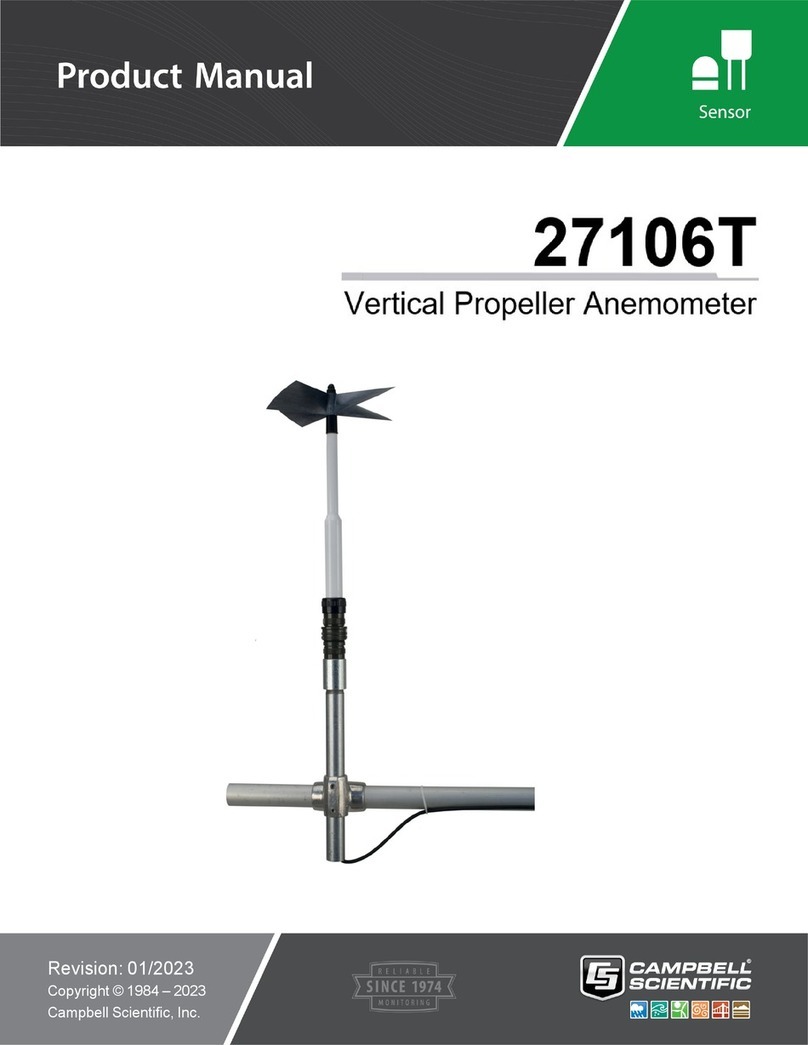

Iijima PACK LEADER RO-105LS User manual

Residual Oxygen / Carbon Dioxide Meter

PACK LEADER/RO-105LS

Operation Manual

With Warranty

Thank you for purchasing the PACK LEADER.

The PACK LEADER is an analyzer that samples gas from bags, bottles, cans, etc.,

and measures the residual oxygen concentration (O2), gas replacement rate (REP),

and carbon dioxide concentration (CO2).

This manual describes how to operate the PACK LEADER and the precautions that

must be observed to ensure proper and safe use. Always read this manual and fully

understand the operation before starting use.

Keep this manual near the device for quick reference at any time.

Before starting use

1. Safety precautions

This section explains the precautions that must be observed to prevent injury to the user or other persons

or damage to property.

■ Thefollowingsymbolsclassifyandexplainthedegreeofharmorpropertydamagethatmayresultifthe

contents of the symbols are ignored and the product is used improperly.

Warning This symbol indicates a dangerous situation that could result in fatal or

serious injuries if the information is ignored and the product is handled

incorrectly.

Caution This symbol indicates the extent of harm or damage that could potentially

result in injury or physical damage if the information is ignored and the

product is handled incorrectly.

Note

This symbol indicates a situation in which the measurement could

be adversely affected, preventing correct measurement results from

being obtained if the information is ignored and the product is handled

incorrectly.

■ Thetypesofinformationtobeobservedarecategorizedandindicatedwiththefollowingsymbols.

This symbol indicates

“Warnings”, “Cautions”,

and “Notes” that must be

observed.

This symbol indicates

“Prohibited” matters that

must not be conducted.

This symbol indicates

“Instructions” that must

always be enforced.

(Always observe)

Suspend operation immediately when any

abnormality occurs.

Continuing use can lead to fires or electric shocks.

Immediately turn OFF the power switch and

disconnect the power plug from the outlet. Contact

the dealer from which you purchased the product

for repairs.

Take care not to stab the human body with

the needle.

A needle is used for the measurement. Handle it

with extreme caution.

There is a risk of blindness, puncture wounds, or

cuts.

Do not touch the oxygen sensor with bare

hands if it is leaking.

A highly concentrated acetic acid solution is used

for the electrolyte inside the sensor. There is a risk

of serious eye injury if the electrolyte gets into the

eyes. Immediately rinse the eyes (including under

the eyelids) with clean running water for at least 15

minutes, and immediately seek medical attention

from an ophthalmologist.

If the electrolyte gets on the skin, wash with plenty

of water and seek immediate medical attention.

Perform measurements in an adequately

ventilated room.

Do not place your face near the unit or

smell odors during the measurement.

The PACK LEADER samples a mixture of low

oxygen gas or carbon dioxide gas, and discharges

it into the atmosphere when the measurement is

completed.

Conducting measurements in a poorly ventilated

room or taking a deep breath to smell the odors

can cause the user to lose consciousness or feel

unwell due to a lack of oxygen.

Do not touch the battery with bare hands if

it is leaking.

There is a risk of serious eye injury or inflammation

if the fluid leaking from the battery gets in the

eyes or on the skin. Immediately wash with clean

running water, and seek immediate medical

attention.

Warning

Do not damage the power cord or power

plug.

Do not damage, process, place heavy objects

on, heat, place near a source of heat, forcibly

bend, twist, or pull the power cord or plug. There

is a risk of fire or electric shock resulting from

core wire exposure, short-circuit, or breakage.

Do not use a power plug that is contami-

nated with foreign matter, such as dust.

There is a risk of fire or electric shock if the

foreign matter absorbs moisture, etc., and

causes an insulation fault.

Insert the power plug completely to the

base.

There is a risk of electric shock or fire from

heating if the power plug is inserted incompletely.

* Do not use a damaged plug or loose outlet.

Use only the specified battery.

Failure to do so could prevent the device from

operating.

<Permitted batteries>

• Nickel-metal hydride batteries (Eneloop)

• Alkaline batteries

<Prohibited batteries>

• Do not use any type of battery other than that

listed above.

Handle the battery correctly.

The battery could rupture or ignite if handled

incorrectly. If the battery fluid leaks, it could

corrode the device or contaminate hands or

clothing.

Always observe the following cautions.

・

Make sure the polarity (+ and -) is correct

when inserting the battery.

・

Remove the batteries when suspending use

for a long time.

・

Do not leave spent batteries in the device.

・

Safely dispose of spent batteries with the

designated method.

・

Do not use new and old batteries or different

types of batteries together.

・

Do not heat or disassemble the batteries or

place them in water or fire.

・

Do not put batteries together with metal items.

・

Do not use the battery if the outer sheath is

peeling.

Do not use in an environment, including

temperature, humidity, pressure, vibration,

dust, or acidic or corrosive gases, that

could adversely affect the device.

Failure to observe this could result in faults.

Caution

[Measurement atmosphere gas]

Mixed gas

The instrument is adjusted for measurements for gas mixtures of nitrogen (or argon), oxygen, and carbon dioxide. Do

not use other gas mixtures, as accurate measurement may not be possible.

[Use prohibited gases]

• Oxidizing gases

Oxidizing gases, such as sulfur dioxide and hydrogen sulfide, can cause high readings and can cause the sensor

performance to drop quickly.

• Reducing gases

Reducing gases, such as fluorine, chlorine, bromine, iodine, and ozone can cause high readings and significant

degradation of the sensor performance in a short time.

• Other obstructive gases

Hydrogen chloride and nitrogen oxide will be indicated at high levels, and hydrogen will be indicated at a low level.

In either case, the sensor performance can degrade significantly in a short time.

[Operating environment]

Static electricity

In rare cases, static electricity can cause the measured value to vary instantaneously or cause the device to stop oper-

ating. If the device operation stops, turn the power OFF and ON.

