Illinois Tool Works 5750-440 User manual

Ink Jet Printer

Operations Manual

5750-440

Revision D

English

Prompts in some languages do not fit inside the twenty-character lines of the liquid crystal display.

When a prompt extends beyond twenty characters, the full text of the prompt appears in this book.

Always check this book when you are uncertain about the meaning of a prompt on the display.

OPERATIONS MANUAL – 5750440 – REVISION D

Not for use in a computer room as

defined in the Standard for the

Protection of Electronic

Computer/Data Processing

Equipment, ANSI/NFPA 75.

Ne peut être utilissé dans une salle

d’ordinateurs telle que définie dans

las norme ANSI/NFPA 75 Standard

for Protection of Electronic

Computer/Data Processing

Equipment

The information contained in this manual is

correct and accurate at the time of its

publication. Illinois Tool Works reserves the

right to change or alter any information or

technical specifications at any time and

without notice.

© 2005 Illinois Tool Works Inc

All rights reserved.

Printed in the United States of America

OPERATIONS MANUAL – 5750440 – REVISION D

Table of Contents

Warranty & Introduction

SAFETY ................................................................ i

Ink Jet Printer Features...................................... ii

Controller ........................................................... iii

Basics A

Printing a Message...........................................A1

Creating a Simple Message.............................A2

Editing a Message ............................................A3

Deleting a Message ..........................................A4

Viewing System Information ...........................A5

Frequently Asked Questions...........................A6

Maintenance B

Loading Ink .......................................................B1

Purging All Channels ......................................B2

Purging a Single Channel................................B3

Purging With Conditioner................................B4

Broaching the Orifice.......................................B5

Startups & Shutdowns.....................................B6

Changing Ink Colors ........................................B7

Adjusting the Screen Contrast........................B8

Resetting Factory Defaults .............................B9

Print Adjustments C

Changing an Individual Message Indent ........C1

Setting the Default Message Indent................C2

Changing Character Width in a Message.......C3

Setting the Default Character Width ...............C4

Changing the Printed Dot Size........................C5

Changing the Font in a Single Message.........C6

Changing the Default Font...............................C7

Rotating the Message ......................................C8

Adjusting a Single Dot Diameter.....................C9

First Dot Adjustment .....................................C10

Sizing Dots in Columns .................................C11

Setting Message Variables D

Setting the Date ................................................D1

Setting an Expiration Date...............................D2

Setting the Time ...............................................D3

Setting Work Shifts ..........................................D4

Setting the Shift Start (Code Date)..................D5

Setting the Item Count .....................................D6

Setting a Pallet Count ......................................D7

Placing Variables in Messages E

Placing the Date in a Message ........................E1

Placing the Expiration Date in a Message..... E2

Placing the Time in a Message....................... E3

Placing a Work Shift in a Message................. E4

Placing an Item Count in a Message.............. E5

Placing a Pallet Count in a Message.............. E6

Using Alternate Characters ............................ E7

System Operation F

Selecting a Language.......................................F1

Setting the Date ................................................F2

Setting Units of Measure..................................F3

Setting the Print Mode......................................F4

Setting the Message Gap .................................F5

Setting the Box Length ....................................F6

Setting the Print Speed ....................................F7

Setting the Print Direction ...............................F8

Using a Password.............................................F9

Using the External Photocell Model..............F10

Sample Messages G

New Message ................................................... G1

Message with Date and Count........................ G2

Message with Expiration Date ........................ G3

Message with Alternate Characters ............... G4

Wide Message with Time Mark ....................... G5

Message with Pallet and Item Count.............. G6

Troubleshooting H

Not Printing ...................................................... H1

Unsatisfactory Print......................................... H2

Printhead Leaking............................................ H3

Printhead Preload Adjustment ....................... H4

Ink Regulator Maintenance Procedure .......... H5

Alternate Ink Regulator Maintenance............. H6

System Specifications App A

Controller/Ink Delivery System....................... A1

Printhead .......................................................... A2

Parts and Supplies App B

Service Parts Kits ............................................ B1

Consumables ................................................... B2

Assembly Drawings......................................... B3

Theory of Operation App C

Mechanical ....................................................... C1

Electrical........................................................... C2

OPERATIONS MANUAL – 5750440 – REVISION C

OPERATIONS MANUAL – 5750440 – REVISION D

Warranty

The Ink Jet System (excluding printhead) carries a 365 day limited warranty from the date of shipment.

