IHP BHS Series User manual

* We reserve the right to amend specification without prior notice.

INDRA HYDRO TECH PUMPS PVT. LTD.

316, 1st Floor, 8th Cross, 4th Phase, Peenya Industrial Area, Bengaluru - 560 058, Karnataka, India

Tel.: +91 80 2836 2916, Fax: +91 80 2836 3048, Email: [email protected], www.ihpindia.in

Instruction Manual

An certified company byISO 9001:2008

BHS SERIES 4" & 6"BHS SERIES 4" & 6"

BHP SERIES 4"BHP SERIES 4"

BHS SERIES 4" & 6"BHS SERIES 4" & 6"

BHP SERIES 4"BHP SERIES 4"

BHS SERIESBHS SERIES BHP SERIESBHP SERIES

INDRA HYDRO TECH PUMPS PVT. LTD.

316, 1st Floor, 8th Cross, 4th Phase, Peenya Industrial Area, Bengaluru - 560 058, Karnataka, India

Tel.: +91 80 2836 2916, Fax: +91 80 2836 3048, Email: [email protected], www.ihpindia.in

* We reserve the right to amend specification without prior notice.

1

2

3

4

5

6

7

8

9

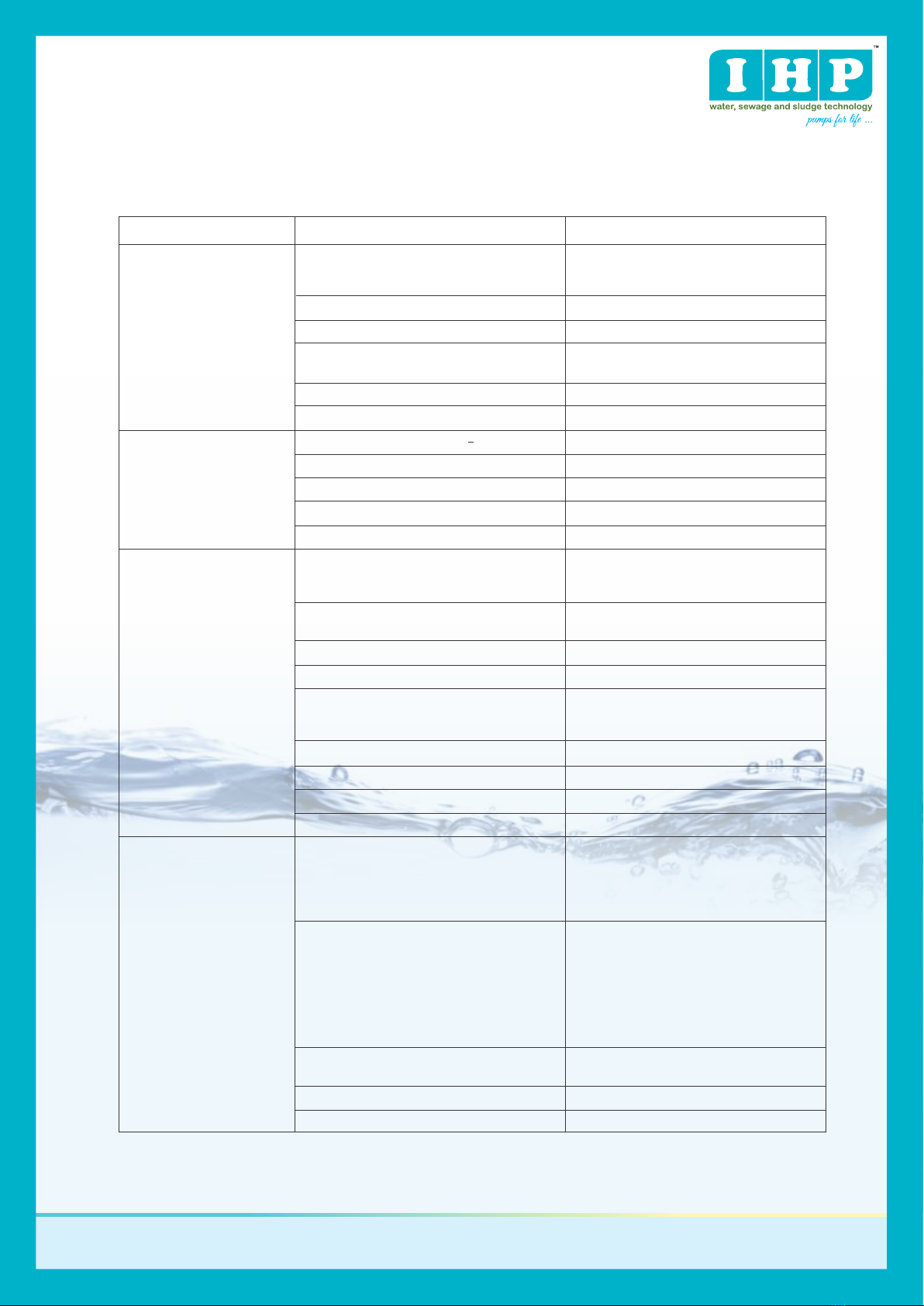

1. Hook with Ω shape design Non-welding method keeps material not damaged.

2. Top bearings with sand channels design, avoid shaft swing and sand damaged while operating

3. Shaft with flower shaped design(SUS 304) robustness leads superior hydraulics

4. Intermediate chamber with N-shape design, 18kg water pressure resistance to prevent

leakage.

5. Strap with HV260 hardness better intensity against pumping pressure

6. Sand flush vane design, leave the sand with the pumped liquid and prevent sand-block inside

7. Coupling with HRC 78 forged coupling increases robustness to avoid abrasion and perfectly

fitted into different types of motors

8. Suction inter connector inlet with R-angle design, 200kg tensile strength against outside

impacts.

9. Suction inter connector plate with S-shape design, 900kg tensile strength leads better

sustainability for pump.

6” Stainless Steel Borehole Pump Features

1. Strap with HV-260 Hardness better intensity against pumping pressure

2. Shaft with round shaped design (SUS-431-QT) robustness leads superior hydraulics

3. Impeller and guide vane with "straight line" design, increase pump in efficiency

4. Neck ring with "inner pressure coarctation" design, special design to prevent water

backflow

5. Diffuser vane contains moving bearings with HRC50~55 leads much lower abrasion

and better lifespan

6. Interconnector fixer with L-shaped design, tighten the s trap and interconnector and

leads strap much more stable

1

2

3

4

5

6

4” Stainless Steel Borehole Pump Features

INDRA HYDRO TECH PUMPS PVT. LTD.

316, 1st Floor, 8th Cross, 4th Phase, Peenya Industrial Area, Bengaluru - 560 058, Karnataka, India

Tel.: +91 80 2836 2916, Fax: +91 80 2836 3048, Email: [email protected], www.ihpindia.in

