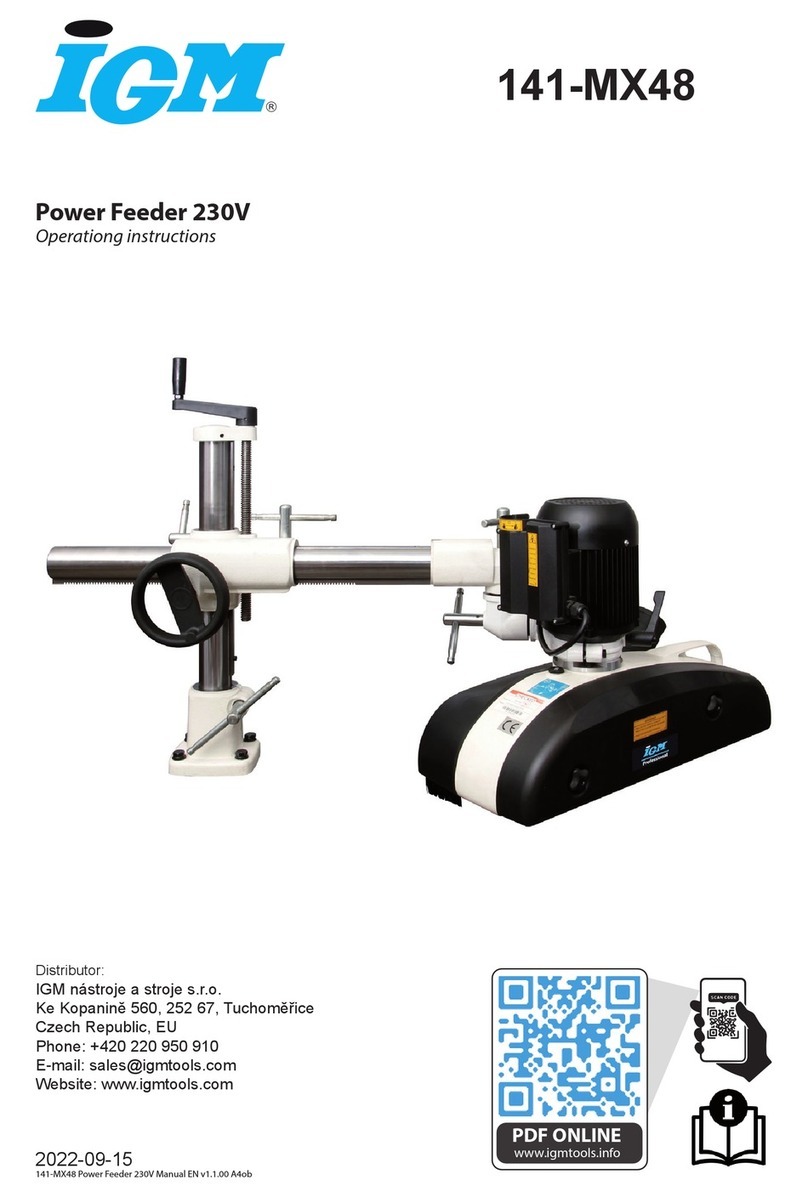

IGM 141-DC30 User manual

Distributor:

IGM nástroje a stroje s.r.o.

Ke Kopanině 560, 252 67, Tuchoměřice

Czech Republic, EU

Phone: +420 220 950 910

E-mail: [email protected]

Website: www.igmtools.com

Easy power feeder

Operationg instructions

2022-07-11

141-DC30,DC40 IGM Easy Power Feader Manual EN v2.7.00 A4ob

141-DC30,DC40

www.igmtools.info

PDF ONLINE

-2-www.igmtools.com

Operating instructions EN

Please read this manual thoroughly and follow the safety instructions in it! Technical changes

and printing errors reserved!

Dear customer,

This manual contains important instructions and information for the installation and proper use of

DC30 and DC40 Power feeders.

This manual is a part of the machine and therefore it should not be kept elsewhere than in the vicinity

of the machine so that you can be consulted at any time by you or other persons operating the

machine.

