

slope

to

positive

(+).

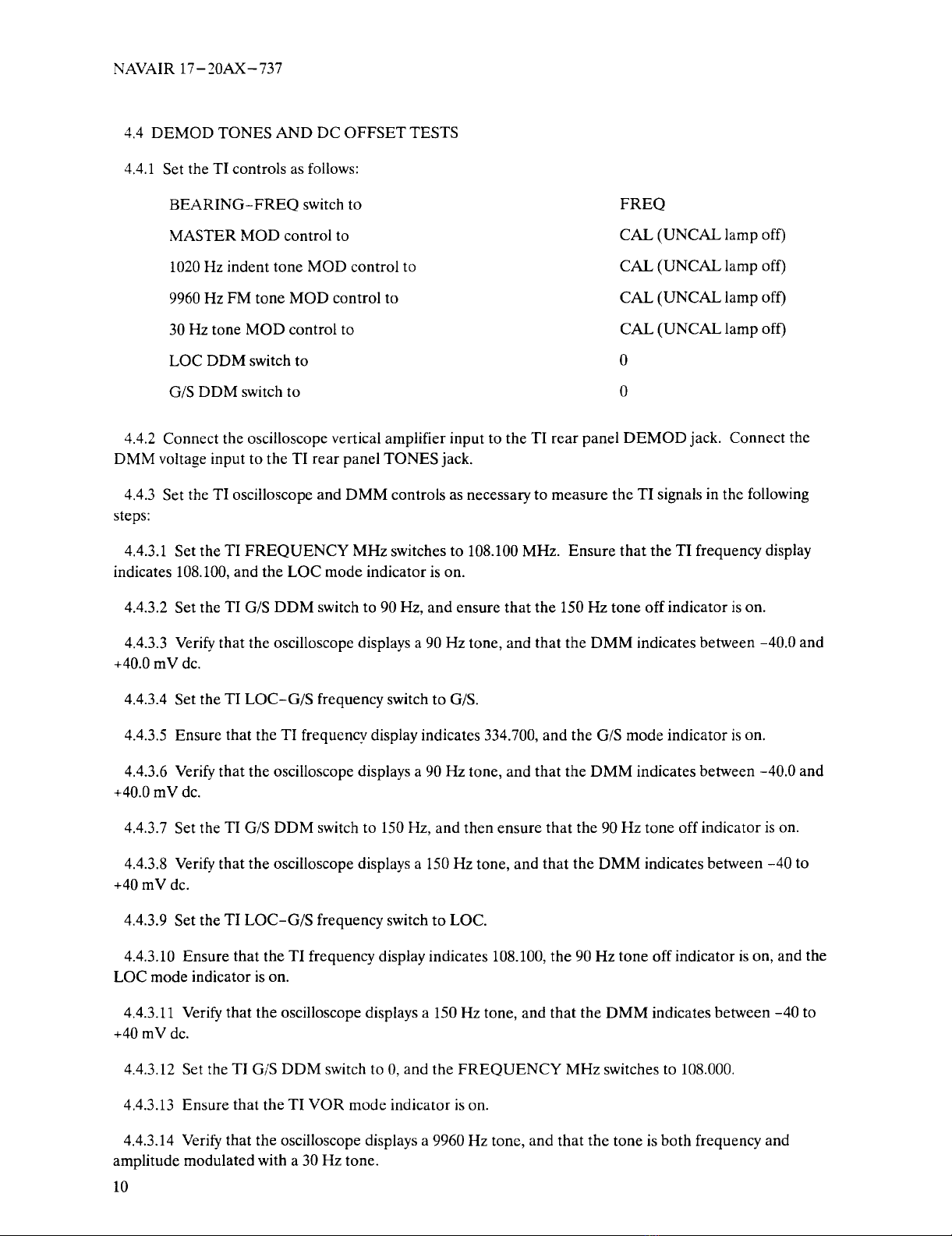

4.5.17

Adjust

the

oscilloscopetrigger

and

position

controls

to

vertically

centerthe

TI

9960

Hz

signal

on

the

oscilloscope

CRT display,

and

position

the

sweep

trigger

point

at

the

left

edge

of

the

horizontal

center

line.

(See

Figure

1.)

Figure

1.

FMDeviation

Display

..,~.I

~

Expand

—~

I

:(“

~

12

NAVAIR

17—2OAX—737

4.5.18

Use

the

oscilloscope

delayed

sweep

function

to

expand

the

portion

of

the

TI

signal

indicated

in

Figure

1,

with the

oscilloscope

delayed

timebase

set

for

10

p.s/div.

such

that

the

display

is

similar

to

Figure

2.