Note

Spare sensor (unopened)

After one year

使用中センサー

Warranty term

Service life

Service

life

保証期限のお知らせ

30 days

One year

If the sensor fails in 8 months

Approx. 4 months

One year

Spare sensor (unopened)

Replace with new sensor

Replace with

new sensor

Original warranty term

One year

One year

After two years

Sensor package opened

Notice of warranty term

(Recommended to prepare sensor)

Equals remaining warranty term

Malfunction replacement

One year

Sensor package opened

Sensor package opened

Sensor package opened

Quick Sampler

(Model: PO-1)

Eliminates the need to attach adhesive

rubber or pierce needle through

adhesive rubber.

Quick Sampler 2

(Model: PO-2)

Suitable when the top of the sample is

indented, such as with a cup.

Printer (printer cable sold separately)

(Model: CBM-910II-40)

Use to print out the measured

values.

-Ordering consumable parts

Printer paper (Model: RP5860) 20-roll set

Ink ribbon (Model: IR91B) 5 ribbon set

Gas sampling glass tube (Model: GS-2)

Use this tube to collect small amounts of

sample gas from the container, such as a

can, bottle, or ampule.

Can opener (Model: KO-1)

Use this opener to measure the remaining

oxygen concentration in a can.

Opener (Model: KO-X1)

Use this opener to measure the remaining

oxygen concentration in a bottle.

Storage case (Model: ROPSC1)

Storage case dedicated for the RO-105

series.

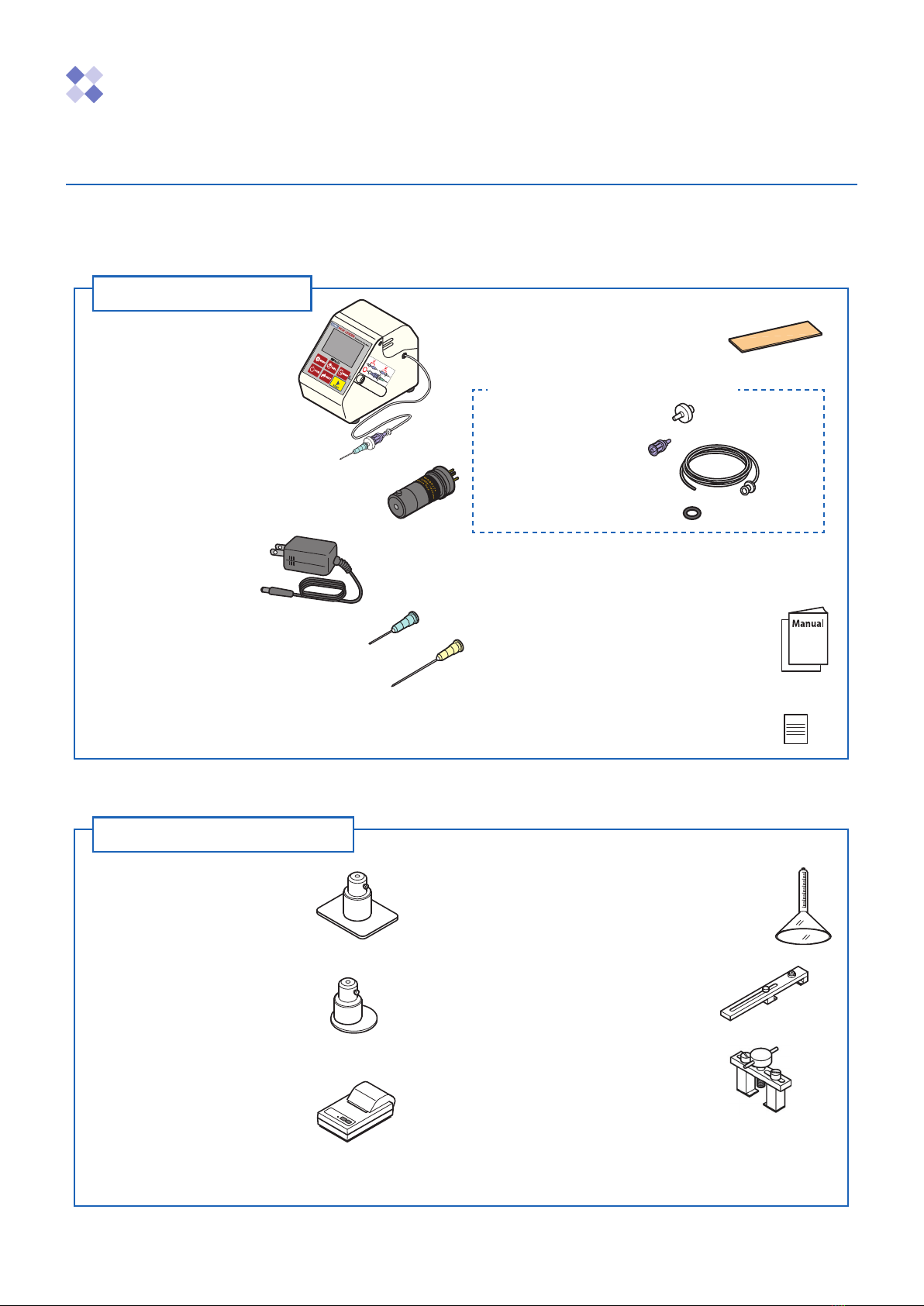

PACK LEADER x 1 unit

Main unit

Sampling adapter

Oxygen sensor (WAGNIT®) x 1 unit

(Model: WA-SGF2)

Already mounted in the main unit housing.

AC adapter x 1 unit

(Model: AC-105)

Needle (vertical slot type) x 2 pcs.

Needle (horizontal slot type) x 1 pc.

Switch the type when measuring a sample, such as

an adhesive, that can easily clog the needle.

Adhesive rubber x 20 pcs.

Size: 20mm x 100mm x t1

Maintenance kit (model: MK-105)

Membrane filter x 3 pcs.

Check valve x 1 pc.

Sampling tube with fitting

(length: 50cm) x 3 pcs.

O-ring for housing x 1 pc.

AA alkaline batteries x 4 pcs.

Already mounted in the main unit.

Operation manual and

warranty (this document) x 1 copy

Handy User’s Guide x 1 copy

Oxygen sensor warranty x 1 copy

Before starting use

2. Conrmationofpackagecontents

When unpacking the PACK LEADER, confirm that the following items are included and that the contents have

not been damaged. If any parts are missing or damaged, contact the dealer from which you purchased the

product.

Package contents

“WAGNIT®” is a registered trademark of the Iijima Electronics Corporation oxygen sensor.

Accessories (options)

Output 6 VDC

* Refer to the instructions enclosed with each product for details on handling.

Spare sensor (unopened)

After one year

使用中センサー

Warranty term

Service life

Service

life

保証期限のお知らせ

30 days

One year

If the sensor fails in 8 months

Approx. 4 months

One year

Spare sensor (unopened)

Replace with new sensor

Replace with

new sensor

Original warranty term

One year

One year

After two years

Sensor package opened

Notice of warranty term

(Recommended to prepare sensor)

Equals remaining warranty term

Malfunction replacement

One year

Sensor package opened

Sensor package opened

Sensor package opened

Oxygen sensor (WAGNIT®)

(Model: WA-SGF2)

Always confirm the information in

“3. Precautions for oxygen sensor”

before purchasing.

AC adapter (Model: AC-105)

Output 6 VDC

Needle (TERUMO NN-2116R-12)

Vertical slot type, 12-pc. set

Needle (Model: T-30-12)

Horizontal slot type, 12-pc. set

Membrane filter (5-pc. set)

(Model: RO-MF)

Adhesive rubber (Model: RG-1)

Size: 20mm x 100mm x t1

100-piece set

Check valve (3-pc. set)

(Model: RO-CV)

Sampling tube with fitting (5-pc. set)

(Model: RO-SC) Length: 50cm

Sampling adapter

(Model: SA-5)

Needle (vertical slot type), membrane filter,

check valve, tube set

Maintenance kit (model: MK-105)

<Contents>

Membrane filter x 3 pcs.

Check valve x 1 pc.

Sampling tube with fitting x 3 pcs.

O-ring for housing x 1 pc.

O-ring for housing (10-pc. set)

(Model: P-8-10)

Main cover (Model: RO-C)

With knurled screws for the main cover

When purchasing consumable parts for new replacements or spare part inventory, please refer to the following

section, and contact the dealer from which you purchased the product.

[Accessories (Consumable parts)]

3. Precautions for oxygen sensor (Model: WA-SGF2)

In principle, the oxygen sensor (WAGNIT®) Model: WA-SGF2 will deteriorate over time and become unusable at

the end of its service life. Please understand and agree to the following precautions before making a purchase.

