Illinois Tool Works IJ4000 User manual

Operations

Manual

1 Missouri Research Park Drive • St. Charles, MO 63304 • Service Line 1-800-526-2531

Illinois Tool Works Inc © 2021

IJ4000 Impulse Jet System

5765-018

Revision J

IJ4000 Impulse Jet

Ink Jet System

Operations Manual

5765-018

The information contained in this manual

is correct and accurate at the time of its

publication. ITW reserves the right to

change or alter any information or

technical specifications at any time and

without notice.

©2021 Illinois Tool Works Inc.

All rights reserved

The IJ4000 Impulse Jet System, including all components unless otherwise specified, carries a limited warranty.

The inks and conditioners used with the IJ4000 Impulse Jet System carry a limited warranty.

For all warranty terms and conditions, contact Diagraph an ITW Company for a complete copy of the Limited Warranty

Statement.

Warranty:

IJ4000 System

Section 1: Safety and Ink Usage ..........................................................................................................................................................................6

Section 2: Quick Start ...........................................................................................................................................................................................7

Step 1: Assemble Bracketry to Conveyor ...................................................................................................................................................8

Step 2: Assemble Print Head onto Bracketry .............................................................................................................................................9

Step 3: Adjust Print Head to Substrate .....................................................................................................................................................11

Step 4: Install SMART-IDS ......................................................................................................................................................................12

Step 5: Install IJ4000-HMI Controller ......................................................................................................................................................15

Step 6: Electrical Cable Connections ........................................................................................................................................................16

Step 7: Install Tubing ................................................................................................................................................................................18

Step 8: Prime Ink Lines ............................................................................................................................................................................19

Step 9: Priming the Print Head and Testing Print Quality ........................................................................................................................21

Step 10: Mount Photosensor and Encoder ................................................................................................................................................24

Step 11: Configure the Print Head via the Controller ...............................................................................................................................25

Step 12: Create a Message ........................................................................................................................................................................27

Step 13: Print a Message ...........................................................................................................................................................................28

Section 3: Maintenance and Shutdowns ...........................................................................................................................................................29

System Maintenance .................................................................................................................................................................................29

Print Head Maintenance ............................................................................................................................................................................29

ACS - Automatic Cleaning System ..........................................................................................................................................................31

SMART-IDS Maintenance .......................................................................................................................................................................33

Section 4: Troubleshooting ................................................................................................................................................................................35

Print Quality ..............................................................................................................................................................................................35

IJ4000 Impulse Jet System Trouble-Shooting ..........................................................................................................................................38

Detailed Guide to Determine Proper Ink Flow Issue Resolution .............................................................................................................42

Appendix A: System Specifications ...................................................................................................................................................................48

System .......................................................................................................................................................................................................48

SMART-IDS ............................................................................................................................................................................................49

IJ4000-HMI Controller .............................................................................................................................................................................50

384E Print Head ........................................................................................................................................................................................51

768E Print Head ........................................................................................................................................................................................52

System Interconnect Diagram ...................................................................................................................................................................53

Customer System Connections .................................................................................................................................................................54

Appendix B: Theory of Operation ....................................................................................................................................................................55

Functional Description ..............................................................................................................................................................................55

Impulse Jet 384E and 768E Print Heads ...................................................................................................................................................55

Print Head Daisy Chain ............................................................................................................................................................................56

Print Trigger Photosensor .........................................................................................................................................................................56

Encoder .....................................................................................................................................................................................................56

SMART-IDS (Ink Delivery System) ........................................................................................................................................................57

SMART-IDS Ink and Vacuum Control PCB ...........................................................................................................................................64

Appendix C: Updating the HMI & SMART-IDS via USB or Ethernet ........................................................................................................71

Appendix D: InkJet Demo Software for Windows ..........................................................................................................................................71

Appendix E: Software Interface ........................................................................................................................................................................71

Appendix F: Part Numbers ................................................................................................................................................................................72

System .......................................................................................................................................................................................................72

