13

WI-130 SimPoser Software User’s Manual

Units tab

By default, when the PRINT key

is pressed, a print operation

and an accumulation take

place. If you do not want the

accumulation to occur, a WT-

BASIC program assigning only

the DOPRINT command to the

PRINT key needs to be down-

loaded to the WI-130. A WT-

BASIC program can also define

an ACCUM. soft key and

assign accumulation to that

key only.

Setpoint and configuration

parameters such as capacity,

bargraph, checkweigher, and

analog output values are based

on the calibration unit, not on

displayed unit of measure.

Accum Return to Zero % To accumulate weight, the weight must be

above this percentage of scale capacity and stable.

Before you can perform another accumulation

operation the weight must return to zero.

Print Return to Zero % To print, the weight must be above this percentage of

scale capacity and stable. Before you can perform

another print operation the weight must return to

zero.

Calibration Weight The amount of test weight used to calibrate the

scale. We recommend entering the test weight most

commonly used to calibrate this scale capacity by

your organization. (Minimum of 25% of capacity.)

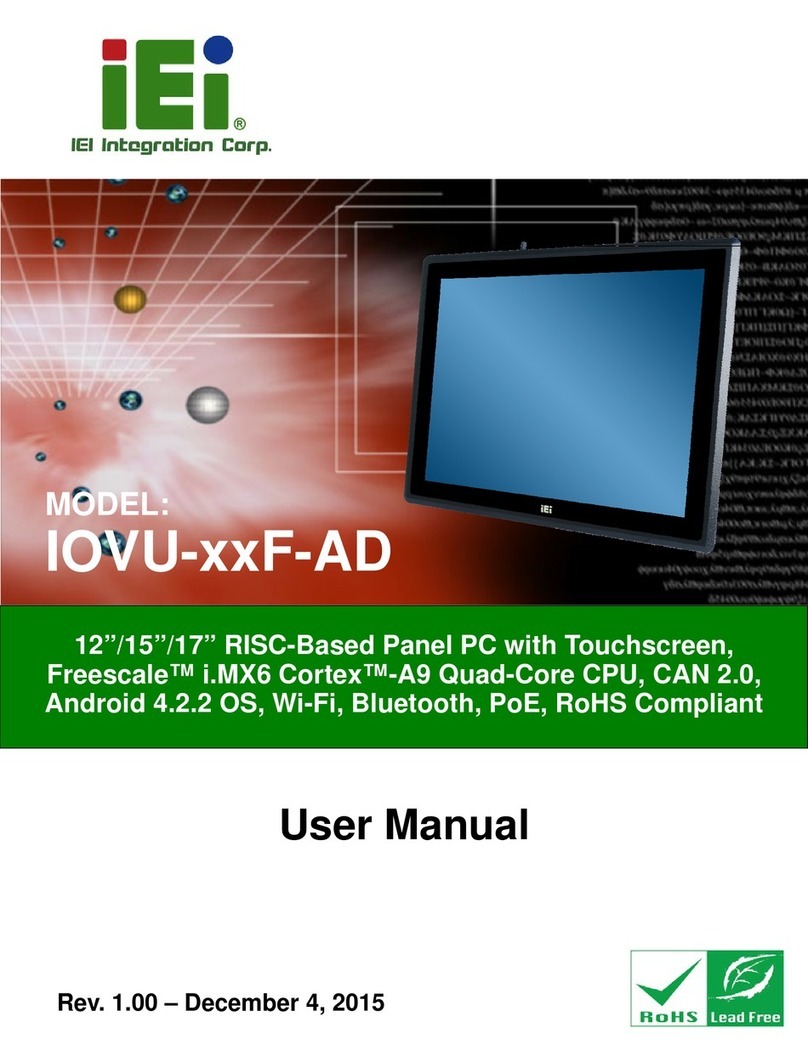

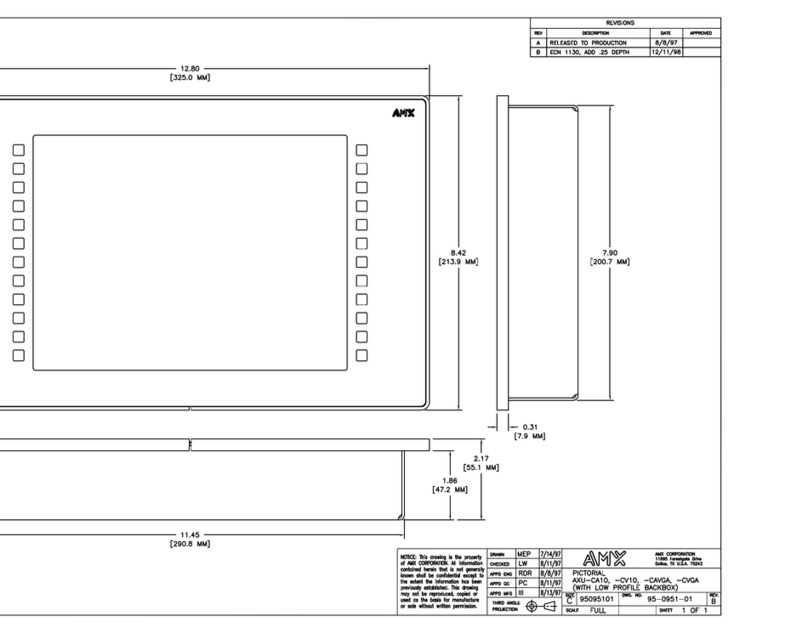

The next tab is Units. This is shown in Figure 4.

Figure 4

Units dialog box

Following is a brief description of each of the unit of measure items you see

in Figure 4.

lb, kg, grams, oz,

lb/oz, Custom

Unit 1 & 2 Select the units of measure you want to use. Those you

enable will be available to you as the UNITS key is

pressed on the WI-130. Conversion factors are preas-

signed by the factory for lb, kg, grams, oz, and lb/oz.

Calibration Unit Select the unit of measure used in the calibration of your

scale. Choose from lb, kg, grams, or oz.

Custom Units If you select a custom unit, you can choose from a list of

possible units or create your own name for a unit of

measure. You must also enter in a conversion factor for

that custom unit of measure based on your calibration

weight unit.

The custom units conversion

factor is the number to be

multipied by the weight (in

calibration units) to get the

desired custom unit. Example:

1 lb = 5 inches of a certain

steel rod. Custom unit is

inches. Calibration unit is lb.

Conversion factor is 5. With six

lbs of weight on the scale, 30

inches would be displayed.

(Six lbs x 5 = 30 inches of

steel)