Igema IGEMA SC32-SC132 Technical specifications

Edition 03/2021

D-11-B-53616-EN-00

Installation and maintenance instruction

IGEMA SC32-SC132

Sample cooler

2

Product philosophy

Thank you for placing your trust in IGEMA and deciding in favour of one of our

high-quality products.

For more than 100 years, measuring and control systems have been developed,

produced and sold worldwide under the IGEMA brand name.

“Steam is our passion” and we offer you the entire programme for the safe and

economic operation of your plants, especially in the steam and condensate sector.

Please read the installation and operating instructions carefully to ensure a safe and

reliable operation.

In addition to the information on installation and operation, you will also find important

information on maintenance, care, safety and value retention of your measuring and

control system.

3

Table of contents

1. Important safety instructions.............................................................................5

1.1 Symbols used in these instructions...................................................................5

1.2 Intended use of the device................................................................................6

1.3 Safety at work ...................................................................................................7

1.4 Safety instructions for this device......................................................................8

1.5 Exclusion of liability...........................................................................................8

2. Contents of the packaging.................................................................................8

3. General.................................................................................................................9

3.1 Note ..................................................................................................................9

3.2 General Safety Instructions...............................................................................9

4. Transport and Storage......................................................................................10

4.1 Safety instruction ............................................................................................10

5. Installation.........................................................................................................11

5.1 Safety Instructions ..........................................................................................11

5.2 Installation area requirements.........................................................................11

5.3 Procedure .......................................................................................................11

5.4 Dimensions.....................................................................................................12

6. Start up...............................................................................................................13

6.1 Safety instruction ............................................................................................13

6.2 Procedure to take boiler samples....................................................................14

6.3 Periodical checking.........................................................................................14

4

Table of contents (cont.)

7. Maintenance ......................................................................................................14

7.1 Limiting Conditions..........................................................................................14

8. Products-returning............................................................................................15

8.1 Safety Instructions ..........................................................................................15

9. Loss of warranty ...............................................................................................15

5

1. Important safety instructions

KEEP THESE INSTALLATION AND OPERATING INSTRUCTIONS IN A SAFE PLACE!

Commissioning as well as maintenance and repair work may only be carried out by qualified

persons in compliance with the installation instructions given in this operating manual. The

correct installation, commissioning, maintenance and operation of the device presupposes that

the person in charge is familiar with measurement and control systems and complies with the

general installation and safety instructions. In addition, the correct and intended use of tools

and the handling of safety devices must be ensured. Unqualified personsmust not be assigned

the above tasks!

IGEMA GmbH accepts no liability for damage to property or personal injury caused by

unqualified persons or by failure to observe these installation and operating instructions. If no

sufficiently qualified person can be found, IGEMA GmbH can be commissioned with the

installation/maintenance.

1.1 Symbols used in these instructions

In the following installation and operating instructions, safety instructions are marked with the

following symbols:

Danger

This symbol and signal word refer to a potentially

hazardous situation which could result in death or

injuries if ignored.

Caution electrical voltage

This symbol and signal word indicate live parts

with an immediate danger of death from electric

shock.

Caution hot

This symbol with a signal word indicates a

potentially hazardous situation that can result in

severe burns and scalds all over the body.

6

Caution

This symbol and signal word refer to a potentially

hazardous situation which could result in

personal injury, property and environmental

damage if ignored.

Caution

This symbol and signal word refer to a potentially

hazardous situation which could result in damage

to the equipment if ignored.

Info

This symbol indicates useful information and

recommendations as well as measures that will

prolong the value of your measuring and control

system.

1.2 Intended use of the device

Use these installation and operating instructions, the identification on the rating

plate and the technical data sheet to check whether the device is suitable for the

intended use/application. The device complies with the requirements of the

European Pressure Equipment Directive 2014/68/EU.

The device may only be used to indicate fill levels on containers.

The maximum values of the pressure and temperature range of the device must be checked

before installation. If the maximum allowable operating values of the device are lower than

those of the system on which it is to be installed, protective instruments for the device, such

as pressure reducers or similar, must be provided to avoid limit situations. The device may

only be used in accordance with the information in these installation and operating instructions

or for the parameters and applications agreed in the supply contract (see rating plate). The

operator of the direct water level indicator is obliged to familiarise himself on the compatibility

of the medium and the device. In case of doubt, contact the relevant installation manager or

site manager.

The correct installation position, alignment and flow direction of the device must be observed!

Before installing the IGEMA product on boilers or containers, it is essential to remove all

protective covers and, if necessary, the protective film from rating plates and sight glasses.

