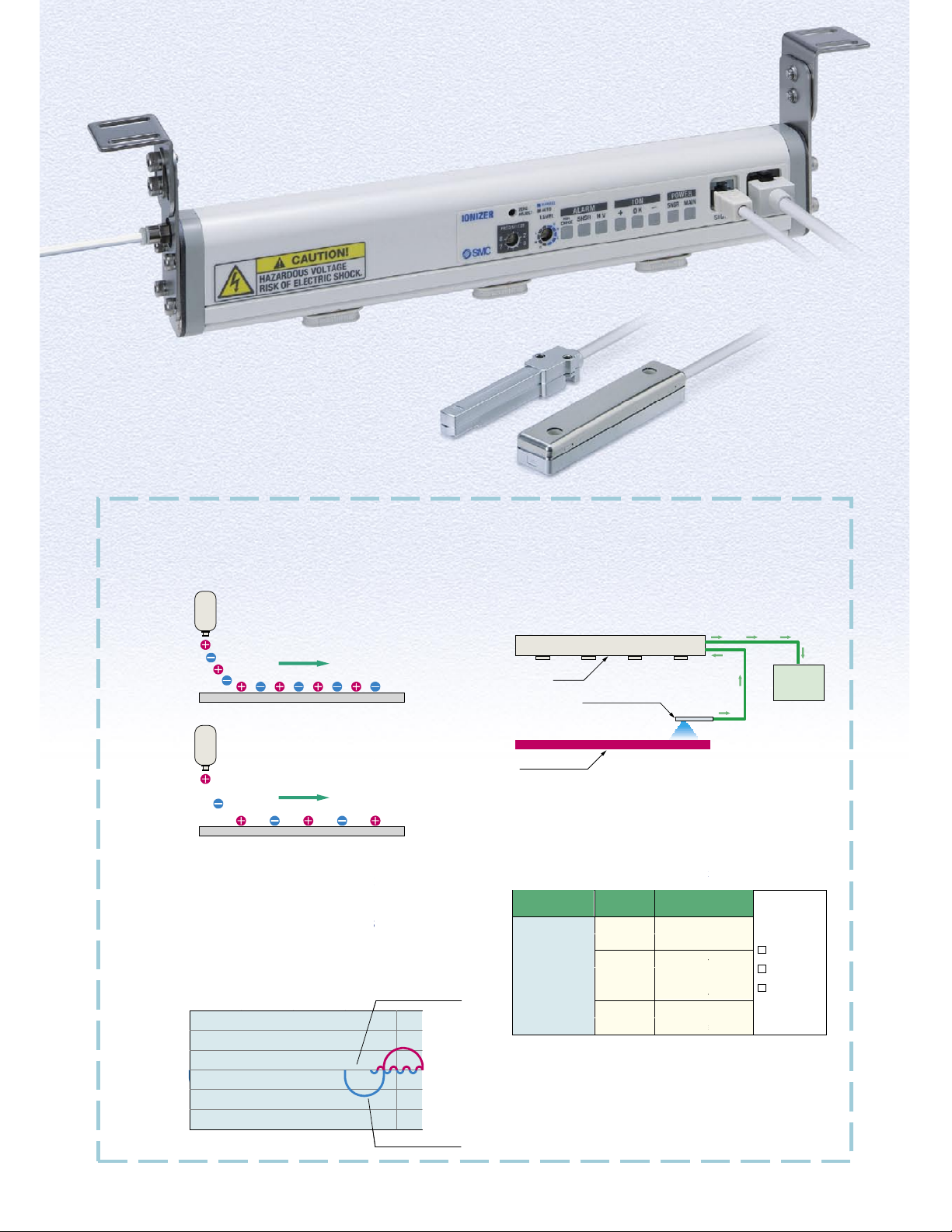

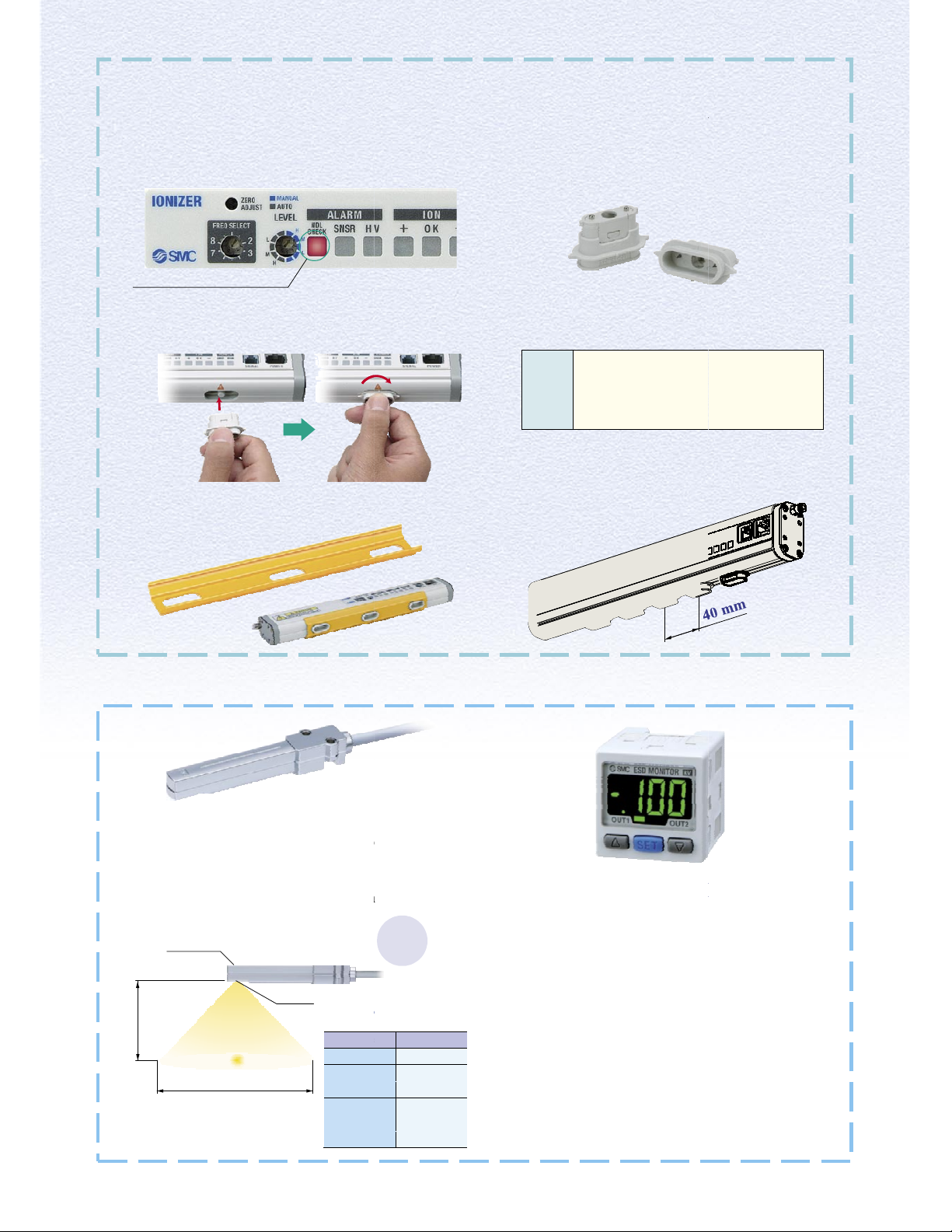

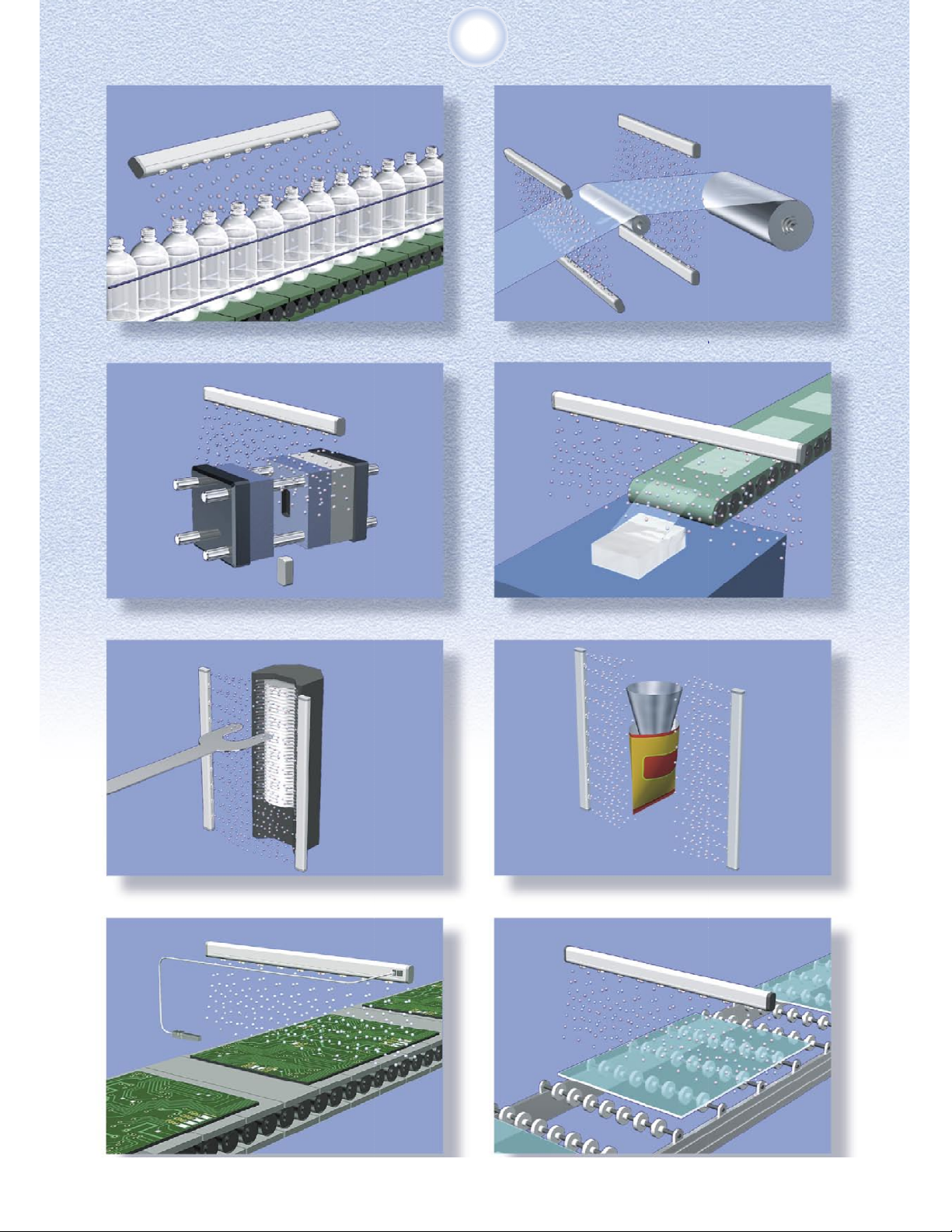

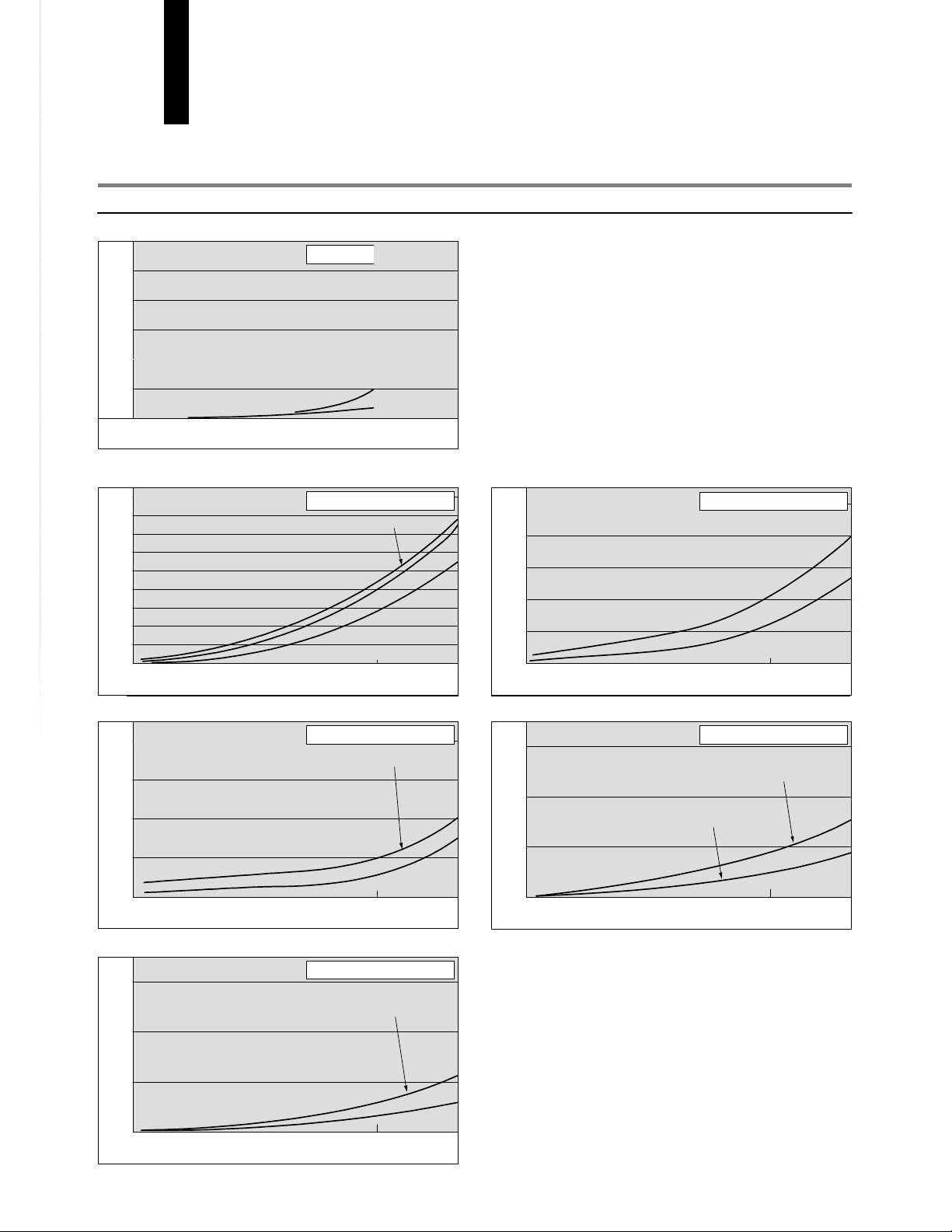