Bracketry ...................................................................................................................................................................................................73

Fittings and Tubing ...................................................................................................................................................................................74

IJ4000-HMI ..............................................................................................................................................................................................74

IJ4000 SMART-IDS .................................................................................................................................................................................75

Cables ........................................................................................................................................................................................................76

Print Head Replacement Parts ..................................................................................................................................................................76

Consumables .............................................................................................................................................................................................77

Service Parts and Optional Equipment .....................................................................................................................................................78

IJ4000 Impulse Jet Section 1: Safety and Ink Usage

5765-018 Operations Manual Rev J Page 6

Section 1: Safety and Ink Usage

Following is a list of safety symbols and their meanings, which are found throughout this manual. Pay attention to these symbols where they

appear in the manual.

Wear safety goggles when performing the procedure described!

Caution or Warning! Denotes possible personal injury and/or damage to the equipment.

Caution or Warning! Denotes possible personal injury and/or equipment damage due to electrical hazard.

NOTE: (Will be followed by a brief comment or explanation.)

CAUTION: The SMART-IDS (Ink Delivery System) contains hazardous voltage (115/230VAC). Disconnect from mains power before:

• Performing preventive maintenance.

• Performing any repairs to the unit.

• Servicing the equipment in any manner.

ESD protection should be worn when servicing internal printed circuit boards.

After service to the equipment is completed, replace all protective devices such as grounding cables and covers before operating the equipment.

It is extremely important to:

• Clean up all spills with the appropriate conditioner immediately and dispose of all waste according to local and state regulations.

• Wear safety glasses and protective clothing, including gloves, when handling all inks and conditioners.

• Store inks and conditioners under the recommended conditions found on the SDS (Safety Data Sheet).

Service is to be performed by trained or ITW personnel only.

!

!

IJ4000 Impulse Jet Section 2: Quick Start

5765-018 Operations Manual Rev J Page 7

Section 2: Quick Start

The figure at right illustrates a typical installation with a controller and a print head. (Cables and ink lines are not shown.)

System Components:

• Bracketry Kit (Item 1)

• Print Head (Item 2)

•S

MART-IDS (Item 3)

• IJ4000-HMI Controller (Item 4)

• Power Cord (not shown)

• Serial Cable (not shown)

• Tubing (not shown)

• Software (not shown)

(Ink is not included.)

NOTE: See limitations in “Tubing Limitations -

Vertical” on page 13.

TYPICAL INSTALLATION

4

3

1

2

IJ4000 Impulse Jet Section 2: Quick Start

5765-018 Operations Manual Rev J Page 8

Step 1: Assemble Bracketry to Conveyor

NOTE: Mount bracketry as square and as level as possible.

PRINT HEAD

CONVEYOR MOUNT

(5765-246 for 384E Print Head)

(5765-253 for 768E Print Head)

HMI CONTROLLER /

SMART-IDS MOUNT

(5765-250) OPTIONAL T-STAND

(5765-249)

IJ4000 Impulse Jet Section 2: Quick Start

5765-018 Operations Manual Rev J Page 9

Step 2: Assemble Print Head onto Bracketry

ROLLER / RETRACTING

BRACKET MOUNT FOR

384E PRINT HEAD

(5765-246)

SINGLE-POLE FLOOR

MOUNT

(5760-355)

RETRACTING

BRACKET CAN BE

MOUNTED ON EITHER

SIDE OF PRINT HEAD

ROLLER / RETRACTING

BRACKET MOUNT FOR

768E PRINT HEAD

(5765-253)

IJ4000 Impulse Jet Section 2: Quick Start

5765-018 Operations Manual Rev J Page 10

Print Head Mounting Limitations

Print Head Tilt

Maximum Print Head Tilt:

• Clockwise Tilt: 5°

• Counterclockwise Tilt: 5°

NOTE: Tilt angles are given when looking at

the rear of the print head. Front to rear tilt

should be less than + 1.5°, as indicated by the

digital level LED readout on the top rear of the

print head.