The Printhead carries a 180 day limited warranty from the date of shipment. For all terms and

conditions, refer to the full warranty statement packaged with the Ink Jet Printer.

Use of the wrong fluid type in the system is not covered under warranty.

Introduction

NOTE: This manual describes operation of both the porous (water-based) and non-porous (alcohol-

based) printers. Water-based fluids can NOT be used in non-porous (alcohol-based) systems. Alcohol-

based fluids can NOT be used in porous (water-based) systems.

The ink jet printing system is compact and easy to use. It prints a single line of alphanumerics at

speeds as slow as 5 fpm and as fast as 250 fpm. Print quality is excellent and it offers message

control and printhead flexibility. There are three font choices: 5-dot (3/8”), 7-dot (1/2”) and 7-dot bold

and it can print with multiple fonts on the same line. The ink is contained in a 13 fluid ounce (392 ml)

pressurized canister. Ink canisters can be replaced without interrupting production. You can choose

from six high-visibility ink colors: black, blue, green yellow, orange and red.

The printhead has patented I.V. (Integrated Valve) print technology and individual dot control

capability, resulting in better print quality. Ink does not touch the internal electronics of the printhead,

ensuring long-term operational reliability. It has flexible mounting and a dual-axis 180° rotation that

allows printing on the side, top or bottom of cartons as well as printing on inclined surfaces. There are

two built-in photosensors that measure speed and direction and are located in the face of the

printhead. The printhead requires daily maintenance measures (purging) performed at the beginning

of the work day, and following an extended shutdown of a week or more.

The controller offers a QWERTY keypad with ALT key for multiple key combinations, separate

number keys, icon function keys, four keys for cursor control and four LEDs (that warn or show status

of power, photosensor, print mode and low ink). It has autocode capabilities that allow for

Julian/Gregorian date, time sequential numbering, shift, item count, pallet/batch count and expiration

date. It also has message storage capabilities of 99 fifty-character messages and an “ink out” alarm.

Tubing comes attached to the controller and connects to the back of the printhead. A power supply

unit connects to the controller and sets in a holster on the mounting bracket.

OPERATIONS MANUAL – 5750440 – REVISION D

SAFETY i

Following is a list of safety symbols and their meanings, which are found throughout

this manual. Pay attention to these symbols where they appear in the manual.

Wear safety goggles when performing the procedure described!

!

Caution! Denotes possible personal injury and/or damage to the

equipment.

Caution! Denotes possible personal injury and/or equipment damage

due to electrical hazard.

NOTE: (Will be followed by a brief comment or explanation.)

CAUTION: Turn off the equipment’s main power before:

•Performing preventive maintenance.

•Performing any repairs to the unit.

•Servicing the equipment in any manner.

ESD protection should be worn when servicing internal printed circuit boards.

After service to the equipment is completed, replace all protective devices such as

grounding cables and covers before operating the equipment.

It is extremely important to:

•Refer to your supervisor for complete instructions on personal protective

equipment (PPE) required to work safely with this system.

•Read the MSDS (Material Safety Data Sheet) and follow its instructions for proper

storage, handling and disposal of inks and conditioners.

OPERATIONS MANUAL – 5750440 – REVISION D

Ink Jet Printer Features ii

The Ink Jet Printer has a variety of features that make it uniquely suited to print in industrial printing

applications.

•Self-contained printing system for marking products moving on conveyors.

•Adjustable printhead that allows for side, top, or inclined conveyor printing at line speeds up to 250

feet (76 meters) per minute.

•Prints characters up to seven dots high, one half-inch tall.