■WA-SGF2warrantyterm

When the sensor is already mounted in the main unit, the warranty is valid for one year from the date of shipment from Iijima Electronics Corporation.

When purchasing the single sensor unit, the warranty is valid for one year from the date that the sensor package is opened. (Note that the maximum

warranty term is two years, including the storage term*and warranty term.) * "One year storage" is only in the case of using in Japan.

■Warrantydetails

Iijima Electronics Corporation will send a “malfunction replacement” if the sensor becomes unusable due to a malfunction within one year after the

sensor package is opened. (The “malfunction replacement” is not a new part. The usable service life will correspond to the remaining warranty term.)

■Storageterm(OnlyinthecaseofusinginJapan)

Only when this instrument is used in Japan, the oxygen sensor can be stored in an unopened state for up to one year. The sensor can be stored as a

spare sensor, thus preventing missing measurements if the sensor suddenly becomes unusable due to a malfunction.

There is a very slight chemical reaction even during storage. Thus, the sensor should be opened and used within one year. If the sensor is stored for

longer than the maximum storage period of one year, it can still be used, but the warranty term and service life will be reduced by the number of days it

was stored.

<Image of storing one spare sensor and replacing once a year>

The oxygen sensor in the unopened package must be set on its side in the bag and stored in a temperature range of

0 to 30°C. If the storage conditions are not satisfied, the sensor may not operate properly when opened.

Note

Before starting use

1. Safety precautions (Warning, Caution, Note)

2. Confirmation of package contents

Package contents, Accessories (options), Accessories (Consumable parts)

3. Precautions for oxygen sensor (Model: WA-SGF2)

Contents

Names and functions of each part 1

Main unit section

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 1

Housing section /Oxygen sensor (WAGNIT®) /CO2sensor

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • 2

Operation Methods

3

1. Preparing for use •••••••••••••••••••••••••••••••••••••••••••••••••••••••

3

Using the PACK LEADER with batteries /Using the PACK LEADER with 100 VAC power

••••••••• 3

2. Preparing for measurement ••••••••••••••••••••••••••••••••••••••••••••••

3

Power ON/OFF

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 3

Switching the measurement mode /Automatic stability decision function /Key Lock / Unlock function • • • • • • • 4

Japanese / English selection function

•••••••••••••••••••••••••••••••••••••••••••••••••• 5

3. Calibration (O2measurement) ••••••••••••••••••••••••••••••••••••••••••••

6

Span calibration

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • 6

Zero calibration

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 7

4. Measurement and recording •••••••••••••••••••••••••••••••••••••••••••••

8

Preparing to measure

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • 8

O2/CO2Measurement (Auto mode) /O2/CO2measurement (Manual mode)

•••••••••••••••••••• 9

Memory function /Confirming the measurement history

•••••••••••••••••••••••••••••••••••10

Erasing the measurement history /Guidance display function [Procedure display]

••••••••••••••11

Various Settings and Functions

12

Setting the O2displays [O2DISP SET]

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • 12

Setting the time [TIME SET]

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • 13

Time zone selection function [TIMEZONE]

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • 14

Output setting [OUT SET]

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••15

Checking for clogging [CLOG CHECK]

•••••••••••••••••••••••••••••••••••••••••••••••••16

Initialization [INITIALIZE]

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••18

Erasing the entire history [CLR ALL HST]

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • 19

CO2functions and settings •••••••••••••••••••••••••••••••••••••••••••••••••

20

Disabling the CO2display [CO2OFF]

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • 20

Upper limit setting [UP LIMIT SET]

•••••••••••••••••••••••••••••••••••••••••••••••••••••21

CO2Calibration [CO2CAL]

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • 23

Connecting to an external device (Serial communication)

25

Connecting a printer /Connecting to a personal computer

•••••••••••••••••••••••••••••••••25

Maintenance

26

Replacing the oxygen sensor /Replacing the CO2sensor /Replacing the needle

••••••••••••26

Replacing the membrane filter /Replacing the check valve

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • 27

Replacing the sampling tube with fitting

•••••••••••••••••••••••••••••••••••••••••••••••••27

Troubleshooting

28

Troubleshooting • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •28

Displaying the product information

•••••••••••••••••••••••••••••••••••••••••••••••••••••28

Error Messages •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

32

Product Specifications

36

After Sales Service

37

1

-

+-

+

+

-+

-

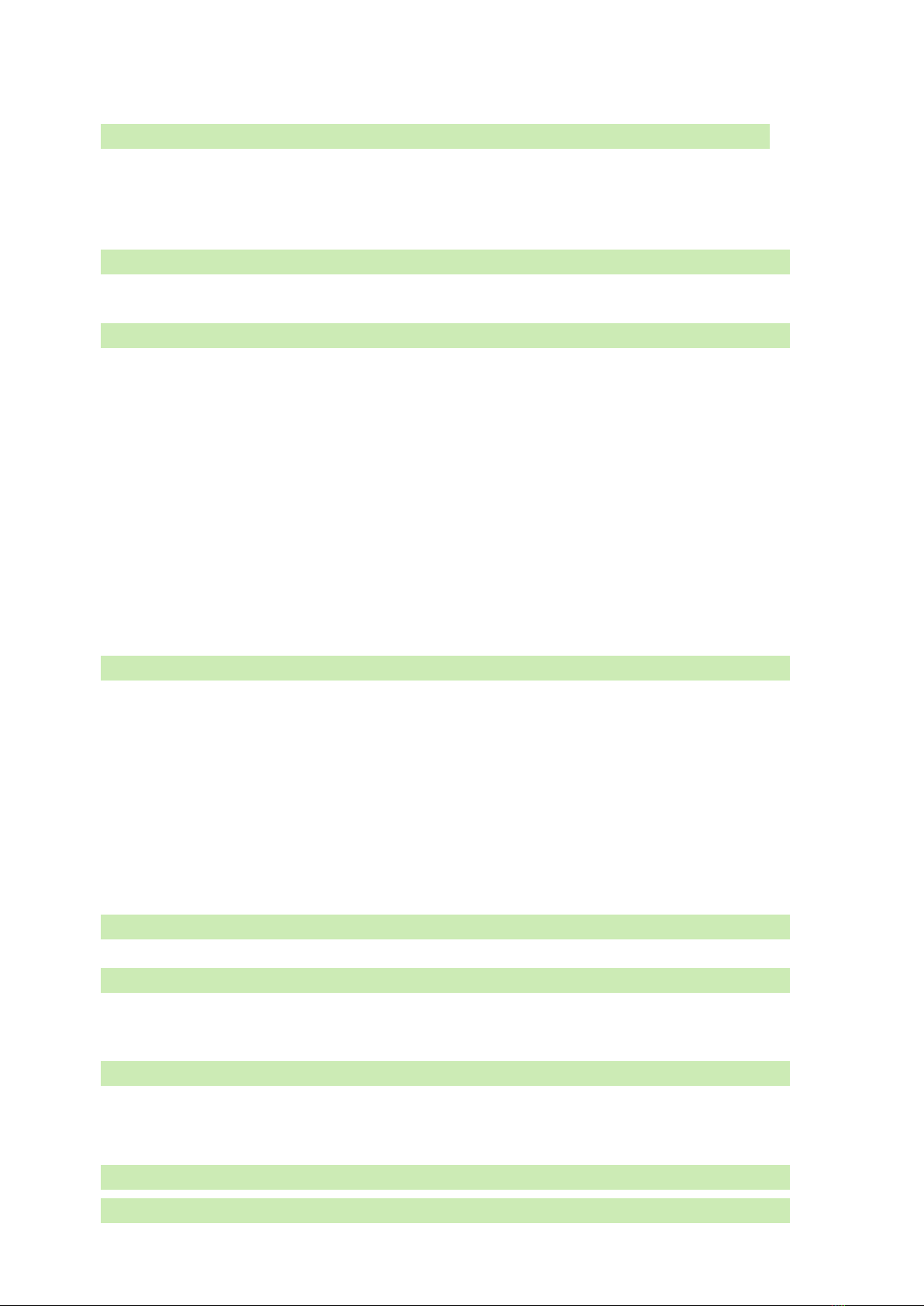

Names and functions of each part

Main unit section

LCD display area

Displays measured value, etc.

Measurement

mode

Title

(The following example shows the Measurement Complete screen.)

Operation guide

display

Membrane filter

Needle

Battery level

Date / time

Unit

Check valve

Knurled screws for the main cover

Remove the main cover when replacing

the oxygen sensor.