AB

768E PRINT HEAD

27,2mm [1.07in] TO LOWEST ORIFICE

101,6mm [4in] SOLID

CHARACTER HEIGHT

CD

50,8mm [2in] SOLID

CHARACTER HEIGHT

ABC

22,9mm [0.90in] TO LOWEST ORIFICE

384E PRINT HEAD

± 5° MAX

± 5° MAX

IJ4000 Impulse Jet Section 2: Quick Start

5765-018 Operations Manual Rev J Page 11

Step 3: Adjust Print Head to Substrate

Use the bracket handle to adjust print head vertically.

Loosen the adjustment knobs on the Retracting Bracket to slide the print head toward or away from substrate.

BRACKET HANDLE

VERTICAL

ADJUSTMENT

ADJUSTMENT

KNOBS

3mm [.1in] GAP

RECOMMENDED

HORIZONTAL

ADJUSTMENT

IJ4000 Impulse Jet Section 2: Quick Start

5765-018 Operations Manual Rev J Page 12

Step 4: Install SMART-IDS

SMART-IDS

OPTIONAL FLOOR

MOUNT

IJ4000 Impulse Jet Section 2: Quick Start

5765-018 Operations Manual Rev J Page 13

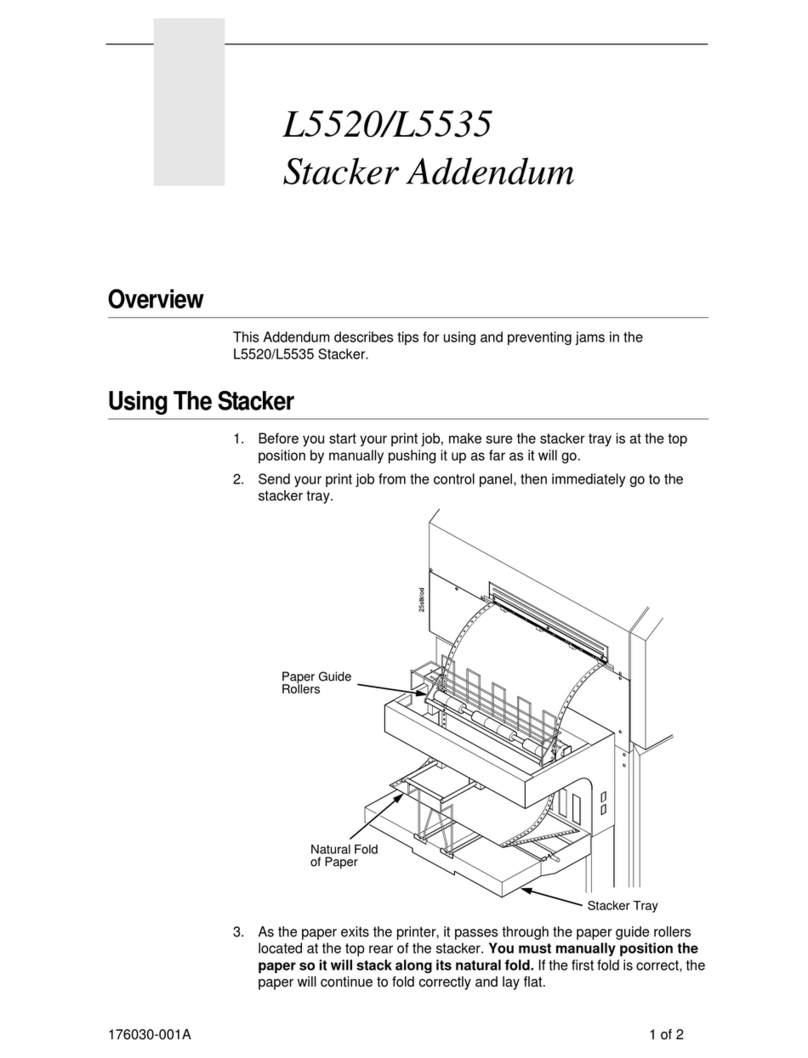

Tubing Limitations - Vertical

Best Practices

SMART-IDS

1.5m (5ft)

(Consult Factory

if longer)

HMI

Alternate Configurations

Conveyor

SMART-IDS

1m (3ft)

1m (3ft)

SMART-IDS

HMI

Conveyor

SMART-IDS

HMI

Conveyor

• Mount Smart-IDS below the height

of the print heads.

