Igneus Ceramiko 600 Installation and operating instructions

Igneus Ceramiko 600 wood fired oven

Assembly and operation manual

Contents

1. About your Igneus Ceramiko 600 oven

1a. Oven finish

1b. Soot

1c. If your oven chips or cracks

1d. Oven reinforcement fibres

1e. Oven maintenance

2. Igneus Ceramiko 600 Oven assembly

2a. Oven and Flue Clearances

2b. Oven Delivery

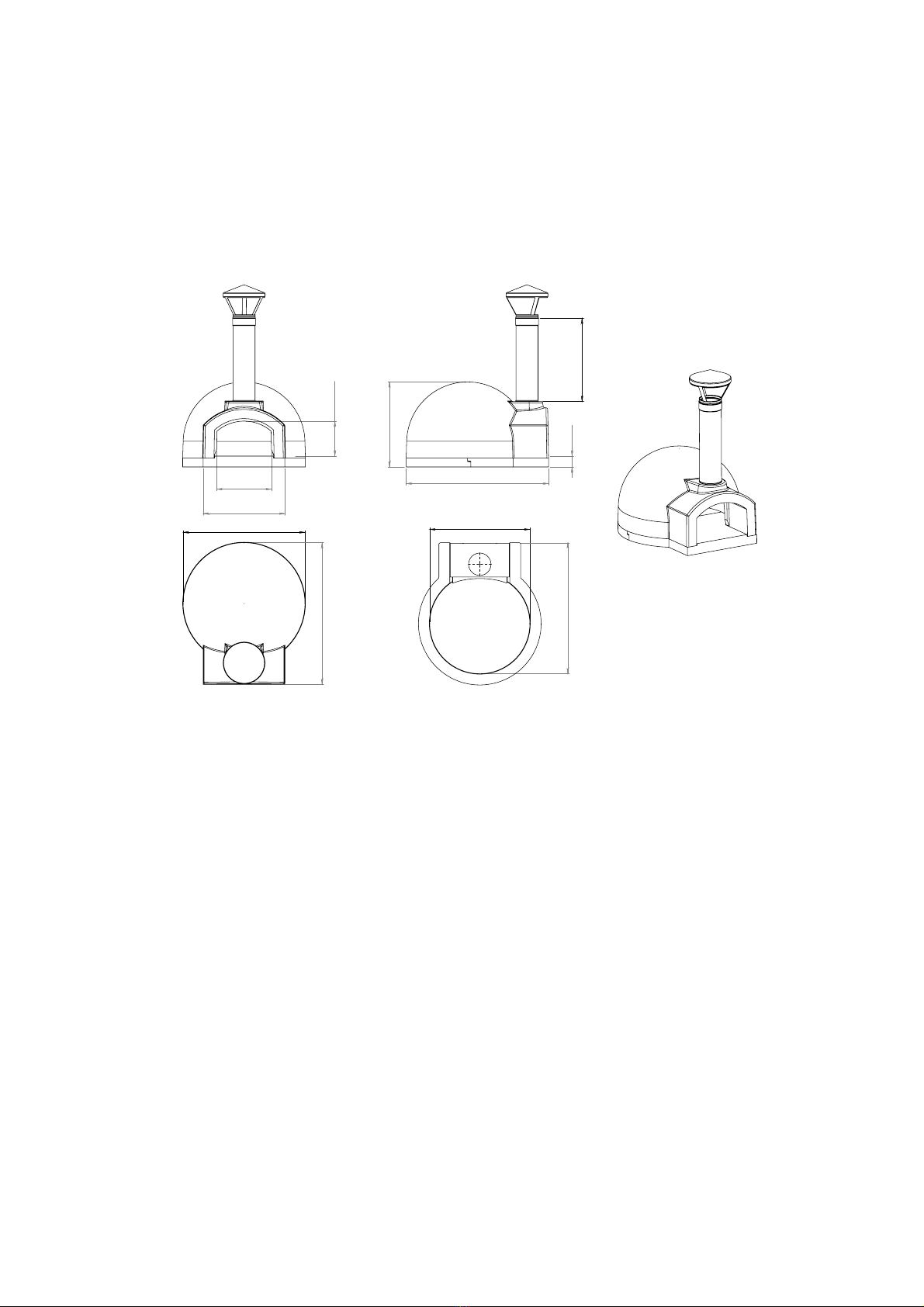

2c. Oven dimensions

2d. Oven Location

2e. Oven Installation

2f. Oven Assembly

2g. Metal stand assembly

2h. Rendering your oven

3. Igneus Ceramiko 600 oven use

3a. The don’ts when using your oven

3b. What wood to use in your oven

3c. How to make fire

3d. Lighting your oven for the first time (or lighting during Autumn and Winter)

3e. How to cook in your oven

3f. How to dispose of ashes safely

3g. Oven tools

4. The Clean Air Act 1993 and smoke control areas

4a. Use in Smoke Control Areas

4b. Refuelling

4c. Overloading

5. Igneus Ceramiko 600 oven warranty

5a. Investigation of claims against warranty

5b. Warranty Qualifications

5c. Limitation Liability

5d. How to register a claim against the warranty

6. Important fire and safety notice

1. About your Igneus Ceramiko 600 oven

Congratulations, you are now the owner of an Igneus Ceramiko 600 wood fired pizza oven

which has Micro-Mesh reinforcement and is hand cast in the UK by a factory which

specialises in producing some of the best professional pizza ovens in the country.

Before using the oven, follow the Manual installation steps, check that there are no obvious

defects in the oven and that the safety information has been read and understood by

anyone using the oven. Failure to do so may void the oven warranty.

1a. Igneus Ceramiko 600 oven finish

The Igneus Ceramiko is a refractory based oven, which means that due to the nature of the

materials used to make your oven and the hand casting process, natural variations between

ovens is expected. From variations in colour, minor pitting in the oven surface to minor

surface chipping. This means that each oven we produce is unique, adding to its rustic and

individual charm.

