CALIBRATION STATION INSTRUCTION MANUAL 1

1.0 Introduction

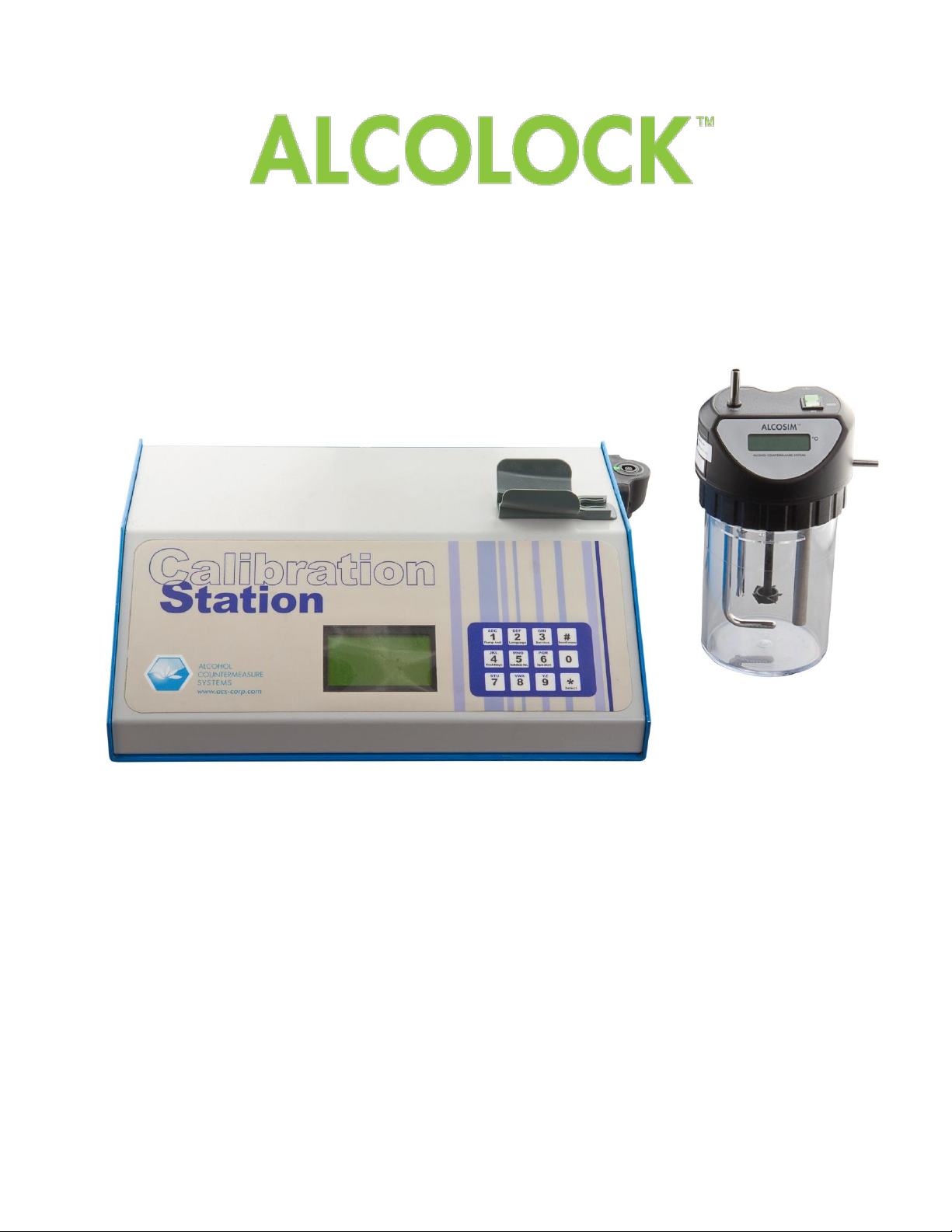

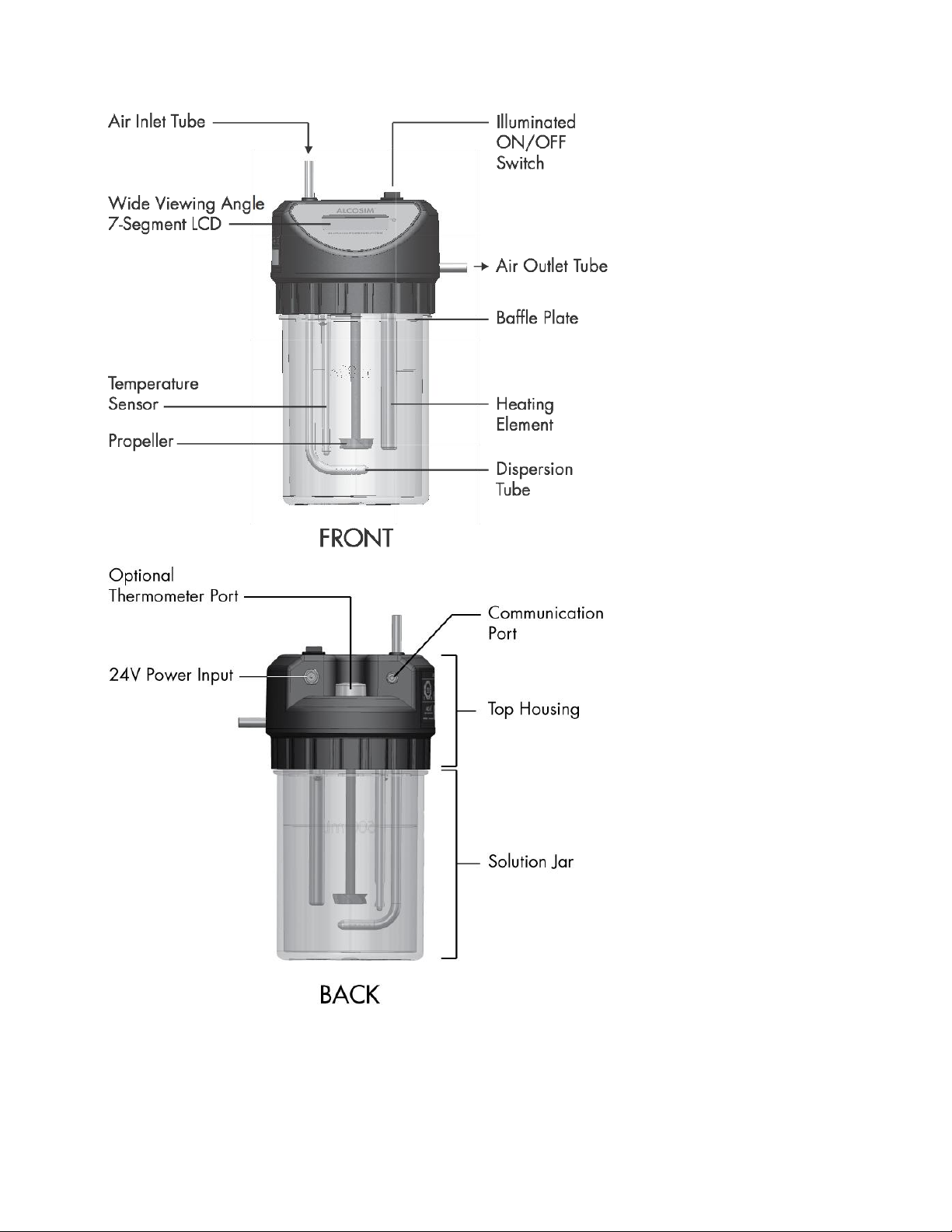

The ACS Calibration Station (CS) is diagnostic equipment designed to establish and maintain compliance of the ALCOLOCK

WR3 alcohol interlock Handset (HS). The following are the main components required for calibration:

Calibration Station (CS)

ALCOSIM breath alcohol simulator

INTERTRACKTM Enterprise Software (ITE)

For successful calibration, ensure that all components of the CS assembly are connected correctly. This manual will show you

how to safely connect and operate the CS assembly, and to calibrate the ALCOLOCK WR3 device.

ATTENTION!

General

This manual is for authorized service technicians only

Do not use ALCOSIM simulator with toxic liquids, flammable liquids or in explosive atmospheres

Use the product for its intended purpose only. Failure to do so will void the warranty and may cause injury and

damage the components

Avoid contact with the ALCOSIM heating element: CAUTION –Hot Surface

Only use parts supplied by Alcohol Countermeasure Systems

Do not open any enclosures. Doing so will void the warranty and may cause injury and damage the components

within. Contact your Service Provider if any hardware is not working

Ensure that the proper amount of solution is added; do not under-fill or over-fill the ALCOSIM simulator

If the ALCOSIM simulator overheats considerably beyond 34°C, turn it off and contact your Service Provider

Before use, inspect all components for visible cracks or damage. Failure to do so may cause injury or additional

damage

Do not force a cord into a port or input, as doing so will damage the components

Moisture, contamination and cleaning

The mouthpieces and all tubing must be completely dry before setup. Even slight condensation may disrupt the

procedure. Before beginning a calibration, make sure that all moisture has been completely removed from the

ALCOSIM simulator

The ALCOSIM jar must be completely clean and dry before you apply the alcohol reference solution. Remove the

ALCOSIM top housing before cleaning the solution jar

If liquid spills onto the CS or any other components, remove liquid with a cloth and allow the CS to dry

thoroughly. If there is substantial moisture damage, keep all components powered off and contact your Service

Provider

To clean the CS and ALCOSIM simulator: use a water dampened cloth to remove dirt or dust from the surface, and

allow it to dry thoroughly. Do not use cleaning products on the surface, as doing so may cause damage

