Igema EWLI-3B Owner's manual

ElectronicRemoteWaterLevel

IndicatorTypeEWLI-3B

forusewithlevelprobes:EL65orEL60

D-05-B-30869-EN-0

Issuedate11/2015

2

TableofContents

1.RisksandSafetyPrecautions..........................................................................................................................................................................3

1.1Generalsafetyinstructions...................................................................................................................................................................3

1.2Exclusionofliability................................................................................................................................................................................4

2.Contentsofthepackaging.............................................................................................................................................................................5

3Useincompliancewithregulations..............................................................................................................................................................5

4.SystemDescription..........................................................................................................................................................................................5

4.1Components............................................................................................................................................................................................5

4.2Function....................................................................................................................................................................................................6

4.3Setup.........................................................................................................................................................................................................7

4.4Componentsofthecontrolunit(CU)..................................................................................................................................................8

4.5Operation..................................................................................................................................................................................................8

4.6Errormessages........................................................................................................................................................................................9

4.7Overviewofthesystemproperties.....................................................................................................................................................9

4.8Displayunit(DU)...................................................................................................................................................................................10

5.AssemblyandInstallation............................................................................................................................................................................11

5.1Add-onhousing.....................................................................................................................................................................................11

5.1.1Installationdimensionsanddescriptions..............................................................................................................................12

5.1.2Installation...................................................................................................................................................................................13

5.2.ControlunitCU.....................................................................................................................................................................................13

5.2.1Installationdimensionsanddescriptions..............................................................................................................................13

5.2.2Powerconnection......................................................................................................................................................................14

5.3.MeasuringunitMU..............................................................................................................................................................................16

5.4DisplayunitDU(optional)...................................................................................................................................................................17

5.4.1Installationdimensionsanddescriptions..............................................................................................................................17

5.4.2Powerconnection......................................................................................................................................................................18

5.5Systemconnection...............................................................................................................................................................................18

6.ConfigurationviaMenu................................................................................................................................................................................19

7.Specialfeaturesofsystemsetup.................................................................................................................................................................22

8.Commisioning.................................................................................................................................................................................................22

8.1Systemsetup..........................................................................................................................................................................................22

8.2Factorysettings.....................................................................................................................................................................................22

8.3Commisioningwhenstartinguptheboiler.....................................................................................................................................23

8.4Commisioningduringboileroperation............................................................................................................................................23

9.TechnicalData.................................................................................................................................................................................................23

9.1Devicedata.............................................................................................................................................................................................23

9.2Mainstransformer................................................................................................................................................................................25

9.3Maximumratingsofpotentialfreecontacts...................................................................................................................................25

9.4Dataplate...............................................................................................................................................................................................26

10.SystemMaintenance...................................................................................................................................................................................26

10.1Depressurisingadd-onhousing.......................................................................................................................................................26

10.2Dismantlingandfittingprobes........................................................................................................................................................27

11.Faultanalysisandrectification..................................................................................................................................................................27

12.Warranty........................................................................................................................................................................................................29

13.DeclarationofConformity..........................................................................................................................................................................30

14Attachment....................................................................................................................................................................................................32

3

Safetyinstructions

1.RisksandSafetyPrecautions

1.1Generalsafetyinstructions

1.Avoidanceofriskstopersonsandproperty

Onlyusethedevicesuppliedinaccordancewiththeintendedplanning.

Extensionsandmodificationstothedevicemustonlybecarriedoutwithourapproval.

Observeaccidentpreventionregulationsandsystem-specificsafetyinstructions.

Readandobservefittingandoperatinginstructions.

Thedevicemustonlybefittedandputintooperationbyappropriatetrainedpersons.

2.Limitationsofuse

Thedevicemustonlybeusedinaccordancewiththedetailsintheseoperatinginstructionsorfor

theparametersagreedinthesupplycontract(seenameplate)andtheapplication.

Approvalforthisdevicelosesitsvalidityifchangesnotauthorisedbyushavebeenmade.

Thesafetyofthewholeboilersystemintowhichthisdeviceisfittedliesintheresponsibilityofthe

installerofthesystem.

Ifthisdeviceisinsertedincorrectlythefunction/protectionexpected from this device may be

impaired.

3Avoidanceofrisksanddamage

DisseminatetheInstallationandoperatinginstructionstothedepartmentsresponsiblefor“goods

in,transport,assembly,commissioningandmaintenance”.

If this device is passed on to third parties, these Installation and operating instructions in the

relevantlanguageofthecountrymustaccompanyit.

Assemblyworkonthedeviceshouldonlybecarriedoutbytrainedstaffspeciallycommissioned

andonlyifthedeviceisdisconnected.

ReadandobservetheInstallationandoperatinginstructionscarefully and keep them in a safe

place.

Takenoteofandfollowthesafetyinstructionsprintedinbold and highlighted in the

individualsections!

Whentransporting,avoide.g.knocksandputtingdownheavily,thiscanleadtodamage.