•Ink supply system from a pressurized can. Cans can be changed during operation for uninterrupted

printing.

•Detects product direction and speed of movement with photosensors mounted in the front of

printhead. An external photosensor option is available.

•Prints one message per item or many messages per item.

•Twelve function keys for easier editing and system operation.

•Built-in count, shift, time and date codes including expiration dates.

•Prints in three different fonts: 3/8 inch (9.5 mm), 1/2 inch (12.7 mm) and 1/2 inch (12.7 mm) bold.

•Screen menus in multiple languages.

•Two-line, twenty character per line, liquid crystal display.

•Power supply operates on 100 to 240 VAC input.

•May be used between 40° F (4.4° C) and 110° F (43.4° C).

•Modular printhead design that incorporates Quick Disconnects for easy maintenance.

•Modular spare parts kits for easy maintenance.

•Long printhead bracket for easy printing on top of a product.

•Ink and electronics are separated throughout the system to ensure reliability and industrial

durability.

•Ink available in several colors: Black, Blue, Green, Red, Orange and Yellow.

•Supplies available worldwide.

OPERATIONS MANUAL – 5750440 – REVISION D

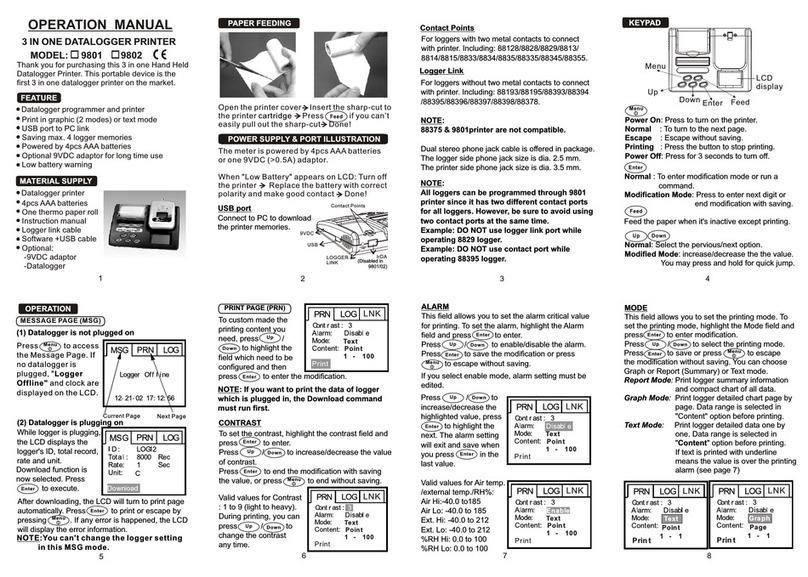

Controller iii

DISPLAY

1Two-line, twenty character per line, liquid

crystal display (LCD).

LEDs

2Power LED; lit when the printer has power.

3Photo-eye LED; on while a product passes by.

4Print LED; lit when the printer is in print mode.

5Ink out LED; blinks when the ink can is out of ink.

FUNCTION KEYS

6PRINT: Starts and stops printing.

7EDIT: Create, edit or delete a message.

8PURGE: Purge all ink channels; with ALT

(24), it purges single channels.

9MESSAGE INDENT: Sets the message

indentation from the leading edge of the

product.

10 FONT: Selects the font to print.

11 TIME: Inserts the printed time into a message.

With ALT (24), it inserts a work shift code..

12 SET-UP: For configuration of the system.

13 INFORMATION: Provides status and setting

information.

14 DOT SIZE: Increases or decreases all dot

sizes at once.

15 CHARACTER WIDTH: Changes the width of

printed characters which produces changes in

the length of printed messages.

16 DATE: Inserts the date into a message. With

ALT (24), it inserts an expiration date.

17 ITEM COUNT: In print mode, it shows the last

count for Item, Pallet and Total; in edit mode,

it inserts the item count into a message. With

ALT (24), it inserts a pallet count.