Please read and follow the safety instructions!

Carefully read these instructions before using the machine. Operation of the machine will

be simpler and you will also lower the risk of injury while eliminating the probability of

incorrect operation and possible damage to the machine. Because of our policy of constant

improvement, the design, construction or pictures may differ slightly. Should you discover

1. DECLARATION OF CONFORMITY

The undersigned: IGM nástroje a stroje s.r.o.

Address: Ke Kopanině 560

Tuchoměřice, Praha-západ, PSČ 252 67

Czech Republic, EU

Tel. +420 220 950 910

Certifies

Product: Power Feeder

Model: DC30 and DC40

Manufacturer: CO-MATIC Machinery Co., Ltd.,No.

473-16,

San Feng Road, Houli District, Taichung

City,Taiwan, R.O.C. 42156

We declare under our sole responsibility that the

product described in this manual is in conformity

with the following standards: EN ISO 12100, EN ISO

13857, EN 349, EN 953, EN 60204-1, EN ISO 11202,

TABLE OF CONTENTS page

1. DECLARATION OF CONFORMITY 2

2. WARRANTY SERVICE 3

3. SAFETY INSTRUCTIONS 3

3.1 Notice 3

3.2 General safety instructions 3

3.3 Risks 4

3.4

Important notice

4

3.5

Safety rules

4

4. SPECIFICATIONS OF THE MACHINE 4

4.1 Machine description 4

4.2 Technical data 4

4.3 The package includes 4

5.

TRANSPORT, UNPACKING AND ASSEMBLY

5

5.1 Transport and unpacking 5

5.2 Assembly 5

5.2.1 Fastening to a machine 5

5.2.2. Assembly 5

5.3 Electrical connection 6

6. SETUP AND ADJUSTMENT 6

6.1 Basic movements of the feeder 6

6.1.1 Feeding from the side 6

6.1.2 Feeding at an angle 6

6.2 Control panel features 7

7. OPERATING THE MACHINE 7

8. MAINTENANCE AND CONTROL 7

8.1 Replacing rollers 7

8.2 Greasing 7

8.3 Transmission fluid replacement 8

9. MALFUNCTION ASSISTANCE 8

9.1 Error messages 8

10. PROTECTION OF THE ENVIRONMENT 8

11. ACCESSORIES SPARE PARTS 8

-3-www.igmtools.com

Operating instructions EN

EN 55014-1, EN 55014-2 podle s ustanoveními

směrnic 2006/42/EC, 2004/108/EC, 2006/95/EC,

2002/95/EC.

Signed: Ivo Mlej

Managing Director

2. WARRANTY SERVICE

The warranty is subject to Terms and Conditions and

Warranty Conditions of IGM nástroje a stroje s.r.o.,

the current version of which are available at www.

igmtools.com.

3. SAFETY INSTRUCTIONS

3.1 Notice

This machine is designed for work with wood and

wooden materials.

Proper use also includes compliance with the regular

operational and maintenance work described in this

manual.

The machine can be operated only by persons

familiar with the operation procedures, maintenance

and are aware of potential risks involved.

Comply with the minimum age limits specified by

law. The machine may only be used when in perfect

technical condition.

All safety and protective components must be

installed when operating the machine.

Besides these instructions, also adhere to the safety

instructions of your country and to the generally

recognized technical practices concerning the

operation of woodworking machinery.

The manufacturer or the supplier is not responsible

for any damage resulting from improper use.

Every user is responsible for their own actions.

The warranty cannot be claimed if any of the

following principles are broken:

- Unsuitable work environment: high humidity,

contamination.

- Damage caused by an improper assembly and/or

improper storage.

- Use of damaged machinery.

- Failure to follow the operating instructions:

transport, storage, assembly, putting into operation,

cleaning and maintenance of the machine.

- Use of unauthorized spare parts.

3.2 General safety instructions

The machine can pose danger when improperly

operated.

Completely read the operating instructions before

working with the machine and follow all the

instructions in this manual.

