IGM 141-MX48 User manual

Distributor:

IGM nástroje a stroje s.r.o.

Ke Kopanině 560, 252 67, Tuchoměřice

Czech Republic, EU

Phone: +420 220 950 910

E-mail: [email protected]

Website: www.igmtools.com

Power Feeder 230V

Operationg instructions

2022-09-15

141-MX48 Power Feeder 230V Manual EN v1.1.00 A4ob

141-MX48

www.igmtools.info

PDF ONLINE

-2-www.igmtools.com

Operating instructions EN

Please read this manual thoroughly and follow the safety instructions in it! Technical changes

and printing errors reserved!

Dear customer,

This manual contains important instructions and information for the installation and proper use of

MX48 Power feeder.

This manual is a part of the machine and therefore it should not be kept elsewhere than in the vicinity

of the machine so that you can be consulted at any time by you or other persons operating the

machine.

Please read and follow the safety instructions!

Carefully read these instructions before using the machine. Operation of the machine will

be simpler and you will also lower the risk of injury while eliminating the probability of

incorrect operation and possible damage to the machine. Because of our policy of constant

improvement, the design, construction or pictures may dier slightly. Should you discover

1. DECLARATION OF CONFORMITY

The undersigned: IGM nástroje a stroje s.r.o.

Address: Ke Kopanině 560

Tuchoměřice, Praha-západ, PSČ 252 67

Czech Republic, EU

Tel. +420 220 950 910

Certies

Product: Power Feeder

Model: MX48

Manufacturer: CO-MATIC Machinery Co., Ltd.,No.

473-16,

San Feng Road, Houli District, Taichung

City,Taiwan, R.O.C. 42156

We declare under our sole responsibility that the

product described in this manual is in conformity

with the following standards: EN ISO 12100, EN ISO

13857, EN 349, EN 953, EN 60204-1, EN ISO 11202,

TABLE OF CONTENTS page

1. DECLARATION OF CONFORMITY 2

2. WARRANTY SERVICE 3

3. SAFETY INSTRUCTIONS 3

3.1 Notice 3

3.2 General safety instructions 3

3.3 Risks 4

3.4

Important notice

4

3.5

Safety rules

4

4. SPECIFICATIONS OF THE MACHINE 4

4.1 Machine description 4

4.2 Technical data 4

4.3 The package includes 4

5.

TRANSPORT, UNPACKING AND ASSEMBLY

5

5.1 Transport and unpacking 5

5.2 Assembly 5

5.3 Tools Required 5

5.4 Installation steps 5

6. OPERATION CONTROL 6

6.1 Stand 6

6.2 Control- Joint 7

6.3 Feeding 7

7. POWER CONNECTION & GROUNDING 8

8. SPEED CONTROL 10

9. ROLLER REPLACEMENT 11

10. MAINTENANCE 11

11. FEEDER OPERATION INSTRUCTION 12

12. ASSEMBLY AND PARTS LIST 14

-3-www.igmtools.com

Operating instructions EN

EN 55014-1, EN 55014-2 podle s ustanoveními

směrnic 2006/42/EC, 2004/108/EC, 2006/95/EC,

2002/95/EC.

Signed: Ivo Mlej

Managing Director

2. WARRANTY SERVICE

The warranty is subject to Terms and Conditions and

Warranty Conditions of IGM nástroje a stroje s.r.o.,

the current version of which are available at www.

igmtools.com.

3. SAFETY INSTRUCTIONS

3.1 Notice

This machine is designed for work with wood and

wooden materials.

Proper use also includes compliance with the regular

operational and maintenance work described in this

manual.

The machine can be operated only by persons

familiar with the operation procedures, maintenance

and are aware of potential risks involved.

Comply with the minimum age limits specied by

law. The machine may only be used when in perfect

technical condition.

All safety and protective components must be

installed when operating the machine.

Besides these instructions, also adhere to the safety

instructions of your country and to the generally

recognized technical practices concerning the

operation of woodworking machinery.

The manufacturer or the supplier is not responsible

for any damage resulting from improper use.

Every user is responsible for their own actions.

The warranty cannot be claimed if any of the

following principles are broken:

- Unsuitable work environment: high humidity,

contamination.

- Damage caused by an improper assembly and/or

improper storage.

- Use of damaged machinery.

- Failure to follow the operating instructions:

transport, storage, assembly, putting into operation,

cleaning and maintenance of the machine.

- Use of unauthorized spare parts.

3.2 General safety instructions

The machine can pose danger when improperly

operated.

Completely read the operating instructions before

working with the machine and follow all the

instructions in this manual.

Keep this user manual clean and protect it from dirt

and moisture; in case of re-selling, pass the manual

onto the new owner.

Any alterations or changes to the machine are

prohibited.

Daily try out if the machine runs smoothly and check

the function of protective covers before operating the

machine. Replace any deciencies and immediately

remove any damaged parts like covers.

The machine may only be used when in perfect

technical condition.

Use a hairnet or a hat to protect long hair. Wear tight-

tting clothes, remove all bracelets, rings, necklaces or

ties. Wear work boots only, do not wear casual shoes

or sandals during work. Abide by the regulations for

personal protection.

Always wear safety eyewear. Always use hearing

protection. The tools are sharp and can cause severe

injury, use them with care.

Keep in mind the necessary space for operation when

installing and positioning the machine. The machine

must stand on a stable surface and must be adequately

lit.

Always use respiratory protection when working in a

dusty environment.

Make sure you have good lighting.

Make sure the power cord is not in your way when

working. Keep your work area clean. Never touch the

machine when it‘s running.

Make sure you are concentrating and paying attention.

Use caution. Never work under the inuence of drugs

and/or alcohol.