Caution

7

1.3 Safety at work

Before installation or carrying out maintenance work on the device, safe access

must be ensured and a secure working area with sufficient lighting must be

defined and marked out. Always use lifting equipment for heavy loads!

Before starting any work, carefully check which liquids or gases are or have been in the

pipeline. (flammable substances, irritating substances, substances hazardous to health) When

opening or dismantling the device, residues of the medium can escape. Subsequent fumes

are also possible in unpressurized and cold systems. Use designated PPE such as safety

goggles and respiratory protection!

Special attention must be paid to the condition of the environment around the installation or

maintenance site. Be aware of e.g.: potentially explosive atmospheres, lack of oxygen in tanks

and pits, dangerous gases/liquids,extreme temperatures, hot surfaces, firehazard (e.g. during

welding) and moving machine and system components. Protect yourself from excessive noise

by taking the required protective measures.

For all maintenance work or new installations, on new or existing boilers or vessels, it is

imperative to check thatthe boiler or vessel has been depressurised and that the pressure has

been safely reduced to atmospheric pressure. In principle, no system should be regarded as

unpressurized even if indicated by pressure measuring devices such as pressure gauges or

sensors. When releasing the pressure, make sure that no persons are in the release area.

Carefully check whether you and/or other persons in the vicinity need PPE to protect yourself

from external influences such as high and low temperatures, radiation, noise, danger to eyes,

loose objects that can fall down or chemicals.

There is always a risk of injury when handling large and/or heavy equipment. Observe the load

handling regulation as a minimum requirement for working with loads. Avoid handling the

device with your own physical force, e.g. by lifting, pulling, carrying, pushing or supporting it,

especially to prevent back injuries. Use lifting equipment to move heavy and bulky equipment

in accordance with Article 1, Section 2 of the German Load Handling Regulation

(LasthandhabV).

Under normal operating conditions the surface of the device can become very

hot! Under the maximum operating conditions, the surface temperature can

exceed 350°C. After shutting off or, if necessary, shutting down the boiler, wait

until the temperature has normalized to room level. To avoid the risk of burns

and scalds, always use PPE including safety goggles!

Danger

Caution

hot!

8

1.4 Safety instructions for this device

These installation and operating instructions are an integral part of the device

and must be forwarded to the responsible departments "Goods inward,

Transport, Installation, Commissioning and Maintenance". They must be kept in

such a way that the technical staff have access to these documents at all times.

If the device is passed on to a third party, these installation and operating

instructions must also be included in the national language of the third party.

Avoid shocks and hard contact during transport, as this can lead to damage. During

intermediate storage, the device must be kept dry and secured against damage.

When servicing the unit, make sure to use sharp-edged internal parts and avoid shards of

broken glass. There is a risk of cutting hands and arms! Always wear work gloves when

changing packing, valve seat and valve plug.

When returning goods to IGEMA GmbH, the applicable safety and environmental laws

according to GGVSEB [German ordinance on the national and international carriage of

dangerous goods by road, rail, and inland waterways] must always be observed. If there are

any risks to health or the environment due to residues or the device has a mechanical defect

this must be indicated when returning the device and the necessary precautionary measures

must be taken. If the returned goods are devices that have come into contact with or contain

hazardous substances, a safety data sheet must be enclosed, and the goods must be clearly

marked. In addition, the hazardous substance must be reported to the logistics service

provider.

1.5 Exclusion of liability

IGEMA GmbH Measuring and control technology will assume no liability if the above

regulations, instructions and safety precautions are not observed and followed. If they are not

expressly listed in the installation and operating instructions, changes to an IGEMA device are

carried out at the risk of the user.

2. Contents of the packaging

1. Sample cooler

2. Installation and maintenance instruction

Caution

9

3. General

•

These instructions must be carefully read before any work involving products supplied by

IGEMA is undertaken.

•

The installation procedure is a critical stage in a life of any device and care should be taken

to avoid damage to the sample cooler or equipment.

•

IGEMA sample coolers are designed to cool samples of boiler water or steam for analysis.

They prevent steam flashing-off from hot pressurized liquid samples, which can be

dangerous and will result in an incorrect water sample.

3.1 Note

•

Current regional safety regulations should be taken in to account and followed, while doing

the installation and maintenance work.

•

Handling, installation and maintenance work must be carried out by trained personnel. A

supervisor must follow and check all activities.

•

For the problems that cannot be solve with the help of this instructions, please contact the

supplier or the manufacturer.

