BEING BOV-20 User manual

Quick Start Guide

Vacuum Ovens - BOV-20, BOV-50 & BOV-90

Professional

Instrument

Supplier

document number

1. Observation window

2. Door lock handle

3. Vacuum pump electrical outlet - Not available on BOV-90

4. Circuit breaker & Power switch

5. Power cord

6. Air (inert gas) inlet (3/8” ID hose barb)

7. Balance hole

8. Vacuum KF-25 ange

9. Vacuum guage

10. Controller

11. Observation light power switch

12. Purge switch

13. Pump switch

14. Articulating glass door

15. Swinging metal door

16. Feet - Non-adjustable

17. Casters - Non-locking (BOV-90 only)

18. Casters - Locking (BOV-90 only)

19. Removable/adjustable shelves

20. Electic plug

BOV-20 & BOV-50: NEMA 5-15

BOV-90: NEMA 6-20

Accessories

21. 13mm ID x 29mm OD x 925mm long vacuum hose

22. 14mm x 17mm open-end spanner wrench

23. 8mm x 10mm open-end spanner wrench

24. KF-25 clamp

25. KF-25 o-ring

26. KF-25 x 16mm hose barb

Oven Components

Set Up

STEP 1: Remove protective covering(s).

STEP 2: Position unit for use.

Position the vacuum oven on the oor or

a work surface strong enough to carry the

oven’s weight.

Model Weight

BOV-20 60 KG / 132 LBS

BOV-50 95 KG / 210 LBS

BOV-90 145 KG / 320 LBS

Additionally, the oven requires a minimum

clearance area as shown in the diagram (left).

STEP 2a: Lock the front casters. (BOV-90 only)

Using your foot, press down on the caster’s pedal to lock the oven in place.

Lift up on the bottom of the pedal to unlock the caster to reposition or move

the oven.

STEP 3: Relieve oven chamber vacuum.

Rotate the balance hole 180Oto relieve the vacuum applied at the

factory prior to shipping. Upon relieving the applied vacuum, close

the balance hole.

STEP 4: Unlock and open door. Remove

supplied accessories.

STEP 5: Push hose onto KF-25 hose barb

and your vacuum pump or cold trap tting.

STEP 6: Assemble the KF-25 hose barb, seal

ring, and clamp to the oven’s KF-25 ange.

Attach your tting to your vacuum pump or

cold trap.

STEP 8: Plug your vacuum pump electrical

cord into the outlet on the oven and turn

the vacuum pump on. (BOV-20 & BOV-50)

For BOV-90 plug vacuum pump into nearest

electrical outlet.

STEP 7: Attach your inert gas or air hose to

the oven’s air inlet hose barb.

STEP 9: Plug the oven’s electrical cord into

appropriate outlet.

Rotate the door handle counterclockwise 90O

to unlock the door and carefully pull the

door open. Remove the supplied accessories

and shelves. Remove protective shelf covering.

If the door does not move easily, DO NOT TUG on the door.

Doing so can damage the door seal. Use your nger or a at

blade (standard) screwdriver to ick the door seal to release

the seal from the glass door.

Review the vacuum pump specications to ensure it is a

two-stage pump and has the following ow rate capacity.

BOV-20 and BOV-50: 2 liters/second (4 CFM)

BOV-90: 4 liters/second (8 CFM)

Drawing Vacuum

STEP 1: Close and lock door.

STEP 2: Ensure balance hole is closed.

STEP 4: Turn the PUMP switch on.

Rotate the PUMP switch clockwise 90O.

Vacuum pump will instantaneously turn on,

solenoid valve will open, and vacuum will be

applied to the chamber.

It will take approximately 3-4 minutes to reach

-14.7 PSI / -1 bar. Use the balance hole to lengthen

the time to reach maximum applied vacuum.

Remove the black cap from the hose barb tting.

Option 1: Leave the barb tting bare

Option 2: Push a 3/8”ID hose onto barb tting. Attach other end of hose to

your inert gas or air supply, or if neccessary, attach the hose to a cold trap.

Lift the outlet cover. Push

the vacuum pump’s power

cord into the 120 VAC, 5

Amp rated receptacle. Turn

the vacuum pump’s power

switch on.

After placing specimens on the oven

shelves, close the door and turn the door

handle clockwise 90O.