Make sure there are no children around when working

with the machine.

-4-www.igmtools.com

Operating instructions EN

4. SPECIFICATIONS OF THE MACHINE

4.1 Machine description

1

2

3

5

6

78910

11

12

14

13

15

4

Never leave the machine unattended. Always switch

the machine o when leaving the workspace.

Watch your ngers and other body parts when

working. Never walk away from a machine without

protective guards.

Do not place anything on the machine.

Electrical connections malfunctions can be repaired

by an electrician only. Damaged electric cord must be

replaced immediately.

Any adjustments and maintenance may be carried out

when the machine is disconnected from the power

source.

3.3 Risks

Risks may arise even during proper and prescribed use

of the machine.

The danger of a workpiece ying o. Beware of noise

and dust.

Wear eye, ear and dust protection.

Use a suitable dust extraction device! Watch out for

damaged electrical cords.

3.4 Important notice

Only use the feeder in an appropriate environment.

Keep your workspace well ventilated and lighted,

avoid wet or damp environments.

Only operate the machines under temperatures

ranging from +5°to +40°C. Humidity from 30% to 95%.

3.5 Safety rules

The tool must reach working speed before feeding.

Do not overload the machine by feeding material too

quickly.

ALWAYS keep your hands away from rotating parts.

Provide additional support and stability for larger

workpieces.

Always switch o the feeder rst, only then switch o

the machine that is being fed material.

Always disconnect the power cord before any repairs

or adjustments.

1 base

2 locking lever (turning)

3 height-adjustable arm

4 locking lever (height adjustment)

5 stand

6 height control (turning alters height)

7 locking lever (protrusion)

8 feeder arm

9 screws (positioning joint)

10 locking lever (turning)

11 locking lever (angle of the feeder)

12 motor

13 control wheel of arm protrusion (turning moves

the arm)

14 feeder grip

15 rollers housing

4.2 Technical data

Type MX48

Motor power (230V) 750W

Horizontal Movement 460mm

Vertical Movement 250mm

No. of rollers 4

Size of rollers 120x60mm

Feed speed 3.5-32m/min

Weight with stand 62kg

4.3 The package includes

feeder

feeder stand arm

quick adjustment joint

plan for base drilling 1:1 manual

-5-www.igmtools.com

Operating instructions EN

5. TRANSPORT, UNPACKING AND ASSEMBLY

5.1 Transport and unpacking

The machine is not assembled due to transport.

Remove the feeder from the packaging and place

on a at surface. Check for any apparent transport

damages, these could damage the machine or your

health.

5.2 Assembly

We recommend to greasing the metal parts before

assembly.

5.3 Tool Required

- Power drill, 10.2mm Drill, M12 Tapping (Tapper) Tool

kits.

- Open-end wrench 13“, 14“, 17“, 19MM

- Allen Key 4MM

- M12 x 50MM Long Screw and 4 sets of M12 Spring

washers attached with packages.

5.4 Installation Steps

NOTE: Ensure there is sucient weight support to

prevent power feeder tilted while Swing aside.

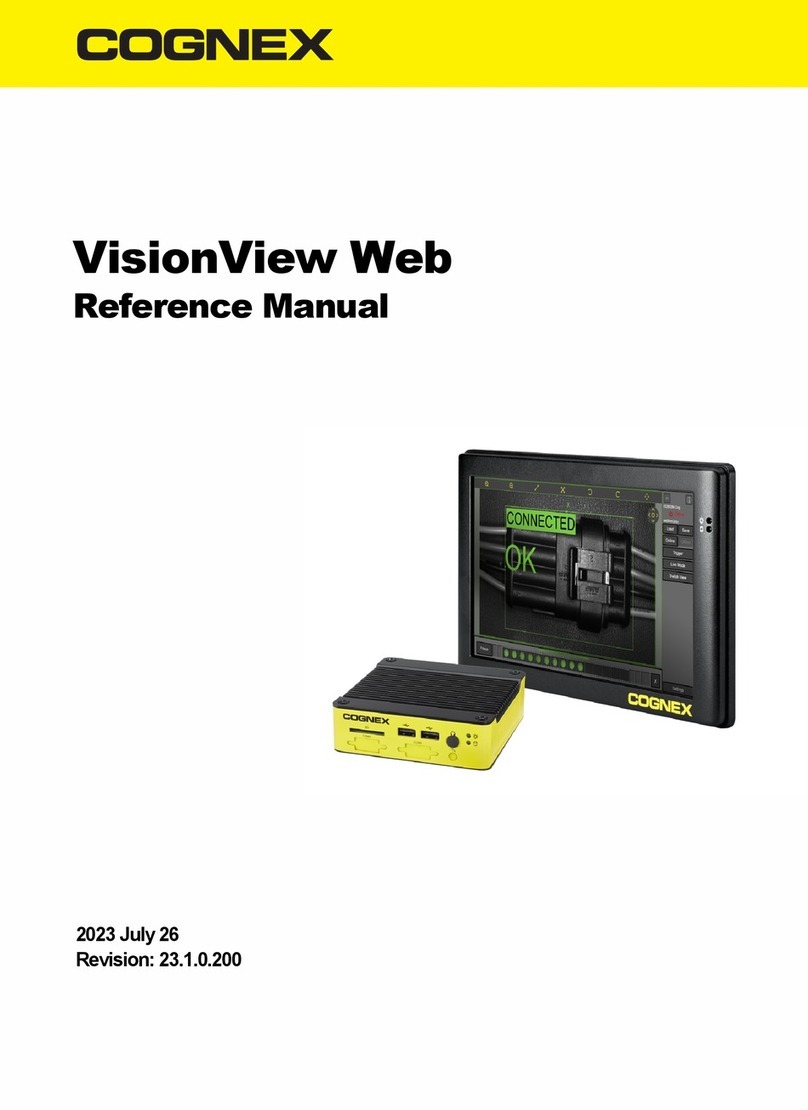

1. Conrmation of Power Feeder stand base

mounting position:

For small machine table, an extension bracket (no

provided) is recommended.