Forintermediatestorageensurethatthestoragelocationissuitableforthedevice.

Thestoragelocationmustbedryandthedevicesecuredagainstdamage.

Thisdevicemustnotbeusedinareasatriskofexplosion.

4

4.Symbols

IntheseInstallationandoperatinginstructions,safetyinstructionsarespeciallymarkedwiththe

followingsymbols:

meansthatiftheyarenotobservedthereisrisktolifeand/orsignificantdamageto

propertymayoccur.

Danger

meansthatattentionisparticularlydrawntotechnicalrequirements.

Attention

1.2Exclusionofliability

IGEMAGmbHMess-undRegelsystemewillassumenoliabilityiftheabove-mentionedregulations,

instructionsandsafetyprecautionsarenotnotedandfollowed.

5

2.Contentsofthepackaging

1EWLI-3Bconsistingof:

Add-onhousingwithnumberofprobesordered(EL65(<=32bar)orEL60(>32bar))

Measuringunit(MU);fittedontotheadd-onhousingandfullywired

Controlunit(CU)

1Powersupply(top-hatrail)forsupplyingthecontrolunit(CU)with24VDC

1setofinstallationandoperatinginstructions

3Useincompliancewithregulations

The EWLI-3B (electronic water level indicator) is used as a remote water level indicator for steam

boilersor(pressure)tankswithelectricallyconductiveliquids.Dependingontheregulationsapplied

theEWLI-3Bcanalsobeusedasamulti-controlsystem(indicator-limiter‒controller),bymeansof

theprogrammableassignmentofoutputs(change-overcontacts)relativetothelevels.TheEWLI-3B

add-onhousingisfastenedtotheprocessconnectionsprovidedonthetank.

The EWLI-3B has been developed in accordance with the requirements of EC Directive 97/23/EC

(2003)andthestandards:

DINEN129521-7, DINEN129531-6,

DINEN610006-2 DINEN610006-4

DINEN610003-2 DINEN610003-3

DINEN610101

Thedeviceisusedformeasuringthelevelofaliquid.Itisusedpredominantlyonsteamboilers.With

the aid of probes the EWLI-3B measures the current level in theadd-onhousingandthusinthe

boiler.Withtheabilityofhavingupto32Probes(minimum2)oneachievesaquasi-continuouslevel

display,takingintoaccountaminimumprobespacingof36mm.

4.SystemDescription

4.1Components

-Add-onhousingwithnumberofprobesordered(EL65(<=32bar)orEL60(>32bar))

-Measuringunit(MU);fittedontotheadd-onhousingandfullywired

-Controlunit(CU)withseparatepowersupplyunit;fortop-hatrailfittinginthedistributioncabinet

-Displayunit(DU)‒optional

-variousCAN-Busconnectingcables

6

4.2Function

TheEWLI-3Blevelindicatorworksonthebasisoftheconductivefilllevelmethodofmeasurement

whereby the electric conductivityofthemediumisused.Theconductivity of the medium is

measuredinµS/cm.Forthesecurefunctioningofthismethodof measurement a minimum

conductivityofthesubstancetobemeasuredisrequired.

Theconductivemethodofmeasurementmakestwostatements:electrodesubmergedorelectrode

emerged.

Themeasuringunit(MU)feedsandevaluatestheinstalledprobes(2to32innumber).Thestateof

theprobesattachedintheadd-onhousingisthensenttothecontrolunit(CU).

Thecontrolunit(CU)determinesthereactionsnecessaryfromthereceiveddatafromthemeasuring

unit(MU).

SystemstatusLCDdisplayLEDs1*4mA..20mAOutputcontact2*

Correct

operation

IGEMA

EWLI3-CU

4mA+

(16mA/numberofprobesfitted)

x

Numberofprobessubmerged3*

A:activated

F:activated

Z:dependingonassignment/

programming

correctoperation

withfailureofone

24Vsupply4*

(40)PIN1

powertoolow5*

4mA+

(16mA/numberofprobesfitted)

x

Numberofprobessubmerged3*

A:activated

F:activated

Z:dependingonassignment/

programming

Systemerror(65)MU

CANBUSnodata5*

2mA A:nopower/stateofrest

F:nopower/stateofrest

Z:allwithoutpower

Waterlevel

alarm

(LLW/HHW)

(33)

LLWalarm5*

4mA+x(LLW)

20mA‒y(HHW)

x,ycorrespondingto

programmedProbe

A:nopower/stateofrest

F:activated

Z:dependingonassignment/

programming

Wateroversteam (“No”)please

checkprobe:“No”5*

2mAA:activated

F:nopower/stateofrest

Z:dependingonassignment/

programming

Probeerror7*

(LLW/HHW)

(33)

LLWalarm5*

2mAA:nopower/stateofrest

F:nopower/stateofrest

Z:dependingonassignment/

programming

7

Probeerror6*

(assigned)

(“No”)please

checkprobe:“No”5*

2mAA:nopower/stateofrest

F:nopower/stateofrest

Z:assignedwithoutpower;

Rest:dependingon

assignment/progr.

