Illuminating Perception LiftLyte 1000 Instruction manual

LiftLyte Operating Manual - DCNMAN101814 Rev. 3

22

Important!

Read this entire document before attempting to install your LiftLyte™

Introduction

As a unique alternative to hand held lights, the LiftLyte™ is designed to provide service personnel and car

enthusiasts with a highly effective, full range, under vehicle lighting system. High intensity automobile trouble lights

produce glare and deep shadows that can mask problem areas. Flashlights, floodlights and daylight all share this

same issue.

The LiftLyte™ uses LED Strip Technology to produce a bright, uniform no-glare light devoid of obscuring shadows.

The system is designed to be installed on the side rails of vehicle lifts or the side walls of inspection pit areas. Even in

the brightest of day time conditions, the LiftLyte can and will be highly effective. Service personnel can effectively and

rapidly scan the vehicle underside, assisting them in searching out trouble areas or for general maintenance purposes.

Before

After

Special LiftLyte Features

•Full area illumination.

•No shadows.

•Plug and Play installation. No hand tools required.

•Eliminates lamp or filament breakage in demanding work applications.

•Over 30,000 hours of lamp life resulting in lower maintenance costs.

•Resists vibration, impact, sudden movements and shock.

•Efficient light transmission and emission.

•Pre-determined light emission pattern for maximum effectiveness.

•Environmentally protective coatings for maximum durability and long life.

Components Provided

Item

Qty.

DWG Ref No.

Product Part Number

Light Strip (Magnetized or double stick tape)

2

1

SUB2-090 Rt. or Lt.

AC Transformer Power Supply

1

2

SUB2-091

Primer Stick (for double stick tape version only)

6

3

M9N-089

Self-Adhesive Tie Down Points

8

N/A

C9N-039

Zip Ties

10

N/A

C9N-011

Self-Adhesive Velcro Tape (optional for mounting Switch)

1

N/A

N/A

LiftLyte Operating Manual - DCNMAN101814 Rev. 3

3

Figure 1: LiftLyte™ Main Components

Installation Procedure

Before starting the installation of the LiftLyte™, understand that you will be providing power and the electrical

power

cord to the LiftLyte. Determine the best location that will allow for the easiest power access. Also note

that your

electrical extension cord may rise and fall with your lift depending on where you mount the AC

Transformer Power

Supply. Always keep your power cords in an area where they will not be damaged in any

way.

Note: All installation procedures must be performed with the power disconnected. The Procedures

below

primarily pertain to the double stick tape version of the LiftLyte but serves as a guide for

installation of

the magnetized version which is basically plug and play.

The LiftLyte™is designed to accept power from either the left or the right. The AC Transformer Power Supply

(item 2)

maybe positioned on the opposite side from that shown in Figure 1.

1. Verify all parts and associated quantities to the list of provided components on page 2. If there are any

discrepancies please contact Illuminating Perception.

2. Remove the LED Light Strips from their plastic packaging. NOTE their triangular shape. NOTE also

that one

side has double stick tape pre-attached or magnets. Each LED Strip has a power input end

and a terminated

end. (See figure 1) The power input end of each strip is placed on the lift end where

the electrical power is to

be supplied.

3. IMPORTANT: The LED Light Strips must be attached at the proper angle when installed on your vehicle lift.

Placement of each strip is critical. (The high quality tape used to attach the LED Light Strips is almost

impossible to remove when installed properly.) The light emitted from the LED Strip must be directed under

and across the underside of the vehicle (See Figure 2). The magnetized version can be

moved to determine

the most effective illumination.

Figure 2: Correct Angle of Light Output When Attached to Lift Runways

LiftLyte Operating Manual - DCNMAN101814 Rev. 3

4

1. Determine where you will install the LED Light Strips on your runways and where the AC Transformer

Power

Supply will be located (See Figure 3 & Detail A). IMPORTANT: Make sure there will be no

interference with

any accessory components used on the lift. Clean the surface area of the inside

horizontal rail of the lift or wall

of the lube pit using a grease cutting solvent. Allow the surface to dry

completely. Apply the primer stick

mixture in a thin straight line along the complete length of the lift

runway or lube pit wall where the LED Light

Strip will be installed. This will remove any residual oil that

maystill be on the surface. This is critical for the

adhesion of the double stick tape to the metal or

concrete wall (for lube pit application). Repeat on the

opposite runway or wall.

2. Prior to installing the LED Light Strips be certain that the plug end of the Light Strips will be positioned

so the

power cords from the AC Transformer power supply will be able to reach them. It is

recommended to use a

guide when applying the LED Light Strips to keep them straight on the

runways. Remove about a foot of the

protective cover from the double stick tape from the plug end of

one length of light strip. AGAIN –be sure you

are attaching the LED Light Strip so the light shines up.