* We reserve the right to amend specification without prior notice.

2

ŸThe borewell should fully be developed and flushed free of cutting and sand.

ŸDetermine the maximum depth of well and the draw down level at max pump capacity. Pump setting depth should be

atleast one meter below the max draw down level.

ŸEnsure a minimum velocity of 0.2 m/s part of the motor for proper cooling.

ŸThe motor should be filled with pure drinking water free of any silt or suspended particles. Replace the water filling drain

plugs without fail.

ŸThe electrical connections should be carried out by a qualified electrician.

ŸEarthing should be provided with the motor body.

ŸEnsure correct size of cable and suitable electrical protection devices like MCB, cut-off relay, contactors, etc. are provided.

ŸRelay should be set for full load current mentioned and single phasing, dry run protection should be used to avoid coil

burning on account of dry running and single phasing.

ŸCheck for free rotation of pump and motor before coupling.

ŸCheck for vertical play before and after coupling.

ŸEnsure that only recommended size of piping is used and the pump should be gripped by two flats of pipe wrench.

ŸThe threaded joints of pipe must be well cut and fit together tightly to ensure they do not work loosely.

ŸEnsure the motor cable is not damaged when pump is lowered into the well.

ŸEnsure the pump is completely submerged in the liquid before starting.

ŸEnsure the pump is not stopped till the water becomes clearer, free of impurities, otherwise pump parts and check valve

gets clogged. Operate pumpset for atleast five minutes daily to avoid pump jamming.

ŸEnsure no oversize backup fuse wires are used. This will damage the motor winding in case of short circuiting.

ŸEnsure the valve is throttled to avoid dry running in case of low discharge. Do not test the pumpset outside bore in dry

conditions as this damages seals and bearings.

ŸDo not use pump to handle water containing solid/fibrous substances.

INSTALLATION AND OPERATING INSTRUCTIONS

INDRA HYDRO TECH PUMPS PVT. LTD.

316, 1st Floor, 8th Cross, 4th Phase, Peenya Industrial Area, Bengaluru - 560 058, Karnataka, India

Tel.: +91 80 2836 2916, Fax: +91 80 2836 3048, Email: [email protected], www.ihpindia.in

* We reserve the right to amend specification without prior notice.

Instruction Manual

a. The fuses are blown

b. The circuit breaker has tripped

c. No electricity supply.

d. The motor protection has cut off the

electricity supply due to overload.

Cause RemedyFault

e. The drop cable is defective.

f. Over-voltage has occurred.