Verify

that

the

deviation

of

the

expanded

display

corresponds

to

delta

time

(st)

=

48.5

p.s

±2.4

p.s.

Figure

2.

9960

Hz

Deviation

(Expanded)

4.5.19 Verify

that

the

electronic

counter

indicates

between

9958.008

and

996

1.992

Hz.

4.5.20

Adjust

the TI

9960

FM

tone modulation

control

to

UNCAL

[fully

ccw

(0)].

4.5.21

Setthe

TI

30

Hz

tone modulation

control

to

the

CAL

(UNCAL

lamp

off)

position.

4.5.22 Verify

that

the

electronic

counter

indicates

between

29.994

and

30.006Hz.

4.5.23

Setthe

TI

9960

FM

tone modulation

control

to

the

CAL

(UNCAL

lamp off)

position,

the

FREQUENCY

MHz

switches

to

118.000,

and

the

Meter

function

switch

to

OFF.

4.5.24 Verify

that

the

electronic

counter

indicates

between

1014.9

and

1025.1 Hz.

4.5.25

If

the TI is a

NAV—750B,

proceed

with

step

4.5.26.

Otherwise,

if the

TI

is

not

a

NAV—750B,

skip

to

step

4.5.32.

4.5.26

Set

the TI

FREQUENCYMHz

switches

to

075.000,

and

the

Meter

function

and

Tone

Selector

switch

to

400

Hz.

4.5.27 Verify

that

the

electronic

counter

indicates

between

397.2

and

402.8 Hz.

4.5.28

Set

the

TI

meter

function

and

tone

selector

switch

to

1300

Hz.

4.5.29 Verify

that

the

electronic

counter

indicates

between

1290.9

and

1309.1

Hz.

Deviation

13

NAVAIR

17—2OAX—737

4.5.30

Set

the

meter

function

and

tone

switches

3000

Hz.

•

4.5.31

Verify

that

the

electronic

counter

indicates

between

2979.0

and

3021.0 Hz.

4.5.32

Disconnect

the

electronic

counter

and

the

oscilloscope

from

theTI.

4.6

TONE

DISTORTION

TESTS

4.6.1

Set the

TI

controls

to

the

following

positions:

FREQUENCY

MHz

switches

to

LOC-G/S

frequency

switch

to

BEARING-FREQ

switch

to

MASTER

MOD

control

to

9960

Hz FM

tone

MOD

control

to

1020

Hz

indent

tone

MOD

control

to

30

Hz

tone

MOD

control

to

LOC

DDM

switch

to

G/S

DDM

switch

to

Meter

function

switch

to

108.000

LOC

FREQ

CAL

(UNCAL

lamp

off)

CAL

(UNCAL

lamp

off)

CAL

(UNCAL

lamp

off)

CAL

(UNCAL

lamp

off)

0

0

0-100

or

OFF

4.6.2

Connect

the

distortion

analyzer

input

to

the

TI

rear

panel

30

Hz

REF

jack.

Setthe

distortion

analyzer

controls

for

distortionmeasurement

of

a

30

Hz

fundamental,

as

applicable.

4.6.3

Verify

that

the

distortion

analyzer

indicates

~0.5%

total

harmonicdistortion.

4.6.4

Set

the TI

FREQUENCY

MHz

switches to

108.100,

and

set the G/S

DDM

switch

to

90

Hz.

4.6.5

Disconnect

the

distortion

analyzer

from

the

30Hz

REF

jack,

and

connect

it

to

the

TI

rear

panel

TONES

jack.

4.6.6

Set

the

distortion

analyzercontrols

for

distortion

measurement

of

a

90

Hz

fundamental,

as

applicable.

4.6.7

Verify

that

the

distortion

analyzer

indicates

~0.4%

total

harmonicdistortion.

4.6.8

Set

the

TI

LOC—G/S

frequency

switch

to

G/S.

4.6.9

Verify

that

the

distortion

analyzer

indicates

0.4%

total

harmonicdistortion.

4.6.10

Set

the

TI

G/S

DDM

switch

to

150

Hz.

4.6.11

Set

the

distortion

analyzercontrols

for

distortion

measurement

of a

150

Hz

fundamental,

as

applicable.

4.6.12 Verify

that

the

distortion

analyzer

indicates

~0.4%

total

harmonicdistortion.

