Illinois Tool Works Simco Aerostat XC Instruction Manual

INSTRUCTIONS

Operation/Maintenance

Aerostat XC™ Ionizing Air Blower

2257 North Penn Road

Hatfield, PA 19440

(215) 997-0590

(800) 538-0750

Fax: (215) 997-3450

Publication 5100550 rev F

February, 2002

SIMCO’s Aerostat XC was designed for use with sensitive electronic components where

electrostatic discharge (ESD) is a problem. It can be applied in inspection, testing, and

assembly environments. The Aerostat XC can also be used where static electricity causes

problems such as attraction of dirt to product, misalignment of small parts due to electrostatic

"jumping", and undesirable adhesion of plastic films due to electrostatic charge.

SECTION 1 Description

SECTION 2 Features

SECTION 3 Specifications

SECTION 4 Safety

SECTION 5 Installation

SECTION 6 Operation

SECTION 7 Maintenance

SECTION 8 Replacement Parts

SECTION 9 Warranty

SECTION 1 Description

The Aerostat XC ionized air blower produces an air flow that is rich in positive and

negative ions. Directing the air flow on an object that has a static charge will neutralize

the charge. If the object has a positive static charge, it will draw negative ions from the

air flow. If the object has a negative static charge, it will draw positive ions from the air

flow. The ions are attracted to the oppositely charged object and neutralize the

electrostatic charge on the object.

The Aerostat XC uses a three-speed tangential blower to produce a uniform air flow.

This air flow is directed into a duct, which shapes the airflow. The duct also contains a

heater and ionizer. The low-wattage heater can be turned on at any time for user

comfort. The ionizer uses a transformer which produces high voltage AC. This unit is

current limited for safety. The transformer output also contains a current limiting resistor

which provides redundant safety and enhances the ionization stability. The AC is

applied to a row of stainless steel ion emitters, which results in an intense alternating

electric field at the tip of the emitters. It is this intense electric field that introduces

alternating polarity ions into the air flow. The shaped air flow exiting the Aerostat XC

carries these ions over a broad area for control of electrostatic charge. To ensure that

the unit is working properly, the output is monitored by an ionization indicator lamp.

The ionizer of the Aerostat XC features an exclusive balancing circuit which works by

isolating the transformer secondary from electrical ground. This results in the equal

production of positive and negative ions. The Aerostat XC also features a patented built-

in emitter cleaner. Taking a few seconds to clean the emitters on a weekly basis

prevents the build-up of airborne debris, keeping your Aerostat XC working in top form

for the life of the unit.

SECTION 2 Features

• Rapidly neutralizes static charges

• Covers an extended area with ionized air

• Three-speed fan with wide range of air flow

• Low-wattage heater for operator comfort

• Bench stand or optional pedestal mount with 360' adjustability

• Inherently balanced ion output

• Built-in ion emitter cleaner

• Ionization indicator lamp

• Durable, electrically grounded steel enclosure

2

SECTION 3 Specifications

Unit Part Number: 4002612 4002667

Line Voltage: 120 VAC, 60 Hz. 220-230 VAC, 50 Hz

Current Draw: Max. 3.6 Amp* 1.8 Amp*

Min. 0.6 Amp 0.3 Amp

*Heater on

Air Volume Output: Fan Speed Flow

Low 70 CFM

Medium 95 CFM

High 102 CFM

Air Velocity Fan Speed 1 ft. 2 ft. 3 ft. 4 ft.

Low 600 300 180 150

Medium 800 400 220 180

High 1000 500 250 200

Velocity in FPM measured at center line of air stream

Air Flow Characteristics: 3’ x 6’ Area Coverage

Heated Air Temperature: Fan Speed Above Ambient

(where applicable) Low 11°F (6°C)

Medium 9°(5°C)

High 7°F (4°C)

Measured 6” in front of unit.

Operating Temperature: 32°F (0°C) -- 122°F (50°C)

Ozone Production: 0.005 ppm measured 6” in front of unit

Test conducted in accordance with EPA EQOA-0577-

019 using Dasibi Ozone Monitor model 1003AH

Audible Noise: Fan Speed

Low 52 dB

Medium 58 dB

High 64 dB

measured 2 ft. from unit.