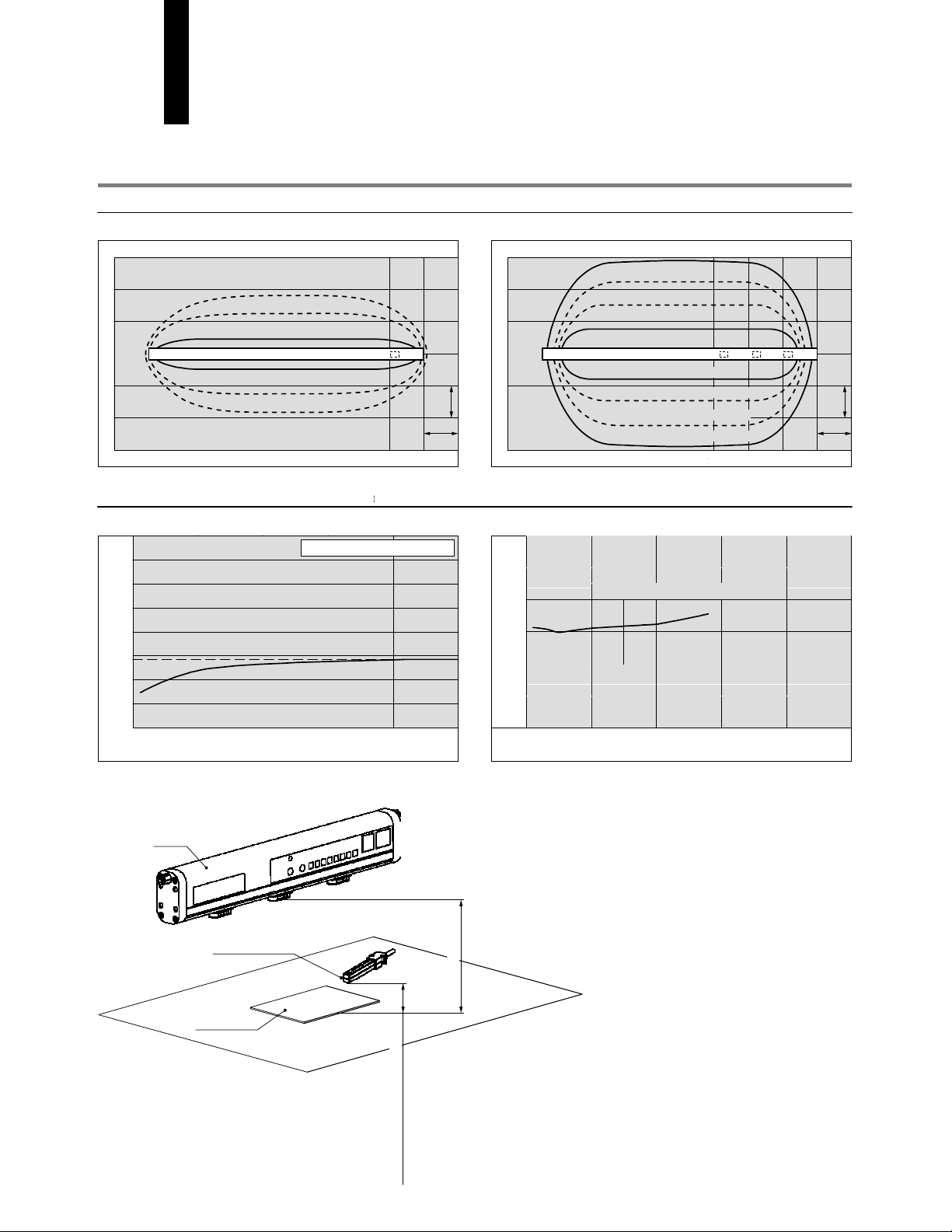

EMC IZS31 Series User manual

Popular Air Ionizer manuals by other brands

ELTEX

ELTEX ES60 Series operating instructions