Keep this user manual clean and protect it from dirt

and moisture; in case of re-selling, pass the manual

onto the new owner.

Any alterations or changes to the machine are

prohibited.

Daily try out if the machine runs smoothly and check

the function of protective covers before operating the

machine. Replace any deficiencies and immediately

remove any damaged parts like covers.

The machine may only be used when in perfect

technical condition.

Use a hairnet or a hat to protect long hair. Wear tight-

fitting clothes, remove all bracelets, rings, necklaces or

ties. Wear work boots only, do not wear casual shoes

or sandals during work. Abide by the regulations for

personal protection.

Always wear safety eyewear. Always use hearing

protection. The tools are sharp and can cause severe

injury, use them with care.

Keep in mind the necessary space for operation when

installing and positioning the machine. The machine

must stand on a stable surface and must be adequately

lit.

Always use respiratory protection when working in a

dusty environment.

Make sure you have good lighting.

Make sure the power cord is not in your way when

working. Keep your work area clean. Never touch the

machine when it‘s running.

Make sure you are concentrating and paying attention.

Use caution. Never work under the influence of drugs

and/or alcohol.

Make sure there are no children around when working

with the machine.

-4-www.igmtools.com

Operating instructions EN

4. SPECIFICATIONS OF THE MACHINE

4.1 Machine description

1

2

3

5

6

78

9

10

11

12 14

13

15

17

16

4

pic.1

Never leave the machine unattended. Always switch

the machine off when leaving the workspace.

Watch your fingers and other body parts when

working. Never walk away from a machine without

protective guards.

Do not place anything on the machine.

Electrical connections malfunctions can be repaired

by an electrician only. Damaged electric cord must be

replaced immediately.

Any adjustments and maintenance may be carried out

when the machine is disconnected from the power

source.

3.3 Risks

Risks may arise even during proper and prescribed use

of the machine.

The danger of a workpiece flying off. Beware of noise

and dust.

Wear eye, ear and dust protection.

Use a suitable dust extraction device! Watch out for

damaged electrical cords.

3.4 Important notice

Only use the feeder in an appropriate environment.

Keep your workspace well ventilated and lighted,

avoid wet or damp environments.

Only operate the machines under temperatures

ranging from +5°to +40°C. Humidity from 30% to 95%.

3.5 Safety rules

The tool must reach working speed before feeding.

Do not overload the machine by feeding material too

quickly.

ALWAYS keep your hands away from rotating parts.

Provide additional support and stability for larger

workpieces.

Always switch off the feeder first, only then switch off

the machine that is being fed material.

Always disconnect the power cord before any repairs

or adjustments.