Probeerror6*

(notassigned)

(“No”)please

checkprobe:“No”5*

2mAA:activated

F:nopower/stateofrest

Z:dependingonassignment/

programming

1*FullylitLED:continuouslight/halflitLED:flashing

2*Description: “A”Alarmoutput “F”Erroroutput “Z”Assignedoutput

3*Example: 12probes/4submerged: ...mA=9.3mA(4mA+(16mA/12)*4)

16probes/7submerged: ...mA=11.0mA(4mA+(16mA/16)*7)

15probes/13submerged: ...mA=17.9mA(4mA+(16mA/15)*13)

4*Whenusing2powersupplyunits

5*Example

6*SeeChap.7Specialfeaturesofsystemsetup

7*AsLLW/HHW-Alarmhaspriority,thismessageisshown.However,consideringtheLED-display(yellowflashesalso)the

probefaultisrecognisable.

Safe operating mode during which the output contacts of the device go into rest position,

correspondsatthesametimetothede-energisedstateofthecontrolunit.

TheDU(optional)displayunitcanbeusedasaremoteindicator.ThestatusLEDsshowthesameas

theLEDsoftheCU.InadditioneachprobeislinkedtoanLED.Greenshowsasubmergedprobe,reda

probeinthesteamspaceandaflashingLEDmeansaprobeinanincorrectstate.Theoutputcurrent

ofthe4mA..20mAoutputoftheDUiscalculatedlikethatoftheCU.

4.3Setup

ForensuringhighavailabilityIGEMArecommendstheuseof2powersupplyunits(redundancy).In

termsofhardwaretheCUisdesignedforoperationwith2powersupplyunits.

Boththemeasuringunit(MU)andthecontrolunit(CU)have2independentelectroniccircuitswith

their own processors. All processorscarryoutregularself-tests for internal faults in the electronic

circuit.Thisprovidesself-monitoringofthedeviceandthusahighersafetystandard.

Measuringunit:

Bothelectroniccircuitsrecordthestateoftheprobesandsendittothecontrolunit.

Controlunit:

Bothelectroniccircuitsevaluatethestatusmessagesofbothelectroniccircuitsofthemeasuring

unit.Ifbothstatusmessagesareidenticaltherequiredreaction(Chap.4.2)iscarriedout.

Aplausibilitychecktakesplace.

8

Eachelectroniccircuitswitchesits“own”relay(SPDT)forthecorrespondingoutput.Onlywhen

bothrelaysofbothelectroniccircuitsaredriven(activated)equally(e.g.duringnormaloperating

status)istheoutputactive.

Theoutputcontactsdonothaveanylatching.Theswitchingbehaviouris

exclusively in line with the desired specified (programmed) state. If latching is

required,thismanuallocking(latching)mustbecarriedoutonsite.