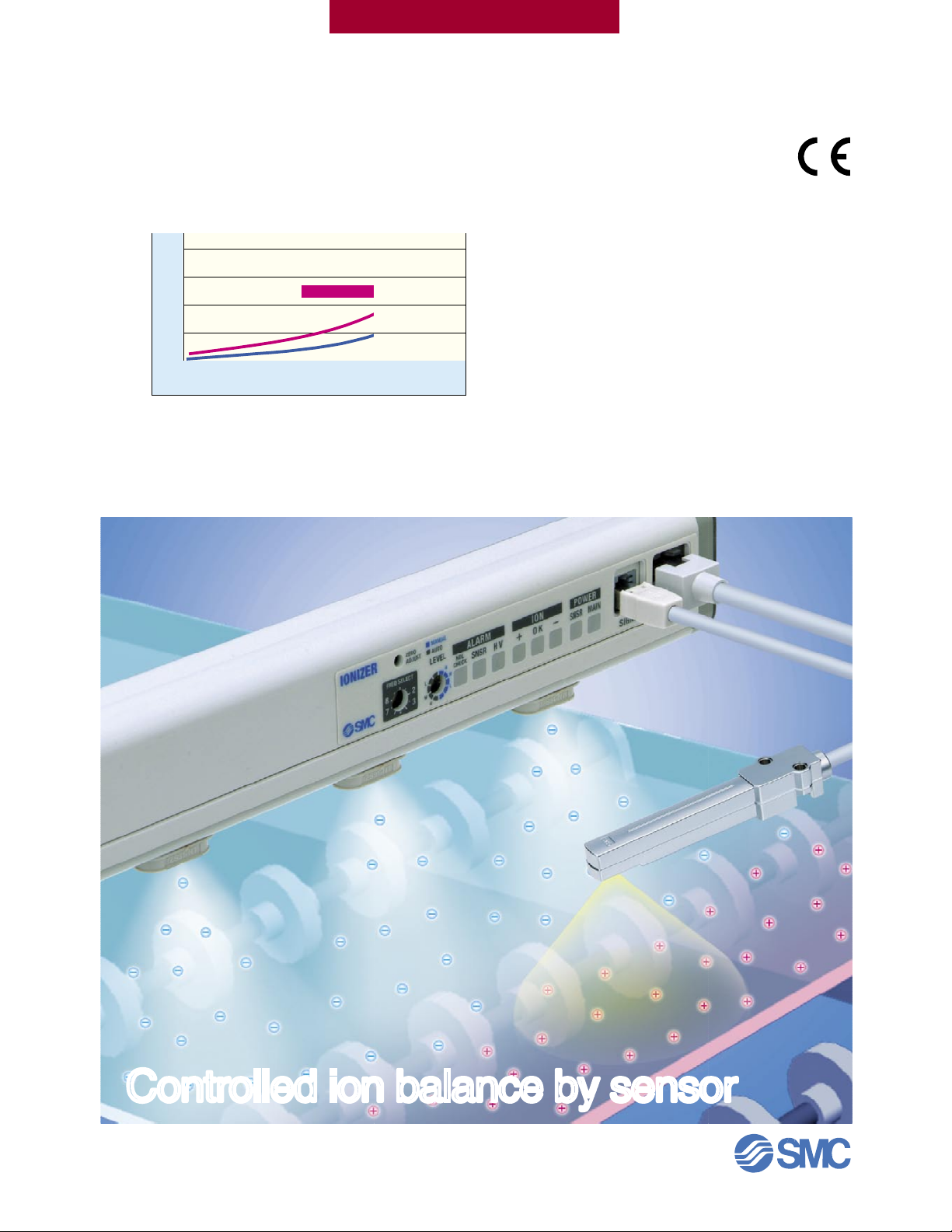

SMC Networks

SMC Networks IZN10E Series Operation manual

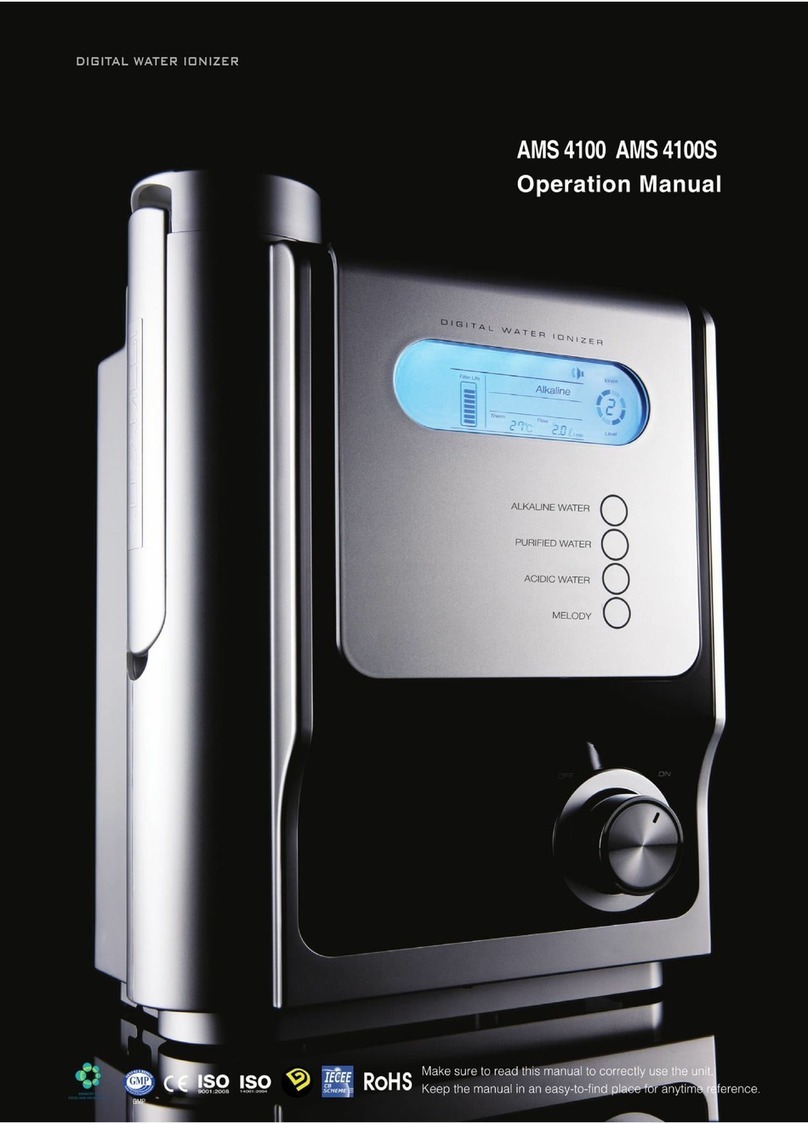

Alkamedi