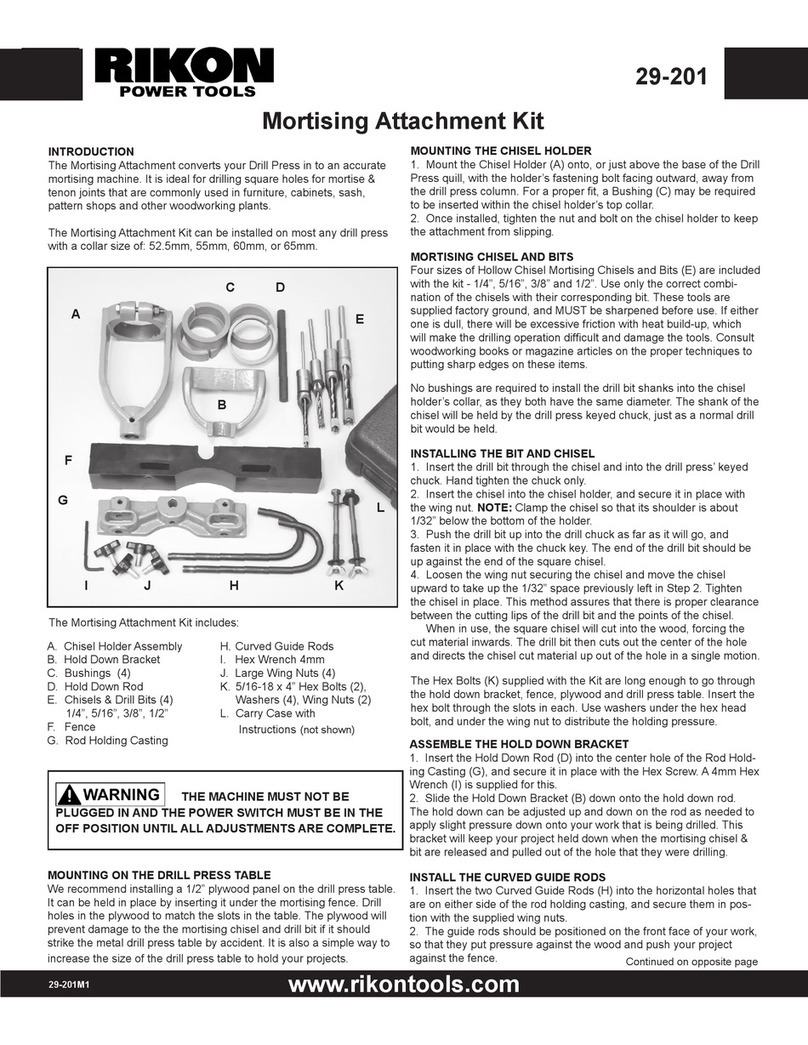

1 base

2 locking lever (turning)

3 height-adjustable arm 4 locking lever (height

adjustment)

5 stand

6 height control (turning alters height) 7 locking lever

(protrusion)

8 feeder arm

9 screws (positioning joint) 10 locking lever (turning)

11 locking lever (angle of the feeder)

12 angle locking pin 13 control display

14 motor

15 control wheel of arm protrusion (turning moves

the arm)

16 feeder grip

17 roller

4.2 Technical data

Type DC30 DC40

Motor power (400V) 500W 500W

Arm reach 460mm 460mm

Max. workpiece height 250mm 250mm

No. of rollers 3 4

Size of rollers 120x60mm 120x60mm

Feed speed 2-22m/min 2-22m/min

Weight with stand 53kg 56kg

4.3 The package includes

feeder

feeder stand arm

quick adjustment joint

plan for base drilling 1:1 manual

-5-www.igmtools.com

Operating instructions EN

5. TRANSPORT, UNPACKING AND ASSEMBLY

5.1 Transport and unpacking

The machine is not assembled due to transport.

Remove the feeder from the packaging and place

on a flat surface. Check for any apparent transport

damages, these could damage the machine or your

health.

5.2 Assembly

We recommend to greasing the metal parts before

assembly.

5.2.1 Fastening to a machine

- Mounting the base. The feeder is supplied with a 1:1

template that facilitates the mounting of the feeder

onto a base.

1. Unpack the feeder base and adjust it according to

the mounting template.

opening on the side of the arm (8.1, pic.7). Insert the

cable into the sleeve up to the double insulation.

It‘s necessary to take the cable apart from the

terminal plate - Only an electrician with a proper

permission is allowed to do that. Mount the joint

end and so far tighten only with one screw.

De-grease the surface with rubbing alcohol and put

TAP

M12 x P1.75

BORE 10.3-10.5mm

BORE 8.5-8.7mm

UNIVERSAL BORING TEMPLATE

TAP

M10 x P1.5

(1:1

SELF-ADHESIVE

)

1.

MATCH TEMPLATE TO YOUR BASE

。

2.

CUT OFF THE EXCESS PORTION

。

3.

CLEAN MOUNTING LOCATION

。

SCREWS NOT INCLUDED

F

F

Heavy Duty

pic.2

2. Prepare 4 bolts and spring washers (not included).

Bolt size - M10, length = feeder base (thickness) +

table top (thickness)

3. Select position of the base to avoid ribbing on the

bottom of the table.

5.2.2. Assembly

- Fasten the base of the feeder to the table top using

four M12 bolts, place the stand into the base. Screw

the handle into the lever using the nut under the

handle.

