Illinois Tool Works SIMCO CENTURION Manual

INSTRUCTIONS

Operation / Maintenance 2257 North Penn Road

Hatfield, PA 19440

CENTURION Phone: (215) 997-0590

Single-Fan DC Ionizer Fax: (215) 997-3450

(patents pending)

Publication 5200789

January, 2001

The Centurion has been designed specifically for use by the disk drive industry in critical

cleanroom applications. This single-fan DC ionizer offers superior balance performance

with its novel emitter array design and high-gain dual feedback circuitry. The Centurion

eliminates static charges cleanly, quickly and reliably, provides true next generation

performance, meeting the demands of the disc drive industry with corona ion technology.

SECTION 1 Description

SECTION 2 Features

SECTION 3 Specifications

SECTION 4 Safety

SECTION 5 Installation

SECTION 6 Operation

SECTION 7 Maintenance

SECTION 8 Replacement Parts

SECTION 9 Warranty

SECTION 1 Description

The Centurion single-fan DC ionizer eliminates electrostatic charges cleanly, quickly

and reliably in cleanroom workstation applications where electrostatic discharge (ESD)

is a concern. The Centurion is designed for applications where even very low levels of

static charge can damage sensitive components.

The Centurion produces ionized air with balanced ion content. The ion offset voltage is

continuously monitored and corrected through the combination of a unique emitter array

design and control circuit. Directing the airflow onto an object or work surface will

eliminate existing static charges and prevent the formation of additional charge.

Charged objects attract charge of the neutralizing polarity from the ion-rich air stream.

The Centurion includes a fan speed control used to tailor the amount of air delivered to

the work surface. Internal to the unit, air flows past the components used to generate air

ions. The ion emitter design of the Centurion is patented and provides superior delivery

of ions to the air stream through the use of 8 emitters and a unique geometry which

controls airflow over the emitters. The design also aids the closed loop feedback control

of offset voltage. Adjustments made to the output of the emitter array are seen promptly

as ion output changes in the air. The resulting balanced stream of ionized air is

delivered to the work area to provide static neutralization.

Ion balance is maintained with a high-gain dual feedback circuit. This circuit, combined

with the unit’s patented emitter array design, offer superior offset voltage performance.

With regular maintenance, using the unit’s integrated cleaning brush, the unit is capable

of +/-3V performance. If the unit becomes unable to track its set point or some other

failure condition occurs the built-in monitoring circuit indicates the fault condition.

Specially selected components insure cleanliness of the Centurion’s output air to meet or

exceed Class 10 particle limits. All fans feature a specially designed bearing system and

use silicone-free lubricants. All other air bearing surfaces in the ionizer are manufactured

free of silicones. Fan assemblies are run-in and particle-tested to Class 10 (209E; ISO

Class 4) particle limits. The Centurion’s final assembly, final test, and packaging take

place in a Class 100 cleanroom. Great lengths have been taken in design and fabrication

of this unit to minimize the risk of any form of contamination.