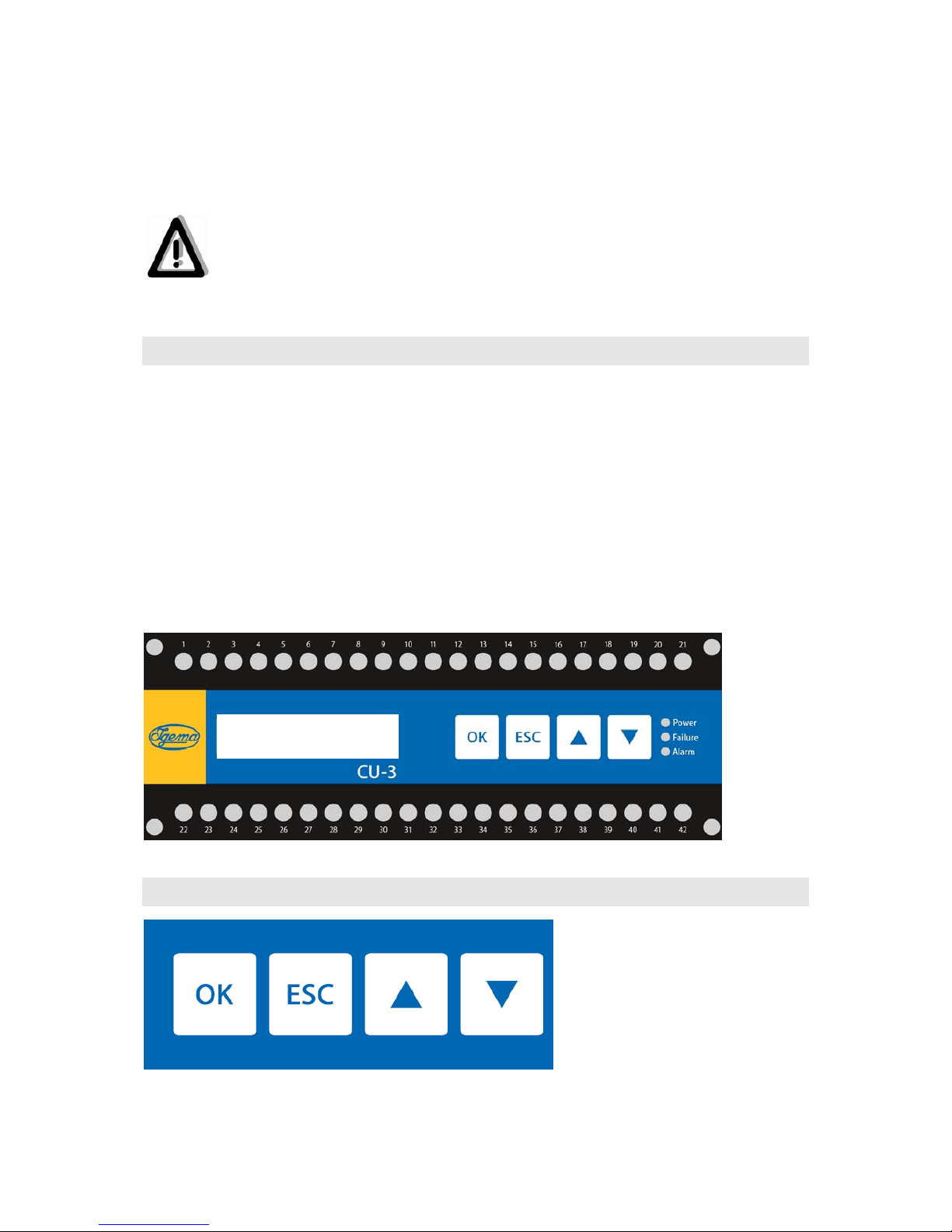

4.4Componentsofthecontrolunit(CU)

Thecontrolunitcontains:

1LCDdisplay(2-lineeach16characters)forcommunicationwiththeoperator

(programmingandinformationdisplay)

4buttonsforprogramming

3LEDsasstatusindication

1SPDTalarmoutputforfilllevelsignalling(fixed);thecorrespondingprobes(LWand/orHW)

canbefreelychosen

1SPDTerroroutput(fixed);outputisinstateofrest,ifanysystemerroroccurs

7SPDToutputsfreelycontrollable(seeassignmentplanChap.:5.2.2)

14mA..20mAoutputforloadsupto500Ω,notgalv.isolated

4.5Operation

OperationoftheEWLI-3Biscarriedoutbythe4buttonsoftheCU.ThisisdescribedinChap.6

“ConfigurationviaMenu”.

IGEMA

EWLI3-CU

9

4.6Errormessages

IntheLCDdisplayerrorsfromtheevaluatorandprobesaredisplayednumber-codedandinplaintext

abbreviations.

IfthereisaDUpresent(optional),errorsbyevaluatorandprobesare displayedinthe7-segment

displaynumber-codedand2-digit.

ForanalysisanderrorcorrectionseeChap.10.

4.7Overviewofthesystemproperties

-Upto32probes(minimum2probes)forquasi-continuouslevelmeasuring

-CanbeuseduptoPS=200bar//TS=367°C

-Doublepowersupplyforhighavailability(redundancy)withdisplayoffailureofonepowersupply

-Self-monitoringelectronicsforhighsystemsafetyduringmonitoringfunctions

-wirebreakagemonitoring

-Adjustableswitchingdelayonalloutputsforavoidingfalsesignals

-1alarmoutput(SPDT)forthereactionincaseoflowwaterand/oroverfilling

-1erroroutput(SPDT)forthedisplayof(electronic)systemerrors

-7userspecificandprogrammableoutputs(SPDT)enable:

*individualswitchpointse.g.hornwhenexceedingorfallingbelowafilllevel

*doubleswitchpointse.g.forapumpcontrol

Inthecaseofidenticalprogrammingoftwooutputsa“DPDToutput”ispossible.

-14mA..20mAoutputforloadsupto500Ω,notgalv.isolated

-Remoteindicator(DU,optional)with4mA..20mAoutputforloadsupto500Ω,notgalv.isolated,