1b. Soot

After the first use, your oven may become blackened in parts, usually (but not exclusively)

on the inside roof of the oven. This is due to soot accumulation and is a normal expectation

of any refractory based wood fired oven.

1c. If your oven chips or cracks

Take care when manoeuvring your Igneus Ceramiko oven into position, as some parts are

heavy, (the dome for example) and therefore slight chipping may occur. If chipping does

occur and you are using your oven in its raw state, simply ask our team for a patch kit if

needed. If you are rendering or tiling your oven, you will find that the build process you use

conceals the chipping, so a kit will not be needed.

Please note that due to the expansion and contraction of your oven during operation, the

appearance of hairline cracks, visible during and after operation inside or outside your oven

is to be expected, however please be assured that because the Igneus Ceramiko range has

steel fibre woven into the canopy to reinforce it, so it is very unlikely that the integrity of the

oven will be affected if small cracks occur. This is a normal expectation of any refractory

built wood fired oven, but be assured this will not affect the longevity and effectiveness of

your oven.

1d. Oven reinforcement fibres

On very rare occasions, there is potential for the fine steel fibres to protrude from the oven

base or dome usually on the edges. Please take care by wearing gloves when manoeuvring

and handling the oven. If needed, these fibres can simply be removed or trimmed away.

1e. Oven maintenance

At last, a self-cleaning oven! The Igneus Ceramiko 600 needs very little cleaning and

maintenance. Any spilled or food which drops onto the cooking floor will be burnt off by the

heat achieved within the oven in a matter of minutes. When your oven has totally cooled

down, (which can take up to 24+ hours if your oven has been insulated) simply dust out the

ash before the next firing in a safe way (see section 3f).

Ensure you regularly clean your oven flue to prevent a build-up of soot within the chimney

(in the same way that you would get a chimney sweep to regularly clear the chimney of a

log burner). This will prevent the possibility of a flue fire.

2. Oven Assembly

2a. Oven and Flue clearances

The oven clearances quoted in this document are recommended for your safety and the

safety of your property. It is essential that these clearances are maintained from any

combustible materials, failure to do so may result in fire.

When rendering your oven, please allow at least 80-100mm on the exterior dimension of

your oven to allow for the insulation blanket and render. Please note that the Igneus

Ceramiko 600 cannot be insulated if it is built on the Ceramiko stand.

When your Igneus Ceramiko 600 is installed, we recommend that you ensure that the

external wall of the oven has a clearance of 100mm from any fence panels or walls, and a

clearance of at least 900mm from the flue length to any fence panels or walls are observed.

Ensure nothing obstructs the flue from directly above. If building into a structure or kitchen,

please consult a professional chimney installer who will ensue that your oven is vented and

flued out correctly and safely.

2b. Oven Delivery

When your oven is delivered, it will be delivered kerbside to the front of your property by a

pallet delivery company.

We recommend that you move the oven into position by lifting the individual pieces, rather

than trying to move the pallet in its entirety. Note, your oven weighs 180kg in total, split

between the 2 x base pieces and the 1 x dome piece. Each oven piece is designed to be

manageable to lift with 2-3 strong adults who are trained in lifting techniques. Please take

care when lifting, manoeuvring and assembling the pieces.

Included in the Igneus Ceramiko 600 package: The Igneus Ceramiko 600, oven door, single

skinned flue length, flue rain cap.

Accessories available include the insulation kit (high heat refractory insulating blanket,

calcium silicate insulating board, high heat fire cement and a decorative archway) and the

rendering kit.

2c. Oven dimensions

2d. Oven Location:

Ensure that your oven is being installed in a sheltered location, taking common wind

direction and drafts into consideration – make sure that the oven is sheltered from wind

blowing directly into the mouth of the oven as this will dramatically affect the performance

of the oven. If you are installing your oven under a cover such as a pergola, then appropriate

measures to meet local government fire regulations, local restrictions/laws and health and

safety measures must be undertaken. Igneus Wood Fired Ovens do not accept any liability

where these or similar measures have not been met when the oven is installed.

2e. Oven Installation

If being installed onto a pre-constructed stand or outdoor kitchen area, the structure it is to

be built onto must be able to bear a total weight of 250kg. The structure must have a solid,

non-combustible surface, with the total being spread evenly across the structure. For the

oven dimensions, please refer to section 2c above, and remember to allow at least 80-

100mm extra all the way round the circumference of the oven for the insulation and render.

The Igneus Ceramiko 600 oven can be finished in a range of different designs using differing

non-combustible materials such as render, brick, stone or mosaic tiles. For inspiration, why

not visit our website gallery for design ideas to suit your home or garden.

2f. Oven Assembly

Important Notes

• Wear protective mask and goggles when cutting and handling the insulation board

and when insulating the external canopy of the oven.

• DO NOT place fire cement between the oven base joints, this will affect its ability to

fit together.

• Heavy: The oven dome and base parts are heavy and fragile, handle with extreme

care when moving to prevent oven chipping.

• We recommend anyone lifting the oven is adequately trained in lifting techniques.

Lift the heavy oven pieces with two or more people.

• To ensure the oven floor is installed level, you can bed under the base pieces using

sand or fire cement for a level finish.

• Keep fingers and clothing clear from oven base and joints during set down and

assembly.

After building your oven base to the Igneus Ceramiko 600 the above specification, lay your

insulation board onto your oven base to cover the total shape and footprint of the oven

floor including allowing the extra 80-100mm all the way round for the insulation and render

layers. Trim the board into shape using a saw and use ‘cut offs’ to fill in any gaps. When

laying the insulation board into position, check that it is flat and totally level using a spirit

level.

With the base of the oven complete and your insulation boards in position, follow these

steps to assemble your oven;

Laying the oven floor:

Step 1: Set down the front floor segment into position first. Notice the front floor

segment is the mouth of the oven and has a squared end. Check the front segment is

in the desired location and check that it is level and centralised.

Step 2: Set down the rear floor segment and lock it into position by sliding the

overlaps together. Once these are in position, check they are level. If the floor is not

level, then please use a fire cement or sand bed beneath the oven floor segments to

level. The oven floor is now laid. Important – do not use fire cement between the

oven floor pieces.