•

The manufacturer reserves the right to change the design and material of this product

without notice.

3.2 General Safety Instructions

➢If malfunctionof any other equipment or system operationfailure may result in adangerous

overpressure, over temperature or even vacuum condition, a safety device must be

included in the system to prevent such situations.

➢Do not touch the equipment without appropriate protection during working operation

because it may conduct heat if the used fluid is at high temperature.

➢Before starting maintenance be sure that the equipment is not pressurized or hot. Even if

upstream and downstream isolating valves have been closed care should be taken since

fluid under pressure may be trapped between them.

➢The equipment must be used within the working temperature and pressure limits laid

down for them, otherwise they may fail (refer to nameplate and/or IS- Information Sheet).

Danger

10

➢Manual handling of products may present a risk of injury. You are advised to assess the

risks taking into account the task, the individual, the load and the working environment.

➢Before starting work ensure that you have suitable tools and/or consumables available.

Use only genuine IGEMA replacement parts.

➢Do not remove the nameplate attached to the equipment. Serial number and other useful

information are stamped on it.

➢This unit must not be used for oxygen applications, it has been specially designed for the

use specified here.

➢During the assembly work, apply protective measures against dirt.

➢Correct installation of the equipment is full responsibility of the contractor.

➢Sample coolers are designed to be applied in places protected from exposure to weather.

➢We recommend special constructions or protective measures for applications on the

outside or in adverse environments like corrosion-promoting conditions (sea water,

chemical vapours, etc).

4. Transport and Storage

4.1 Safety instruction

➢Handling and lifting of materials should be made with adequate equipment.

➢The sample coolers and equipment should be protected from impacts and forces during

transportation and storage.

➢The manufacturer doesn’t assume the responsibility of damaged equipment due to

inappropriate handling during the transportation and storage.

Danger

11

5. Installation

5.1 Safety Instructions

➢Account for over pressure conditions, according with the local laws or standards.

➢For the problems that cannot be solve with the help of this instructions, please contact the

supplier or the manufacturer.

5.2 Installation area requirements

•

The installation area should have easy access and provide enough space for maintenance

and removing operations.

•

The pipework before and after the sample cooler, must be sized in order to avoid that the

max flow speed recommended, for the fluid in question, is exceeded.

•

In order to allowinstallation and maintenance work without emptying the system, stop valve

should be installed upstream of the sample cooler water and steam supply.

5.3 Procedure

•

Prior to install check that the product is suitable for the intended application: materials and

pressure/temperature ratings.

•

Before installing remove plastic covers placed on flanges or connection ends. The

equipment has arrows or inlet/outlet designations. Be sure that it will be installed on the

appropriate direction.

•

Take care with jointing material to ensure that none may be permitted to block or enter the

sample cooler.

•

Sample coolers are recommended to be fitted with the centre line of the cooler in a vertical

position to ensure that the best results are obtained.

•

Stop valves are necessary on the cooling water and sample inlet.

•

The outlet cooling watershould be piped into a drain and be free of obstructions or isolation

valves.

•

The sample cooler pipe work should be properly supported and free from strain and it

should not be subjected to undue surges of pressure. The start-up condition should be

considered.

Danger

12

5.4 Dimensions

Pos.

Description

Sample cooler

1

Sample intake

2

Cooling water intake

2a

Colling water valve

3

Draining connection

4

Funnel to take a measuring jug

5

Sample outlet

5a

Thermometer unit

13

6. Start up

6.1 Safety instruction

Safety notice!

The device may become very hot as a result of the flow of the sample medium through

it and it must be regularly checked for a good seal. There is a risk of being burnt or

scalded. So appropriate protective clothing should be worn and relevant accident

prevention regulations should be observed.

➢

Current regional safety regulations should be taken into account and followed.

➢

Protective insulation and warning notice may be required.

➢

Until the start-up of an existing or a new plant, the following must be checked:

➢

All works are completed.

➢

The sample cooler is correctly installed.

➢

All the necessary safety devices have been installed.

➢

At start up, the presence of small particles in the fluid (dirt, scale, weld splatters, joint

particles, remains of Teflon tape, etc) may cause an imperfect operation of the cooler. If

this occurs, proceed to an accurate cleaning.

➢

Protection varnishes from pipes and flanges, fats, leftover paint, graphite, etc, should also

be carefully clean, because they can be dissolved in the fluids (like steam) and contaminate

the system.

➢

During operation high flow noises can be heard.