After drying, remove all cloths or paper towels from the UCS and its components

Power

Check that the ALCOSIM simulator power ratings conform to the local supply rating

Power off the ALCOSIM simulator after use

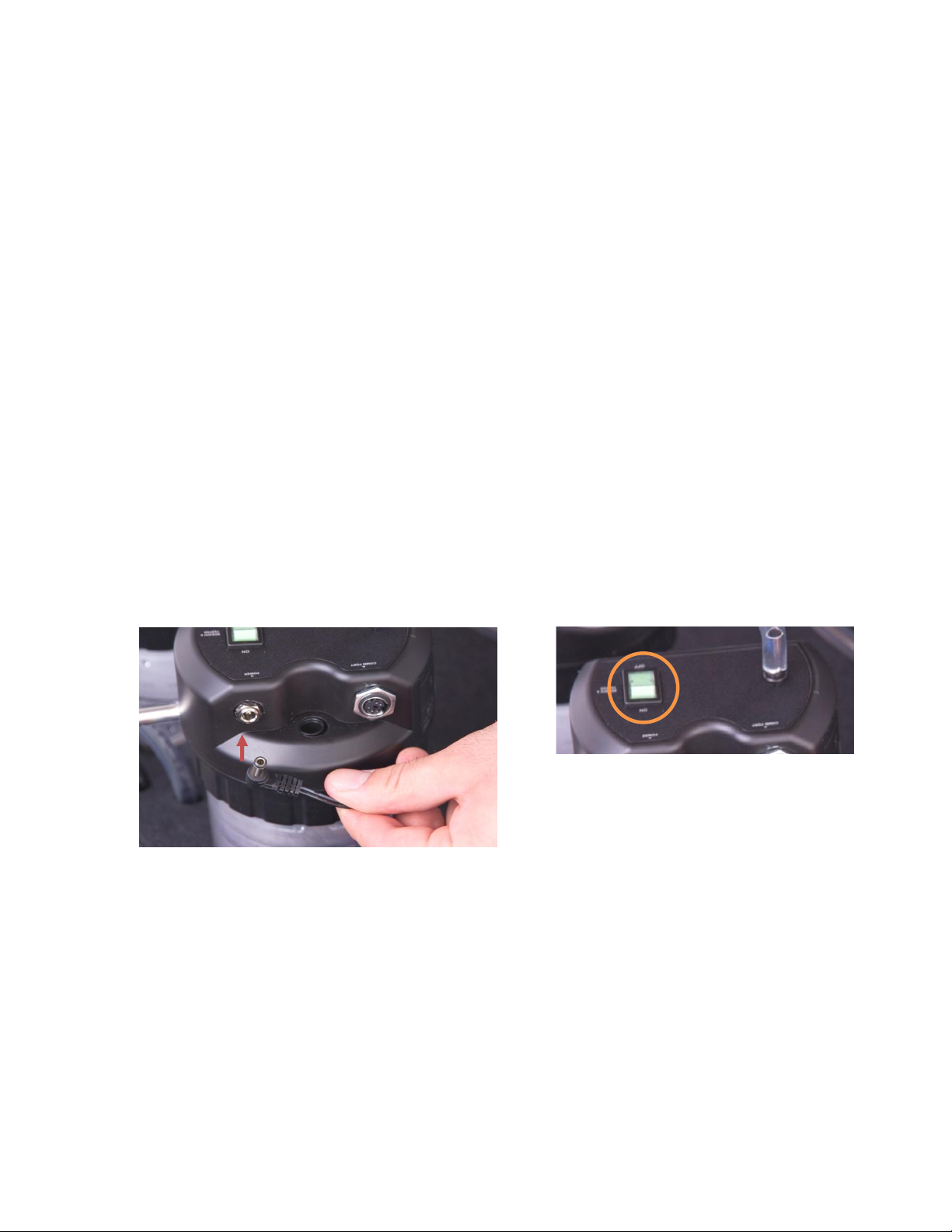

When assembling, disassembling or preparing ALCOSIM simulator for use, ensure that it is not plugged into an

electrical outlet until you have been instructed to do so

Do not switch on the ALCOSIM simulator and CS until instructed

Do not plug in the ALCOSIM simulator and CS power cables until instructed

If the ALCOSIM was powered on, wait 15 minutes for the components to cool off before removing the top housing

Never open the ALCOSIM top housing when the simulator is switched on or plugged in

Do not disconnect any components while calibration is in progress

Failure to follow these instructions may result in injury or may damage the devices

Alcohol reference solution

Keep away from eyes. In case of contact, flush eyes with water. If irritation continues, contact your local poison

control centre

Do not ingest. In case of ingestion, do not induce vomiting. Contact your local poison control centre

Do not use a solution bottle with a broken seal, or a solution bottle that has expired

Keep at room temperature. Do not freeze or refrigerate

It is safe to dispose of alcohol reference solution in the drain. Refer to your local environmental regulations for

more information about safe disposal amounts