Setting the oven dome in place:

Step 3: The 600 dome is a single piece and is heavy, so you will need at least 3 strong

men in order to position it. To position the dome, place 3x rounded broom handles

(wide enough for the oven dome to fully sit onto them) onto the top of the oven

floor. Once in position, lift the dome onto them and roll the dome into position.

Once correctly positioned, lift the front of the dome archway up, so that the wooden

brooms can be removed. Lower the oven dome into position, so that it locks into the

base below.

Step 6: Once the oven is assembled, use the included fire cement to ‘seal’ the

external joints between the four dome segments. See below: Sealing the Oven.

Sealing the Oven:

1. Using a damp sponge, generously dab water on the joint lines on the external

surface of the oven dome.

2. Generously apply fire cement to entirely fill the external joint lines on the oven

dome surface. Do not use fire cement inside the oven.

3. Once the oven has been assembled and the fire cement has been applied and has

set, check the seal of the oven by lighting a small fire with two pieces of newspaper

to check for smoke leaks. If any leaks are found, use more fire cement on the

external dome to fully close the seal.

The oven is now ready for insulating and for the archway to be installed. Refer to section 2h.

Installing the Flue Manifold:

The Igneus Ceramiko 600 oven is supplied with a 6 inch/150mm single skinned flue as

standard. Place your flue into the flue hole in the Igneus Ceramiko 600 oven, this should be

a snug fit, but not tight, as chimney expansion occurs when the oven is in use.

If you are extending the chimney or installing the oven into a structure, then additional

chimney parts will be required. Different shapes and finishes can be achieved with a flue

system extension, ask the Igneus Wood Fired Oven team for recommended flue suppliers.

Warning

Please be aware that some flue lengths, flue caps and angle bends may have sharp edges, so

be careful when handling chimney sections and wear protective gloves if necessary.

Single Walled Flue Systems are for outdoor installation ONLY. The Igneus Ceramiko 600 is an

outdoor oven and must not be installed inside a walled structure. It can be installed into a

Pergola, but it must be vented out using twin walled flue. For more information on Pergola

installation, contact the Igneus Wood Fired Oven team.

It is your responsibility to ensure your flue meets local council and government guidelines

and is regularly cleaned to reduce the risk of flue fires.

Insulating the oven:

Note – the Igneus Ceramiko 600 cannot be insulated if it is built onto the metal stand. If

built onto a pre-built structure, it can be insulated and rendered. Once your oven dome is

built and fully sealed and tested, lay the insulation wool over the oven, ensuring you overlap

all joints. DO NOT leave any part of the oven’s dome on show. Insulation thickness is

dependent on your requirements, with a minimum of one to two layers thick, but bear in

mind the external space you have available – the more you insulate, the bigger your oven

becomes. You may want to add additional insulation wool to your oven dome such as rock

wool or loft insulation on top of the provided insulation wool layer – this is at your

discretion. For more details, refer to section 2h.

Top tips

For an igloo style finish, follow this step by wrapping the entire oven with chicken wire and

pinch together to create the finished shape, Repeat using plasterers Lath. Finish with our

approved render.

For brick enclosed ovens, install the oven as above, including your chimney as required.

Brick around the oven, then layer the oven with insulation wool and fill the void with extra

fireproof insulation from above. Finish the structure by building the roof, allowing for the

chimney to be safely installed.

Always wear a protective mask and goggles when cutting and handling insulation wool and

board.

Finishing Your Oven:

There are many different types of enclosures you can create with an Igneus Ceramiko 600

oven using different building materials from wood to brick, tiles, render and stone, the

options are almost endless.

To finish your oven, ensure that you follow the installation instructions above, then apply

the final layer of finish such as render or brick using normal building methods. For more

inspiration on build styles for the Igneus Ceramiko 600 oven, see

www.igneuswoodfiredovens.com

2g. Metal stand assembly

If you have purchased the Igneus Ceramiko 600 stand, you will need to assemble this before

placing your oven into position. The stand can be built by bolting the legs onto the bottom

shelf and top. To do this you will need two adjustable wrenches, which will be used to

tighten up the nuts and bolts. This is a simple job which should take you two people no

more than 15-20 minutes.

Important note

If you are placing your oven onto an Igneus Ceramiko 600 stand, please note that you

cannot add insulation or render to the oven, so your oven must be kept in its raw state. We

advise applying the approved sealant by painting it onto the exterior of the oven at least

every 6 months to protect your oven from excessive damp ingress. If you need more

information on this, please contact one of the team at Igneus Wood Fired Ovens.

2h. Rendering your oven

NOTE – Do not try to render your oven if you have built it onto the Igneus Ceramiko metal

stand as it will not work

Step 1

Using the fireproof cement, set the arch into position and allow to set.

Step 2

Next drill holes into the base structure all the way round your oven 50-60mm from the outer edge of

the oven wall, at a frequency of every 150mm, then screw in eye screws or hooks to attach the mesh

to in the next step.