NUMERIC KEYPAD

18 Keys for number entry which will show alternate

characters when scrolled with the arrow keys

EDIT KEYS

19 DELETE: Erases the character under the cursor and

does not repeat.

20 BACKSPACE: Deletes the character to the left of the

cursor and will continue to delete when held down.

21 ENTER: Completes entries and enacts changes.

ARROW KEYS

22 Keys that provide cursor movement and screen

scrolling.

ALPHABETIC KEYS

23 Keys for character entry. Each character will show

alternate characters when scrolled with the up and

down arrow keys.

ALTERNATE KEYS

24 ALT: Provides alternate characters and functions when

used in combination with other keys.

25 ENTER: This key duplicates the function of key 21

SPACE BAR

26 Enters spaces in messages; can be scrolled with the

up and down arrows to show alternate characters

Alt

Z X C V B N M / ( “

A S D F G H J K L :

W E R T Y U I O PQ

.0-

1 2 3

4 5 6

7 8 9

i

ABC

ABC

1 2 123

1

23 4 5

678910 11

17

1615

14

19

13

21

20

12

18

23

24 26 25

22

OPERATIONS MANUAL – 5750440 – REVISION D

Basics A

Printing a Message A1

1

1

Press PRINT and the LCD will show

“1-Print” and “2-Stop Print”.

2

2

Press 1 and the LCD will show the

name of the last message printed and

its corresponding text.

The screen example above shows

the message created at the factory.

3

3

Scroll until the

message to print

appears on-screen.

4

4

Press ENTER to print.

5

5

Press 2 to stop printing.

The print sample below is the default message printed with controller default settings.

This feature is a part of sample message G1.

1-Print

2-Stop Print

Name: TEST 123

TEST 123<

1

5

2

3

4

OPERATIONS MANUAL – 5750440 – REVISION D

Creating a Simple Message A2

1

1

Press EDIT and the LCD will show “1-

Press 1 and the LCD will prompt for a

name for the new message.

3

3

Type a name and press ENTER.

4

4

Type a simple message of letters and

numbers only, no codes. Correct

mistakes with DELETE and

BACKSPACE.

5

5

Press ENTER to finish the message. The LCD will offer three choices:

6

6

Press 1 to save the new message.

This feature is a part of sample message G1, G2, G3, G4 and G5.

Name:

<

Name:

TESTMESSAGE<

Editing…

123TESTING123<

1-Save:TESTMESSAGE

2-Cancel chan

g

es: T↓

2-Cancel changes: TE

3-Edit: TESTMESSAGE

NOTE: a down arrow on the

LCD indicates that this menu

has more than two selections.

1

3

2

4

5

OPERATIONS MANUAL – 5750440 – REVISION D

Editing a Message A3

1

1

Press EDIT and the LCD will show “1-New

Message” and “2-Edit Message.”

2

2

Press 2 and the LCD will show a message. If you

want to edit the message on-screen, press

ENTER.

If you want to edit another message, scroll until

your message appears and press ENTER.

3

3

Type changes. Use BACKSPACE and DELETE to

remove unwanted characters.

4

4

Press ENTER to finish editing. The LCD will offer

three choices:

5

5

Press 1 to save the edits.

This feature is a part of sample message G1, G2, G3, G4 and G5.

Deleting a Message A4

1

1

Press EDIT.

2

2

Press 3 for “Delete Message.” The LCD will show the name of a

message and its content.

3

3

Scroll until the message to delete is on-screen.

4

4

Press ENTER. The LCD will prompt to cancel the changes or delete the

message:

5

5

Press 2. The message is now deleted and the LCD shows the Edit

screen:

Name:TESTMESSAGE

123TESTING123<

Name:MESSAGE

MESSAGE<

Name:TEST MESSAGE

12134567890<

1-Cancel Changes:TE

2-Ok. Delete: TEST M

2-Edit Message

3-Delete Message

1-Save:TESTMESSAGE

2-Cancel changes: T↓2-Cancel changes: TE

3-Edit: TESTMESSAGE NOTE: A down arrow on

the LCD indicates that this

menu has more than two

selections.