AC adapter jack

AC adapter connection

Serial communication connector

• Connection with a printer (optional) (for printing the

measured values)

• Connection with a personal computer (for retrieving the

measured values; operating the main unit)

Tube fitting

Main cover

<Back side>

<Base> Battery box

<LCD display area>

Battery

cover

AA alkaline

battery x 4

MENU key Press to display the menu or return to the

previous screen

SELECT key

Press to switch to the measurement history

Hold for 3 seconds to switch displayed language

between Japanese and English

MEMORY key

Press to save a measured value or delete a

measured value

Hold for 3 seconds to lock or unlock operations

POWER key Press to turn the power ON or OFF

NEXT key Press to switch the measurement mode or

selection

START key Press to start the measurement, start calibra-

tion, enter a selection, or stop operation

O2measurement

value

CO2measurement

value

Sampling tube with fitting

Product name

Model

Serial number

Manufacturng

date

The correct order and direction for connecting the

sampling adaptor are indicated with a sticker.

When operating or storing the unit, refer to this sticker and confirm that the

sampling adaptor is correctly connected.

Product name :Residual O2/CO2 Meter

Model : RO-105LS

Serial number : *******

Manufacturing date :

20**.**

2

Oxygen Sensor WAGNIT®

Model:WA-SGF2 Serial number:130****

Iijima Electronics Corp.

Housing section

Oxygen sensor

CO

2

sensor

The CO2sensor (model: CS-105) is built into the PACK LEADER unit and cannot be removed or mounted

by the customer.

When the CO2sensor has reached its life, please send the PACK LEADER unit set to the dealer from

which you purchased.

Oxygen sensor (WAGNIT®)

(Model: WA-SGF2)

The front center

section has a metal

mesh.

Product name

Model Serial No.

Probe

Probe cable

Housing

O-ring for

housing

Oxygen sensor

CO2sensor (already mounted inside)

3

Operation Methods

1. Preparing for use

Using the PACK LEADER with batteries

The batteries are mounted before shipment, so the PACK LEADER can be used right away.

When replacing the batteries, use AA alkaline batteries or nickel-metal hydride batteries (ENELOOP).

Using the PACK LEADER with 100 VAC power

Always use the enclosed AC adapter.

•Always remove the batteries when using the AC adapter or when suspending the use of the

instrument for a long time and putting the unit into storage. The instrument could be damaged

if the battery fluid leaks.

•Always use the enclosed AC adapter. Failure to do so could damage the instrument.

2. Preparing for measurement

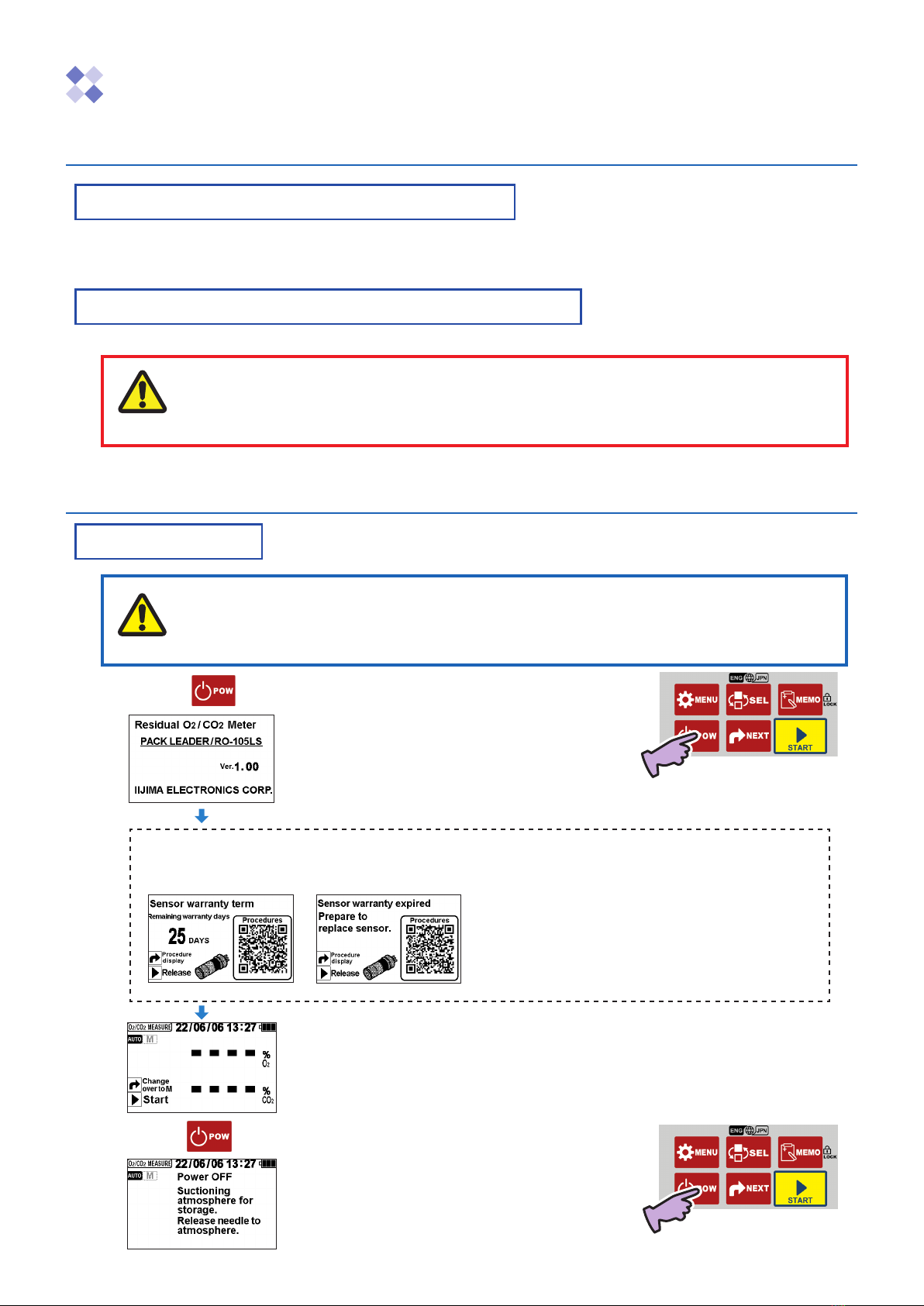

Power ON/OFF * After turning the power OFF, wait at least two seconds before turning it ON again.

•The calibration or measured value could be affected if the ambient temperature changes. In

this case, turn the power OFF with the oxygen sensor set, and wait at least 30 minutes for

the temperature to stabilize.

•Always remove the tip of the needle from the sample before turning the power OFF.

1. Press .

The power turns ON, and the software version displays.

(Approx. 4 seconds)

* The displayed details will vary according to the version.

The Measurement Standby screen opens.

* The screen on the left shows the Auto mode and Concentration

% O2setting.

2. Press again.

The atmosphere is automatically suctioned. After the

screen on the left opens, the power turns OFF.

Sensor warranty term notification function (Displayed when the self-diagnosis function determines that

there are 30 days or less to the end of the oxygen sensor warranty term.)

Display when 25 days are remaining Display when 0 days are remaining (end of warranty term)

* The warranty is valid for one year from the date of shipment.

(When the sensor is replaced, one year from the date the new sensor

package is opened.)

* The display on the left is a guideline.

The self-diagnosis results are also displayed.