Enclosure: Steel

Finish: White Acrylic Enamel

Weight: 17.5 lbs (7.9 kg)

Size: 15-3/8” W x 4-1/2” H x 8-1/8” D

3

(39.1 cm W x 11.4 cm H x 20.6 cm D)

Bench Stand Feet: Nonconductive, Nonstaining Polymer

Optional Air Filter: 30 PPI Open Cell Polyurethane Foam

Ion Balance (offset voltage): 0V + 5

Ion Output (discharge time):

Fan Speed - High 1 ft. 2 ft. 3 ft. 4 ft.

5 5.5 6.5 8.5 12 inches

1.5 2.5 4 5.5 Center Line

5 5.5 6.5 8.5 12 inches

Fan Speed - Medium 1 ft. 2 ft. 3 ft. 4 ft.

6 7 9 11 12 inches

1.7 3.5 5 7 Center Line

6 7 9 11 12 inches

Fan Speed - Low 1 ft. 2 ft. 3 ft. 4 ft.

8 9 10 12 12 inches

2 5 7 9 Center Line

8 9 10 12 12 inches

Offset voltage and discharge time determined as per ESD Association Standard No. 3

using 6” x 6”, 20 pF plate (charge plate monitor). Discharge times are in seconds from

1000 volts to 100 volts.

Note: Discharge times for high speed are 10% longer for 230 V, 50 Hz.

SECTION 4 Safety

4.1 Read all instructions before proceeding with installation or operation. Failure to

follow instructions may result in damage to the ionizer and/or personal injury.

4.2 This unit is supplied with a 3-prong grounding plug, which must be inserted in an

appropriate, properly wired, and grounded receptacle. Do not defeat the electrical

ground, grounding and proper wiring are required for proper operation.

4.3 Keep the unit dry. Do not operate the ionizer in a flammable, volatile or explosive

atmosphere.

4.4 Do not insert objects through the unit’s intake or outlet grilles. Damage to the

ionizer and/or personal injury may result.

4.5 Do not ground or make electrical connections of any kind to the unit’s metal fan

guards located on the intake and output.

4

4.6 A factory-qualified service technician must perform component service and repairs.

Please contact SIMCO Customer Service for information.

SECTION 5 Installation

Carefully remove the equipment from the carton and inspect contents. Empty the carton

to insure that small parts are not discarded. If any damage has occurred during

shipment, notify the local carrier at once. A report should also be forwarded SIMCO,

2257 North Penn Road, Hatfield PA 19440, Phone (215) 822-2171. See Section 9 for

Return Shipment information.

The Aerostat XC is designed for portable or permanent operation. It is supplied with a

bench stand; an optional pedestal mount (part number 5050282) is available. The

bench stand can be used for portable operation or bolted to a sturdy flat surface such as

a wall or under a shelf. If the bench stand is bolted in place, use 5/16-inch diameter

screws or bolts to secure it.

For extremely dirty environments, an optional air filter kit (part number 5050281) is

available. The air filter kit contains user-installed brackets and an air filter that can be

cleaned and reused.

The Aerostat XC should be placed approximately 1 to 3 feet from the critical work area

or objects to be neutralized. It should be positioned to cover as much of the area as

possible with the ionized air stream. The air stream can be directed upward or

downward by tilting the unit on the stand. Tightening the lock knobs on each side of the

unit secure it in position.

The Aerostat XC, part number 4002612, requires 120 VAC 60 Hz for proper operation.

The unit must be grounded for safe operation. Plug the unit into a standard 3-terminal

grounded receptacle.

The Aerostat XC, part number 4002667, requires 220-230 VAC 50 Hz. for proper

operation. The unit must be grounded for safe operation. The unit comes with line cord,

without plug. A plug must be installed on the line cord for operation. Installation of the

plug must be performed by qualified service personnel. The color code for wiring the

plug is as follows: Brown - Line; Blue - Neutral; Green/Yellow - Ground.

5

SECTION 6 Operation

Activate the XC by setting the POWER switch to the ON position. The ionization

indicator will illuminate to indicate the presence of ionized air. Set the air flow as desired

by adjusting the FAN SPEED to low ( I ), medium ( I I ), or high ( I I I ). If warm air is

desired for operator comfort, set the HEATER switch to the ON (I) position. The

direction of the air stream can be adjusted upward or downward by loosening the

lock knobs, tilting the unit and retightening the knobs.