The balance hole arrow must point

between 2 and 10 o’clock for the

balance hole to be fully closed.

Use the balance hole to control

vacuum draw speed.

It must be fully closed to reach a

-14.7 PSI / -1 bar.

BOV-20 & BOV-50

STEP 4: Turn your vacuum pump on.

Rotate the PUMP switch clockwise 90O.

Solenoid valve will open and vacuum will be

applied to the chamber.

It will take approximately 3-4 minutes to reach

-14.7 PSI / -1 bar. Use the balance hole to lengthen

the time to reach maximum applied vacuum.

BOV-90

STEP 5: Turn the PUMP switch on.

It is not required to draw a vacuum to apply heat to the

specimens in the oven. However, applying a vacuum rst

will reduce the humidity in the oven and increase the speed

to reach desired temperature.

STEP 3: Turn on unit power

Push the circuit breaker’s lever

down to turn on the power to

the oven.

BEING Instrument Inc.

847 Palmyrita Ave, Unit A Riverside CA 92507 USA | T: +1 (800) 278-1390 | suppor[email protected] | www.beinglab-usa.com document number

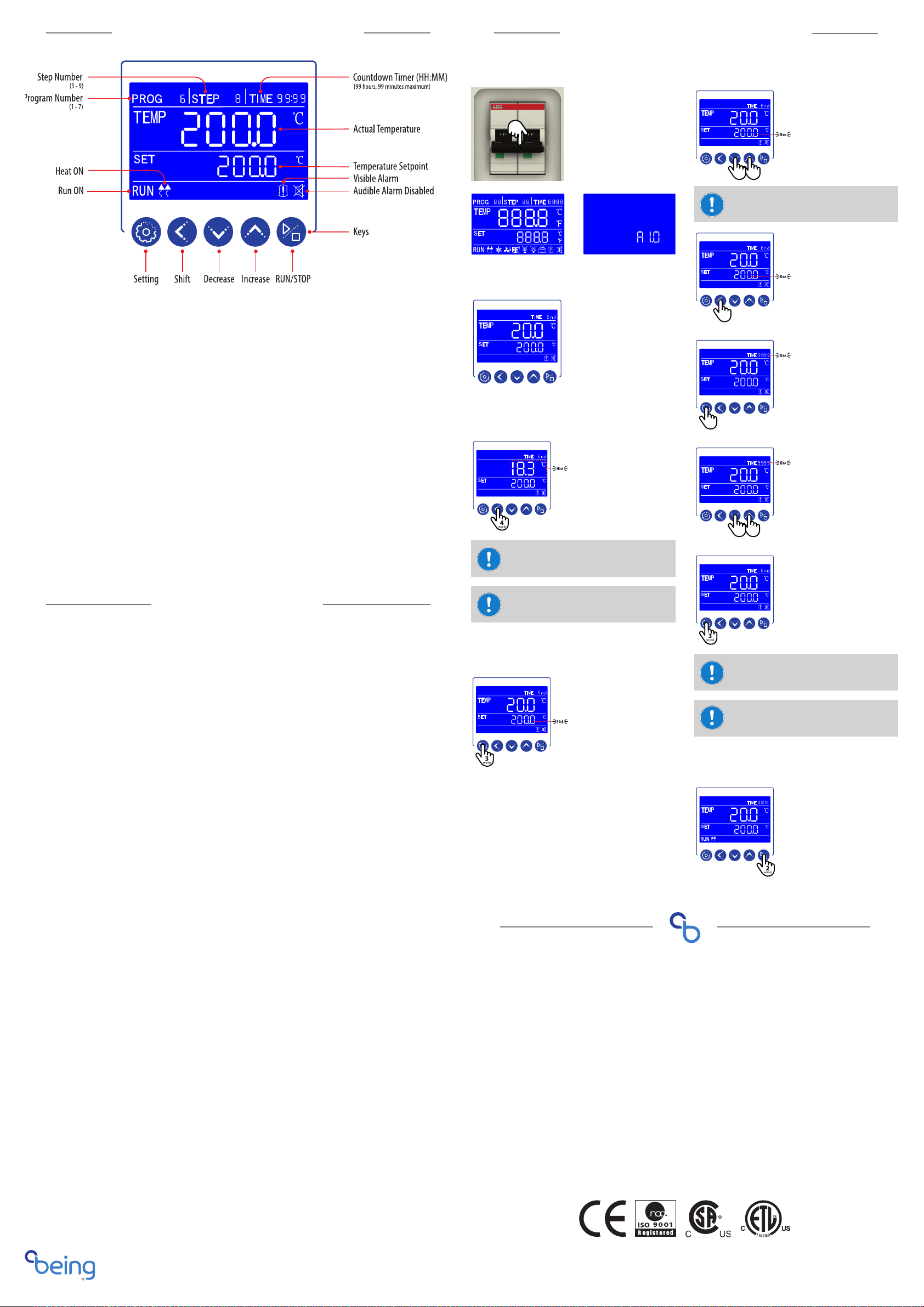

Setting Temperature & Timer

The unit is ready for use.

Upon turning the unit’s power on, the controller will cycle through these

two start-up screens.

STEP 1: Turn on unit power

PROG Area: Displays the program working or setting

group. Controller is capable of programming and storing

up to 7 programs.

STEP Area: Displays the number of the step within a

program. There are 9 steps available for each program.

TIME Area: Displays the running time or parameter

value.

TEMP Area: Displays the measured (actual) temperature

within the oven’s chamber. Also, displays the ambient

room temperature when requested.

SET Area: Displays the temperature setpoint.

RUN: Illuminates when the oven’s program is working.

Turns o when program is stopped.

HEAT: Arrows illuminate and blinks when the oven’s

heater is on. Turns o when heating elements are o.

Visible Alarm: Illuminates when the program has

completed, has been stopped by user, or when an over

temperature condition occurs. Additionally, when the

visible alarm illuminates an audible alarm will start.

Audible Alarm Disabled: Illuminates when the user

presses any key or when the unit’s power is turned o.

Keys

Setting: Starts the programming of the temperature and

run time. Accepts the temperature and run time values.

Shift: For changing the parameter value being set and

viewing ambient temperature.

Decrease: Used for setting parameter value, modication