1

4

3

2

OPERATIONS MANUAL – 5750440 – REVISION D

Viewing System Information A5

1

1

Press INFORMATION.

2

2

Scroll up and down to see all choices.

3

3

Press ENTER at any menu entry to see the associated detail. The chart below

left shows all prompts with explanatory notes.

4

4

Press ENTER when done.

Menu Selection Explanation

1-Unused Messages This selection shows the number or available messages. The system can

store 99 messages.

2-Date This selection shows the date currently set in the system in the year,

month and day format.

3-Time This selection shows the time set in the system in hours, minutes and

seconds.

4-Print Speed This selection shows the speed recorded by the photosensors during the

last printing session.

5-Item Count This selection shows the number of times the current message has been

printed.

6-Version This selection shows the version of firmware in your controller.

7-Support/Supplies This selection displays information on supplies and support for your Ink Jet

printer.

Frequently Asked Questions (FAQs) A6

Q1 How do I create a message?

A1 Follow the directions in Instruction A2, “Creating a Simple Message”. See G1 for an example of a

new message.

Q2 How do I change the parameters of a message I have already created?

A2 See Instruction A3, “Editing a Message.” Determine what variables are in your message such as

Item Count (E5) and Date (E1) and review Section D that explains how to set variables and

Section E that explains how to insert variables in messages.

Q3 How do I select and print a message?

A3 1Press PRINT.

2Press 1. The top line of the LCD will show the name of the message and line two will show the

message contents.

3 Scroll through message names until you find the one to print.

4Press ENTER to print.

Q4 What do I do if my print quality does not match the quality of the print sample supplied

with the unit?

A4 Determine exactly how your print differs from the supplied sample. Is it too light? Is it missing

dots? Look in Section H, “Troubleshooting” to find the solution to your printing problem.

Name: MESSAGE

MESSAGE<

OPERATIONS MANUAL – 5750440 – REVISION D

Frequently Asked Questions (FAQs) continued A6

Q5 If I am using sequential numbers while printing and stop the print, what number will the

print start with when I send it to print again?

A5 The numbers will start over again. Specifically, they will begin with the starting number specified

in either “Setting the Item Count (D6)” or “Setting a Pallet Count (D7)”.

Q6 What do I do if I see no image printed on the substrate but I see that the message has been

sent to print?

A6 See Section H, “Troubleshooting.”

Q7 How far will the built-in photosensors "see"?

A7 The photosensors should be placed no farther than one-quarter inch from the product.

Q8 What do I do if the unit is printing in the wrong area on the case or between cases?

A8 See Section H, “Troubleshooting.”

Q9 What do I do with the unit if I won't be using it for a week or more?

A9 Purge the system with conditioner. See Instruction B4 for details on flushing.

Q10 Can I turn the printhead straight up and print on the bottom of the product?

A10 No.

Q11 Can I print upside down?

A11 Inverted printing requires no changes in position of the printhead or its bracket—the controller has

been programmed to print upside down messages. Follow the directions in Instruction C8,

“Rotating the Message.”

Q12 What happens if I unplug the unit?

A12 The controller memory retains your messages and parameters.

Q13 How often should I purge?

A13 Purge at the start of each workday or more often in dusty environments.

Q14 Do I have to stop printing to put in a new can of ink?

A14 No. There is enough ink in the ink delivery system to allow continuous printing while you install a

new can of ink.

Q15 If I get lost in a menu, what button should I press to find my way again?

A15 INFORMATION ( )is a safe key to press if you are unsure about editing, printing or working in

the Set-Up menu. Some of the other function keys such as Date and Time, will not let you out of

the menu until you have entered a value or pressed ENTER.

Q16 The character I want to print isn’t on the keyboard.

A16 All alphabetic and numeric keys on the keypad can display alternate characters when used with

the up and down arrows. The English vowel set and the consonants C, N and Y have alternate

characters with phonetic marks such as the umlaut (¨) and the acute accent (´). All consonant

keys provide access to the entire alphabet in both uppercase and lowercase. The punctuation

keys provide multiple punctuation marks. Follow the directions in Instruction E7, “Using Alternate

Characters” to create messages with characters not on the keyboard.