• Do not create service loops or coils

of tubing.

•Minimize length of tubing by cutting

to length.

IJ4000 Impulse Jet Section 2: Quick Start

5765-018 Operations Manual Rev J Page 14

Tubing Limitations - Horizontal

12,2m (40ft)

Maximum Total Tubing Length

1 Print Head

2 Print Heads

6,1m (20ft)

Maximum Total Tubing Length

768E Print Heads: 384E Print Heads:

1 Print Head

15,2m (50ft)

Maximum Total

Tubing Length

2 Print Heads

9,1m (30ft)

Maximum Total

Tubing Length

3 or 4 Print Heads

4,6m (15ft)

Maximum Total

Tubing Length

SMART-IDS

SMART-IDS

SMART-IDS

SMART-IDS

SMART-IDS

IJ4000 Impulse Jet Section 2: Quick Start

5765-018 Operations Manual Rev J Page 15

Step 5: Install IJ4000-HMI Controller

CONTROLLER

IJ4000 Impulse Jet Section 2: Quick Start

5765-018 Operations Manual Rev J Page 16

Step 6: Electrical Cable Connections

All controller cables must be routed through the Strain

Relief Cable Clamp in the bottom of the SMART-IDS.

1. Refer to the adjacent diagram for typical electrical

cable routing.

2. Connect all cables to their appropriate sockets.

(Refer to the following page for SMART-IDS internal

connectivity.)

3. Route and connect cables to the conveyor compo-

nents (print heads, encoder, photocell).

4. Customer system connections are made inside the

SMART-IDS. (Refer to the following page.)

NOTE: It is recommended that the Task 1 Print Head

be closest to the IJ4000-HMI.

5. Plug the SMART-IDS into the appropriate mains

power outlet.

NOTE: Ensure that the Smart-IDS is powered off. It will

be activated as part of the ink line bleeding procedure.

SMART-IDS

PRODUCT DIRECTION

IJ4000-HMI

CONVEYOR

ENCODER

PRINT HEAD CABLES

PRINTHEAD

STRAIN RELIEF

CABLE CLAMP

OPTIONAL

BEACON

POWER CORD

PHOTO

SENSOR

PRINTHEAD

PRINTHEAD

PRINTHEAD

PRINT

HEAD

CABLES

NOTE: Connect IDS

directly to upstream

print head.

IJ4000 Impulse Jet Section 2: Quick Start

5765-018 Operations Manual Rev J Page 17

SMART-IDS

INTERNAL CIRCUIT

BOARDS

I/O CABLE FROM

SMART-IDS

PHOTOSENSOR /

ENCODER

CABLE

TASK 2 INTERFACE

BOARD CONNECTIONS

TASK 1 INTERFACE

BOARD CONNECTIONS

PRINT HEAD

CABLES

POWER

CORD

* CUSTOMER SYSTEM CONNECTIONS

(See Appendix A for details)

COM2 *

OPTIONAL I/O BOARD

ENCODER /

PHOTOSENSOR

CABLE

NOTE: In many applications,

Photocell and Encoder may be

shared from Task 1 to Task 2

USB / FILE BACKUP &

TRANSFER ACCESS

ETHERNET

/ HMI *

COM1 *

IJ4000 Impulse Jet Section 2: Quick Start

5765-018 Operations Manual Rev J Page 18

Step 7: Install Tubing

NOTE: Do not attempt plumbing this sys-

tem before all mechanical mounting is

completed.