The Aerostat XC produces an ionized air stream that covers a large area uniformly.

The time required to neutralize a static charge on an item in this area depends on many

factors. Two important factors are: distance to the ionizer and air velocity. Air ions

constantly "neutralize" each other. Positive and negative ions are electrostatically

attracted to each other. When they contact, the charge transfers and the ions

recombine. With high air velocity, the ions travel further before they recombine. Setting

the fan speed to high results in coverage for the greatest possible area. Decreasing the

distance to the ionizer results in more rapid neutralization. For fast neutralizing, the item

should be held within 1 to 3 feet from the Aerostat XC. For virtually instantaneous

neutralizing, the item may be held as close as 6 inches.

When using the Aerostat XC in an electronics assembly area, the ionized air stream

should cover as much of the work area as possible. The constant flow of ionized air will

prevent items such as work surfaces, tools, materials and components from developing

a static charge. Charged items introduced into the work area will be neutralized and will

remain neutral while they are in the air stream.

6

SECTION 7 Maintenance

The Aerostat XC has been designed with low maintenance in mind. The only regular

maintenance suggested is emitter point cleaning, ion balance checking and ion output

checking. Emitter point cleaning takes only seconds with SIMCO’s patented point

cleaner. The Aerostat XC contains a patented balancing circuit that is inherently self

balancing. This circuit compensates for dirt build-up on emitters, emitter point wear, line

voltage fluctuations and variations in air velocity. Scheduled checking of the ion output

and balance should be considered to assure quality audit requirements.

CAUTION! ELECTRICAL SHOCK HAZARD!

Do not insert objects through intake or outlet grille.

7.1 Emitter Cleaning

To clean the ion emitters, simply sweep the emitter cleaner back and forth once across

the ionized air outlet. Recommended frequency of cleaning is once a week.

7.2 Air Inlet and Outlet Cleaning

The air inlet grille on the rear of the unit and the ionized air outlet should remain clean to

prevent restriction of air flow. They can be cleaned with a soft brush or vacuum.

7.3 Optional Air Filter Cleaning

Remove the air filter from the rear of the unit by sliding the aluminum frame of the filter

towards the rear of the unit. Rinse the filter in plain water while gently squeezing. If the

dirt is stubborn, wash the filter in mild soap and water then rinse. Blot the filter dry with

paper towels and allow to dry. Reinstall filter on air inlet by sliding it under brackets

from rear of the unit. IMPORTANT: If an air filter is used, clean the air filter regularly.

7.4 Ion Output Check

To test the unit for ion output, the use of a charge plate monitor such as the SIMCO

EA-4 is recommended. Discharge times can be measured and checked against the Ion

Output tables in Section 3, Specifications. If a charge plate monitor is not available, but

a static meter such as a SIMCO handheld electrostatic fieldmeter is available, ion output

may be checked with the following procedure. Take a piece of plastic and rub it with

cloth until a static charge can be read with the static meter. Turn on the Aerostat XC.

Hold the plastic one foot away from the ionized air outlet for five seconds. Remove the

plastic from the ionized air stream and measure the static charge. The plastic should be

neutralized.

If no instrumentation is available, the XC’s operation can be verified with the following

procedure. Tear off about a 10-inch length of Scotch® brand (or equivalent) transparent

tape. Approach the non-adhesive side of the tape with your free hand and note the

electrostatic attraction of the tape to your hand. Pass the tape through the ionized air

stream approximately 1 foot from the unit and again approach the non-adhesive side of

the tape with your free hand. If the tape has been neutralized, it will not attract.

7

Do not try to verify operation of the unit by drawing a spark from an ion emitter point.

The design of the balancing circuit makes the “spark test” inconclusive. Sustained

grounding of the ion emitters may damage the balancing circuit.

7.5 Ion Balance Check

To test the unit for ion balance, the use of a charge plate monitor such as the SIMCO

EA-4 is recommended. Offset voltage should be measured and checked against the

Ion Balance in Section 3, Specifications.

Do not try to determine ion balance by holding a static meter in the ionized air stream.

This will result in a meaningless reading.

7.6 Calibration

The Aerostat XC’s ion output is inherently balanced by design, so there are no

calibration adjustments. If, after checking the ion balance as outlined above, an

unbalance or offset voltage exists in excess of 0+ 5 volts, contact SIMCO Customer

Service at 800-538-0750.