2. Locate boring position

For your boring convenience and accuracy, a SCALE

1:1 SELF-ADHESIVE DRILLING TEMPLATE is provided

and enclosed in the package.

Clean location free from oil. Tape SELF-ADHESIVE

DRILLING TEMPLATE to desire position. Mark it

with centre punch; Avoid table rib and support

underneath the table.

Prepare 4 sets of M12 bolts & spring washers (not

provided).

5.5 Assembling

NOTE: Get help! Feeder is heavy. Do not try to do it

on your own.

Fasten base to table attached with 4 sets of M12

screws, spring washer.

Insert “STAND” to BASE. Assemble Handle.

-6-www.igmtools.com

Operating instructions EN

Insert OVER-ARM into ELEVATING-BRACKET. Turn

wheel a few turns. Tighten LEVER.

Insert the extension tube (A) into cross slide vise,

push (B) hand-wheel into cross slide vise and

rotating while push-in, ensure the hand-wheel kit are

intermeshing with extension tube kit properly.

Lock the headless hex-screw in to cross slide vise

(C), the rotating the handle-wheel and insert it into

hand-wheel gear groove (D) to ensure the gears can

be rotating smoothly, lock the hex-screw to complete

the installation.

Install control-joint: To slip the end side of the

extension tube into swivel cone (A) and ensure the

alignment of the lever and extension tube centre line

(C) lock with 2 attached screw. (B)

NOTE: The parallelism of the feeder rollers can be

aected by the angle of swivel cone.

Adjust the motor suspension: Loosen the lever(A) to

push motor suspension to the left side of the table

horizontally.

NOTE: Motor suspension level can stable the feeder

and parallel to the worktable.

Power switch positioning: Due to the packaging and

shipping consideration, the power switch was placed

aside. Loosen the attached 4 Hex screw to move the

motor to the front for more convenient operation.

Machine body installation: Loosen the hex-screw(A)

and quick release grip (B), and take o the motor

clamp.

-7-www.igmtools.com

Operating instructions EN

Conrmation:

• Locked the hex-screw (A) and quick release handle

grip (B) to even the gap of two end. Loosen the quick

release lever to rotate the machine body.

• Feeder angle adjustment, Loosen the stand handle

(A) and lower the feeder to adjust the rollers and

worktable until them horizontally.(B)

• Feeder roller level positioning: Lower feeder to table,

alignment“slight o”is acceptable.

- oset by indendent suspension.

• Loosen the handle grip (A), adjusting the motor

suspension level (B)

• Loosen two attached screws(C), and adjust the

motor suspension angle (D).

To complete the installation: Conrm all the handle

and screws are locked properly.