Caution

Note

4

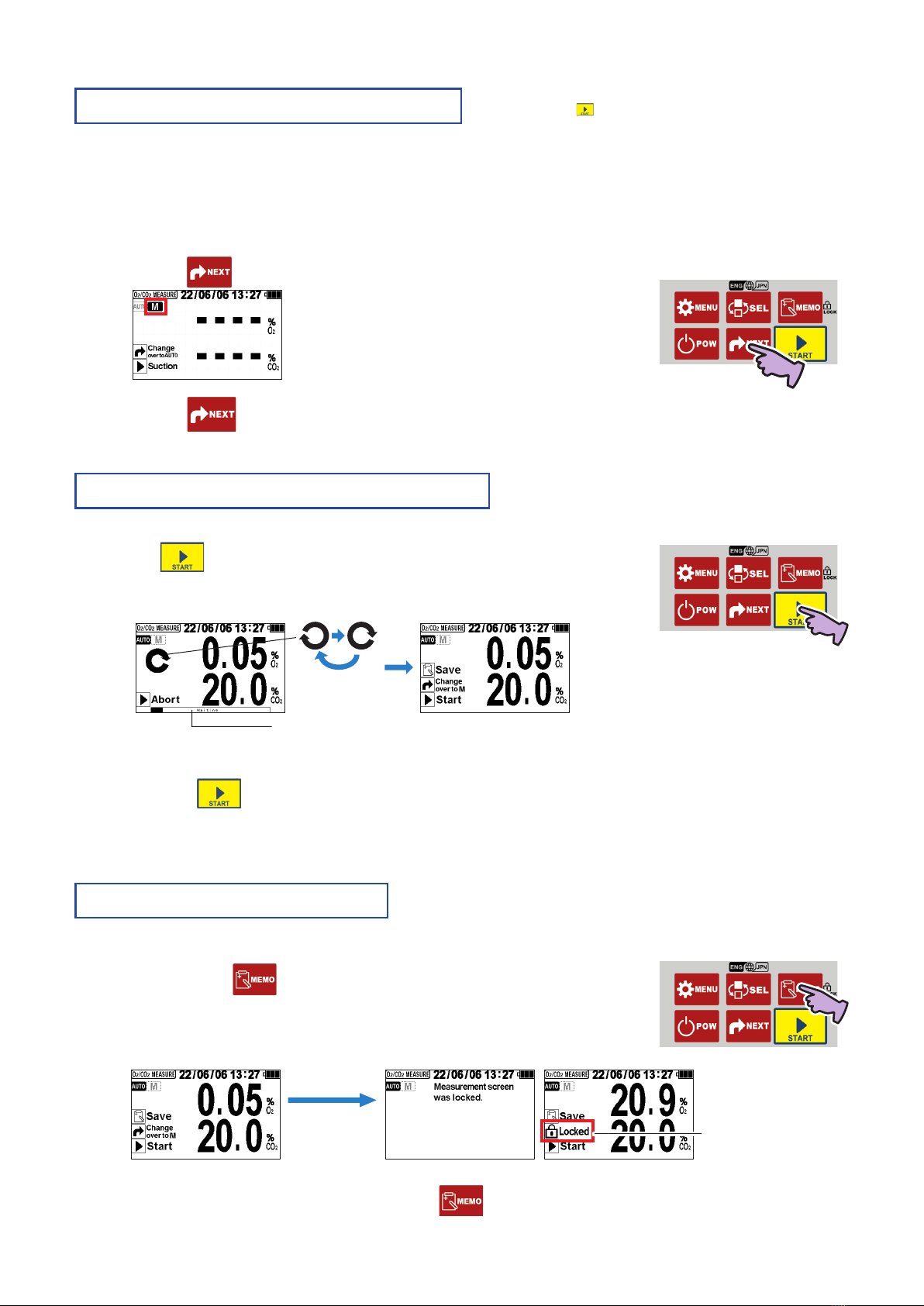

Automatic stability decision function When taking a measurement, the indication value at the

most stable state is automatically held.

The timing for deciding the stability is different for the

Auto mode and Manual mode.

Press .

The measurement starts, and the Stability Decision screen opens.

The decision is completed when a beep sounds and the stabilized measured value appears.

<Manual mode>

Hold down and suction the gas.

The pump operates only while the key is held down, and the stability decision starts when the key is released.

The decision is completed when a beep sounds and the stabilized measured value appears.

Key Lock / Unlock function Lock the keys to prevent operations other than measurement and history

display. Use this function to prevent accidental setting changes, calibration,

measured value switching, or history erasing. Until the keys are unlocked,

the locked state is retained even if the power is turned OFF, the batteries are

removed, or the AC adapter is disconnected.

1. Hold down for 3 seconds or longer on the

O

2

/CO

2

MEASURE Screen.

“Locked” displays.

The key lock function is enabled while “Locked” is displayed.

2. Unlock the lock function by pressing again for 3 seconds or longer.

The “Locked” display disappears.

Switching the measurement mode The mode is set to Auto as the default when the unit is

shipped. When is pressed in the Auto mode, the cycle of

operations from pump and suction of sample gas, automatic

stability decision, and holding of indicated value is completed

automatically.

The Auto mode is usually used. Measurements can be taken in the Manual mode in the following cases.

• When the contents are visible through the packaging, and you want to suction the gas while adjusting the tip of the

needle so that it does not pierce the contents.

• When sampling approx. 6 mL of gas using the optional “Gas sampling glass tube (model: GS-2)” and you want to

suction the gas while adjusting the needle so that the liquid is not suctioned.

1. Press .

The mode switches to the Manual mode.

“M” (MANUAL) is selected.

2. Press .

The mode returns to the Auto mode.

<Auto mode>

Progress status bar display

“Locked” display

Hold down for

3 seconds or

longer

5

Japanese/Englishselectionfunction Japaneseisthefactorydefaultsettingforthedisplay.The

displayedlanguagecanbeswitchedbetweenJapanese

and English from any screen.

Usually, the language can be switched between Japanese and English from any screen if the power is ON. Note that the

language cannot be switched during the following operations. The language can be switched once the operation is fin-

ished or canceled and the built-in pump has stopped.

• During O2/CO2measurement operation

• During calibration (span calibration/zero calibration) operation

• During the clogging check operation

1. With the power turned ON, hold down the for 3 seconds

or longer.

The display language will switch from Japanese to English.

(The displayed contents are saved.)

Hold down for

3 seconds or

longer

JapaneseEnglish

2. When the is held down again for 3 seconds or longer, the language will return to

Japanese.

<WhenusingincountriesorregionsotherthanJapan>

By using the “Time zone selection function,” the time zone can be set to the standard of the region

where the instrument is being used.

Refer to “Time zone selection function” on page 14 for the operation methods.

6

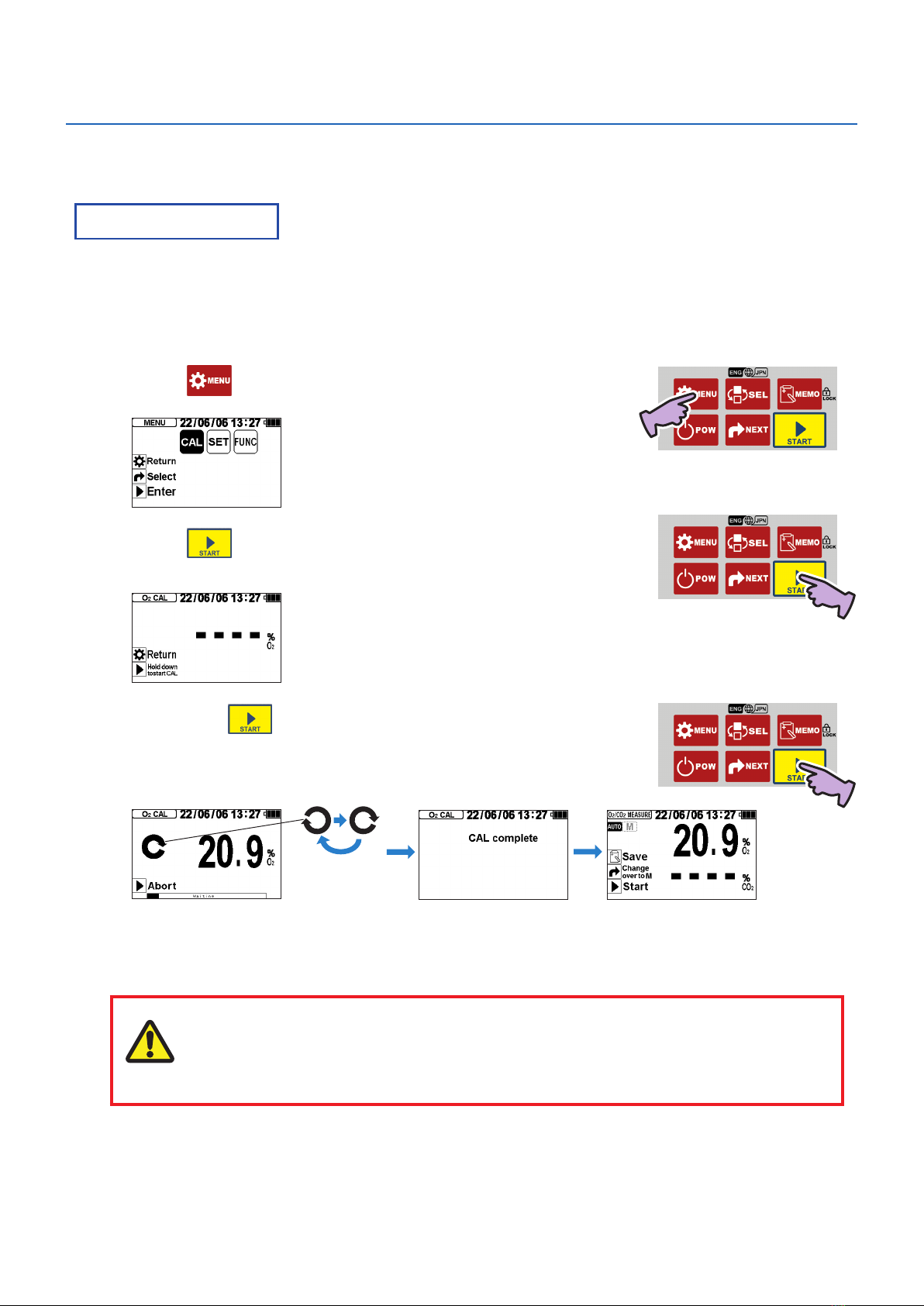

3. Calibration (O2measurement)

The calibration process adjusts the instrument measured value so that the span point and zero point during O2

measurement match the sensor output when the reference gases (atmosphere, nitrogen) were measured.