Alkamedi AMS 4100 Operation manual

Desco EMIT

Desco EMIT 50664 Installation, Operation, and Adjustment Instructions

Aerisa

Aerisa 8100 Installation, operation & maintenance manual

greenfan

greenfan 1600-01 installation instructions

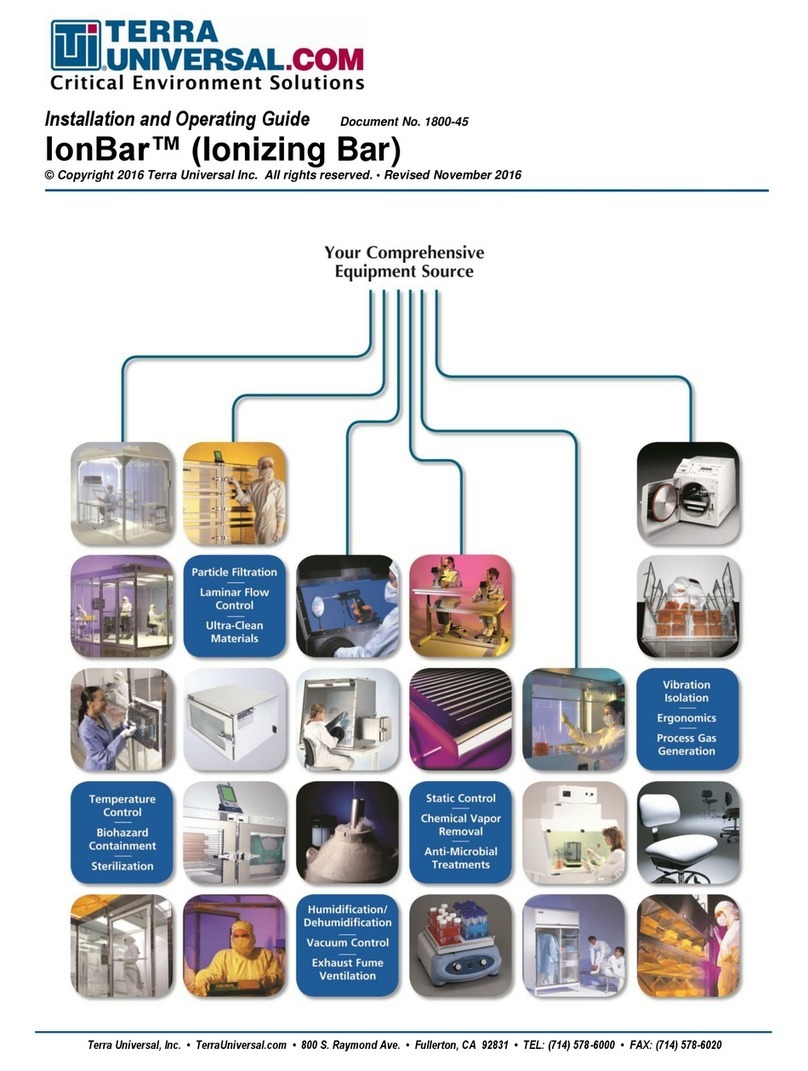

Terra Universal

Terra Universal IonBar Installation and operating guide

Phonocar

Phonocar 04971 instruction manual

Klarstein

Klarstein ST. OBERHOLZ OFFICE manual

Life Ionizers

Life Ionizers Fuzion user manual

ITW

ITW Simco-Ion IQ Power Fantom Installation and operating instructions

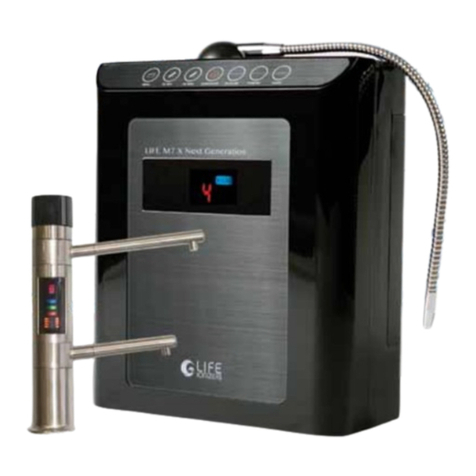

LIFE Ionizer

LIFE Ionizer M7 X NG user manual