6. OPERATION CONTROL

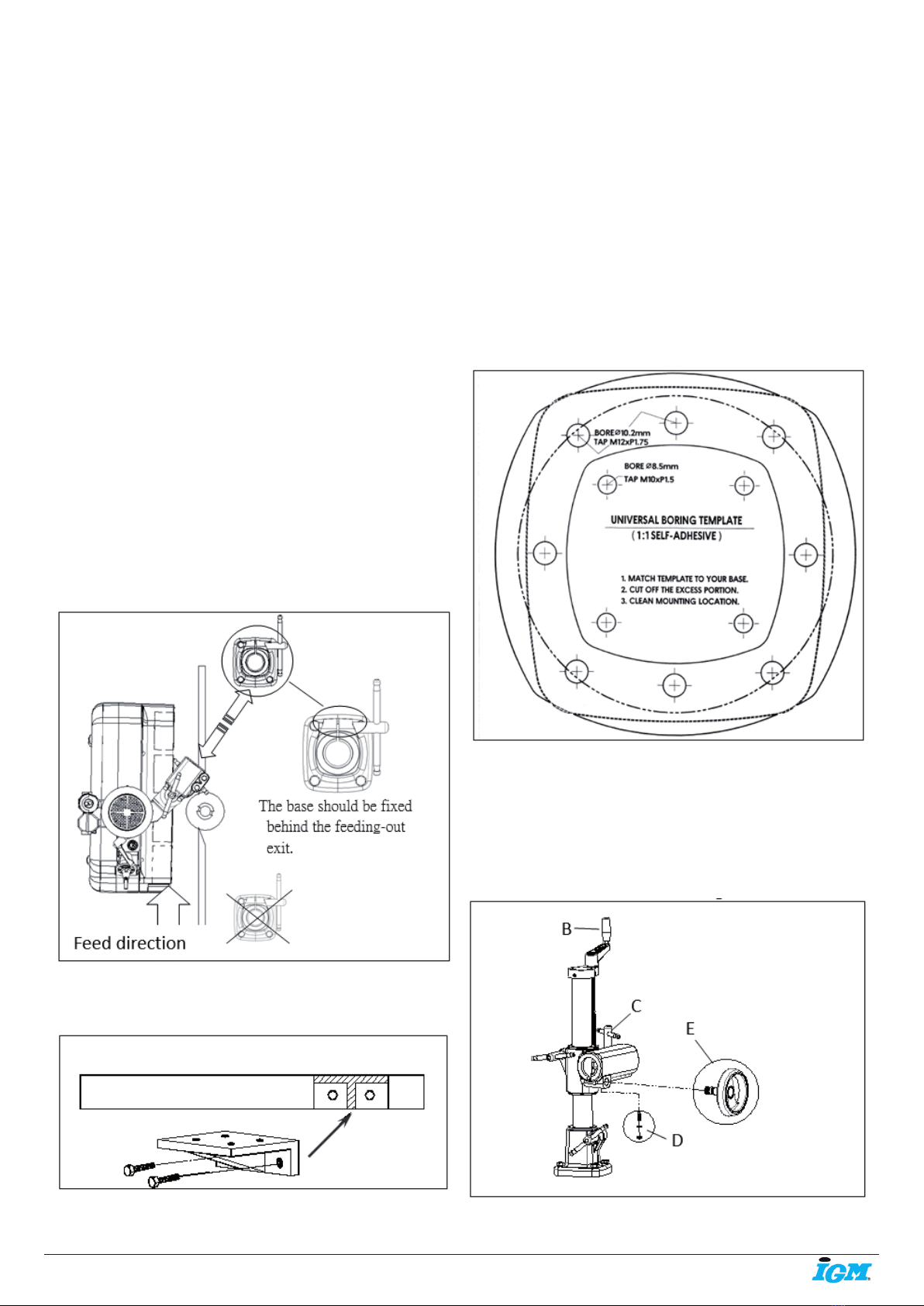

6.1 Stand

Over-Arm rotation: Loosen lever. (A)

Over-Arm extension: Loosen Lever (B),

-8-www.igmtools.com

Operating instructions EN

rotate side-wheel. (C)

Over-Arm elevation: Loosen Lever (D), rotate

TOP-Wheel. (E)

6.2 Control- Joint

Arm-bracket: Loosen 2 attached screws (F)

Angle Joint: Loosen Lever (G)

Motor clamp: Loosen Lever (H)

Machine body: Loosen quick release (I)

6.3 Feeding

Loosen Level (A), then swing the feeder aside then

locked the lever til tight

NOTE: Ensure there is sucient weight support to

prevent power feeder tilted while Swing aside.

Loosen LEVER (B), rotate the machine to left side 90°

(vertical to the ground), rollers faced to right, motor

to left then lock the lever.

Loosen LEVER (C), rotate the machine 90° (Parallel to

the ground) power switch on top, roller at the bottom

the lock the lever.

Loosen LEVER (A), push the machine back to

worktable, postion the roller opposite to the guide

plate then lock the lever.

Lock all ther lever properly to complete the

adjustment.

NOTICE: The purpose of elevating kits tolerance gap is

to allow smooth operation while elevating the feeder;

Please pull back machine body to feed-in direction

after elevating adjustment and lock the hand lever to

tight at the meantime (A).

7. POWER CONNECTION AND GROUNDING

NOTE: Read the motor specication to ensure

thepower source and voltage is compatible. (Range:

±5%)

Ensure power switch is (OFF) before connect the

power source.

Requirement:

• Connected to the repectively non-fuse circuit or

motor circuit breaker.

• The external power switch cord cannot be less than

12AWGl.

• Switch required wired in compliance with your

national or local electrical regulation.

-9-www.igmtools.com

Operating instructions EN

Using the extension cable if needed: 30M or under

using 12AWG cable, 46M or above using 10AWG

cable.

Ensure all the grounding wires connected properly;

impropriate connection may cause the damage to the

motor.

Ensure the groupding wire of the motor (green

or yellow) connected techinician for any further

assistance.

Please contact professional technician for any further

assistance.

Rated current reference:

• 34/38/44/48/04/MX

-10-www.igmtools.com

Operating instructions EN

8. SPEED CONTROL

Notice: cut out the power before adjustment

Appropriate feeding speed rate and well sharped

cutting blade can cause the procedure process quality

and eciency.

Determinate the correct feeding speed by the

hardness of the work-piece, material and the desired

cutting procedure.

Listen attentively while feeder rotating and re-check

the sample after procedure process then adjust

setting to desired result.

Maintain the cutting blade and keep it sharpe all the

time.

Speed shifting: Cut out the power before shifting.

Rotate the rollers while switch the speed to allow the

clutch and derailleur get engaged properly.

Derailleur and gear settle

• Model 34/44/04

(A) +Derailleur control(Fig 16-1)

• Model 38/48 (3PH)

(A) +(C)+ Derailleur control (Fig 16-2)

• Model 38/48 (1PH)

(B) +(C)+Derailleur control (Fig 16-2)

• Model MX

(A) +Derailleur(Fig 16-3)

-11-www.igmtools.com

Operating instructions EN

Gear replacement instruction.

Loosen two attached screws to take o the cover.

Loosen the Hex screw to replace the gear set.

NOTE: The hub of the gear should be turned inward to

avoided possible interference.

NOTE: Optional gear set available

34/44/04/54 model speed(4+4=8)

38/48/68model speed(8+8=16)

9. Roller replacement

Notice: cut o the power source before operation.

Loosen 2 attached M8 screws.

Replace with brand new rollers then tighten the

screws to complete the replacement.

Notice: Conrm all the screws are locked properly

after rst operation.

The rubbers have been tested by high standard QC

control and durability test.

• Its traction friction and durability is incomparable

to other brands. Please replace with Co-matic made

Roller.