asmanyasdesired

10

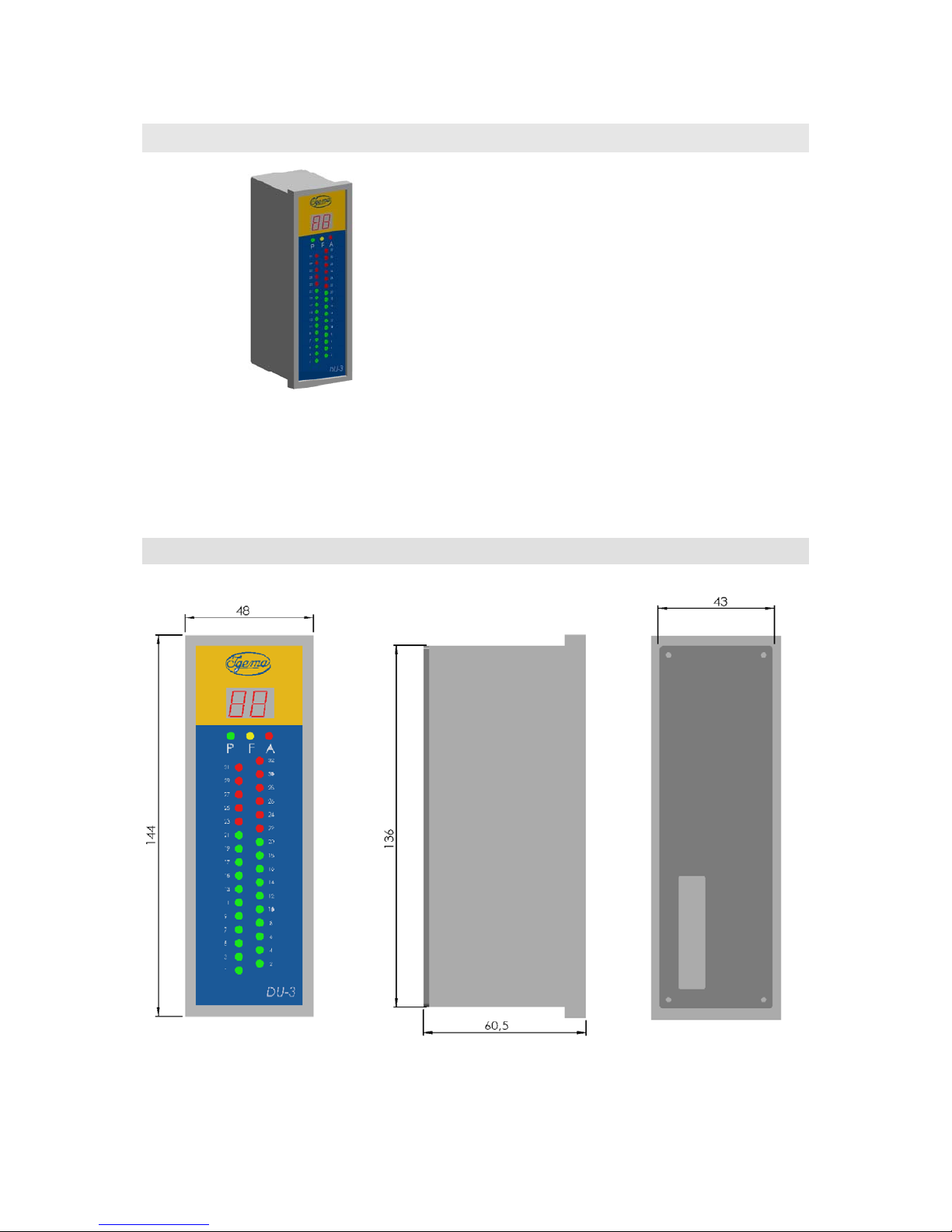

4.8Displayunit(DU)

Therearetwoversionsofthe(optional)displayunitDU:

-systemswithupto16probeshaveasingle-rowLED-display

-systemswith17upto32probeshaveadouble-rowLED-display

ForeachprobeaLEDindicatesthestateoftheprobe:

-green:probesubmergedinwater

-red:probeinsteam

-surplusLEDs(e.g.13,14,15,and16ifthesystemhas12probes)arenotactivatedandremain

dark

Theconditionofthesystemisindicatedvia3status-LEDs(identicaltotheLEDsoftheCU/seeChap.

4.2).

Ifadiscrepancyinthemeasurmentisdetected(waterabovesteam),theprobethatindicateswater

flashesgreen(seeChap.4.2).

IfaprobefailureisdetectedthecorrespondingLEDflashesred(seeChap.4.2).

11

5.AssemblyandInstallation

5.1Add-onhousing

Measuringunit

MU

Processconnection

Probes

Casing

12

5.1.1Installationdimensionsanddescriptions

A: Boilerconnectiondimensions

E: Displayarea

D: Minimumwaterlevel

T: Distancebetweenprobes

L: Lateraldismantlingdimensions

13

5.1.2Installation

Theadd-onhousingissuppliedfullywired.

Itisattachedviatheprocessconnectionsinaccordancewiththerules/regulationsontheboiler.

Becauseofthetemperature-dependentdensityofthemedium,itmustbeensured

thataflowthroughtheadd-onhousingwiththemediumisensured,e.g.througha

forcedcirculation(inclination).

5.2.ControlunitCU

The control unit and also the associated power unit are supplied in a plastic plug-in housing for

fittingintoswitchcabinets.ThehousingisdesignedforquickfittingwithaspringcatchfortheDIN

EN50022standard35mmcarrierrail.

Ensureprotectionclassinaccordancewithcurrentregulations

WithsnapfasteningforstandardDINEN5002235mmcarrierrail

Fixdeviceonstandardcarrierrailbymeansofthesnapfastening(4).

5.2.1Installationdimensionsanddescriptions

Frontview:

Sideview:

IGEMA

EWLI3- CU

14

5.2.2Powerconnection

Thedeviceterminalstripisliveduringoperation!!