Span calibration Perform span calibration once a day before starting measurements. Ideally, span calibration

should be performed when the temperature of the oxygen sensor and temperature sensor

are sufficiently stable, such as first thing in the morning before operating the air conditioning

system.

If the deviation from the true value can be tolerated by about 5%, span calibration should be performed when the

oxygen concentration in the atmosphere is 20% O2or less, or 22% O2or more. In this case, the error will be

0.05% O2when the measurement concentration is 1% O2.

1. Place the needle in the atmosphere.

2. Press .

The MENU screen opens, and “CAL” is selected (flashes).

3. Press .

The O2CAL screen opens.

* If even one measurement has been taken, the previous measured value will display.

4. Hold down for 1 second or more.

The calibration starts, and the Stability Decision screen opens.

A beep sounds, CAL complete appears (approx. 1 second), and then the O2/CO2

MEASURE screen opens. The calibration process is completed.

The calibration value is saved even if the power is turned OFF, the batteries are removed, or the AC adapter is

disconnected.

If the “Sensor error” message appears, refer to the section “Error Messages” (pages 32 ) and confirm and remedy

the situation.

The measured value (calibration value) may be high or low if a strong impact is applied on

the instrument unit or if the temperature changes drastically. In this case, wait for some time

and then perform span calibration again.

Caution

7

Zero calibration To accurately measure low concentrations when measuring O2, use nitrogen gas for calibration.

1. Set the needle so it can suction the nitrogen gas.

2. Press .

The MENU screen opens, and “CAL” is selected (flashes).

3. Press .

The O2CAL screen opens.

* If even one measurement has been taken, the previous measured value will display.

4. Hold down for 1 second or more.

The calibration starts, and the Stability Decision screen opens.

A beep sounds, CAL complete appears (approx. 1 second), and then the O2/CO2

MEASURE screen opens. The calibration process is completed.

The calibration value is saved even if the power is turned OFF, the batteries are removed, or the AC adapter is

disconnected.

If the “Sensor error” message appears, refer to the section “Error Messages” (page 32 ) and confirm and remedy

the situation.

The measured value (calibration value) may be high or low if a strong impact is applied on the

instrument unit or if the temperature changes drastically. In this case, wait for some time and

then perform zero calibration again.

<When nitrogen gas cannot be prepared>

Initialize the instrument and then perform span calibration.

Refer to the sections “Initialization” (page 18 ) and “Span calibration” (page 6 ) for details on the operation meth-

ods.

Caution

8

Adhesive

rubber

4. Measurement and recording

Preparing to measure

•It may not be possible to measure if the sample gas quantity is less than 10mL.

•A measurement can be taken even if the inside of the sample is depressurized, but if the

package’s internal pressure is less than -30kPa, a correct measurement value may not be

obtained. Note that depressurization will occur easily after gas suction, especially if the gas

quantity is low. In this case, a measurement can be taken using the optional “gas sampling

glass tube (model: GS-2)”.

•The measurement may take longer if the inside of the sample is depressurized.

•A measurement can be taken even if the inside of the sample is pressurized. However, if

the package’s internal pressure is higher than +40kPa, the components could break when

the needle is pierced, or a correct measured value may not be obtained. In this case, a

measurement can be taken using the optional “gas sampling glass tube (model: GS-2)”.

1. Shift the contents in the pack to one side and hold with a

hand to create a space for piercing the needle.

2. Attach the enclosed adhesive rubber over the air space.

Adhesive rubber cutting dimension reference: 1cm x 1 cm square

3. Lightly press down on one side of the bag, and set the

needle in the sample gas.

Do not suction the contents.

A measurement error will occur if powder, etc., gets clogged in the needle.

Note that the minute amount of liquid in the sample gas is blocked by the membrane filter.

Warning

Take care not to stab the human body with the needle. There is a risk of blindness, puncture

wounds, or cuts.

•If pressure is applied into the pack from the set needle using an air gun, etc., the internal

pump or sensor could be damaged. If the needle is clogged, replace it with a new needle.

•Continuing use with a clogged needle, membrane filter, check valve, or sampling tube with

fitting will deteriorate the sensor.

•If the liquid is accidentally suctioned, the membrane filter that has absorbed the liquid will not

pass the gas, preventing a correct measurement. Note that if the liquid contains oil, it might

pass through the membrane filter. Refer to “Maintenance” (pages 26 to 27) and replace

the needle, membrane filter, check valve, and sampling tube with fitting contaminated with

liquid or oil with new parts. Check the housing to confirm that the suctioned liquid and oil

have not adhered to the oxygen sensor. If adhered, remove the oxygen sensor and clean

the inside of the housing. The metal mesh at the front center of the oxygen sensor can be

cleaned by lightly wiping with tissue paper.

• Using the needle, membrane filter, check valve, and sampling tube with fitting in a clogged

state may prevent a correct measurement.

Caution

Note

Note

9

O2/CO2Measurement (Auto mode) The measurement starts automatically when is pressed.

Refer to the section “Switching the measurement mode” (page

4 ) for details on switching between the auto mode and

manual mode.

1. When the Measurement Standby screen is displayed, press .

The measurement starts, and the Stability Decision screen opens.

The decision is completed when a beep sounds and the stabilized measured value

appears.

• If the “Sensor error”, “Sensor unstable”, or “Negative pressure detected” message appears, refer to the section “Error

Messages” (page 32) and confirm and remedy the situation.

• To stop the measurement while deciding the stability, press . The measurement will be aborted.

2. To record the measured value, press on the Measurement

Complete screen.

The measured value is saved in the main unit.

Refer to section "Memory function" (page 10 ) for details.

The value indicated when is not lit is read.

O2/CO2measurement (Manual mode)

1. If the Manual mode is not enabled, press .

This step is not required if the Manual mode is enabled.

The selected measurement mode is saved even when the power is turned OFF.

<Auto mode> <Manual mode>

2. With the Measurement Standby screen displayed, hold down (Suction).

The pump operates only while is held down.

In the manual mode, the stability decision is canceled while the pump is operating.

The stability decision starts when the key is released, and the pump stops.

(If the measurement value fluctuates, the Stability Decision screen will appear.)

The decision is completed when a beep sounds and the stabilized measured value appears.

The value indicated when is not lit is read.

3. To record the measured value, press on the Measurement Complete screen.

The measured value is saved in the main unit.

Refer to section "Memory function" (page 10 ) for details.

The pump operates only while is held down. Refer

to the section “Switching the measurement mode” (page

4 ) for details on switching between the auto mode

and manual mode.