(Obr. 4)

4-M12

pic.3

(Obr. 5)

pic.4

(Obr. 6)

1

2

3

4

pic.5

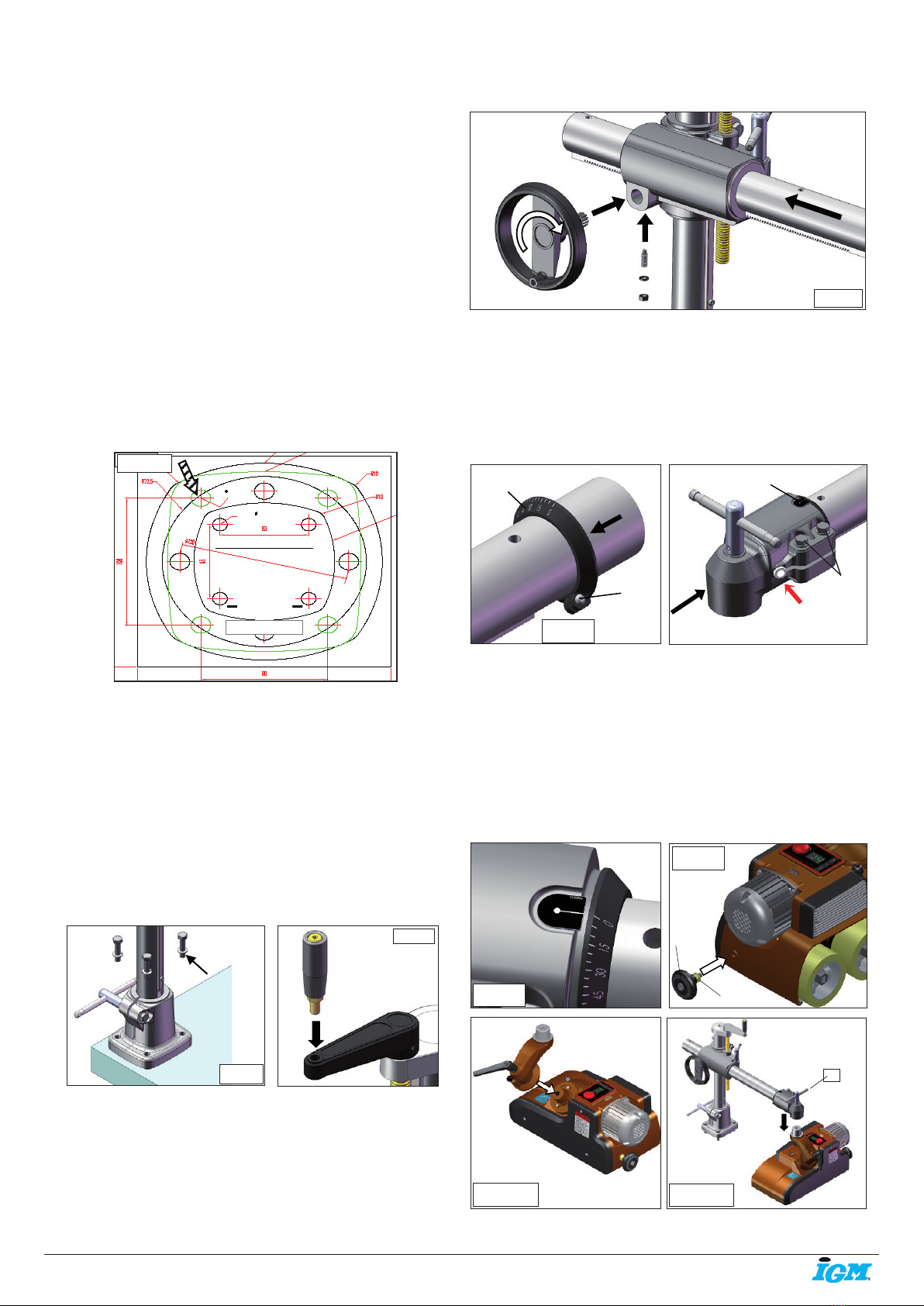

Insert the arm (1, pic.5) into the height-adjustable

holder. Mount the control wheel 4 so that the pinion

2 fits into the teeth of the feeding comb. Screw the

locking screw 3 from the bottom side and tighten

with a contra nut against the screw.(pic.5) Insert the

scale ring (R, pic.6) on the arm of the feeder and slide

further away from the edge. Insert the cable into the

(Obr.