of various values, or start/stop auto-tuning.

Increase: Used for setting parameter value, or press and

hold for more than 2 seconds to view the remaining

program time.

RUN/STOP: Press for 2 seconds to run or stop the controller.

STEP 2: Check ambient temperature.

Press and hold shift key for 4 sec-

onds to view ambient temperature.

Temperature value will blink. Press

and hold shift key for 4 seconds to

return to main screen.

Function also works while program

is running.

Temperature setpoint must be.

ambient + 10OC to 200OC

ambient + 18OF to 392OF

STEP 3: Push setting key

STEP 4: Input temperature & time values

Press decrease or increase key to set

tenths value. Value will blink as it

is being set.

Press the shift key to move to the

next parameter digits. Each move

will cause parameter to blink.

Press the setting key to accept

temperature setpoint.“End”in TIME

area will change to run time digits.

First digit will blink.

Use decrease or increase key to set

each minute and hour value.

Press the shift key to move to the

next parameter digits.

Upon setting the run time, press

and hold the setting key for 3

seconds to complete the program.

TIME area will return to “End.”

If unit power is on and ambient temperature is known,

start programming process at Step 3.

If changing temperature only, press and hold setting key

for 3 seconds, change temperature, press setting key, and

press and hold setting key for 3 seconds.

If changing time only, press and hold setting key for 3

seconds, when temperature blinks press setting key, change

time, and press and hold setting key for 3 seconds.

Safety Messages

Controller Element Overview

STEP 5: Push RUN key

Pushing the RUN key for 2 seconds,

starts the program. RUN, HEAT, and

run time illuminate.

Pushing the setting key for 3

seconds, starts the programming

process.

The tenths temperature value

blinks.

Press and release to decrease/increase one digit at a time.

Press and hold to rapidly cycle through digits.

Push the circuit breaker’s lever

down to turn on the power to

the oven.

This manual suits for next models

2

Popular Oven manuals by other brands

Viking Range

Viking Range VEDO5302T Use & care manual

AEG

AEG BEB331110M user manual

AEG

AEG DE4003020 user manual

Siemens

Siemens HM676G0 1I Series User manual and installation instructions

Summit

Summit SGWO30SS Owner's Manual with Installation and Maintenance Instructions

Siemens

Siemens CN678G4 1B Series instruction manual