SECTION 2 Features

• +/-3V offset voltage

• Class 10 cleanroom compatible

• Patented 8-pin emitter design

• Rapidly neutralizes static charge

• Integrated emitter cleaning brush

• Rugged and aesthetic enclosure

2

SECTION 3 Specifications

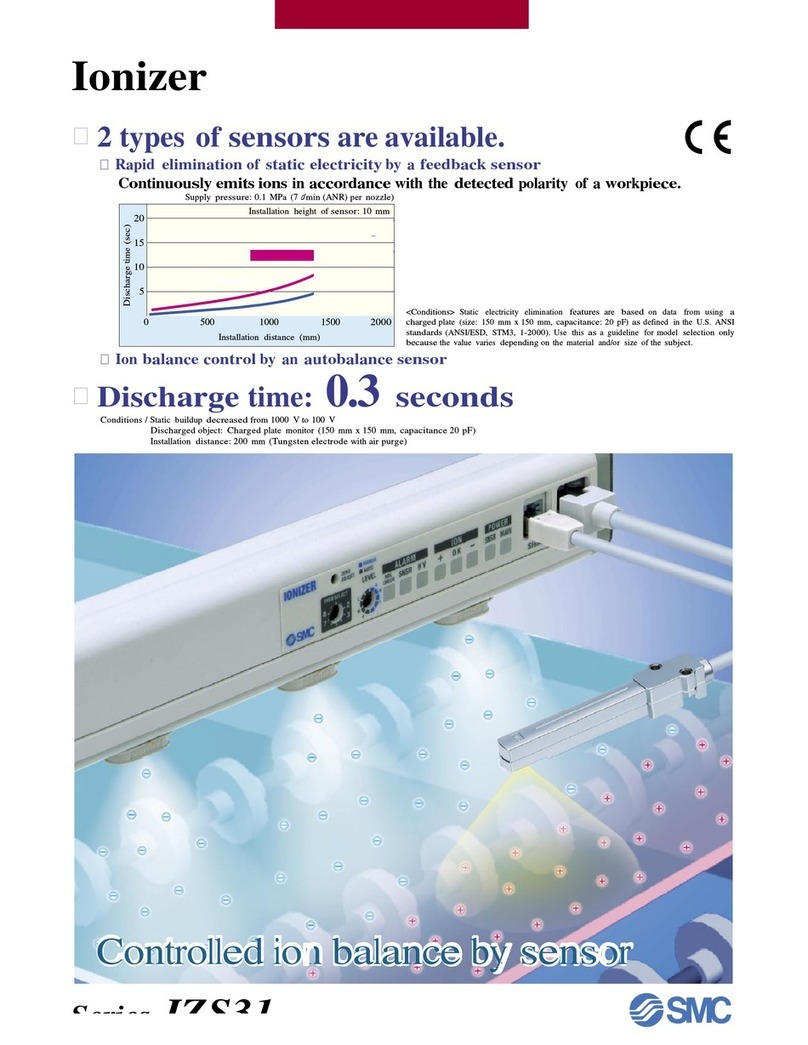

Discharge Time*: 1,000 – 100V < 3 seconds at 12 inches (30.5 cm)

1,000 – 5V < 5 seconds at 12 inches (30.5 cm)

Offset Voltage*: ±3V from set point, set point adjustable to 0V.

OPERATION SPECIFICATIONS

Max. Current Draw: 0.6 A

Line Voltage: 100-240 VAC, 50/60Hz

AC Adapter: Universal input 24VDC output with IEC 320 input with grounded

secondary.

Coverage Area: 1’ x 4’ Area Coverage

Ambient Temp: 32°F (0°C) to 122°F (50°C)

Air Flow Volume: Low Fan Speed 50 CFM (23 l/s); High Fan Speed 90 CFM (42 l/s)

Audible Noise: Low Fan Speed 48 dB(A); High Fan Speed 58 dB(A) measured 2ft.

(61 cm) from unit.

OFF/ON: Rear panel ON/OFF switch

Fan Speed: Adjusted using a potentiometer adjustment tool. Adjustment located on

the rear panel of the unit.

Offset Balance: Adjustable to zero, using a potentiometer adjustment tool. Adjustment

access is located (recessed) on the rear panel of the unit.

Indicators: A green light indicates power on.

Fault light is normally off. A red light indicates an error condition.

(Optional: audible signal)

Reset: Automatic

Maintenance: Rotate emitter cleaner knob clockwise one revolution and release.

MECHANICAL SPECIFICATIONS

Emitters: Machined tungsten

Enclosure: Aluminum

Finish: Gloss white polyester

Dimensions: 9 1/2x 8 x 3 3/8 inches (24 x 20 x 9cm)

Total Weight: 4.25 lbs. (1.9 kg.)

Mount: Stainless steel stand

Approvals Pending: UL, CUL and CE

* Tested in accordance with ESD-STM3.1-2000, IONIZATION. Tested at 12 inches (30.5cm) on centerline.

3

SECTION 4 Safety

CAUTION!

1. Read the complete Operation Manual before operating. Failure to follow instructions

may result in damage to the ionizer and/or personal injury.

2. This unit is supplied with a 3-prong grounding plug, which must be inserted in an

appropriate, properly wired, and grounded receptacle. The 24VDC AC adapter used

with the unit provides a ground connection at its output. Do not defeat the electrical

ground, grounding and proper wiring are required for proper operation.

