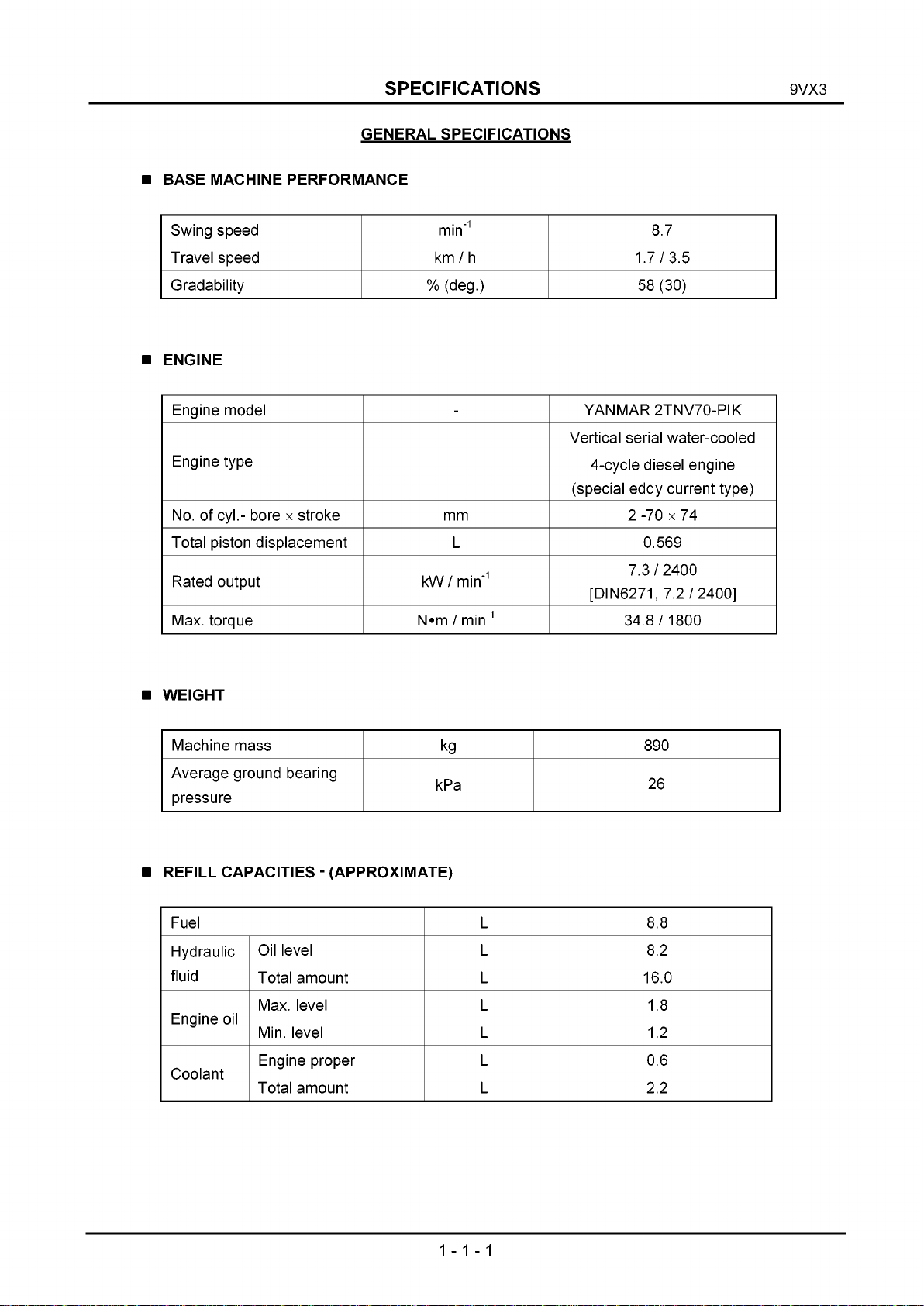

S ECIFICATIONS 9VX3

■ WORKING RANGE (BACK HOE)

Unit: mm

Key Description Std. arm Long arm

Std. o bucket capacity (m3), ISO Heaped 0.022 0.017

A Max. digging radius 2980 3190

В Max. bucket outreach at ground level 2880 3100

С Max. digging depth(Not used blade) 1570 1770

D Radius o max. digging depth 1330 1340

EMax. digging height 2755 2950

F Radius o max. digging height 1740 1820

G Max. dumping height 1970 2150

H Radius o max. digging height 1590 1700

IMin. dumping height 850 660

J Radius o min. dumping height 112 0 12 20

К Max. vertical digging depth 1175 1400

L Radius o max. vertical digging depth 2160 2140

MRadius o min. digging ground level 1040 990

N Max. clean-up radius at loor level 2290 2500

1-3-2