Never open the case of the unit. This exposes hazardous voltages. If repairs are

necessary, call SIMCO for a Return Authorization Number and return the unit to the

factory.

8

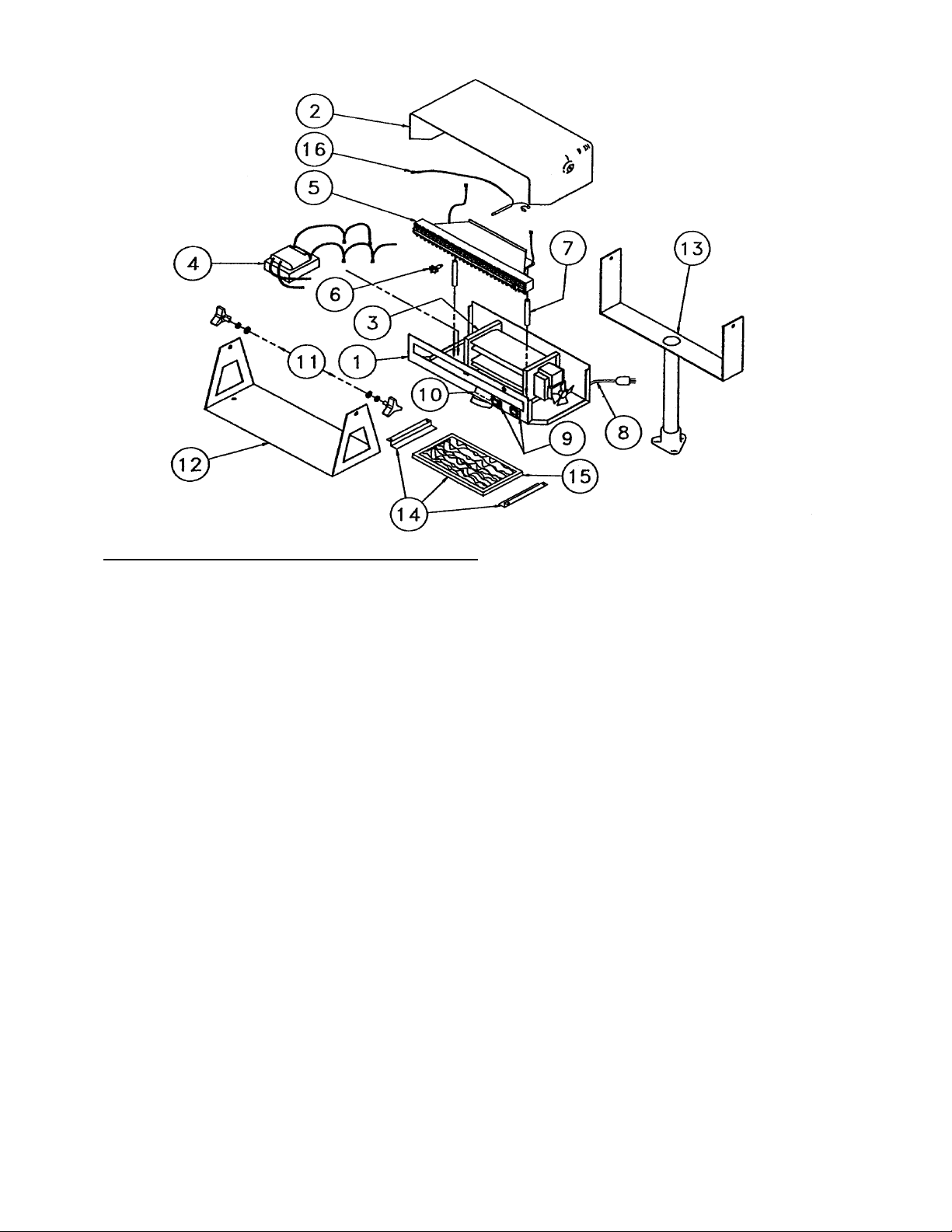

SECTION 8 Replacement Parts

Item Part Number Description

1 4750557 Chassis

2 4340350 Lid

3 5050284 3-Speed Blower, 120 V

3 5050294 3-Speed Blower, 230 V

4 4630136 HV Transformer with Leads, 120 V

4 4630141 HV ransformer with Leads, 230 V

5 4103939 Ionizer Duct Assembly, 120 V

Duct Assembly includes:

5 4104036 Ionizer Duct Assembly, 230 V heater, ionizer, and brush

6 4670700 Brush

7 4401510 Ionizer Duct Standoff (2 required)

8 4103940 Line Cord Assembly, 120 V

8 4104035 Line Cord Assembly, 230 V

9 4610699 Illuminated Rocker Switch, 120 V

9 4610729 Illuminated Rocker Switch, 230 V

10 4610700 3-Position Rotary Switch and Knob

11 4670702 Lock Knob (2 required)

12 4103942 Bench Stand

13* 5050282 Pedestal Mount (includes hardware)

14* 5050281 Air Filter Kit (includes filter, mounting brackets and hardware)

15* 4470059 Air Filter

16 4104354 Ionizer indicator assembly

* Optional Equipment

9

SECTION 9 Warranty

SIMCO warrants its products to be free of defects in components, workmanship, or

materials for a period of one year from date of purchase. This warranty does not apply

to any physical or electrical damage caused by misuse, abuse or negligence (such as

any modifications made to the unit or service work done by any other than SIMCO

authorized technicians). Any unit with altered or removed serial number is ineligible for

warranty.

SIMCO will not be liable for loss or damage due directly or indirectly to an occurrence

or use for which the product is not designed or intended. In no event shall SIMCO be

liable for incidental or consequential damages except where state laws override.

This warranty extends to the original purchaser and is not transferable. No person,

agent, distributor, dealer or company is authorized to change, modify, or amend the

terms of this warranty in any manner whatsoever.

All products returned must have an “RA” (Return Authorization) number regardless of

warranty status. Call SIMCO for an assigned RA number.

Information in this document is subject to change without notice and does not represent

a commitment on the part of SIMCO. No part of this manual may be reproduced or

transmitted in any form or by any means, electronic or mechanical, including

photocopying and recording, for any purpose other than the purchaser’s personal use

without written permission of SIMCO.