Step 3

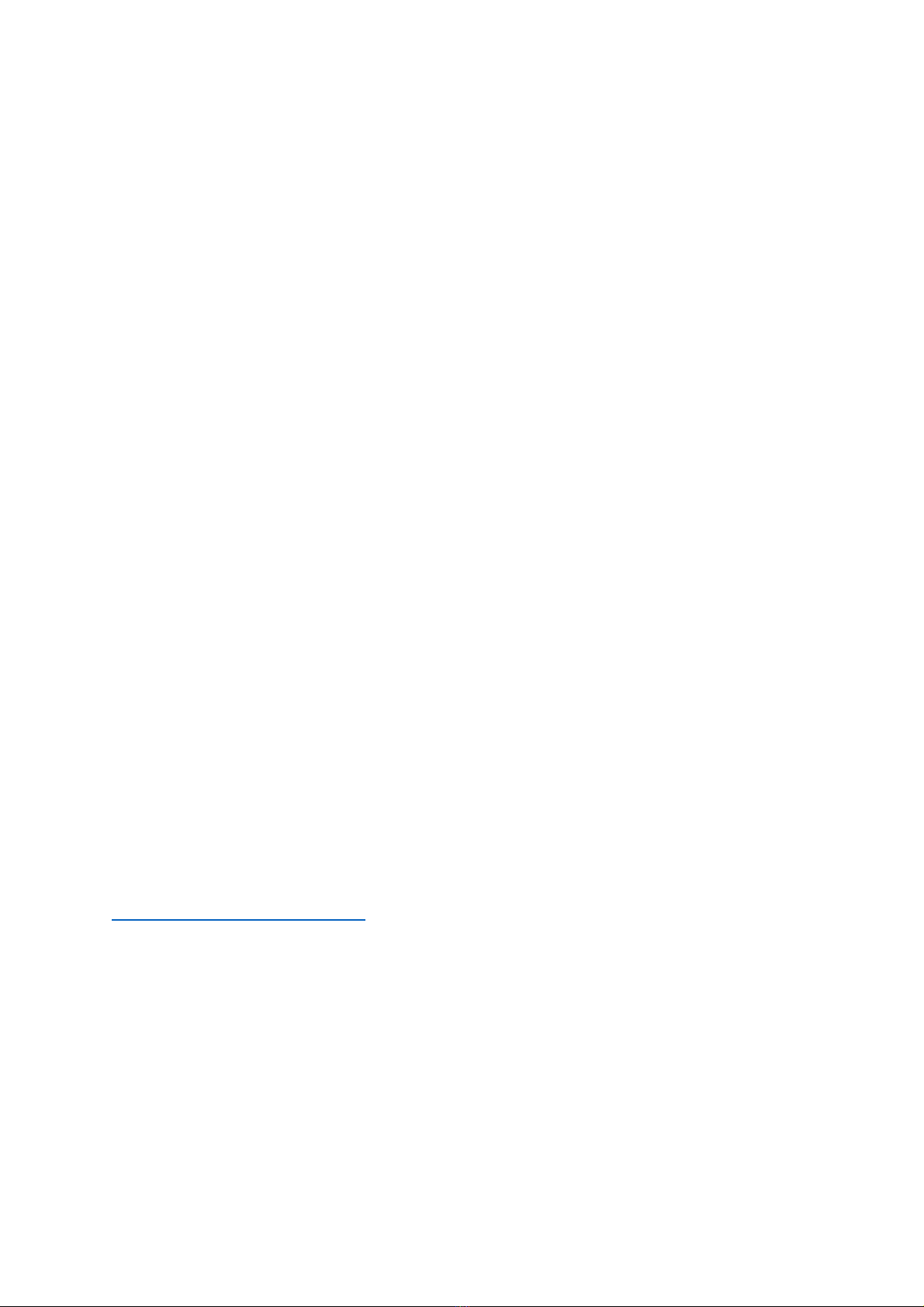

Loosely place your insulation material around the oven, you are using the insulation not only for

insulation purposes but also to generate an aesthetic shape. The Igneus Ceramiko insulation kit

includes a large amount of ceramic wool blanket, however you may need to still add additional

fireproof insulation to generate your preferred oven shape. Note, your chimney can be set to go

straight up (as supplied), or it can be profiled using additional chimney parts to be centred at the top

of the oven as shown in the image below.

Once you have loosely laid the insulation around the oven, it is time to attach chicken wire to the

hooks that you earlier drilled into the base structure. Pull the chicken wire around the oven encasing

the insulation layer and form your shape. You can pack additional fireproof insulation in if your shape

is not even. Once a satisfactory shape and finish is achieved, tie your chicken wire to the hooks using

metal wire or cable ties to secure it in place.