3. Do not ground or make electrical connections of any kind to the unit’s metal fan

guards located on the intake and output.

4. A factory-qualified service technician must perform component service and repairs.

Please contact SIMCO Customer Service for information.

WARNING!

5. Keep the unit dry. Do not operate the unit in flammable, volatile or explosive atmosphere.

6. Do not insert objects through the unit’s intake or outlet grilles. Damage to the ionizer

and/or personal injury may result.

SECTION 5 Installation

5.1 Unpacking

Carefully remove the equipment from the carton and inspect contents. Note that the unit

has been bagged and vacuum sealed in a Class 100 cleanroom. To prevent

contamination and eliminate the need for additional wipe downs, the unit should be un-

bagged in a cleanroom environment.

5.2 Installing

The Centurion single fan ionizer is designed for portable or permanent operation.

Typically, the unit should be positioned such that there is good airflow provided to the

critical area. Generally this requires that the unit be within 36” inches of the intended

target. The stand provided with the unit can be used in a permanent operation by bolting

it to a sturdy flat surface such as a wall or shelf. The unit can be mounted horizontally if

required. The stand may be removed if required.

4

CAUTION!

5.3 Electrical Connections

The Centurion is provided with a 24VDC AC adapter. This AC adapter provides

electrical ground to the unit via a direct connection through the adapter to the wall

outlet. For this reason the unit should be used with this AC adapter only. The unit’s line

cord should be plugged in to a standard 3-terminal grounded receptacle with line

voltage and frequency of 100-240 VAC, 50/60 Hz. Note that an instrumentation ground

is provided on the rear of the unit for testing and calibration purposes.

SECTION 6 Operation

The Centurion’s ON/OFF switch is located at the rear of the unit. The unit should be

turned on using the switch when 24VDC is provided via the AC adapter. Do not ‘hot

plug’ the AC adapter into a unit when the switch is in the ON position. Switch the unit

off, then insert the 24VDC connection into the unit.

Fan speed is adjustable at the unit’s rear panel using a potentiometer adjustment tool or

small screwdriver. Turning the control clockwise increases the fan output; turning

counter clockwise reduces the airflow. Note that the time required to neutralize static is

dependent on the fan speed setting. For fastest charge neutralizing performance, the

unit should be adjusted for the highest fan speed.

The Ion Balance adjustment located on the rear of the unit tunes the Centurion’s offset

voltage to zero. Typically this adjustment is made as part of scheduled maintenance or

setup. Adjustments to this control should not be made without using the correct

calibration instrumentation.

SECTION 7 Maintenance

7.1 Ion Balance Calibration

The Centurion is delivered from the factory calibrated to a zero volt offset set point. As

part of regular maintenance, or if the unit’s fan speed is changed, the ion balance

calibration should be checked. For calibration, a charge plate monitor (CPM) such as

SIMCO’S EA-4 is required. The CPM should have its ground connected to the

instrument ground provided on the rear panel of the Centurion; this jack accepts a

standard banana plug. For most accurate calibration results, the unit should be

operated at least 30 minutes and the test location should not be subject to other

ionization sources. The operator should wear a grounding wrist strap. With the charge

plate located 12” from the outlet grille of the unit, the ion balance control can be

adjusted for 0V using a potentiometer adjustment tool or small screwdriver.

5

7.2 Ion Balance / Performance Check

For checking balance and performance a charge plate monitor (CPM) such as SIMCO’S

EA-4 is required. The CPM should have its ground connected to the instrument ground

provided on the rear panel of the Centurion; this jack accepts a standard banana plug.

With the charge plate located 12” from the outlet grille of the unit, the ion balance

control can be checked. Note that if an adjustment to the Ion Balance is required, the

emitters should be cleaned (see 7.3 below) before this adjustment takes place. By using

the CPM to measure discharge times of the charge plate, ion content of the air and ion

delivery to the target area can be verified.

7.3 Emitter Cleaning

Recommended frequency of cleaning is once per week. To clean ion emitters, simply

rotate the emitter cleaner knob located at the center of the fan grille on the rear of the

unit. Rotate the knob clockwise until it stops and release. The spring-loaded emitter

cleaning brush will return to its parking spot.