7)

M4

R

pic.6

(Obr. 8)

S

8.1

pic.7

2

on the sticker with a scale (S, pic.7 and 8).

Mount the handle (1, pic.9) into the feeder but

don‘t tighten too much, it should rotate. Mount the

positioning joint onto the pin on the feeder and

screw in using the locking lever. (pic.10)

Place the feeder on your workbench. Move the joint

end towards the pin screwed into the arm. Mount

on the pin and tighten the locking lever (1, pic.11).

Tighten the screws on the joint ending (2, pic.7).

(Obr. 10)

1

2

pic.9

(Obr. 9)

pic.8

pic.10 pic.11

1

-6-www.igmtools.com

Operating instructions EN

5.3 Electrical connection

WARNING: Make sure the electrical connection

corresponds to the motor specification (see engine

cover.) WARNING: Make sure the switch is in the

„OFF“ position before turning on the feeder.

A power feeder is an auxiliary machine that

cooperates with your spindle moulder, table saw or a

planer.

If you need to use an extension cord; use a 18AWG x

4C when not exceeding 5 metres and a 16AWG x 4C

when over 5 metres.

6. SETUP AND ADJUSTMENT

- Place a 3-4 mm high pad under the output roller

and slowly run the feeder down until the input roller

lies on the surface and the output roller is touching

the pad. Now tighten the screws (K, pic.13) and set

the scale ring to zero. Tighten the locking pin (H), this

secures stronger downforce on the infeed roller.

6.1 Basic movements of the feeder

6.1.1 Feeding from the side

- Release the locking lever (A) and turn the feeder off the

workbench.

- Release the lever (H), grab the handle of the feeder and

lift the locking pin, turn the feeder to a vertical position.

Turn it back on the workbench and tighten all the levers.

- The workpiece must be leaning on a guiding fence

when feeding. The rollers must push the workpiece

against the fence. The difference between the distance

of the feeder and the fence should be greater on the

infeed roller by 3-4 mm than on the outfeed roller (pic.

15).

6.1.2 Feeding at an angle

- Release the locking lever (A) and turn the feeder off the

workbench.

- Release screws (K) on the end of the arm, turn the

positioning joint and set up the required angle (S), and

then tighten screws (K). (pic.13)

- Release levers (F and G), pull out the locking pin and

align the feed so that all rollers are in the same height

over the workbench, then tighten all the levers (pic. 14).

- The workpiece must be leaning on a guiding fence

when feeding. The rollers must push the workpiece

against the fence. The difference between the distance

of the feeder and the fence should be greater on the

infeed roller by 3-4 mm than on the outfeed roller (pic.

15).

pic.12

1

- For rotation around the axis of the base:

release lever (A), and turn the feeder to the

requested position.

- To extend or compress the arm of the

feeder: release the lever (B) and

rotate (C).

- To alter the height: release the lever (D)

and turn the handle (E).

- To rotate the feeder: release the lever

(F) and turn the whole feeder.

- To adjust the angle of the feeder: release

lever (G). Pull out the locking pin (H) and

use a handle (1, pic.9) to turn the feeder.