From the plug end of the LED Light Strip and working back to the terminated end, peel about a foot of

the

protective cover off at a time and attach the LED Light Strip to the thin straight line that was cleaned

in step 4

until the entire LED Light Strip is installed. Press firmly along the entire length of the LED Light

Strips to assure

proper adhesion. Repeat on the opposite runway or wall.

3. The LiftLyte™is designed to accept power from the left or from the right. Position the AC Transformer

Power

Supply (2) where electrical power will be easily available. Attach the plug ends of each Light

Strip to the plug

ends of the AC Power Cord and Transformer. To prevent damage to the plug contacts

be sure to match up the

alignment tabs on the plugs when attaching the power cords to the LED Light

Strips. Use the supplied zip ties

and mounts to secure the wiring as required. Clean the areas where

the tie down points will be located with a

grease cutting solvent and allow it to dry. Additionally clean

those spots with one of the provided primer sticks.

DO NOT APPLY ELECTICAL POWER TO THE

TRANSFORMER AT THIS TIME.

4. Clean the area you have chosen to mount the power supply with a grease cutting solvent and allow it to

dry.

Additionally clean that area with the primer sticks if provided. Remove the protective surface from

the Velcro

strip on the backside of the AC Transformer power supply. Stick the AC Transformer Power

Supply to the

cleaned area and press firmly. DO NOT place the transformer in an area where it can be

damaged by raising or

lowering the lift or by automobile tires or other items. IMPORTANT: Carefully

raise and lower the lift completely

several times to make certain there are no areas where power cords

could get snagged on or crushed by any

parts of the lift.

5. Run an extension cord to the AC Transformer Power Supply. Apply electrical power at this time. Push

the on/off

button on the transformer. The LiftLyte™should activate within 2 seconds. Note that there is

a very slight delay

between activation and illumination of the LED Light Strips.

Figure 3: Total Lift Configuration

LiftLyte Operating Manual - DCNMAN101814 Rev. 3

55

Maintaining LiftLyte™

Follow these maintenance guidelines to keep your LiftLyte™in good working condition.

To remove any film or oil, periodically wipe the Light Strips with a clean cloth dampened with

potable

water and mild detergent (dish soap).

Periodically inspect the power cords for chaffing, cuts etc.

LiftLyte

™Safety Considerations

Before supplying power to your LiftLyte™carefully fully raise and lower the lift several times to

be

certain there are no interference points that could damage (pinch, cut, chafe, crush etc.)

any of the

components of your LiftLyte-M™or, could prevent the full range of motion of the

lift.

Be sure all AC Transformer Power Supplycords and your extension cord are safely secured

using

the supplied zip ties and mounts.

Always review the location of all components of your LiftLyte™before installing or removing a

vehicle

from the lift.

Regularly inspect all components of the LiftLyte™for any possible damage.

If welding or using a torch in the vicinity of your LiftLyte™use care to prevent open flame or

molten

metal from coming into contact with any component of the LiftLyte™.