Beforeworkingonthedevicedisconnectitfromthemains!!

If inductive equipment is connected, voltage peaks occur when switching off.

For this reason connected inductiveequipment(e.g.contactor)must be

providedadditionallywithanRCcircuit:e.g.0.1µF/100Ω.

The output contacts are only switched when both electronic circuits energise the

correspondingrelays(Chap.4.3)

Assignmentplan:

Upperbar/contacts1‒21(fortheoutputcontactstherestpositionisdisplayed):

Whenusingonlyone24Vsupply,contacts1and2mustbebridged.

AlarmOut

FailureOut

15

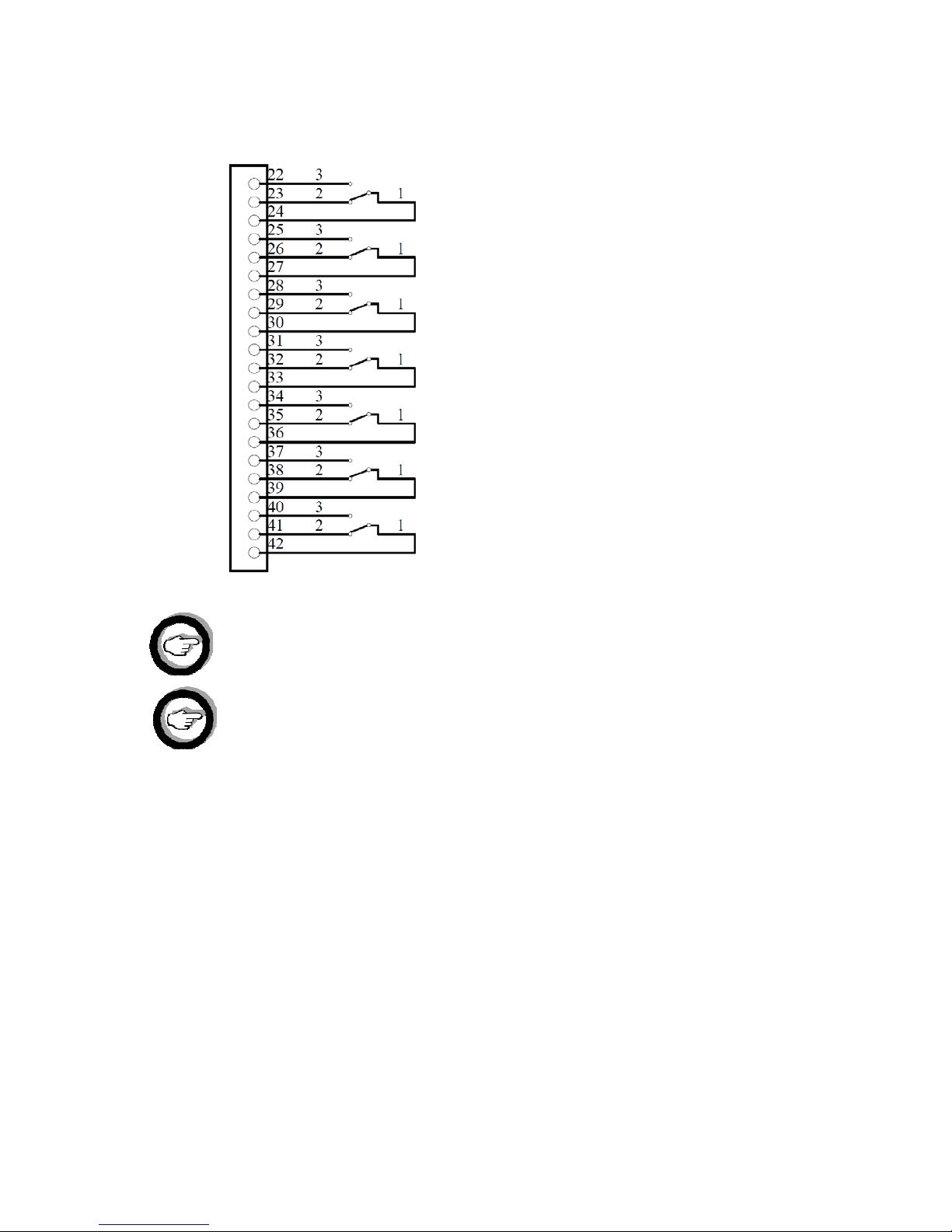

Lowerbar/contacts22‒42:(freelyprogrammableoutputchangecontacts)

(restpositiondisplayed)

TheCAN-Buscontrol cable has to be a 4-wire, twinstranded, shieldedcable(e.g..

UNITRONIC®FDPDeviceNetTMTHICK(PUR)//option:IGEMAArt.no.35-10058).

Forthecurrentloopinterface(4mA..20mA)ashieldeddatacable(2x0,34mm2or

2x0,75mm2)(e.g.UNITRONIC®PURCP)hastobeused.