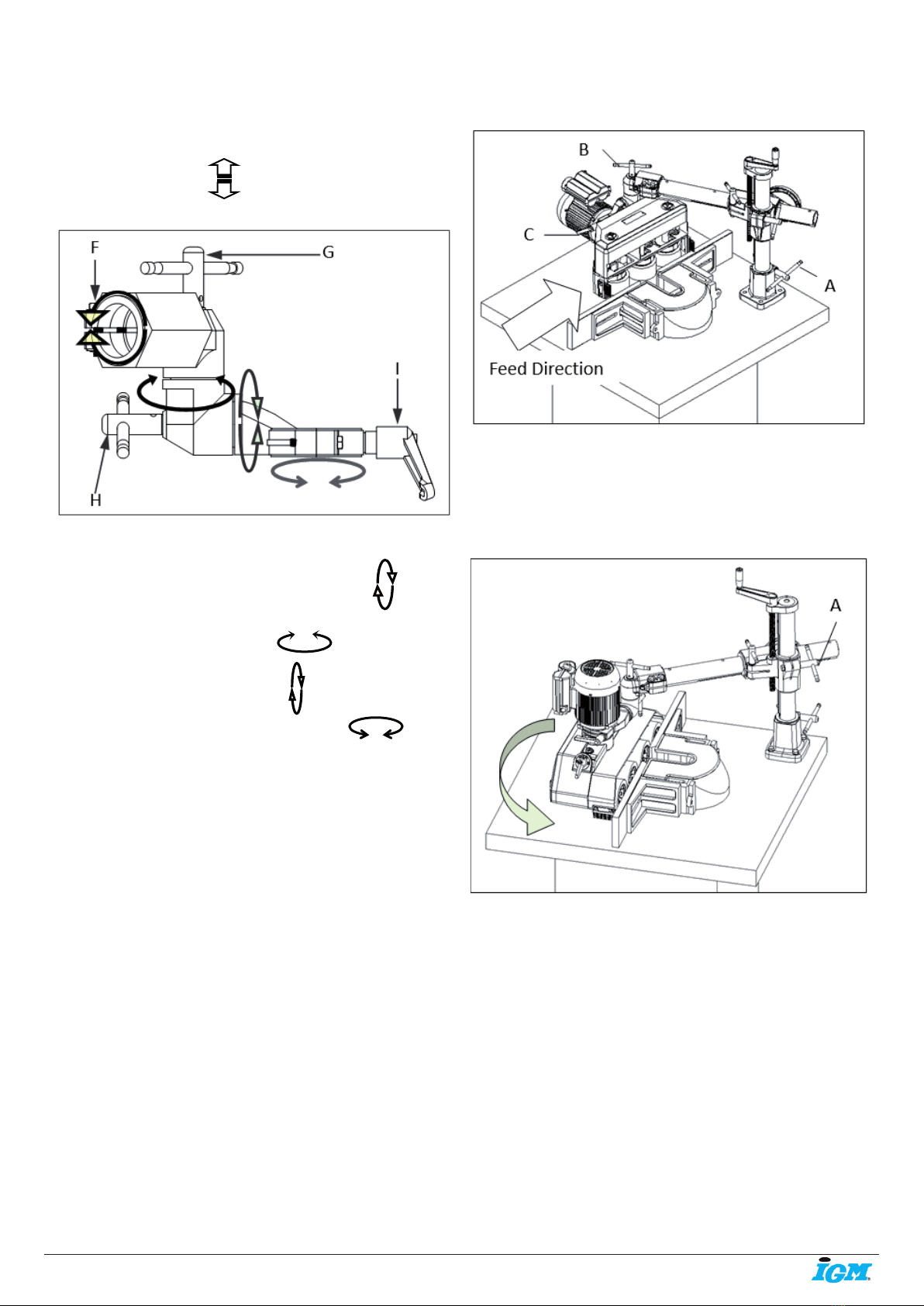

10. MAINTENANCE

Notice: Cut o the power source before operation.

Rollers:

Grease rollers and chains every 200 hours or 30 days

through ttings by using grease gun.

Chain wheel and chain should be maintained

regularly.

Recommended Grease:

• SHELL Alvania (SHELL Alvania R. 2);

• (SHELL GADUS S2 V220 2);

-12-www.igmtools.com

Operating instructions EN

• (MOBILUX EP 2);

• (FUCHS RENOLIT EP 2);

• (BP ENERGREASE MM-EP 2)

Turbine oil:

Exchange turibine oil rst 200 hours of 30 day while

rst starts the machine. Change oil after 1000 working

hours or 90 days after purchase of new feeder.

Using same brand of turbo oil or equivalent oil as

following:

• MOBIL - MOBILGEAR 630;

• SHELL - OMALA 150;

• BP - ENGERGOL GR-SP 150

Turbine oil replacement:

Refer to page 7: operation and adjustment please pay

attention to the balance of the feeder and worktable

while moving the feeder aside, then ip it over and

open the oil plug to allow the oil ow out, follow the

instruction to ll up the turbo oil.

Turbine oil lled up standard

• 38/48 300CC (38mm, 1-1/2“)

• MX 200CC (38mm, 1-1/2“)

Using wind gun to maintain the feeder after every

operation.

Model MX: Using tool to pry open inside of dust

collector ; Please seal up with tape while not in use.