2257 North Penn Road

Hatfield, PA 19440

Phone: (215) 997-0590

(800) 538-0750

Fax: (215) 997-3450

http://www.simco-static.com

10

This manual suits for next models

2

Table of contents

Other Illinois Tool Works Air Ionizer manuals

Popular Air Ionizer manuals by other brands

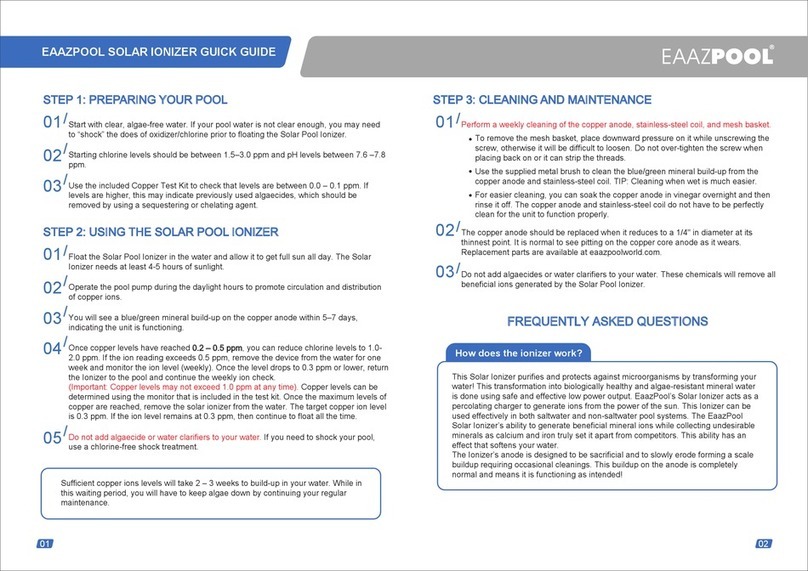

EAAZPOOL

EAAZPOOL SOLAR IONIZER manual

Terra Universal

Terra Universal IonBar Installation and operating guide

ITW

ITW Simco-Ion IQ Power Fantom Installation and operating instructions

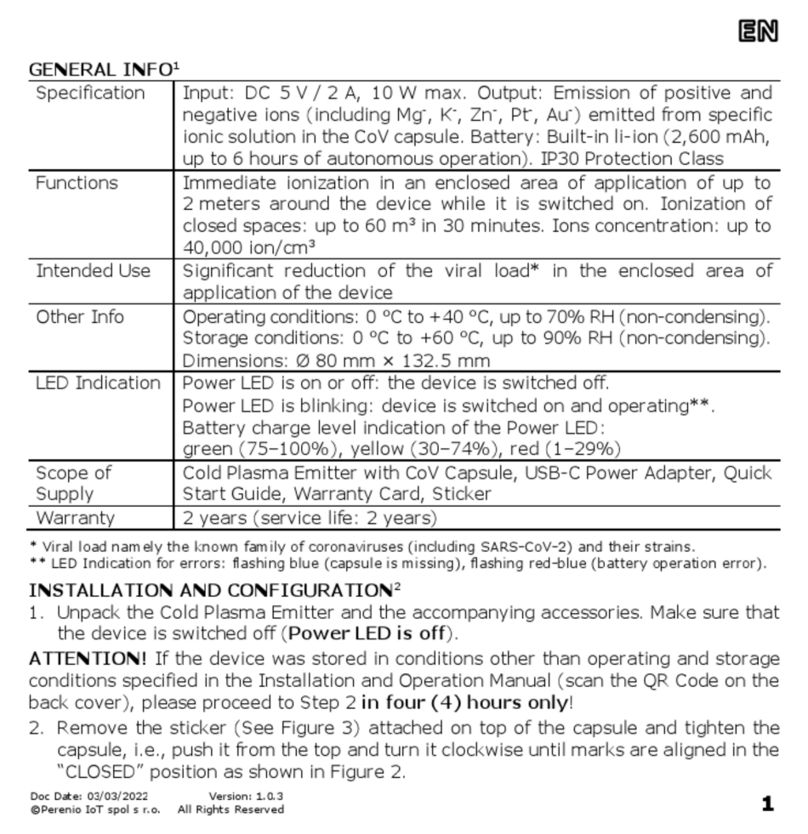