Out1

Out2

Out3

Out4

Out5

Out6

Out7

16

5.3.MeasuringunitMU

Themeasuringunitisfixedtotheadd-onhousingandtheprobesarefullywired.Theconnectionto

thecontrolunittakesplaceviaa5-pinplugatthebottomoftheswitchingcabinetofthemeasuring

unit.

Ifnoassembledcableisordered,theassemblingoftheenclosedplugsocketisdoneaccordingtothe

DeviceNetTMBUSsystem.

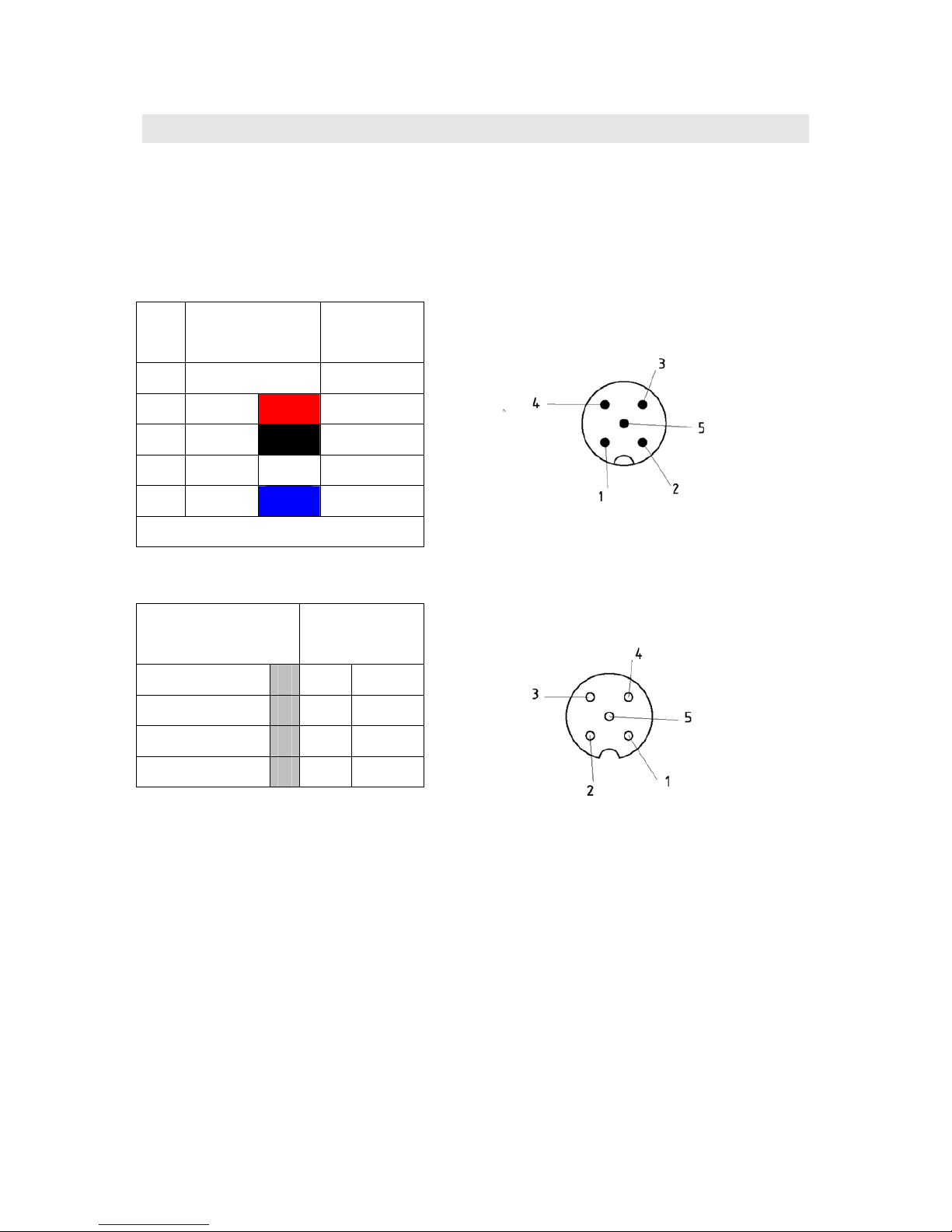

assignmentofterminalsontheMUcircuitboard:

connectingterminal signal

DeviceNetTM

2 o CANL

3 o CANH

4 o V-

5 o V+

PIN Leadcolor signal

DeviceNetTM

1 Drain

2 RD V+

3 BK V-

4 WH CANH

5 BU CANL

Screenfixedtohousing

plugsocketM12,5-pin,A-coded

plugM12,5-pin,A-coded

17

5.4DisplayunitDU(optional)

The(optional)displayunitisdesignedasswitchboardmountabledevice.

Forfastening,ascrewsystem(switchboard)oratop-hatrailadapterisavailable(seeAccessories).