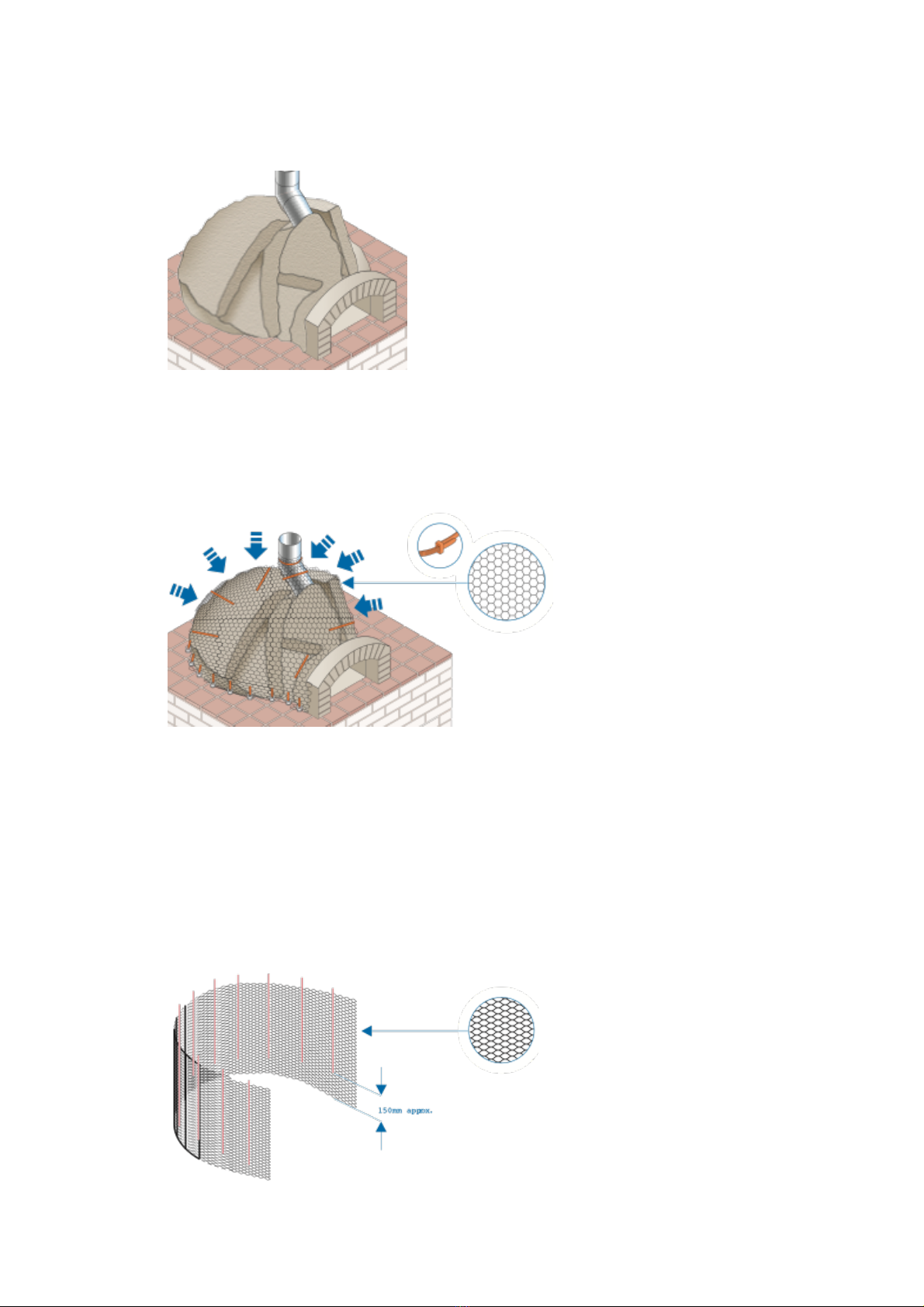

Step 3.

Once your chicken wire is safely in place and your desired shape has been achieved, attach the

bottom of a piece of metal plasterers lath round the oven onto the hooks earlier inserted, Using an

angle grinder make incisions in the lath to make it more pliable, stopping around 150mm from the

bottom of the lath, this will allow you to fold the lath in on itself and mould to your chosen shape.

Fold all the lath in onto your chicken wire and secure with metal wire or cable ties to hold in place. Do

this until all the lath is fully supported. Apply the lath to the top of the arch, so the render can be

applied to the front face of the arch.

You are now ready to render your oven.

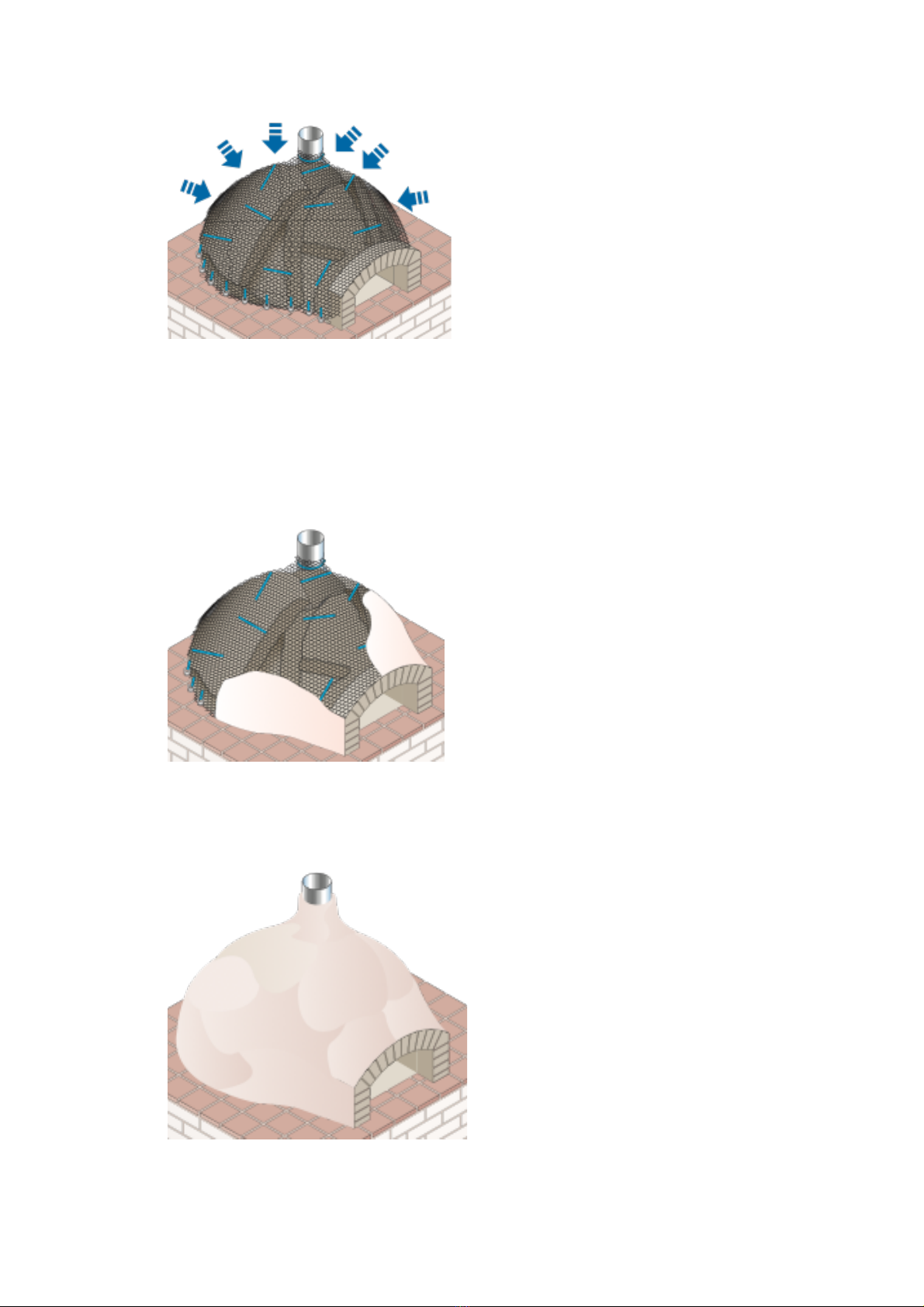

Step 4.