G

F

Obr. 19

pic.14

Obr. 20

X+3~4mm

X

podávání

pic.15

pic.13

-7-www.igmtools.com

Operating instructions EN

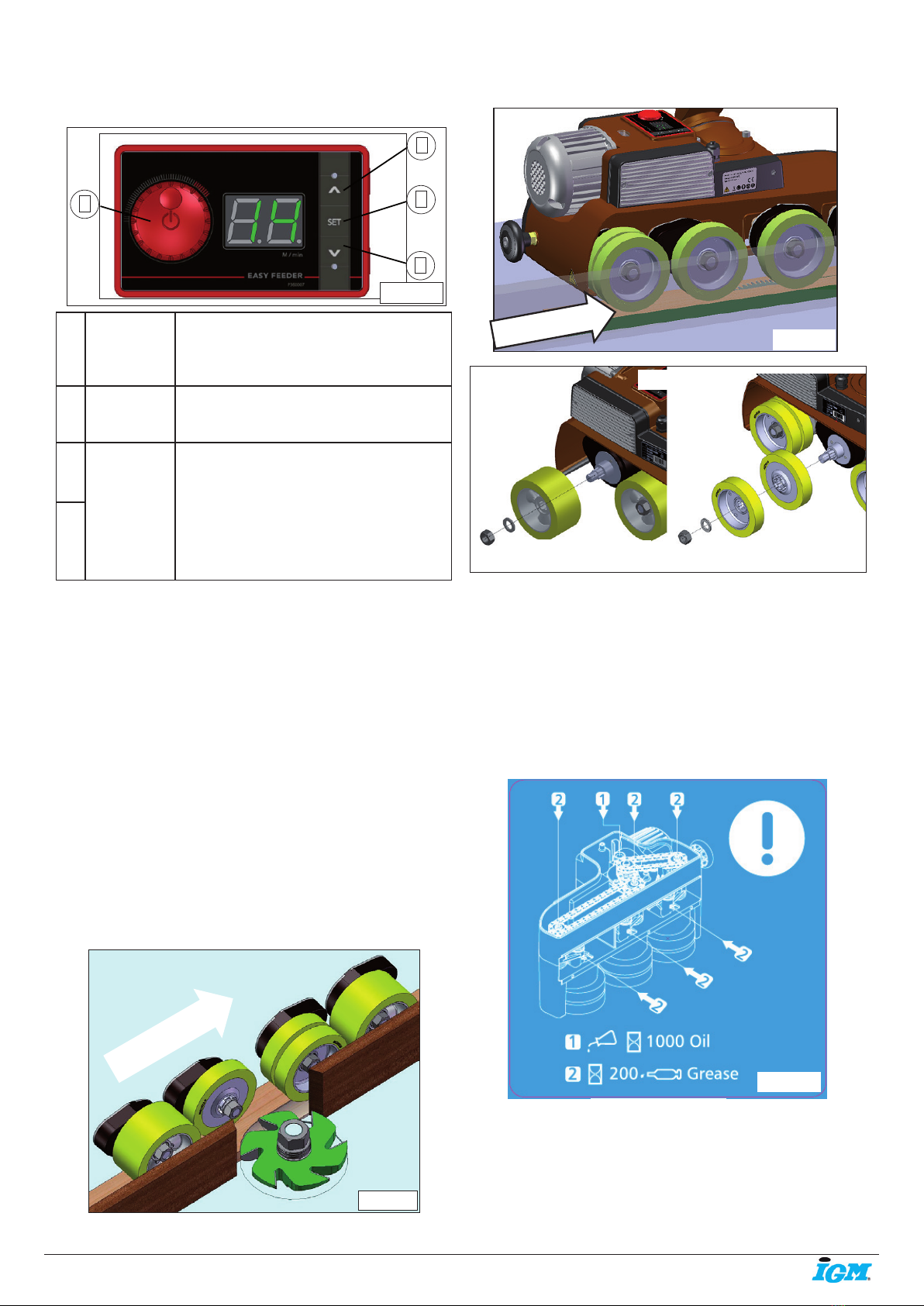

6.2 Control panel features

8.2 Greasing

- The wheels and chains should be greased every 200

hours or 30 days using a grease gun, see section 2, the

location of grease on the displayed label (pic.20).

- Gears and chains: grease regularly.