It is not necessary to turn off the unit during cleaning of the emitters when using the

integrated cleaning brush.

7.4 Emitter Replacement

To replace emitters, the rear of the unit must be removed. Loosen the #8 Phillips-head

screws located on the bottom of the chassis. The rear cover can now swing open for

removal from its pivot pins. The emitters are installed in sockets for easy insertion and

removal. Using a long-nose pliers, pull the emitters out along the radial direction,

gripping the shaft only, taking care not to damage the sharp tip. Position each emitter

carefully during insertion, as excessive force can damage the emitter sockets. Using

long-nose pliers, push the emitters into the sockets along the radial direction.

7.5 Troubleshooting / Diagnostics

This information provides a quick troubleshooting reference for the Centurion single-fan

ionizer. Should any of these possible solutions not solve the problem, contact SIMCO.

PROBLEM CAUSE SOLUTION

UNIT FAILS TO OPERATE POWER CORD NOT CONNECTED PLUG IN TO SPECIFIED VOLTAGE SOURCE

UNIT FAILS TO OPERATE FAULTY AC ADAPTER REPLACE AC ADAPTER

FLASHING FAULT LIGHT POWER INCORRECTLY SUPPLIED TO

UNIT

CYCLE POWER TO THE UNIT USING THE

UNIT’S REAR PANEL SWITCH

FLASHING FAULT LIGHT POWER INCORRECTLY SUPPLIED TO

UNIT

ENSURE THAT PROPERLY GROUNDED

RECEPTICLE IS USED

FAULT LIGHT ON STEADY DIRTY OR DAMAGED EMITTERS,

INCORRECTLY CALIBRATED

CLEAN EMITTERS USING INTEGRATED

BRUSH, REPLACE AS NECESSARY,

RECALIBRATE

EXCESSIVELY LONG DISCHARGE

TIMES

DIRTY OR DAMAGED EMITTERS,

INCORRECTLY CALIBRATED

CLEAN EMITTERS USING INTEGRATED

BRUSH, REPLACE AS NECESSARY,

RECALIBRATE

UNIT FAILS TO HOLD SETPOINT DIRTY OR DAMAGED EMITTERS

CLEAN EMITTERS USING INTEGRATED

BRUSH, REPLACE AS NECESSARY,

RECALIBRATE

FAN IS SLOW FAN SPEED IS SET SLOW ADJUST FAN CONTROL CLOCKWISE

6

SECTION 8 Replacement Parts

PART NUMBER DESCRIPTION

4008395 CENTURION SINGLE-FAN DC IONIZER

4630206 GROUNDED 24V DC-AC ADAPTER

4370806 TUNGSTEN EMITTERS, .88” LG

SECTION 9 Warranty

SIMCO warrants its products to be free of defects in components, workmanship, or

materials for a period of one year from date of purchase. This warranty does not apply

to any physical or electrical damage caused by misuse, abuse or negligence (such as

any modifications made to the unit or service work done by any other than SIMCO

authorized technicians). Any unit with altered or removed serial number is ineligible for

warranty.

SIMCO will not be liable for loss or damage due directly or indirectly to an occurrence

or use for which the product is not designed or intended. In no event shall SIMCO be

liable for incidental or consequential damages except where state laws override.

This warranty extends to the original purchaser and is not transferable. No person,

agent, distributor, dealer or company is authorized to change, modify, or amend the

terms of this warranty in any manner whatsoever.

All products returned must have an “RA” (Return Authorization) number regardless of

warranty status. Call SIMCO for an assigned RA number.

Information in this document is subject to change without notice and does not

represent a commitment on the part of SIMCO. No part of this manual may be

reproduced or transmitted in any form or by any means, electronic or mechanical,

including photocopying and recording, for any purpose other than the purchaser’s

personal use without written permission of SIMCO.

2257 North Penn Road

Hatfield, PA 19440

Phone: (215) 997-0590

(800) 538-0750

Fax: (215) 997-3450

http://www.simco-static.com

7

Table of contents

Other Illinois Tool Works Air Ionizer manuals