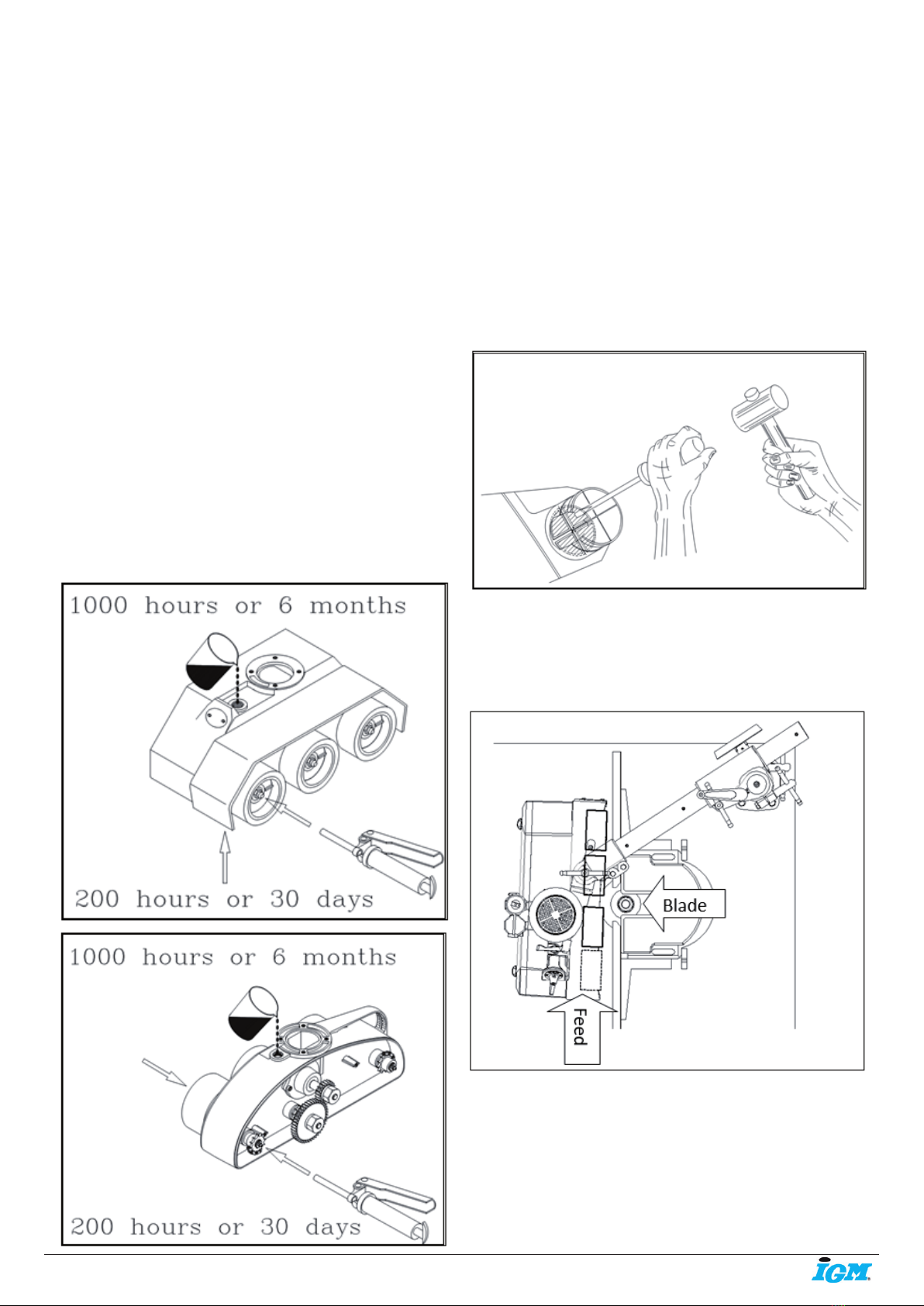

11. FEEDER OPERATION INSTRUCTION

Jointer operation:

• Rollers & cutting blade:

Pic. 11-1

• Feeder position & guiding plate:

-13-www.igmtools.com

Operating instructions EN

Pic. 11-2

• Feeding pressure & Work-piece:

Pic. 11-3

Table-saw operation:

• Rollers & cutting blade:

Pic. 11-4

• Feeder position & guiding plate (pic. 11-2).

• Feeding pressure & Work-piece (pic. 11-3).

Manual operation

• Rollers & cutting blade:

• Feeder position & guiding plate (pic. 11-2)

• Feeding pressure & Work-piece: light pressure.

NOTE: The space between feed-in rollers and the

guide plate sould be at least 3~5mm wider than

Feed-out rollers to ensure the roller can fully cover

and give enough presssure to the work-piece.

