CLAMP ON

AC/DC HiTESTER

Apr. 2016 Edition 1

Printed in Japan

3287C961-00 16-04H

3287

3288

3288-20

EN

Instruction Manual

Symbols afxed to the device

Precaution or hazard (See corresponding topic.)

Risk of electric shock

Protected throughout by double insulation or reinforced insulation

Device may be connected to or disconnected from a live conductor

Grounding

terminal DC (direct current) AC (alternating

current)

Accuracy

We dene measurement tolerances in terms of rdg. (reading) and

dgt. (digit) values,with the following meanings:

rdg.

(reading or

displayed value)

The value currently being measured and

indicated on the measuring instrument.

dgt.

(resolution)

The smallest displayable unit on a digital measuring

instrument,i.e.,the input value that causes the digital

display to show a “1” as the least-signicant digit.

Measurement categories

This instrument’s current measurement part conforms to the safety

requirements for CAT III 600 V and the voltage measurement part

conforms to the safety requirements for CAT II 600 V,CAT III 300 V

measuring instruments.

Service entrance

Distribution panel

Service drop Internal wiring

Power meter

Fixed Installation

Outlet

CAT IV CAT III CAT II

DANGER

Measuring a location with a higher category number

than the measurement category indicated on this

device may result in a serious accident such as

electric shock.

To avoid electric shock, do not touch the portion

beyond the protective barrier during use.

Never apply voltage to the test leads when the

resistance and continuity functions are selected.

Doing so may damage the instrument and result in

bodily injury. To avoid electrical accidents, remove

power from the circuit before measuring.

WARNING

•To avoid electric shock,short circuits and damage

to the instrument,disconnect the test leads from the

measurement object before switching the rotary switch.

•To prevent electric shock,when measuring the voltage

of a power line use a test lead that satises the

following criteria:

•Conforms to safety standards IEC61010 or EN61010

•Of measurement category III or IV

•Its rated voltage is higher than the voltage to be measured

•

The optional test leads for this instrument conform to the

safety standard EN61010. Use a test lead in accordance

with its dened measurement category and rated voltage.

•To avoid an electric shock,operate the instrument at

below a lower rated voltage between that indicated on

the instrument and on test leads.

WARNING

•Installing the instrument in inappropriate locations may

cause a malfunction of instrument or may give rise to

an accident. Avoid the following locations:

•Exposed to direct sunlight or high temperature

•Exposed to corrosive or combustible gases

• Exposed to a strong electromagnetic eld or

electrostatic charge

•

Near induction heating systems (such as high-frequency

induction heating systems and IH cooking equipment)

•Susceptible to vibration

•Exposed to water,oil,chemicals,or solvents

•Exposed to high humidity or condensation

•Exposed to high quantities of dust particles

WARNING

•Since there is a risk of electric shock,check that the

insulation on the test lead are neither ripped nor torn,and

no metal conductor inside the wire are exposed before

using the instrument. If damaged,replace them with those

specied by our company.

•To prevent a short circuit accident,be sure to use the

test leads with the sleeves attached when performing

measurements in the CAT III measurement category.

•If the sleeves are inadvertently removed during

measurement,stop the measurement.

•

With regard to the electricity supply,there are risks of

electric shock,heat generation, re, and arc ash due

to short circuits. If persons unfamiliar with electricity

measuring instrument are to use the instrument,another

person familiar with such instruments must supervise

operations.

•This instrument is measured on a live line. To prevent

electric shock,use appropriate protective insulation and

adhere to applicable laws and regulations.

•Handle and dispose of batteries in accordance with

local regulations.

CAUTION

•Do not place foreign objects between the jaw tips or

insert foreign objects into the gaps of the jaws (or exible

loop couplings). Doing so may worsen the performances

of the sensor or interfere with clamping action.

•

Be careful to avoid dropping the instrument or otherwise

subjecting them to mechanical shock,which could

damage the jaw and adversely affect measurement.

Poor performance or damage from battery leakage

could result. Observe the cautions listed below:

•Do not use batteries after their recommended expiry date.

•Do not allow weak batteries to remain in the instrument.

• Replace batteries only with the specied type.

•Remove the batteries from the instrument if it is to be

stored for a long time.

•The indicator lights up when the remaining battery

capacity is low. In this case,the instrument's reliability is

not guaranteed. Replace the battery immediately.

•To avoid battery depletion,turn the rotary switch OFF

after use (the auto power save feature consumes a small

amount of current).