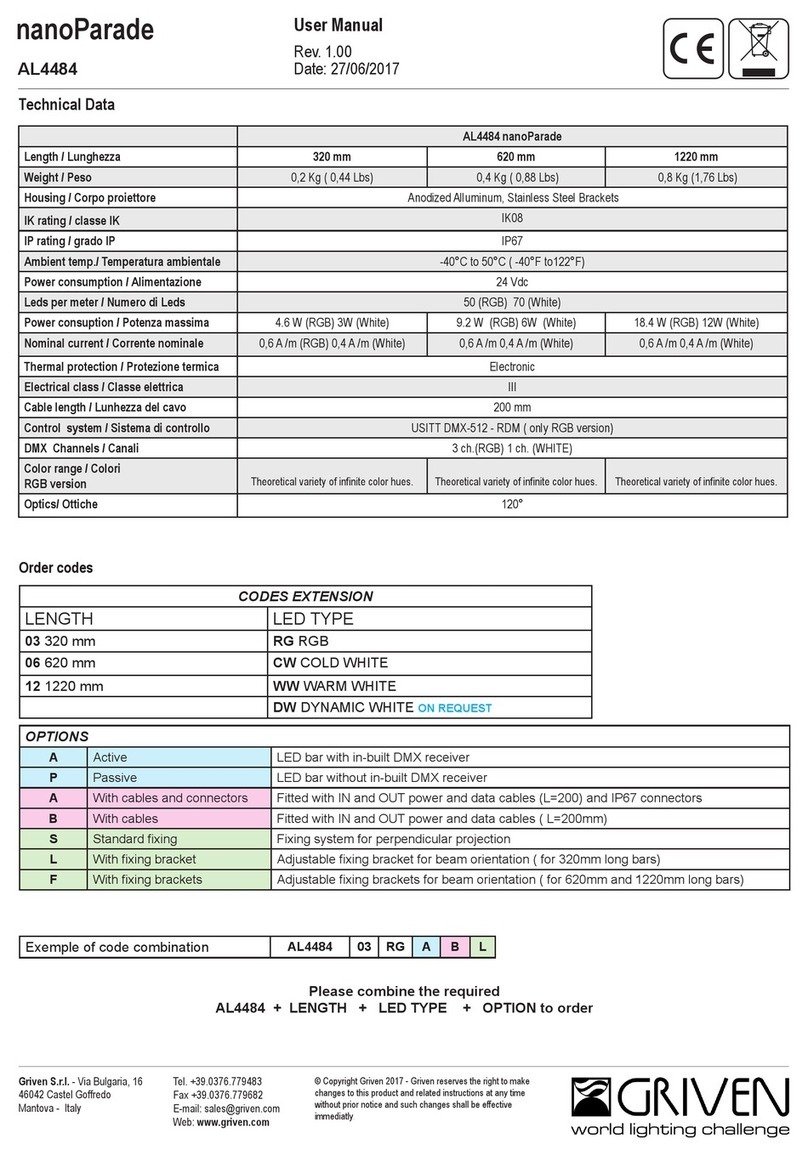

LiftLyte™Technical Specifications

Standard Light strip

Watts –LiftLyte 1000 model 36W, LiftLyte 1003 model 43W

Amps –LiftLyte 1000 model 3.0A, LiftLyte 1003 model 3.6A

Voltage –12V -15V

Length –LiftLyte 1000 model 2 x 140”, LiftLyte 1003 model 2 x 170”

Viewing Angle - 120°

Typical System Lumens 125 lm per foot –1000 model total Lm (2900lm), 1003 model

total Lm (3500lm)

Color temperature –6000K –7000K

Magnets –Neodymium N42

Protective Sheath –Vinyl with UV, anti-blushing, anti-fungicidal inhibitors

Listings - UL CE ROHS

Life Expectancy –30,000 hrs.

Power Supply

Watts –60W

Voltage - Input 100V –240V 1.2A, Output 15V 4.0A

Hertz –50/60

IP64

Class 2

Listings –UL CE ROHS

Common US 120V plug with switch Standard

LiftLyte Operating Manual & Warranty - DCNMAN101814 Rev. 3

6

IlluminatingPerception Corp

LiftLyte™and Transportation Lighting

2 Year Warranty

Warranty Terms: Illuminating Perception (IPC) will replace or repair, at its sole option,

any IPC transportation lighting product which is considered defective as a direct result of

manufacturing or material defect. Products are defined as those products listed on the

current Illuminating Perception price list. Products purchased from IPC are measured

from the date that the item was shipped to the purchaser by IPC or its

supplier/distributor. During the Two (2) Year Warranty Period the material will be

repaired or replaced at no charge to the purchaser. IPC hereby assigns to the

purchaser any warranty given to IPC, which may be so assigned, subject to the terms

herein. This warranty is given to the purchaser from IPC and may not be assigned or

otherwise transferred to any other party. All products purchased under these warranty

terms must be purchased directly from IPC or an authorized Distributor.

Warranty Conditions: This warranty will be void if the warranted items are not

used, installed and/or maintained as specified or recommended by the manufacturer,

including, but not limited to: (a) abuse of products as determined by IPC, (b) failure to

follow installation and maintenance manuals and/or instructions provided by the

manufacturer; (c) are modified or altered in any way by anyone other than IPC; or (d)

are not made available to IPC or its authorized representatives for inspection, along

with all receipts, installation, maintenance and other appropriate documents, when a

warranty claim is made. No incidental, consequential or other damages (including, but

not limited to, costs of dismantling, shipping, reinstalling or other related costs) will

be paid under any circumstances. Call IPC Customer Service to obtain an RMA

number or a list of Certified Installers.

Disclaimer of Other Warranties: This warranty is the sole and exclusive remedy for

any claims relating to items purchased from or through Illuminating Perception; no other

warranties, express or implied, are given, including warranties or merchantability or

fitness for any particular purpose. Illuminating Perception will not be responsible for

any representation, promise or expansion on this limited warranty by any dealer, sales

or manufacturing representative or distributor of the products covered by this warranty.

In the event that there is any statutory expansion of the provisions of the warranty

expressed herein, the item will be deemed purchased on an as-is basis as to such

expansion. Except as provided in this limited warranty all items are purchased in an as-is

condition.

This manual suits for next models

1

Table of contents