➢

To avoid the risk of scalding, before open or close the sample inlet valve, make sure that

the cooling water it is in the maximum flow.

Danger

14

6.2 Procedure to take boiler samples

1.

The cooling water stop valve (3) and the sample needle valve (2) should be closed.

2.

Open the cooling water valve slowly in order to avoid water hammer damaging, until the

input pressure reaches its limit.

3.

Open the needle valve slowly so that flashing does not occur. Allow to run approximately

10 seconds until fresh sample is drawn.

4.

Adjust the sample outlet temperature (if necessary), by regulating the sample needle valve

and the water valve.

5.

Make sure that there is an adequate equipment to collect the sample in place.

6.

After the sample collection, close first the sample valve and then the water valve but only

after a small period of time in order to condense or cool the remaining steam inside the

sample cooler.

6.3 Periodical checking

•

24 hours after the start up, it is recommended to check the pipe connections for leaks and

retighten the connections if necessary.

7. Maintenance

•

The sample cooler don’t need any specific type of maintenance. Regular inspection may

be recommended by local authorities according to specific or general pipe and/or vessels

assembly procedures.

•

For further information refer to relevant SC brochure or consult our sales office.

•

When reassembling make sure that all gasket faces are clean and always use a new

gasket.

7.1 Limiting Conditions

Minimum operating temperature: -10ºC

Design code: Igema - Merkblatt

LIMITING CONDITIONS

BODY

COIL

Model

Pressure

ba

r

Related

Temp. °C

Pressure

bar

Related

Temp. °C

SC32-

SC132

20

120

110

400

90

450

15

8. Products-returning

8.1 Safety Instructions

➢

Information regarding any hazards and precautions to be considered because of

contaminating fluids and residues or mechanical damage that may represent a health,

safety or environmental risk, must be provided in writing by the distributors and costumers

when returning products to IGEMA engineering.

➢

Health and safety data sheets regarding substances identified as hazardous or potentially

hazardous must be provided with the information mentioned above.

9. Loss of warranty

➢

LOSS OF WARRANTY: Total or partial disregard of above instructions involves loss of any

right to warranty.

This high-quality IGEMA product was designed, manufactured and tested with the

application of the QM System guidelines in accordance with DIN EN ISO 9001:2000.

If the device supplied indicates transport damage or gives cause for complaint in

spite of our final quality control, please contact our SERVICE department on

telephone +49 2501 92424-0 by return.