4.6.13

Set

the

TI

LOC—G/S

frequency

switch

to

LOC.

4.6.14 Verify

that

the

distortion

analyzer

indicates

0.4%

total

harmonicdistortion.

14

NAVAIR

17—2OAX—737

4.6.15

Set

the TI

FREQUENCY

MHz

switches

to

108.000.

4.6.16

Adjust

the

TI

9960

FM

tone modulation

control

to

the

UNCAL

[fully

ccw

(0)]

position.

Setthe

distortion

analyzercontrols

for

distortionmeasurement

of a

30

Hz

fundamental,

as

applicable.

4.6.17 Verify

that

the

distortion

analyzer

indicates

~0.5%

total

harmonicdistortion.

4.6.18

Set

the TI

9960

FM

tone modulation

control

to

the

CAL

(UNCAL

lamp

off)

position.

4.6.19

Set

the

TI

frequency

switch

to

118.000

MHz.

Setthe

distortion

analyzercontrols

for

distortion

measurement

of a

1020

Hz

fundamental,

as

applicable.

4.6.20 Verify

that

the

distortion

analyzer

indicates

~0.5%

total

harmonicdistortion.

4.6.21

If

the

TI

is

a

NAV—750B,

proceed

withstep

4.6.22.

Otherwise,

if

the

TI is

not

a

NAV—750B,

skip

to

step

4.6.28.

4.6.22

Set

the TI

FREQUENCY

MHz

switches to

075.000,

and

the

Meter

function

and

Tone

Selector

switch

to

400 Hz.

4.6.23

Set

the

distortion

analyzer

controls

for

distortionmeasurement

of

a

400

Hz

fundamental,

as

applicable,

and verify

that

the

distortion

analyzer

indicates

~.0.7%

total

harmonicdistortion.

4.6.24

Set

the TI

meter

function

and

tone selector

switch

tol300

Hz.

4.6.25

Set

the

distortion

analyzercontrols

for

distortionmeasurement

of

a

1300

Hz

fundamental,

as

applicable,

and

verify

that

the

distortion

analyzer

indicates

0.7%

total

harmonicdistortion.

4.6.26

Set

the TI

meter

Function

and

the

Tone

Selector

switch

to

3000

Hz.

4.6.27

Set

the

distortion

analyzercontrols

for

distortionmeasurement

of a

3000

Hz

fundamental,

as

applicable,

and

verify

that

the

distortion

analyzer

indicates

~0.7%

total

harmonicdistortion.

4.6.28

Disconnect

the

distortion

analyzer

from

the

TI.

4.7

PERCENT

AMPLITUDE

MODULATION

OF

TONESAND

MODULATION

METER

TESTS

4.7.1

Setthe

TI

controls

as follows:

FREQUENCY

MHz switches

to

108.000

Meter

function

switch

to

0—30

9960

Hz FM

tone

MOD

control

to

UNCAL

[fully

ccw

(0)]

30

Hz

tone

MOD

control

to

CAL

(UNCAL

lamp

off)

1020

Hz

indent

tone

MOD

control

to

CAL

(UNCAL

lamp

off)

MASTER

MOD

control

to

CAL

(UNCAL

lamp

off)

Output

attenuator

control

to

—20

dBm

LOC—G/S

frequency

switch

to

LOC

LOC

DDM

switch

to

0

G/S

DDM

switch

to

0

15

NAVAIR

17—2OAX—737

4.7.2

Connect

the

signal

generator

calibratorsensor

module

input

to

the

TI

RF

outputconnector.

4.7.3

Press

the

signal

generator

calibratorINSTR

PRESET

key

(Blue

key,

AUTOMATIC

OPERATION

key),

andensure

that

the

signal

generator

calibrator

is in

the

FREQ

measurement

mode

and

tunes

to

the

TI

FREQUENCY

MHz

switches

setting.

Set

the

signal

generator

calibrator

for

AMmodulation

measurements

with

the

DETECTOR

set

to

PEAK

±12.

Activate

the

signal

generator

calibrator

3

kHz

LP

FILTER.

4.7.4

Verify

that

the

signal

generator

calibrator

indicates

between

28.8%

and

31.2% AM

modulation,

and

record

the

reading.

4.7.5

Verify

that

the

TI

meter

indicates

within

±1.2%

(AM

depth)

of

therecorded

value

in

step

4.7.4.

4.7.6

Set

the

TI

meter

function

switch

to

0—100,

and

then

set the TI

30

Hz

tone modulation

control

to

the

fully

cw

position.