-14-www.igmtools.com

Operating instructions EN

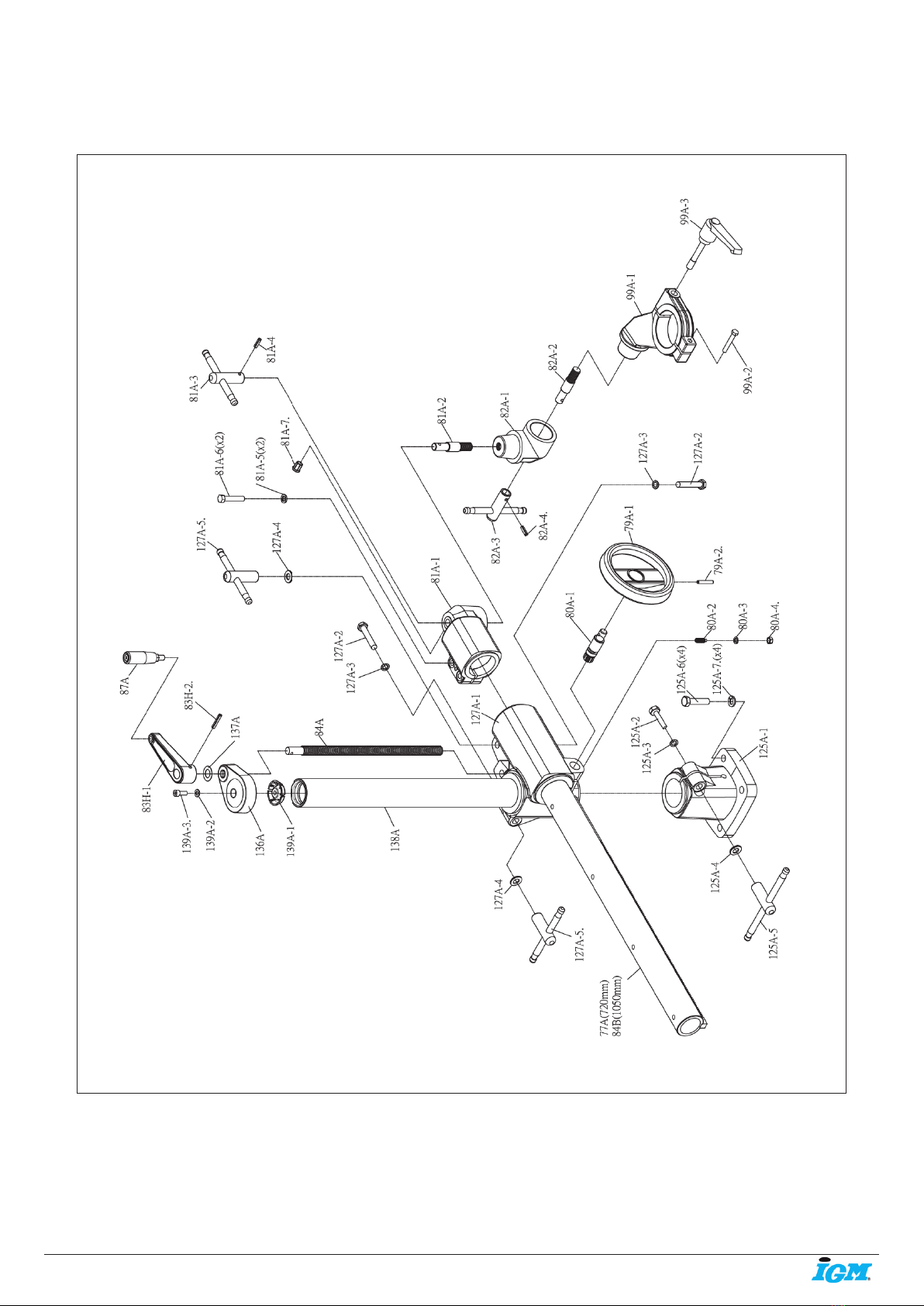

12. MX48B HOUSING ASSEMBLY

-15-www.igmtools.com

Operating instructions EN

HEAVY-DUTY UNIVERSAL STAND ASSEMBLY

IGM nástroje a stroje s.r.o., Ke kopanině 560,

Tuchoměřice, 252 67, Czech Republic, E.U.

+420 220 950 910,www.igmtools.com

© 2022 IGM nástroje a stroje s.r.o.