1. After mechanical mounting is com-

pleted for the SMART-IDS and the

print heads, remove all vent caps and

install the supplied filter.

2. Route all ink and vacuum lines, and

connect lines at the SMART-IDS.

Refer to diagram at right for typical

print head plumbing connections.

NOTE: Do not connect lines to print

heads at this time.

4,6mm [15ft] MAX

VACUUM

INK

CONVEYOR

PRINT HEAD PRINT HEAD

TEE FITTING

(2460-120)

DO NOT CONNECT

TO PRINT HEAD YET

DO NOT CONNECT

TO PRINT HEAD YET

INK FITTING

(5361-329)

SMART-IDS

INK

VACUUM

FILTER

REMOVE AND

SAVE CAP

REMOVE AND

SAVE ALL 3 CAPS

VACUUM

FITTING

(5765-721)

INK

OUTLET

VENT

VACUUM

PORT

STRAIGHT

FITTING

(5765-719)

CHECK VALVE

(5765-720) STRAINER

(5765-713)

"Y" FITTING

(5765-717)

VACUUM

FITTING

(5765-721)

ONLY USED

TO PRIME

INK LINES

CAUTION

REMOVE

INSTALL

FILTER

CAP

RED

INCORRECT

CORRECT

IJ4000 Impulse Jet Section 2: Quick Start

5765-018 Operations Manual Rev J Page 19

Step 8: Prime Ink Lines

CAUTION:

• Ensure all vent caps, top and bottom, have been removed from the print head(s) and SMART-IDS.

• Ensure no tubing is connected to the print heads.

1. Remove the foil seal on the ink bottle and install it into the SMART-IDS reservoir. Clean and save

the reservoir cap.

NOTE: Never mix ink types because they are not miscible. Irreversible internal damage will occur.

2. Turn on the SMART-IDS.

3. At the print head located nearest the SMART-IDS, connect the ink supply and vacuum fittings to

each other to form a loop.

4. The SMART-IDS vacuum cycle will be running as the print heads come up to temperature.

5. Disconnect the loop as soon as ink has flowed through the connected fittings. Wipe off both con-

nectors.

6. Cut off the vacuum line fitting (5765-721) noted in red on the previous page. Remove the plug

from the print head vacuum line and push the now raw tubing end into the print head vacuum fit-

ting.

NOTE: It is critical that all air be purged out of the ink lines prior to connection to the rear of the print heads.

7. Form a loop for the next closest print head. If the vacuum cycle is still running, allow ink to pass through the loop. Follow steps 5 and 6.

8. If the vacuum cycle stops running and ink lines need to be primed, form the fitting loop at the next print head, then press and hold the ACS/

Prime button on the back of the print head for five (5) seconds. This starts a PRIME cycle. Follow steps 5 and 6.

9. Prime remaining ink supply tubing, following the steps above.

10. Level print heads and secure cables and tubing lines according to diagrams on the next page.

CAUTION

REMOVE

INSTALL

FILTER

CAP

RED

INK QUICK-

DISCONNECT

VACUUM QUICK-

DISCONNECT

CONNECTED

!

IJ4000 Impulse Jet Section 2: Quick Start

5765-018 Operations Manual Rev J Page 20

Confirm the print head(s) are level. The green LED indicates head is level. (384E Print Head is shown.)

WHEN UPPER LED IS

RED, PRINT HEAD IS

POINTED UP TOO FAR

WHEN CENTER LED IS

GREEN, PRINT HEAD IS

READY TO PRINT

WHEN LOWER LED IS

RED, PRINT HEAD IS

POINTED DOWN TOO FAR

BRACKETRY KITS COME

WITH TIE WRAP MOUNTS

INSERT TIE WRAP MOUNT IN

BAR AND TURN 90°. INSERT

TIE WRAPS INTO MOUNTS.

FORM AN 8" MINIMUM

SERVICE LOOP FOR

TUBING AND CABLE.

Table of contents

Other Illinois Tool Works Printer manuals