10

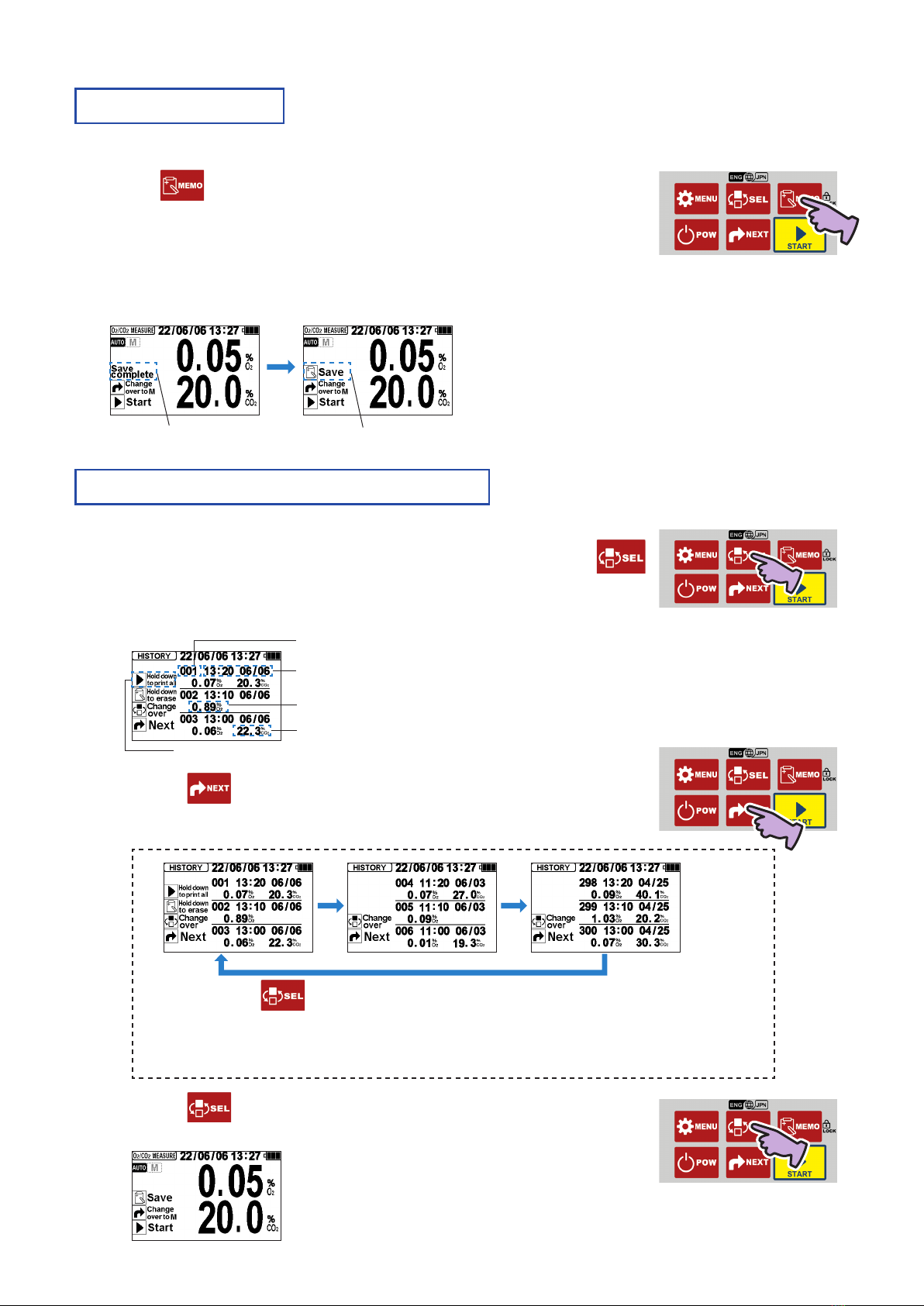

Memory function The measured value is not automatically saved in the internal memory. Using the

following steps, up to 300 values can be saved and retained in the internal memory.

When 300 values are exceeded, the oldest data is automatically deleted.

Press on the Measurement Complete screen.

The measured value for which the stability has been automatically decided is saved.

“Save complete” appears, and the current date and time, O2measurement value, and

CO2measurement value are saved.

(Note that if CO2OFF is selected, the CO2value is not saved.)

The saved details are retained even if the power is turned OFF, the batteries are removed, or the AC adapter is

disconnected.

Displays for approx. 1 sec. Returns to normal display

Conrmingthemeasurementhistory The saved measured values can be displayed and confirmed

later. Note that if CO2OFF is selected, the CO2measurement

value is not displayed.

1. When the Measurement Standby screen is displayed, press .

The HISTORY screen opens.

Immediately after the screen switches, three measurements with the latest date and time are displayed.

2. When is pressed, the older data is displayed three items

at a time.

When the key is held down, the page will switch.

* Press twice to return to the latest history page.

• Up to 300 measurements are saved.

• When 300 measurements are exceeded, the oldest is deleted, and the newest is saved.

3. Press .

The O2/CO2MEASURE screen opens.

CO2measurement value

O2measurement value

(Displayed only when printer output is set)

No. (displayed by latest date and time)

Saved time and date

11

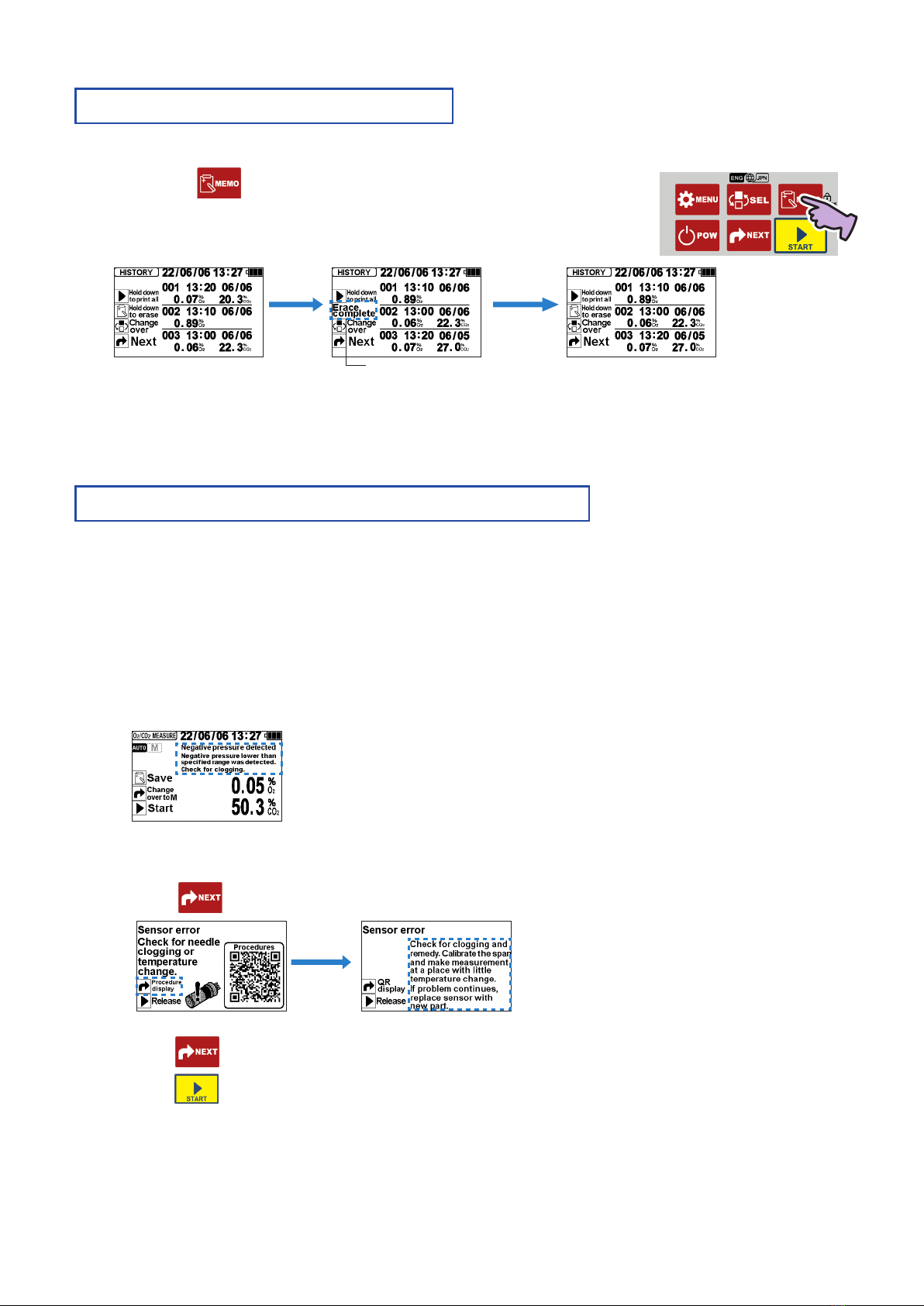

Guidance display function [Procedure display] This function displays and guides the

remedy procedures for malfunctions or

error messages that may occur during use.

If an error message appears, the screen will switch to the one showing the procedures to be taken

depending on the displayed details.

(Some guidance displays do not require switching to the procedure display.)

Follow the instructions on the screen to remedy the error.

<Example 1> When “Negative pressure detected” is displayed

As a remedy, perform a clogging check (refer to page 16 ).