OPERATIONS MANUAL – 5750440 – REVISION D

OPERATIONS MANUAL – 5750440 – REVISION D

Black Adapter

for Porous

Black Receiver

for Porous

Red Adapter

for Non-Porous

Red Receiver

for Non-Porous

Maintenance B

Loading Ink B1

Do not stop printing when you run low on ink. The system has enough ink in its delivery system to

continue printing until you install a fresh can.

1

1

Unscrew the old can and set aside.

2

2

Remove the cap from the new can, invert and screw into

the ink receptacle. Make sure that the ink can adapter and

the receiver on the ink delivery system are the same color.

Black adapter and black receiver indicate water-based

porous.

Red adapter and red receiver indicate alcohol-based

non-porous.

3

3

Dispose of the old can in accordance with local, state and

federal regulations.

CAUTION

1. Use only water-based

porous inks, identified

with black fittings, for

porous printers with

black receivers.

2. DO NOT SHAKE THE

INK CAN.

NOTE: When the ink can empties, ink

pressure drops below normal operating

pressure. This causes ink to collect on the

face plate. The face plate should be

cleaned every time the ink can is replaced.

CAUTION

1. Use only alcohol-based

non-porous inks, identified

with red fittings, for non-

porous printers with red

receivers.

2. DO NOT SHAKE THE INK

CAN.

OPERATIONS MANUAL – 5750440 – REVISION D

1

2

Purging All Channels B2

Purge the printer at the start of the workday.

1

1

Hold a disposable towel in front of the printhead.

2

2

Press PURGE.

The printhead will expel ink for approximately two

seconds.

Continue to press PURGE if you a want a long

purge of ink.

3

3

Clean the face of the printhead with Maintenance

Spray.

Purging a Single Channel B3

Purge a single channel when a dot is missing or

undersized.

1

1

Press and hold ALT and PURGE.

2

2

Press the corresponding numeric key to select a

channel to purge.

3

3

Hold a disposable towel in front of the printhead.

4

4

Press PURGE.

The printhead will expel ink for approximately

two seconds.

5

5

Spray the face of the printhead with Maintenance

Spray.

6

6

Press ito exit or enter another channel to purge

and repeat steps 3 and 4.

Dot: 7

Press i to exit

Hold for long purge

Purge 96/100<

3

1

6

1

OPERATIONS MANUAL – 5750440 – REVISION D

Purging with Conditioner B4

Extended shutdowns will require purging the

printhead with conditioner.

1

1

Remove the ink canister and attach a canister

of conditioner.

2

2

Hold a lint-free disposable cloth in front of the

printhead.

3

3

Press PURGE.

4

4

Continue to press PURGE until the expelled

fluid is clear.

5

5

Remove the conditioner and attach the ink

canister.

Broaching the Orifice B5

If a printhead orifice is clogged or obstructed, and wiping the front plate and purging will not clear it, the

appropriate orifice should be broached.

1

1

Make sure the broach pin does not extend out of the handle any more than

0.10 inch.

2

2

Wipe the front plate clean with a cloth and conditioner.

3

3

Identify the clogged orifice by identifying the missing dot(s) from a print

sample.

4

4

Count the orifices one the front plate up or down until you locate the

clogged orifice. A flashlight or other concentrated light source will help, as

the orifices are very small.

5

5

Carefully insert the broach pin in the clogged orifice until the handle

touches the front plate. Remove the broach pin from the orifice and create

a print sample.

6

6

If the print sample shows that the orifice is still

clogged, purge the printhead and make a second

print sample.

7

7

If the orifice is still clogged, count the orifices

again to make sure that you are broaching the

correct orifice, then repeat steps 5 and 6.