Apply your render to the mesh. We recommend the use of the Igneus Ceramiko Render Kit for this

job, however if making your own render use sand and cement, 4 parts plastering sand, 1 part cement,

and a glug of PVA.

With a trowel apply this to the mesh ensuring an even coat of render is applied to the entire external

surface of the oven, until the entire oven is covered. Wait for the render to be 90% set and then wipe

it over with a damp sponge, to work out any trowel lines and to create a smooth surface.

Once the render has dried this can be painted with a standard masonry paint in your chosen colour to

protect it from the elements.

3. Using your Igneus Ceramiko 600 Oven

3a. The don’ts when using your Igneus Ceramiko 600 oven

DO NOT use flammable liquids or sappy wood

DO NOT use treated wood or non-organic firelighters

DO NOT cover the entrance of the oven with anything other than the door (supplied)

DO NOT place combustible materials within oven clearances

DO NOT overfill the oven with wood

DO NOT use coal or charcoal in the oven

DO NOT touch hot surfaces with naked skin

DO NOT leave the oven unattended whilst in operation

3b. What wood to use in your oven

Igneus Wood Fired Ovens strongly recommend using kiln dried hardwood such as Alder, or

compressed Beech briquettes in your oven. Note – seasoned wood, green wood or any

wood with moisture content above 20% will cause your oven to generate excessive smoke

and it will struggle to reach high temperatures.

Top tip

To ‘kiln dry’ your own wood, simply place a stack of wood into the oven (as far away as

possible from where the fire was set) after cooking one evening, but make sure the oven

temperature has dropped significantly. The lower retained heat in the oven will dry out your

logs for future use, but make sure they don’t ignite whilst inside the oven. Ensure you have

removed all embers before you place the logs in the oven. Do not leave the oven

unattended. Please note, this tip only applies to natural hardwood.

3c. How to make a fire

Follow these instructions when lighting your oven;

Step 1

Using your kiln dried hardwood, chop a few logs down using a small axe or wood

cutter into chunky kindling lengths of around 10 inches and about 2-3 inches thick.

Note - Shop bought, ready cut kindling can often be too small for this oven and will

therefore not reach the desired temperature

Using a natural fire lighter such as Twizzlers, place it in centre of the oven floor, build

a cross sectioned structure around it using your cut kindling to a height of

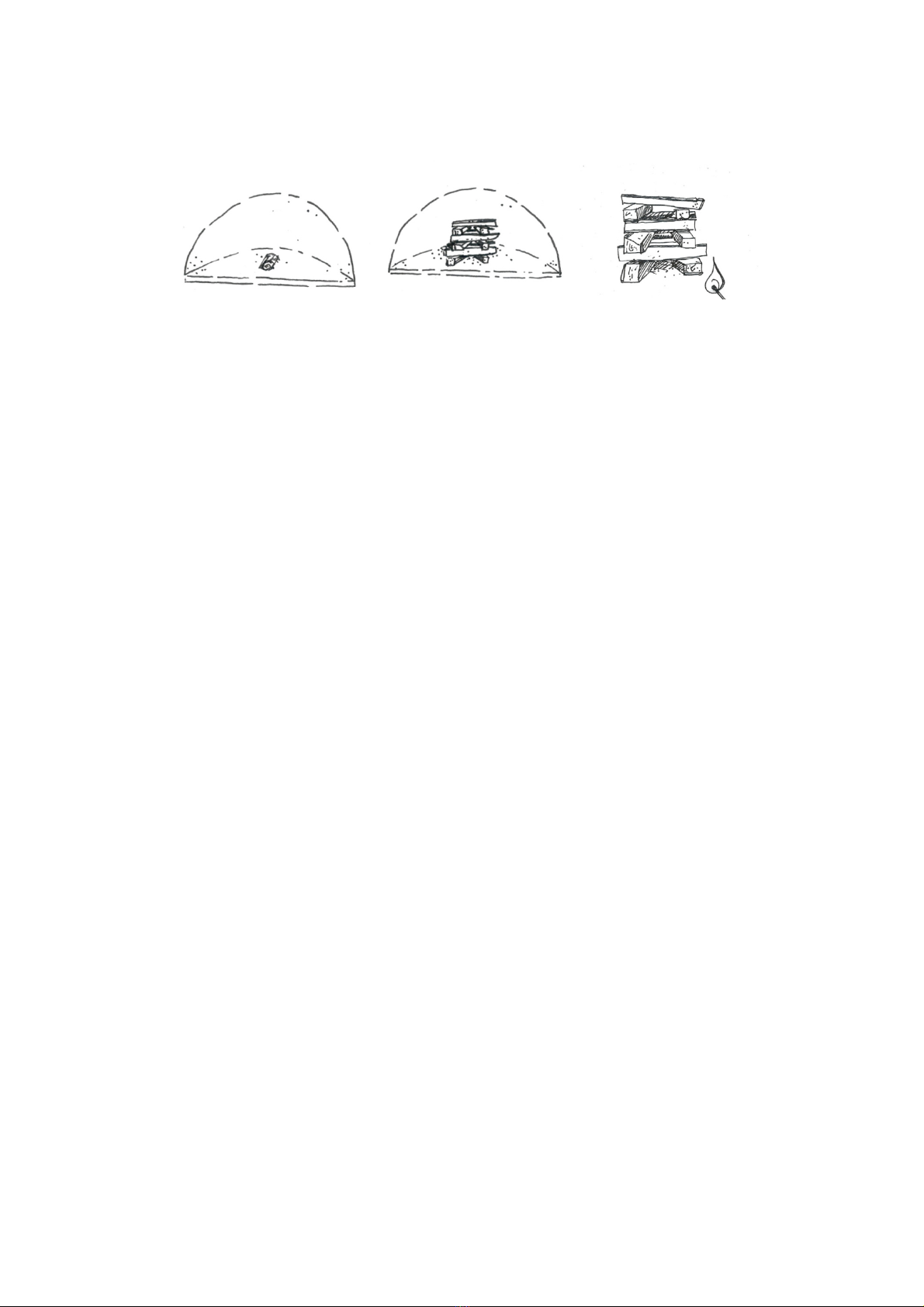

approximately 20cm. Ignite the natural fire lighter with a match. See images;