<Example 2> When “Sensor error” is displayed

Press (procedure display). The remedy procedure will display.

When (QR display) is pressed again, the screen returns to the Error Message screen.

Press to cancel the display.

Hold

down for

1 second

or longer

Erasing the measurement history The latest measurement value records can be deleted one item at

a time.

Use this when a measurement value has been accidentally saved.

Hold down for 1 seconds or longer on the HISTORY Screen.

“Erase Complete” displays for approx. one second, and then contents of the data saved

last are erased from the internal memory.

The display returns to the HISTORY screen.

“Erase complete” displays Returns to HISTORY screen

To erase the entire history, refer to the section “Erasing the entire history” (page 19 ).

Procedure

display

As a remedy, perform a clogging check (refer to

page 16 ) or span calibration (refer to page 6 ).

12

Various Settings and Functions

Setting the O2displays [O2DISP SET] The display method can be changed to display the O2

measurement value as gas replacement rate. However, even

if the display is changed to the replacement rate % display,

the CO2measurement value will not change from the

concentration display to the replacement rate display.

Gas replacement rate (%) = (1 – Oxygen concentration (%O2) )×100

20.9

1. When the Measurement Standby screen is displayed, press .

The MENU screen opens.

Immediately after opening, “CAL” is selected (flashes).

2. Press .

The cursor moves, and “SET” is selected (flashes).

3. Press .

The SETTING MENU screen opens.

Immediately after opening, “O2DISP SET” is selected

(flashes).

4. Press .

The O2DISP SET screen opens.

“CONCN% O2” (currently set O2display) is selected

(flashes).

5. Press .

The cursor moves, and “REP-R%” is selected (flashes).

6. Press .

The setting change screen displays for approx. 1 second, completing the changes to

the settings.

(The screen returns to the SETTING MENU screen.)

13

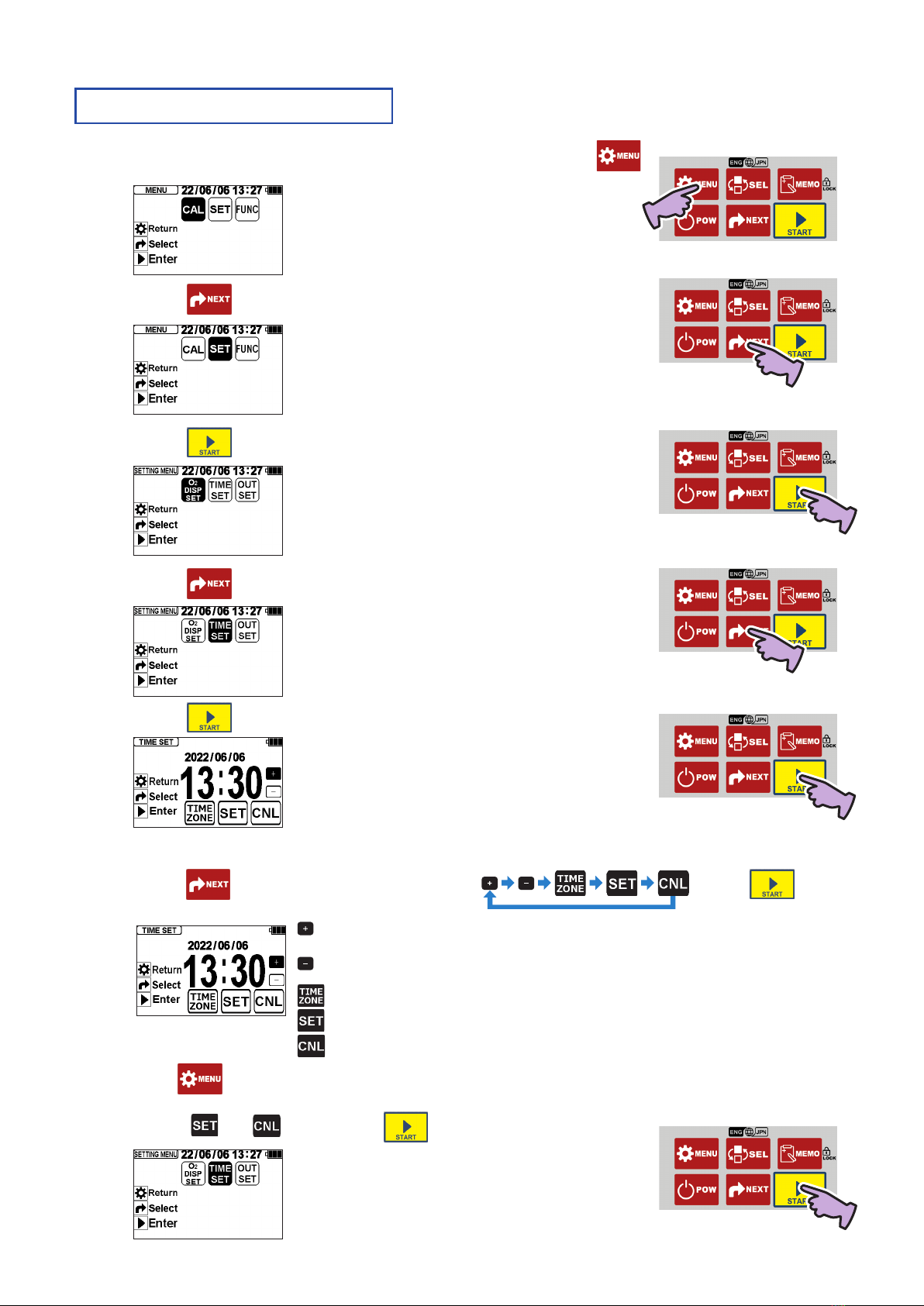

Setting the time [TIME SET] Set the time if the displayed time has deviated.

1. When the Measurement Standby screen is displayed, press .

The MENU screen opens.

Immediately after opening, “CAL” is selected (flashes).

2. Press .

The cursor moves, and “SET” is selected (flashes).

3. Press .

The SETTING MENU screen opens.

Immediately after opening, “O2DISP SET” is selected

(flashes).

4. Press .

The cursor moves, and “TIME SET” is selected (flashes).

5. Press .

The TIME SET screen opens.

Immediately after opening, “+” is selected (flashes).

* The example on the left shows the current date as 2022

June 6 and the time as 13:30.

6. Change the time with the following steps.

Press . The cursor will move in the order of

. When is

pressed, the cursor function will activate.

... The time is advanced by one minute.

* Hold down the key to advance the time 10 minutes in 0.5-second increments.

... The time is returned by one minute.

* Hold down the key to return the time 10 minutes in 0.5-second increments.

... The internal clock can be changed to the local standard time (refer to page 14 ).

... The displayed time is set, and the SETTING MENU screen opens.

... The time changes are canceled, and the SETTING MENU screen opens.

When is pressed, the time changes are aborted, and the SETTING MENU opens.

7. Select or , and press .

The time setting is completed or canceled, and the screen

returns to the SETTING MENU.

14

Time zone selection function [TIMEZONE] When using the instrument in a country or region

otherthanJapan,theinstrument’sinternalclock

can be changed to the local UTC (coordinated

universal time).

A time zone is a geographical region that uses the same standard time. The deviation from the UTC

(coordinated universal time) is expressed with a positive or negative sign, such as “UTC+9:00”.

Japan’sdesignatedstandardtimeis“UTC+9”,sothefactorydefaultsettingis“UTC+9:00”.

1. Refer to the section “Setting the time” on page 13 and proceed with steps 1 to 5.

The “TIME SET” screen opens.

Immediately after opening, “+” is selected (flashes).

2. Press twice.

The cursor moves, and “TIMEZONE” is selected (flashes).

3. Press .

The “TIME SET” screen opens.

Immediately after opening,

“+” is selected (flashes).

4. Change the time zone with the following steps.

Press . The cursor will move in the order of

. When is

pressed, the cursor function will activate.

... The displayed UTC is advanced by one unit.

... The displayed UTC is returned by one unit.

...Thetimezoneisreturned(initialized)toJapan'stimezone"UTC+9:00".

... The displayed UTC is set, and the TIME SET screen opens.

... The time zone selection is canceled, and the TIME SET screen opens.

5. Select , and press .

The internal time is changed to the selected time zone,

and the TIME SET screen opens.

* The display on the left shows the time after changing to

"UTC+6:00".

6. Press . The SETTING MENU opens.

The time zone selection is completed and the screen

returns to the SETTING MENU.

Table of contents

Other Iijima Measuring Instrument manuals