Operating instructions EN

Part No. Code No. Description QTY

B076203 B076203 Bearing 1

02G 02G Housing Frame Kit 1

02G-1 C020037 Housing Frame 1

02G-2 A500302 Bushing 4

02G-3 A500301 Bushing 1

02G-4. A500347 Bushing 4

03A 03A Roller Supporter Kit 4

03A-1 C020333A Roller Supporter 1

03A-2 A500309 Sprocket 1

03A-3 S060616 Cap Screw 2

03A-4. S060840 Cap Screw 2

03G 03G Sprocket Case Kit 4

03G-1 C020349A Sprocket Case 1

03G-2 N950004 Spring 1

03G-3 A500359 Bushing 1

03G-4. U010052 Case Cap 1

04A K330026 Chain 4

04G 04G Sprocket Shaft Kit 3

04G-1 G320023 Sprocket Shaft 1

04G-2 T315106 Grease Nipple 1

04G-3. N510015 Snap Ring 1

05G 05G Main Sprocket Shaft Kit 1

05G-1 G320025 Main Sprocket Shaft 1

05G-2 T315106 Grease Nipple 1

05G-3 N011225 Flat Washer 1

05G-4. N11012H Nut 1

06G 06G Roller Spindle Kit 4

06G-1 T315106 Grease Nipple 1

06G-2 G320028 Roller Spindle 1

06G-3 N030012 Spring Washer 1

06G-4 N510020 Snap Ring 1

06G-5. S601250 Hex Screw 1

07G A500308 Bushing 4

08G C120005 Worm Gear 1

09G C120011 Worm Gear 1

10G 10G Worm Gear Shaft Kit 1

10G-1 G320026 Wormgear Shaft 1

10G-2 K420612 Key 1

10G-3 N011225 Flat Washer 1

10G-4. N11012H Nut 1

12G 12G GEAR SET 1

12G-1 A500344 Gear 1

12G-2. A500345 Gear 1

14G U010078 Housing Cover 1

15G U010087 Knob 2

16G U010014 Brush 2

18G 18G Roller Cover Kit 1

18G-1 U010080 Roller Cover 1

18G-2. S500512 PH. Screw 4

21A 21A Oil-Cap Kit 1

21A-1 U010008 Oil Cap 1

21A-2. Q010012 "O" Ring 1

27A 27A Transmission Kit 1

27A-1 A500303 Sprocket 2

27A-2 K330040 Chain 2

27A-3 A500307 Double-Sprocket 4

27A-4. K330062 Chain 1

35A 35A Gear Kit 1

35A-1 A500310 Gear 1

35A-2. A500311 Gear 1

45M1 45M1 Motor w/ Switch 1

45M3 45M3 Motor w/ Switch 1

46A 46A Switch Box 1

47A 47A Switch Kit 1

114G 114G Wormgear Box Cover Kit 1

114G-1 Q010065 "O" Ring 1

114G-2 C020350 Wormgear Box Cover 1

114G-3 Q021701 Oil Seal 1

114G-4. S060616 Cap Screw 3

RO121 RO121 Roller tire 4

Part No. Code No. Description QTY

77A E580002A Over Arm Kit 1

79A 79A Handwheel Kit 1

79A-1 U010082 Handwheel 1

79A-2. N810636 Lock Pin 1

80A 80A Pinion Kit 1

80A-1 G020001 Pinion 1

80A-2 G000007 Screw 1

80A-3 N030008 Spring Washer 1

80A-4. N11008R Nut 1

81A 81A Over Arm Cone Kit 1

81A-1 A250403 Over Arm Cone 1

81A-2 G020005 Stud 1

81A-3 G020007A Handle 1

81A-4 N810622 Lock Pin 1

81A-5 N030010 Washer 2

81A-6 S601050 Screw 2

81A-7. U010119 Cord Sheath 1

82A 82A Swivel Cone Kit 1

82A-1 A200304 Swivel Cone 1

82A-2 G020005 Stud 1

82A-3 G020007A Handle 1

82A-4. N810622 Lock Pin 1

83H 83H Handle Kit 1

83H-1 U010139A Handle w/ Bushing 1

83H-2. N810636 Lock Pin 1

84A G320090 Elevating Screw 1

84B E580003A Over Arm Kit 1

87A U010011 Handle-Grip 1

99A 99A Motor Clamp kit 1

99A-1 A200305 Motor Clamp 1

99A-2 S600850 Screw 1

99A-3. T060003 Pull Handle 1

125A 125A Base Kit 1

125A-1 A250401 Column Base 1

125A-2 S601275 Hex Screw 1

125A-3 N050012 Lock Washer 1

125A-4 N011225 Washer 1

125A-5 G020010A Handle 1

125A-6 S601250 Hex Screw 4

125A-7. N030012 Spring Washer 4

127A 127A Elevating Bracket Kit 1

127A-1 A250402 Elevating Bracket 1

127A-2 S601275 Hex Screw 2

127A-3 N050012 Lock Washer 2

127A-4 N011225 Washer 2

127A-5. G020006A Handle 2

136A C020110A Column Cape 1

137A G150031 Washer 1

138A E580013A Vertical Column Kit 1

139A 139A Fastener Kit 1

139A-1 U010279 Fastener 1

139A-2 N015816 Flat Washer 1

139A-3. S900825 Cap Screw 1

MX48 HOUSING PARTS LIST HEAVY-DUTY STAND PARTS LIST

Table of contents

Other IGM Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

FLENDER

FLENDER FASTEX IC220 Assembly and operating instructions

Venmar

Venmar AVS HRV EKO 1.5 quick start guide

Zimmer

Zimmer GPH8000 Series Installation and operating instructions

Toshiba

Toshiba CV-10HB instruction manual

ABB

ABB HT846542 Operation manual

Siemens

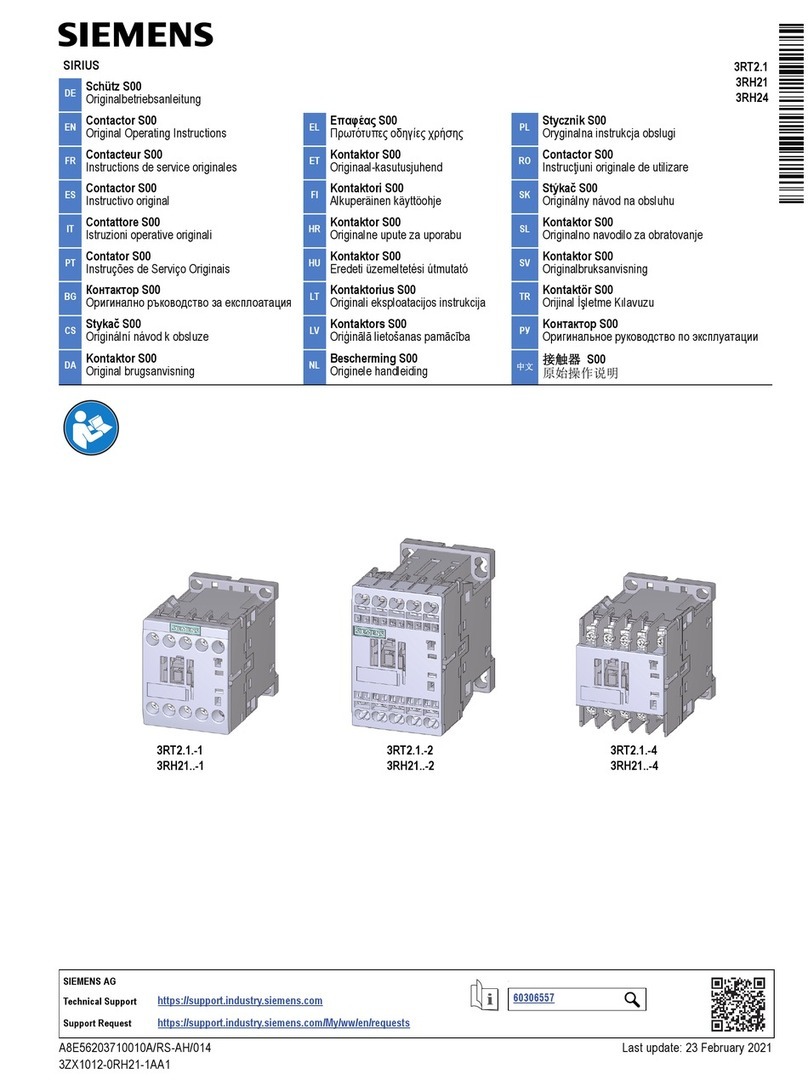

Siemens SIRIUS 3RH21 Series Original operating instructions