SECTION II

Operation

P 2.2

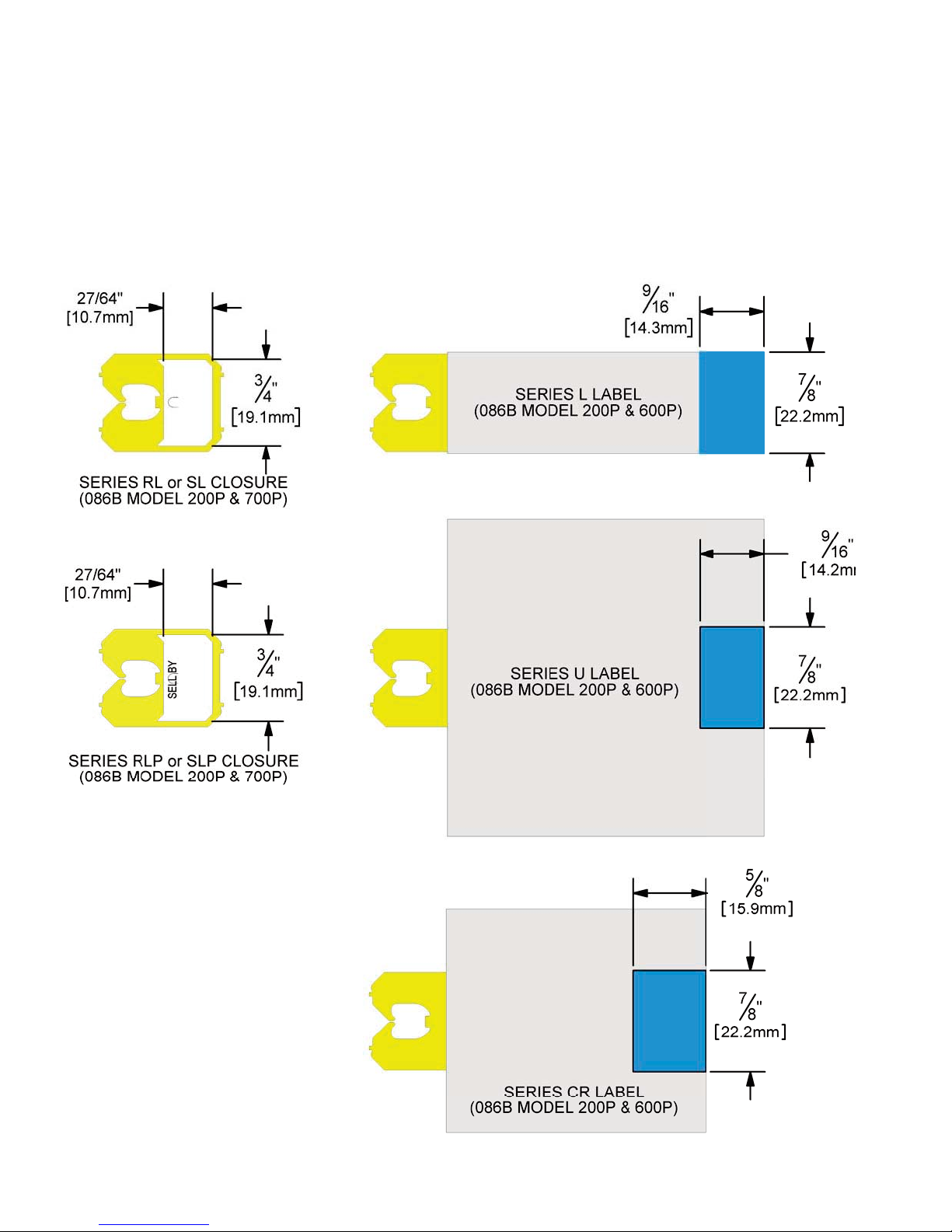

B. LOADING A ROLL OF CLOSURES:

1. Cycle the closer until the closures stop

advancing. Avoid cycling the closer more than

necessary when there is no closure in the

closing position. This will avoid a buildup of ink

residue on the closure track.

2. Move the run switch to “STOP” so the

mechanism is properly positioned.

3. When closing with closures, insert the closure

hub into a new roll of closures. Be certain the

closures feed forward from the bottom of the

roll.

When closing with labels, insert the closure hub

so that the label of the closure is right side up

when the closure strip is in the closure track.

4. Install the hub and roll.

5. Open the printer cover and check to see if there

is any ink residue on the bottom of the closure

track within the printing area. Use a soft cloth

or tissue to wipe any ink off the closure track

so the ink will not smear on the underside of

the closure.

6. Remove the masking tape and feed the end of

the strip into the closure track until the first

closure has passed the check and is against

the stop. Close the printer cover.

7. With the Power switch in the ”ON” position,

press the run switch to “RUN”. The closer will

cycle once and move a closure into the closing

position. Remove the first three unprinted

closures by hand. The closer is now ready to

close bags.

C. PREPARING THE PRINTER:

Figure 2.2 & 2.3

(If the machine is a non printer Model, skip to

Part E, CLOSING BAGS)

1. Open the printer cover.

2. Select the print image.

a. For the band printer, rotate the top of the print-

head toward the front of the closer so the

selected type characters can be easily viewed

through the window on the top of the print head.

Slide the selector knob out to select the desired

band and rotate the knob to select the desired

character. When finished, rotate the bandhead

back against the spacer.

b. For the typeholder block, remove the knurled

knob and slide the printer block off the shaft and

spring pin. Place the selected type in the

grooves that are the farthest away from the

holes in the mounting block. For normal viewing

on the closure the bottom edge of the characters

should be toward the middle of the block. Cen-

ter the type from side to side. Replace the block

on the shaft and pin so the type is close to the

ink roll arm. If the type or typeholder block is not

installed correctly, the type will not be inked

properly.

3. Unscrew the knob (Ink roll) and position the ink

roll between the knob and the cam follower.

4. Mate the ink roll to the end of the cam follower

and screw in the knob to secure it. Under most

conditions the ink roll can be left on the printer

until the ink is used up. The ink roll will not dry

out.

5. Close the printer cover.

6. Cycle the printer and discard the unprinted

closures.

086B 02 18