TheDUissuppliedasstandardwith120Ωbusterminatingresistor(contact3‒contact4//CANL-

CANH)

5.4.1Installationdimensionsanddescriptions

18

5.4.2Powerconnection

Aplug-inconnectorisledoutattherear.Theassignmentis:

*TheDUissuppliedasstandardwith120Ωbusterminatingresistor(terminator).

If the DU is not the last device (see Chap 5.5), it must be removed when fitting (the CAN-Bus).

IftheDUisthelastdevice,theCAN-Busmustsimplybeadded.

5.5Systemconnection

Anoverviewoftheelectricalconfigurationoftheoverallsystemisgivenbythefollowinggraphics:

(Theillustrationshowstheredundantconfigurationwith2powersuppliesand3optionalDUs.)

ThebusterminatingresistorisalreadyimplementedintheMU.Thusonesideofthebus(ontheleft

inthediagram)issealedoff.TheothersideofthebusmustbeterminatedonCANHandCANLon

thelastdeviceviaa120Ohmresistance.

OnlyIGEMAcomponentsbelongingtotheEWLI-3BsystemmaybeoperatedonthisCAN-Bus

controlcable(1xMU;1xCU,XxDU).Theshort-circuit-proof24VvoltageoftheCAN-Busis

120Ω*

Terminator

Terminator

Mainsadapter

Mainsadapter

19

designedexclusivelyforthesupplytothesystemandmustnotbeusedfortheexternalsupply

offurtherdevices.

Themaximumlengthofthebuslinecanbeatotalof500m.

Whenfitting,bearinmindthatthecablemustnotcomeintocontact with heat-

conductingparts.

The CU control unit can supply the measuring unit (MU) and up to 3 display units (DU). The

connectionoffurtherDUsispossible.Howeverthesemustthenbeprovidedwiththeirownseparate

andindependent24Vsupply(observeChap.9.2!).

6.ConfigurationviaMenu

ThemenuoftheEWLI-3Bisdividedintotwolevels:

Level1|Level2

Themenuisaccessedbypressingthe“OK”key.AmenuitemofLevel1willappearintheLCDdisplay.

Withthekeys“▲”or“▼”youcanchoosebetweenthemenuitemsoftherespectivelevel.Theupper

rowis“active”.

Bypressingthe“OK”keyyouwillgettothenextleveldownorconfirmtheentry.

Bypressingthe“ESC”keyyoucangettothenextleveluporoutofthemenuwithoutthecurrent

entrybeingsaved.(With“OK”confirmeddataarealreadysavedandremainso.)

ThemenulanguageisEnglish.

Automaticmenu exit after2minutesifno key operationiscarriedout(without saving /see

“ESC”).

Themenuconsistsof4items.Items1to3arepurelyforinformation!Whereasitem“1.1Probestate”

andaboveallitem“1.2Relaystate”areveryusefulforcheckingthecorrectprogrammingandthe

desiredswitchingoperations.

(Youfindexamplesforprogrammingintheattachment)

20

Diagram:

|---1.SystemInfo---

||-1.1.Probestate|

||-1.2.Relaystate|

||-1.3.MUsystemA|

||-1.4.MUsystemB|

|---2.Supply---

||-2.1.InputPin1|

||-2.2.InputPin2|

||-2.1.OutputPin3|

|---3.Version---

||-3.1.Control|

||-3.2.Measurement|

||-3.3.Display|

|---4.Settings---

||-4.1.Backlight|

||-4.2.Password|

|---|-----Afterenteringvalidpassword------------------

||-4.3.Relaysetup|

||-4.4.LLWAlarm|

||-4.5.HHWAlarm|

The password is: 123; It activates the menu items 4.3, 4.4 und 4.5 and its only

functionisthepreventionofunintentionalprogrammingofsystemfunctions.

Menudescription:

1.1Probestate: Thestateoftheprobesisdisplayed,“w”forwater,“s”forsteam;

For illogical states, for example water over steam, the submerged

probeisdisplayedincapitals(e.g.“W”).

1.2Probestate: Theswitchstateofthe9outputsisdisplayed“0”forrestposition(NO)

and“1”foractivated.

1.3/1.4MUSystemA/B: Temperatureoftherespectiveelectronicsofthemeasuringunit.

2.1InputPin1: Supplyvoltage1(theoretical24V)

2.2InputPin2: Supplyvoltage2(theoretical24V)

2.3OutputPin3: Can-Bus‒voltage(theoretical23.5V)

3.1Control: VersionnumberCU

3.1Measurement: VersionnumberMU

3.1Display: VersionnumberDU

Table of contents

Popular Touch Panel manuals by other brands

Extron electronics

Extron electronics TLP Pro 1230WTG user guide

weintek

weintek MT-600 Series Installation instruction

Winmate

Winmate GC Series quick start guide

PZRacing

PZRacing GearTronic2 GT400 user manual

Intel

Intel Platform Panel PC User manaul

Avery Weigh-Tronix

Avery Weigh-Tronix WI-130 Software user manual