1. The pump does not run.

2. The pump runs but gives

no water.

a. The discharge valve is closed.

b. No water or too low water level in well.

c. Check valve is stuck in its closed position.

d. The suction strainer is closed.

e. The pump is defective.

a. The draw-down is larger than anticipated.

b. The valves in the discharge pipe are

partly closed/blocked.

c. The discharge pipe is partly chocked by impurities.

3. The pump runs at

reduced capacity.

4. Frequent starts and stops.

e. The pump and the riser pipe are partly

chocked by impurities.

f. The pump is defective.

d. The non-return valve of the pump is blocked.

g. Hole in discharge pipe.

h. The riser pipe is defective.

i.Under-voltage has occurred.

a. The differential of the pressure switch

between the start and the stop pressures

is too small.

b. The water level electrodes or level

switches in the reservoir have not been

installed correctly.

c. Non return valve is leaking, stuck half-open

or damaged

d. The supply voltage is unstable.

e. The motor temperature is too high.

Replace the blown fuses. If the new fuses

too blow, check the electrical installation and

the drop cable.

Reset the circuit breaker.

Contact the electricity provider.

Check for motor / pump blockage.

Repair/replace the pump’s cable.

Check the electricity supply.

Open the valve.

Allow water to get collected.

Pull the pump and clean or replace the valve.

Pull the pump and clean the strainer.

Repair or replace the pump.

Increase the installation depth of the pump.

Throttle the pump or replace it with a smaller

capacity model

Check and clean/replace the valves as necessary.

Clean/replace the discharge pipe.

Pull the pump and check/replace the valve.

Pull out the pump. Check and clean or replace

the pump, if necessary. Clean the pipes.

Repair/replace the pump.

Check and repair the piping.

Replace the riser pipe

Check the electricity supply.

Increase the differential. However, the stop

pressure must not exceed the operating pressure

of the pressure tank, and the start pressure

should be high enough to ensure sufficient

water supply.

Adjust the intervals of the electrodes/level

switches to ensure suitable time between the

cutting-in or cutting-out of the pump. See

installation and operating instructions for

automatic devices used. If the intervals between

start/stop cannot be changed via the automatics,

the pump capacity may be reduced by throttling

the discharge valve.

Pull the pump and clean/replace the

non-return valve.

Check the electrical supply.

Check the water temperature.

INDRA HYDRO TECH PUMPS PVT. LTD.

316, 1st Floor, 8th Cross, 4th Phase, Peenya Industrial Area, Bengaluru - 560 058, Karnataka, India

Tel.: +91 80 2836 2916, Fax: +91 80 2836 3048, Email: [email protected], www.ihpindia.in

* We reserve the right to amend specification without prior notice.

Consumer Warranty

How to claim warranty

Indra Hydro Tech Pumps (P)Ltd warrants that, when this product is used for the purpose it was designed, is correctly housed and protected

from weather, vermin and dust etc, that it will be free from material and manufacturing defects at the time of the original purchase.

Our products comes with guarantee that cannot be excluded under Indian Consumer Laws . You are entitled to a replacement or refund for

major failure and for compensation for any other reasonably foreseeable loss or damage. You are also entitled to have products repaired or

replaced it goods fail to be of acceptable quality and failure doesn't amount to major failure

Before doing so, study the instruction booklet provided with the product, and ensure it has been correctly installed. Remember, we as

manufacturer has built thousands of identical units , they have been extensively tested and in field use for many years. Failure of this

products to work correctly, 99% of the time relates to installation, operating or application faults. In the event of a possible warranty problems,

contact nearest distributor or manufacturer

Indra Hydro Tech Pumps (P) Ltd

316, 4th Phase, 8th Cross

Peenya Industrial Area

Bangalore - 560 058

Karnataka State

INDIA

Phone: +91 80 28362916 Fax: +91 80 28363048.

Email: [email protected] and [email protected]

To assist the distributor or Indra Hydro Tech Pumps (P) Ltd to address your request for warranty,

could you please provide:

·Product

·The product must be delivery to IHP's authorized distributor or dealer or Indra Hydro Tech Pumps Pvt Ltd

(as per above address) inspection / repairs

·Proof of date of original purchase must be supplied

·The serial number of the product if any

·Full contact details including name, full address and telephone or mobile number or SKYPE IDs.

Bangalore

INDRA HYDRO TECH PUMPS PVT. LTD.

An certified company byISO 9001:2008

www.ihpindia.in

www.ihpindia.inwww.ihpindia.in

316, 1st Floor, 8th Cross, 4th Phase

Peenya Industrial Area

Bengaluru - 560 058

Karnataka, India

Tel.: +91 80 2836 2916

Fax: +91 80 2836 3048

Email: [email protected]

This manual suits for next models

1

Table of contents

Other IHP Industrial Equipment manuals