Table of contents

Popular Accessories manuals by other brands

Climate+

Climate+ CM-30000AP manual

KIT

KIT PWRP6BKNK user manual

Lightolier

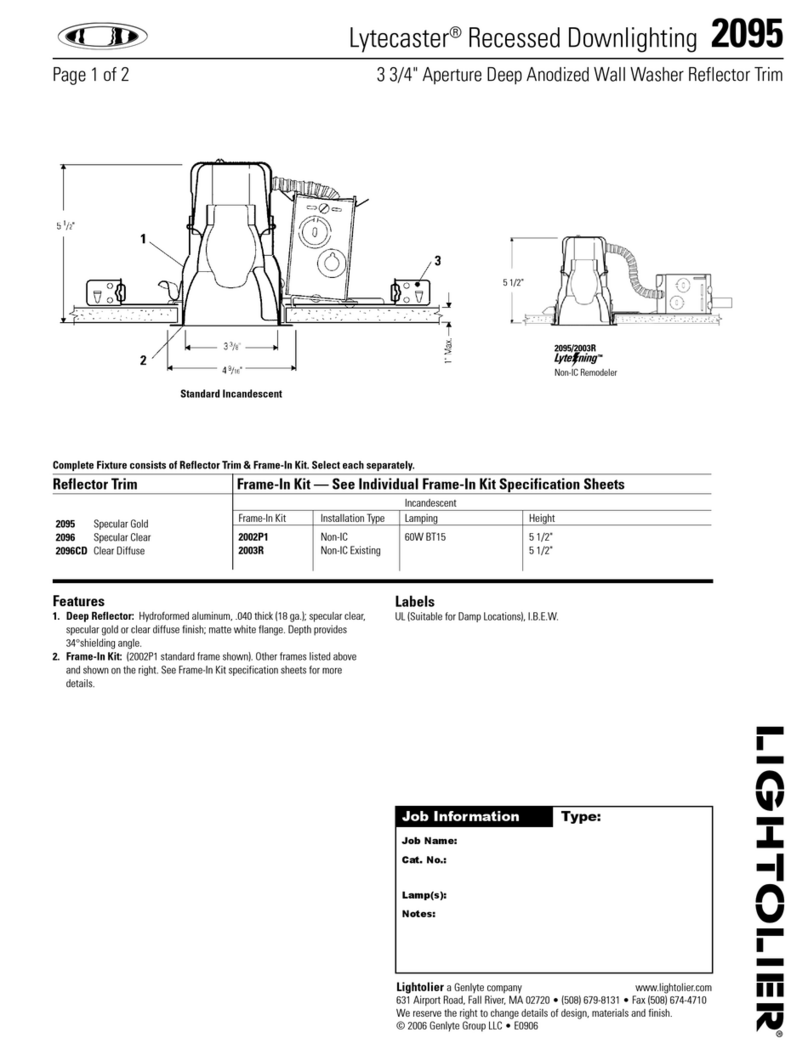

Lightolier Lytecaster 2095 specification

Zephyr

Zephyr Adjustable Depth Liners AK088xAS installation manual

Balluff

Balluff BSI R11A0-XXR-CXP360-S75G user guide

PCB Piezotronics

PCB Piezotronics M221B03 Installation and operating manual

Rice Lake

Rice Lake RL50210 TA installation manual

Niceboy

Niceboy ION ORBIS Motion sensor user manual

krispol

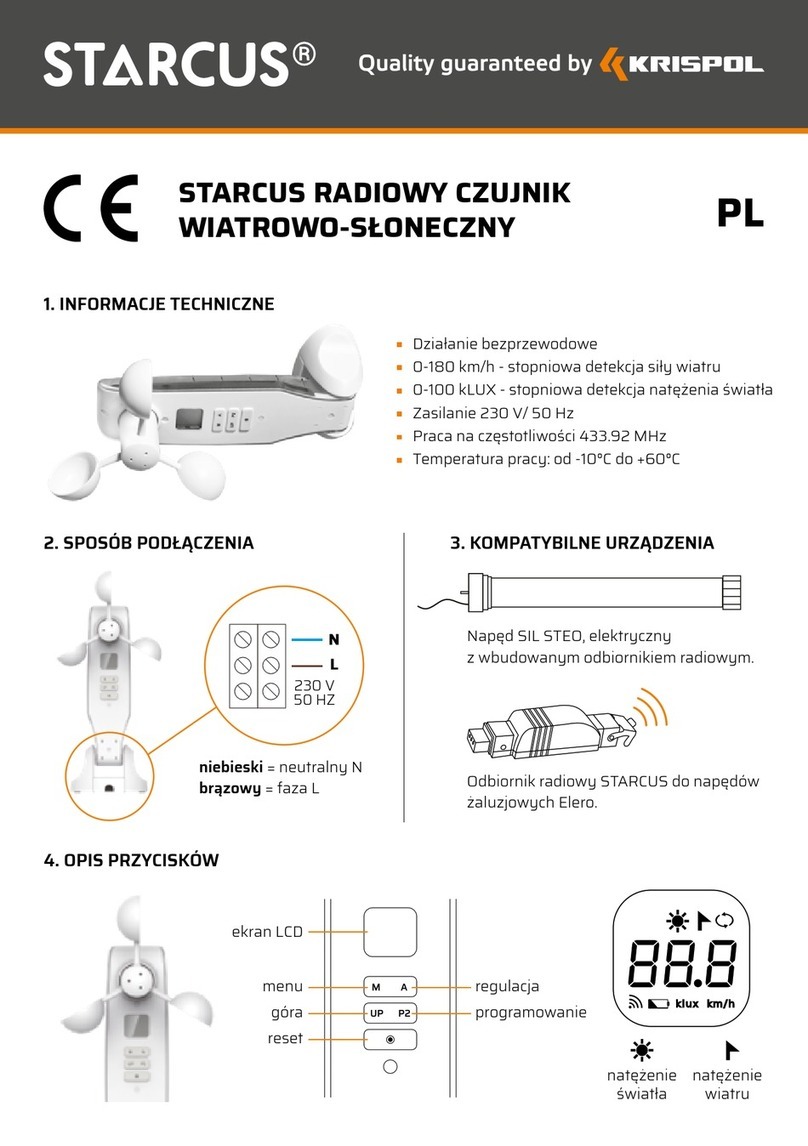

krispol STARCUS ONE manual

LEGRAND

LEGRAND Wattstopper LMDW-102 quick start guide

PCB Piezotronics

PCB Piezotronics M102A14 Installation and operating manual

Jetboards

Jetboards KYMERA BODY BOARD User and safety manual