Perenio

Perenio IONIC SHIELD PEWOW01COVUK instructions

Meech

Meech 200 Series operating manual

Klarstein

Klarstein ST.-OBERHOLZ instruction manual

Desco

Desco Chargebuster 60640 Installation, operation and maintenance

Panasonic

Panasonic ER-F Series instruction manual

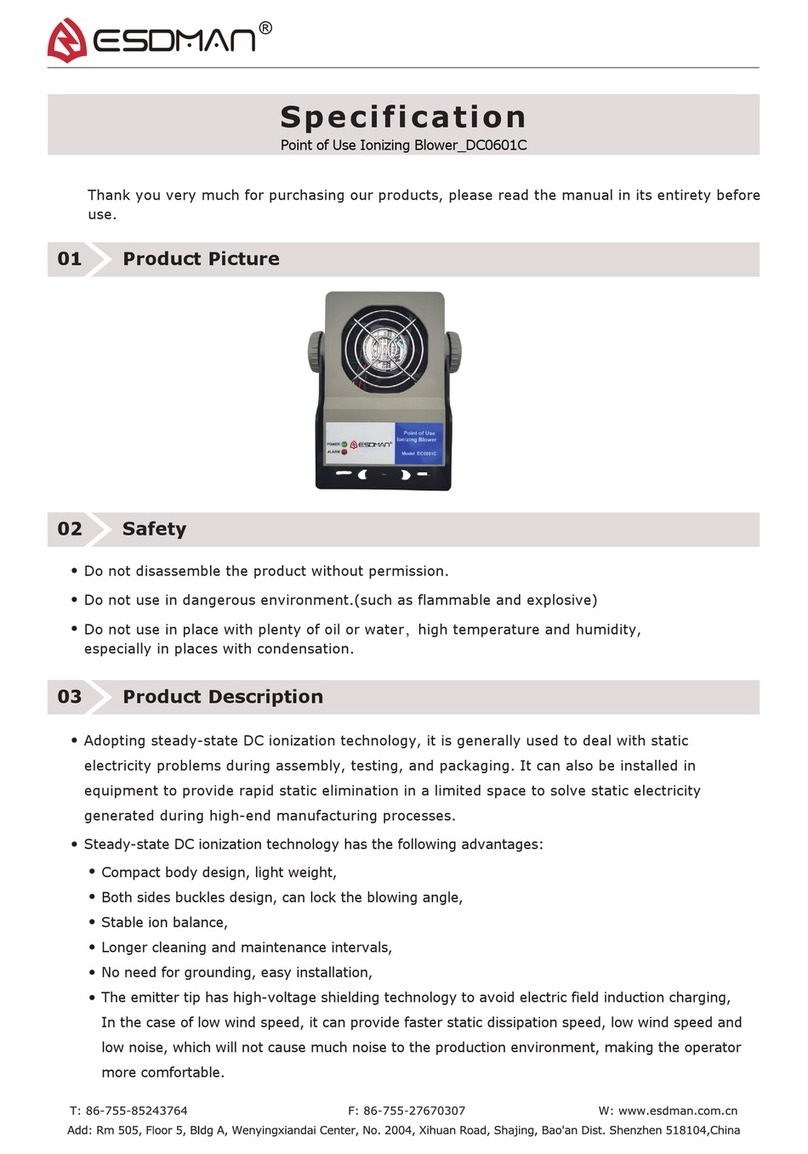

ESDMAN

ESDMAN DC0601C specification

GPS

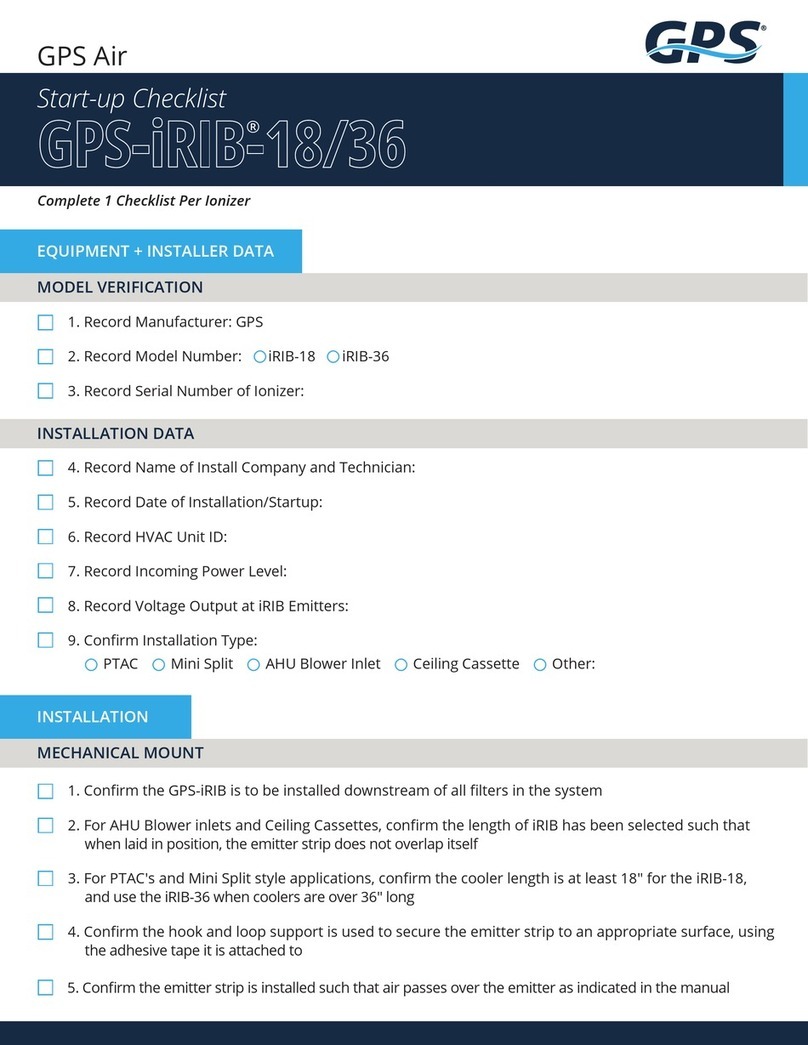

GPS iRIB-18 Start-Up Checklist

Desco

Desco 19500 Installation, operation and maintenance

Simco-Ion

Simco-Ion Ioncell Installation and operating instructions