4.7.7

Verify

that

the

signal

generator

calibrator

indicates

>60%

AM

modulation.

4.7.8

Set

the

TI

30

Hz

modulation

control

to

the

UNCAL

[fully

ccw

(0)]

position.

4.7.9

Setthe

TI

1020

Hz

tone modulation

control

to

the

fully cw

position.

4.7.10

Activate

the

signal

generator

calibrator

50

HzHP

FILTER,

and

the

3

kHz

LP

FILTER.

Verify

that

the

signal

generator

calibrator

indicates

>60%

AM

modulation.

4.7.11

Setthe

TI

1020

Hz

tone modulation

control

to

the

CAL

(UNCAL

lamp

off)

position,

and

the

9960

Hz

tone modulation

control

to

the

CAL

(UNCAL

lamp

off)

position.

4.7.12

Activate

the

signal

generator

calibrator

300

HzHP

FILTER,

and

the >20

kHz

LP

FILTER.

4.7.13 Verify

that

the

signal

generator

calibrator

indicates

between

28.8%

and

3

1.2%

AMmodulation.

4.7.14

Set

the

TI

9960

Hz

tone modulation

control

to

the fully

cw

position.

4.7.15 Verify

that

the

signal

generator

calibrator

indicates

>60%

AM

modulation.

4.7.16

Setthe

TI

30

Hz

tone modulation

control

to

the

CAL

(UNCAL

lamp

off)

position,

and

the

9960

Hz

tone modulation

control

to

the CAL

(UNCAL

lamp off)

position.

4.7.17

Set

the

TI

FREQUENCY

MHz

switches

to

108.100.

Setthe

TI

G/S

DDM

switch

to

90

Hz.

4.7.18

Deactivate

the

signal

generator

calibrator

300

Hz

HP

FILTER,

and

activate

the

3

kHz

LP

FILTER.

4.7.19

Verify

that

the

signal

generator

calibrator

indicates

between

19.2%

and

20.8% AM

modulation.

4.7.20

Set

the

TI

G/S

DDM

switch

to

150

Hz,

and

the

TI

meter

function

switch

to

0—30.

4.7.21 Verify

that

the

signal

generator

calibrator

indicates

between

19.2%

and

20.8%

AM

modulation,

andrecord

the

reading.

4.7.22 Verify

that

the

TI

meter

indicates

within

±0.8%

of

the recorded

value

in

step

4.7.21.

4.7.23

Set

the TI

meter

Function

switch

to

0—100,

the

G/S

DDM

switch to 0,

the

LOC—G/S

switch to

G/S,

and

the

LOC

DDM

switch

to

90

Hz.

4.7.24 Verify

that

the

signal

generator

calibrator

indicates

between

38.4%

and

41.6%

AM

modulation.

16

NAVAIR

17-2OAX-737

4.7.25

Set

the

TI

LOC

DDM

switch

to

150

Hz.

4.7.26 Verify

that

the

signal

generator

calibrator

indicates

between

38.4%

and

41.6%

AM

modulation,

and

record

the

reading.

4.7.27 Verify

that

the

TI

meter

indicates

within

±1.6%

of

the

recorded

value

in

step

4.7.26.

4.7.28

Set

the TI

LOC

DDM

switch

to

0,

and

the

FREQUENCY

MHz

switches

to

118.000.

4.7.29

Activate

the

signal

generator

calibrator

50

HzHPFILTER,

and

the

15

kHz

LP

FILTER.

4.7.30 Verify

that

the

signal

generator

calibrator

indicates

between

28.8%

and

3

1.2% AM

modulation.

4.7.31

If

the

TI is a

NAV—750B,

proceedwithstep

4.7.32.

Otherwise,

if

the

TI

is

not

a

NAV—750B,

skip

to

step

4.7.41.

4.7.32

Set

the TI

controls

as

follows:

FREQUENCY

MHz

switches

to

075.000

MASTER

MOD

control

to

CAL

(UNCAL

lamp

off)

Meter

function

and

toneSelector

switch

to

400

Hz

1020

Hz

indent

tone

MOD

control

to

CAL

(UNCAL

lamp

off)

Output

attenuator

control

to

—20

dBm

4.7.33

Press

the

signal

generator

calibratorINSTR

PRESET

key

(Blue

key,

AUTOMATIC

OPERATION

key),

and

ensure

that

the

signal

generator

calibrator

is in

the

FREQ

measurement

mode

and

tunes

to

the

TI

FREQUENCY

MHz

switches

setting.