1

2

3

4

5

6

7

(Missing Dots)

.010”

3

2

OPERATIONS MANUAL – 5750440 – REVISION D

Startups & Shutdowns B6

Overnight Shutdown

To keep the printheads running smoothly, spray the printhead face

with Maintenance Spray and use a cloth to catch the fluid as it runs off the

faceplate.

DO NOT WIPE THE FACEPLATE.

Overnight Startup

Spray Maintenance spray onto a clean, lint-free cloth and wipe the face

plate of the printhead. Purge with ink by pressing PURGE. If any of the

channels are not ejecting ink, follow the directions on B3, Purging a Single

Channel.

Shutdown for Seven Days or More

For shutdowns lasting a week or longer, it may be necessary to flush all

printheads with Conditioner. Flush and thoroughly purge the printhead.

Keep a cloth handy for wiping up excess ink.

1

1

Remove the ink can and attach the effluent bottle kit (5750-503) to the

male fitting on the back of the printhead. Make sure that the valve on the

effluent line is closed.

2

2

Insert a can of Conditioner in the ink receptacle.

3

3

Open the valve in the effluent line. Allow the liquid to empty into the

effluent bottle until it runs clear.

4

4

Close the valve in the effluent line and disconnect it from the ink outlet in

the back of the printhead.

5

5

Hold a clean wipe in front of the printhead and press PURGE several times

to clean printhead orifices.

6

6

Insert the ink can.

If You Purchased Spare Printheads

Spare printhead(s) should be circulated into operation on a regular basis. Rotate the printheads every

couple of months to keep them performing up to expectations. Rotating spare printheads prevents

hardening of the internal printhead components, making startup much easier. Before returning a spare

printhead to the shelf, please be sure to thoroughly flush with conditioner.

CAUTION

1. Use only water-based

porous inks, identified

with black fittings, for

porous printers with

black receivers.

2. DO NOT SHAKE THE

INK CAN.

CAUTION

1. Use only alcohol-based

non-porous inks, identified

with red fittings, for non-

porous printers with red

receivers.

2. DO NOT SHAKE THE INK

CAN.

OPERATIONS MANUAL – 5750440 – REVISION D

Changing Ink Colors B7

Changing colors of ink requires complete flushing of the

printhead.

1

1

Disconnect the original can of ink.

2

2

Attach the effluent bottle kit to the male OUT fitting on

the back of the printhead (A). Make sure that the

valve on the effluent line is closed (B).

3

3

Insert a can of conditioner in the ink receptacle.

4

4

Open the valve (B) in the effluent line. Allow the liquid

to empty into the effluent bottle (C) until it runs clear.

5

5

Close the valve on the effluent line.

6

6

Remove the can of conditioner and insert the can of

ink with the new color.

7

7

Open the valve on the effluent line and allow the fluid

to run out until the color is undiluted. Turn off the

valve.

8

8

Disconnect the effluent line from the back of the

printhead. Clean up any drips with a lint-free wipe.

9

9

Hold the wipe in front of the printhead and press

PURGE repeatedly until the printhead ejects

undiluted ink.

B

c

A

OPERATIONS MANUAL – 5750440 – REVISION D

Adjusting the Screen Contrast B8

You can change the contrast on the LCD

by using the UP and DOWN arrows with

ALT.

1 Press and hold ALT and the DOWN

arrow. Hold for at least five seconds.

The screen contrast will gradually dim.

2 Press and hold ALT and the UP arrow.

Hold for at least five seconds. The

screen contrast will gradually become

sharper.

Resetting Factory Defaults B9

If you want to reset your printer to factory defaults,

unplug the controller. If you want to see the factory-

default values before you change the settings, look at

the label on the printhead that shows the values set in

final assembly for optimal performance.

1

1

Press and hold ALT and the decimal point on the

numeric keypad.

2

2

Reconnect power. Release the keys when the LCD

asks if you want to “Erase All Messages?”

3

3

Make your selection and press ENTER.

The controller will initialize and you must set a

language for the LCD, the date, the time and the

units of measurement.

Erase all messages?

1-No 2-Yes :2

Table of contents

Other Illinois Tool Works Printer manuals