Place Fire Lighter Form kindling stack Ignite the Fire Lighter

Step 2

Leave the fire stack to burn in the centre of the oven for around 3-4 minutes, then

add more kindling pieces to the stack in a pyramid shape, to encourage the fire to

increase in size and temperature. This process ensures the oven dome and base is

saturated with heat evenly. Continue to add larger kindling pieces or small logs to

the burning kindling stack as the oven heat increases. You will start to approach

optimum cooking temperatures 450+ degrees Celsius and you can read the oven

floor heat using an infrared thermometer or a floor standing thermometer. If you

don’t have a thermometer then keep your eye on the inner roof of the oven for

when the sooty deposits on the oven ceiling diminish. The lighting process typically

takes around 25 minutes in the Igneus Ceramiko 600 oven.

Step 3

Once you have reached optimum cooking temperatures, (450+ degrees Celsius) you

are ready to start the cooking process. Move the embers of the fire to the back or

side of the oven using an ash rake. This will expose the red-hot cooking area which is

where you will place your pizza or food trays or pans. Use a brush to clear any debris

or ash from the oven floor, then using your pizza peel, place 1-2 kiln dried logs onto

the fire inside the oven.

Top tips

Always bring your oven up to optimum cooking temperature whatever you are going

to cook first, this ensures the oven is saturated with heat, and will make sure it stays

hotter for longer.

Remember to rotate your food whilst in the oven to ensure even cooking.

Alternate embers on each side of the oven when cooking over long periods to ensure

an even distribution of heat whilst cooking.

3d. Lighting your oven for the first time (or lighting during Autumn and Winter)

Your oven may take a little longer to reach optimum temperatures on your first firing. This is

normal and is due to residual moisture in the oven from the manufacturing process.

When lighting for the first time, make sure that you light the oven slow and steady, at a

stable rising temperature for around 30 minutes. Then allow the oven to cool off naturally.

This process will ensure that the moisture trapped within the floor and walls of the oven is

slowly drawn out.

In Autumn and Winter during wet weather or low temperatures, ensure you light the oven

slow and steady, at a stable rising temperature for around 30 minutes before using the

oven. Once done, you can resume your normal lighting regime.

Failure to light the oven slowly in these instances may affect your oven warranty.

3e. How to cook in your Igneus Ceramiko 600 oven:

The Igneus Ceramiko 600 oven has the same cooking abilities as all of our wood fired oven

range. You can cook virtually anything in a wood fired oven and achieve a range of different

cooking techniques. Cook pizza, roast, grill, bake and more using the different phases of

heat in the oven. For excellent foodie inspiration, there’s a myriad of wood fired cooking

content online from many top chefs. A great start is searching ‘The Wood Fired Oven Chef’

on YouTube.

Top tip

The door provided with your oven can be used for a range of different cooking techniques

including roasting and baking. Take care whilst using the oven door as it will get hot, so

always wear heatproof gloves when handling it.

3f. How to dispose of ashes safely

Even if it has been over 24 hours since use, the ashes from your oven can still be a fire risk.

Ensure you wait until the oven is cold before attempting to remove the ash. Remove the ash

with appropriate tools e.g., ash rake or oven brush and place them safely into a metal

bucket with a sealable lid away from combustible materials. If required, douse the embers

out in the bucket using plenty of cold water.

3g. Oven Tools

To run your oven safely and effectively, it is essential that you use the correct tools. A range

of tools are available to purchase on our website from our online store. Ensure all pans used

are appropriate for use in ovens capable of very high temperatures. We recommend cast

iron pans for cooking in your wood fired oven, all accessories available from

www.igneuswoodfiredovens.com

4. The Clean Air Act 1993 and Smoke Control Areas

Under the Clean Air Act local authorities may declare the whole or part of the district of the

authority to be a smoke control area. It is an offence to emit smoke from a chimney of a

building, from a furnace or from any fixed boiler if located in a designated smoke control

area. It is also an offence to acquire an “unauthorised fuel” for use within a smoke control

area unless it is used in an “exempt” appliance (“exempted” from the controls which

generally apply in the smoke control area).

The Secretary of State for Environment, Food and Rural Affairs has powers under the Act to

authorise smokeless fuels or exempt appliances for use in smoke control areas in England. In

Scotland and Wales this power rests with Ministers in the devolved administrations for

those countries. Separate legislation, the Clean Air (Northern Ireland) Order 1981, applies in

Northern Ireland. Therefore it is a requirement that fuels burnt or obtained for use in smoke

control areas have been “authorised” in Regulations and that appliances used to burn solid

fuel in those areas (other than “authorised” fuels) have been exempted by an Order made

and signed by the Secretary of State or Minister in the devolved administrations.

Further information on the requirements of the Clean Air Act can be found here :

https://www.gov.uk/smoke-control-area-rules

Your local authority is responsible for implementing the Clean Air Act 1993 including

designation and supervision of smoke control areas and you can contact them for details of

Clean Air Act requirements.

4a. Use in Smoke Control Areas

The Igneus Ceramiko 600 oven is manufactured on our behalf by a UK based factory. The

master design of this oven held by the factory has not been approved by Defra as suitable

for use in smoke control areas when burning wood and in accordance with the instructions

in this manual. This means that the Igneus Ceramiko must be used in an outdoor setting.

4b. Refuelling

When refuelling, smoke emissions can occur if fuel is added to a dying fire/glowing embers.

If the fire has been allowed to die down this far, smaller kindling size fuel will need to be

added to re-ignite the oven.

4c. Overloading

Overloading can cause excess smoke as this will restrict the available oxygen to fully

combust the fuel inside the oven. Do not use more than three kiln dried logs within the oven

at any time.

5. Igneus Ceramiko 600 oven warranty

Igneus Wood Fired Ovens, warrants the Igneus Ceramiko 600 oven to be free from defects

in workmanship and materials for the period of 1 year from the date of delivery.