- Recommended greases: (Shell – Alvania Grease

R2, SHELL GADUS S2 V220 2, MOBILUX EP 2; FUCHS

RENOLIT EP 2; BP ENERGREASE MM-EP 2

and other)

1. Vypínač

s nastavení

m rychlosti

3. Tlačítko směru podávání

2. Tlačítko nastavení

4. Tlačítko směru podávání

1

3

2

4

pic.16

1

Switch

and feed

speed

Speed in the range of 2-22 m/min

Press to turn the feed on and off

2Settings

button

Press to set up the desired feed

speed

3Feed

direction

button

Change of feed direction during

work: press the direction button

twice. The opposite direction will

run at the lowest speed. Press the

on/off switch twice for the original

setting.

4

7. OPERATING THE MACHINE

After switching the machine on, let the feeder reach

its full speed before feeding any material.

8. MAINTENANCE AND CONTROL

8.1 Replacing rollers

- You can choose out of two types of rollers:

Ø120 x 60 mm (141-R12060) and

Ø120 x 25 mm (141-R12025).

- The outfeed roller can be removed when working

with larger routers (pic.17).

- The infeed roller can be removed to avoid contact of

the saw blade with the feeder (pic.18).

- Use various roller combinations for different

conditions and operations.

pic.17

feed direction

pic.18

feed direction

Sada kol

Jedno kolo

pic.19

Obr. 24

pic.20

One roller Set of rollers

IGM nástroje a stroje s.r.o., Ke kopanině 560,

Tuchoměřice, 252 67, Czech Republic, E.U.

+420 220 950 910,www.igmtools.com

© 2022 IGM nástroje a stroje s.r.o.

Operating instructions EN

8.3 Transmission fluid replacement 9. MALFUNCTION ASSISTANCE

9.1 Error messages

E1 - Motor will not start: Check that there isn‘t

anything stuck in the feeder.

E2 - Drive mechanism temperature is too high.

E3 - Engine temperature is too high.

• After removing a probable malfunction - restart the

main switch.

• If you are not sure why a problem occurred, please

contact technical support.

10. PROTECTION OF THE ENVIRONMENT

Protect the environment.

Your machine contains materials that can be recycled.

Please, let specialized institutions handle the

machine.

11. ACCESSORIES SPARE PARTS

IGM Spare roller D120x60 for DC30-DC40 Feeders

141-R12060

IGM Narrow spare roller D120x25 for DC30-DC40

Feeders

141-R12025

IGM Swivel Cone Kit 0 - 90° set for Feeders DC30-DC40

141-KS

- Oil change after 200 hours of operation (30 days)

of a new machine. Afterwards, replace oil every 1000

hours (6 months). The mentioned horizon is based on

the assumption of an everyday 8-hour service.

- The oil indicator is next to the display. Put the feeder

to the displayed position (see pic.22) to see the oil

status.

- Rotate the feeder away from your workbench into

free space, open the cover, turn the feeder upside

down, release the oil cap and let some oil out. When

all the oil is gone, place the feeder to a vertical

position and pour in the transmission fluid according

to the oil indicator.

- Recommended gear oil: MOBIL Mobilgear 630,

Shell/Omala 150 BP, Energol GR-XP 150, and other

equivalents.

- Clean the machine after every use (dust, shavings

etc.).

Obr. 25

pic.21

Obr. 26

pic.22

This manual suits for next models

1

Table of contents

Other IGM Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

MyBinding

MyBinding SealerSales KF-300F instruction manual

Thomas

Thomas SAR 460 SA G DIGIT Use and maintenance manual

Graco

Graco HIGH-FLO Viscount II 300 Series Instructions-parts list

Vaughan

Vaughan ROTAMIX SYSTEM Installation, operation & maintenance instructions

Festo

Festo EGC-TB-KF operating instructions

Vahle

Vahle SMGM-BCC System manual

Manntek

Manntek DCC operating manual

Cee

Cee 1300CSX Operator user manual

RAMMER

RAMMER S 83 STD Operation and maintenance manual

Utile

Utile 700 Series Installation, operation & maintenance instructions

Allied Systems

Allied Systems LONG REACH CCHA Installation maintenance and service manual

Clemco

Clemco SCW-2048 owner's manual