Setthe

signal

generator

calibrator

for

AMmodulation

measurements

with

the

DETECTOR

set

to

PEAK

±12.

Activate

the

signal

generator

calibrator

50

Hz

HP

FILTER,

and

the

15

kHz

LP

FILTER.

4.7.34 Verify

that

the

signal

generator

calibrator

indicates

between

92.

15%

and

97.85%

AMmodulation,

andrecord

the

reading.

4.7.35 Verify

that

the

TI

meter

indicates

within

±3%

of

the

recorded

value

in

step

4.7.34.

4.7.36

Set

the TI

meter

function

and

tone selector

switch

to

1300

Hz.

4.7.37 Verify

that

the

signal

generator

calibrator

indicates

between

92.

15%

and

97.85%

AM

modulation.

4.7.38

Setthe

TI

meter

function

and

tone selector

switch

to

3000

Hz.

4.7.39

Activate

the

signal

generator

calibrator

300

Hz HPFILTER,

and

the

>20

kHz

LP

FILTER.

4.7.40 Verify

that

the

signal

generator

calibrator

indicates

between

92.

15%

and

97.85%

AM

modulation.

4.7.41

Disconnect

the

signal

generator

calibratorsensor

module

from

theTI.

17

NAVAIR

17—2OAX—737

4.8

RF

LEVEL

METER

TESTS

4.8.1

Set

the

TI

controls

as

follows:

FREQUENCY

MHz

switches to

108.000

Meter

function

switch

to

RF

4.8.2

Verify

that

the

TI

meter

needle

is

aligned

over

the RF

level

vertical

mark

within

±1.5

needle

widths.

4.8.3

Set the

TI

FREQUENCY

MHz

switches

to

110.000.

NOTE

NAV—750B

is

tested

from

110.000

to

150.000

MHz,

and

from

330.000 to

335.000

MHz,

only.

4.8.4

Advance

the

TI

FREQUENCY

MHz

switches

in

20

MHz steps

to

335

MHz

(after

330

MHz

setting,

set

to

335

MHz),

and

at

each

setting,

verify

that

the

TI

meter

needle

remainsalignedover

the RF

Level

mark

within

±1.5

needle

widths.

•

4.8.5

If

the TI

is

a

NAV—750B,

proceed

withstep

4.8.6.

Otherwise,

if

the

TI

is

not

a

NAV—750B,

skip

to

subsection

4.9.

4.8.6

Setthe

TI

FREQUENCY

MHz

switches

to

072.000.

4.8.7

Verify

that

the

TI meter

needle

is

aligned

over

the

RF

Level

vertical

mark

within

±1.5

needle

widths.

4.8.8

Advance

the

TI

FREQUENCY

MHz

switches in 2.0

MHz steps

to

78.000 MHz,

and

at

each

setting,

verify

that

the

TI

meter

needle

remains

aligned

over

the

RF

level

mark

within

±1.5

needle

widths.

4.9

VOR

BEARING

TESTS

4.9.1

Set the

TI

controls

as follows:

FREQUENCY

MHz

switches

to

108.000

MHz

30

Hz

tone

MOD

control

to

CAL

(UNCAL

lamp

off)

1020

Hz

indent

tone

MOD

control

to

CAL

(UNCAL

lampoff)

9960

Hz

FM

tone

MOD

control

to

CAL

(UNCAL

lampoff)

BEARING-FREQ

switch

to

BEARING

TO-FROM

switch

to

TO

4.9.2

Connect

the

navigation

indicator

T!S

input

connector

to

the

TI

rear

panel

DEMOD

(J23)

connector.

4.9.3

Press the

TI

0°

VOR

bearing

selectpushbutton,

andensure

that

the

TI

bearing

display

indicates

0.0°.

4.9.4

Verify

that

the

navigation

indicator

TIS

indicates

000.00°

±0.05°.

18

This manual suits for next models

2

Table of contents

Other IFR Test Equipment manuals

Popular Test Equipment manuals by other brands

ACE INSTRUMENTS

ACE INSTRUMENTS ACE II Basic plus operating manual

Keysight Technologies

Keysight Technologies N5990A-301 user guide

Elenco Electronics

Elenco Electronics SP-3B Assembly and instruction manual

Megger

Megger MFT70-US user manual

Smart Start

Smart Start IN-HOM User instructions

FLIR

FLIR VT8-600 user manual