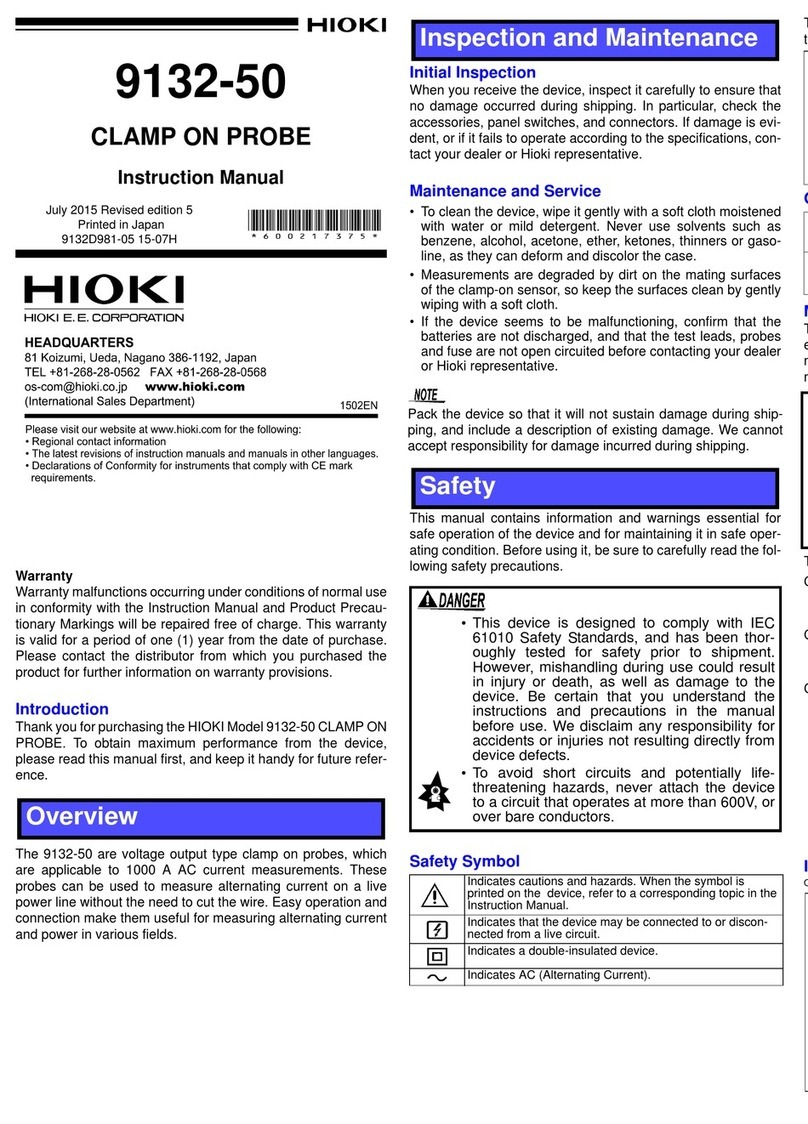

Inspection Before Measurement

•Verify that the instrument operates normally to ensure that no

damage occurred during storage or shipping. If you nd any

damage,contact your authorized Hioki distributor or reseller.

•If damage is suspected,check the section below before contacting

your authorized Hioki distributor or reseller.

(1) Check that the test lead is not broken.

Replace with the specied L9208 Test Lead.

(2) Check that the resistance measurement and continuity test

operates normally.

Have the instrument repaired by the your authorized Hioki

distributor or reseller. The instrument may have been subject to

a voltage of greater than 600 V during resistance measurement

or continuity testing.

(3) Check that the battery voltage is not low.

Replace the batteries.

Maintenance/Inspection

Cleaning

•

Measurements are degraded by dirt on the mating surfaces of the jaw

,so keep the surfaces clean by gently wiping with a soft,dry cloth.

•To clean the device,wipe it gently with a soft cloth moistened with

water or mild detergent.

• Wipe the LCD display gently with a soft,dry cloth.

Insert/Replace Batteries

Necessary tool: Phillips screwdriver and CR2032 Coin-shaped lithium battery

NO

1 2 34

Do not turn the adjustment screw inside the battery case. Doing

so will cause the instrument to report abnormal measured values.

CALIFORNIA,USA ONLY

Perchlorate Material - special handling may apply.

See www.dtsc.ca.gov/hazardouswaste/perchlorate

Warranty

Warranty malfunctions occurring under conditions of normal use in

conformity with the Instruction Manual and Product Precautionary

Markings will be repaired free of charge. This warranty is valid for a

period of three (3) years from the date of purchase. Please contact

the distributor from which you purchased the product for further

information on warranty provisions.

Introduction

Thank you for purchasing the Hioki 3287/3288/3288-20 AC Clamp

Meter. To obtain maximum performance from the instrument,please

read this manual rst,and keep it handy for future reference.

3288 Average value measurement RMS conversion model

3287

3288-20 True RMS measurement model

Safety Notes

This instrument is designed to conform to IEC 61010 Safety

Standards,and has been thoroughly tested for safety prior to

shipment. However,using the instrument in a way not described in

this manual may negate the provided safety features. Before using

the instrument,be certain to carefully read the following safety notes.

Notation

In this document,the risk seriousness and the hazard levels are

classied as follows.

DANGER Imminent risk of operator death or serious injury

WARNING Potential for operator death or serious injury

CAUTION Potential for minor operator injury or device

damage or malfunction

Risk of electric shock

Prohibited actions

Actions that must be performed

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com