5a. Investigation of claims against warranty

Igneus Wood Fired Ovens reserves the right to investigate any/all claims against this

warranty, then subsequently decide upon an appropriate method of resolution.

5b. Warranty Qualifications

The warranty outlined above is subject to accordance with the following qualifications:

1) The warranty does not apply to normal wear and tear of the oven or small/ fine cracks

which may appear due to the natural expansion and contraction under heat of the oven

dome and base.

2) The Igneus Ceramiko 600 oven must be installed in accordance to the Installation

Instructions, as outlined in this manual and it must comply with local building regulations.

3) The Igneus Ceramiko 600 oven is subject to normal use, as defined by the operational

manual. The parent company of Igneus Wood Fired Ovens does not warrant the Igneus

Ceramiko 600 oven when any other fuels apart from dry untreated kiln dried hardwood logs

or briquettes are burnt.

4) This warranty does not apply to cracking after overfilling the oven, or failing to use

recommended fuels and/or failing to follow the guidelines of slow firing in autumn and

winter.

5c. Limitation Liability

Under this warranty and any other warranty expressed or implied by Igneus Wood Fired

Ovens to the purchaser/s, shall be limited to repair, replacement or refund, subject to

warranty qualifications being met as defined above. In no event shall Igneus Wood Fired

Ovens or its parent company be responsible or liable for any incidental and consequential

damages to property, losses, bodily injuries and the like, caused by defects in its products.

Whether or not such damage is caused by Igneus Wood Fired Ovens’ negligence or such

damage is discovered before or after replacement or repair. Igneus Wood Fired Ovens

reserves the right to send you a replacement product that is the same or of a similar style or

a substitute equivalent that may not be of like kind (depending on availability). Replacement

products will be furnished only on an exchange basis. Replacement products are warranted

as above for the remainder of the original applicable product warranty period. Any

replacement provided will cover the goods only. The cost of installation of the replacement

goods will be the responsibility of the customer.

Dealers and Igneus Wood Fired Ovens employees have no authority to make any warranties

or authorise any remedies which are not in accordance, or which are in addition, to those

stated above.

5d. How to register a claim against the warranty

To claim against this warranty and for it to be valid, Igneus Wood Fired Ovens must be

notified by telephone 01423 575885, or in writing to; Igneus Wood Fired Ovens, c/o Quality

Shops Online Ltd, Old Penny Gate, Off Halfpenny Lane, Knaresborough, HG5 0SL.

Claims should include the description of defect, supporting images and original date of

delivery with copy of original delivery/advice note. Claims are to be made within 1 year of

the advice note and delivery date.

6. Important fire and safety notice

The Igneus Ceramiko 600 is a wood fired oven which will reach extremely high

temperatures, so please ensure that you follow the installation instructions carefully. Failure

to follow this Manual and Health and Safety instructions may result in oven damage, cause

damage to property, cause bodily injuries or in some cases even cause death.

If you choose to use the oven, it is done so at your own risk. No liability is accepted by

Igneus Wood Fired Ovens for any injury, damage or loss incurred.

DO NOT burn flammable liquids or similar at any time in the oven, including but not limited

to; firelighter fluid, petrol, diesel, lantern oil or kerosene.

DO NOT artificially attempt to induce airflow through the oven, e.g. using a fan to blow air

into the cooking chamber.

ONLY USE untreated kiln dried hardwood as a fuel and DO NOT burn any refuse, plastics,

treated wood; including laminates, charcoal, chipped wood, pressure treated wood, sappy

wood (for example, pine) or fossil fuels.

ALWAYS WEAR PROTECTIVE CLOTHING: We strongly recommend gloves for use during oven

operation. ALWAYS keep children, groups of people and pets a safe distance from the oven

whilst in operation and whilst cooling.

ENSURE all tools and materials used in the oven are appropriate for high temperatures and

take care whilst handling tools. No liability is accepted for any injury, damage or loss that

occurs because non-approved tools have been used.

BEWARE of high temperatures achieved on the outside and inside of the oven and be

cautious of flying sparks. Ensure wood storage is covered by a non-combustible material. Do

not leave the oven unattended.

ENSURE if you install your oven and flue indoors/under cover that the appropriate building

regulations and safety restrictions are met. Check with your local authority.

DO NOT keep any combustible materials, near or within range of the oven

at any time. This includes clothing, furniture, electrics, nearby shrubs or trees, flammable

materials, liquids or the like.

DO NOT touch the oven or flue, or artificially block or cover the oven entrance at any time

during and after operation.

ALWAYS DISPOSE of ashes in a safe way once they are cold. Ensure you regularly clean your

flue parts, failure to do so may result in flue fires.

DO NOT modify the oven in any way from the manufacturer’s design and specification.

“Building in” as detailed by Igneus Ceramiko Build Manual does not count as a modification.

FIRE PRECAUTION:

Ensure a water fire extinguisher of at least 9 litres capacity (to deal with the oven and

surrounding area) and a bucket of sand are positioned within easy reach. Although we have

tested the use of fire extinguishers on the oven with no adverse effect, in case of an

emergency, we recommend only sand is used to knock down a fire within the oven. In order

to satisfy UK Fire Safety Legislation we strongly suggest that anyone who may tackle a fire

should be adequately trained by a fire safety professional.

For further information, printable manuals and more, visit us at

www.igneuswoodfiredovens.com

© Quality Shops Online ltd (T/A Igneus Wood Fired Ovens) 2022. All rights reserved.

Table of contents

Popular Oven manuals by other brands

Blodgett

Blodgett 1200 Series Installation, operation and maintenance manual

ILVE

ILVE 940SKMP instruction manual

Panasonic

Panasonic NU-SC280WYUE operating instructions

Candy

Candy FCXM625X User instructions

VERDER

VERDER CARBOLITE GERO LGP 4/1500 Installation, operation and maintenance instructions

Dimplex

Dimplex Pizzeria 600 Owners & installation manual