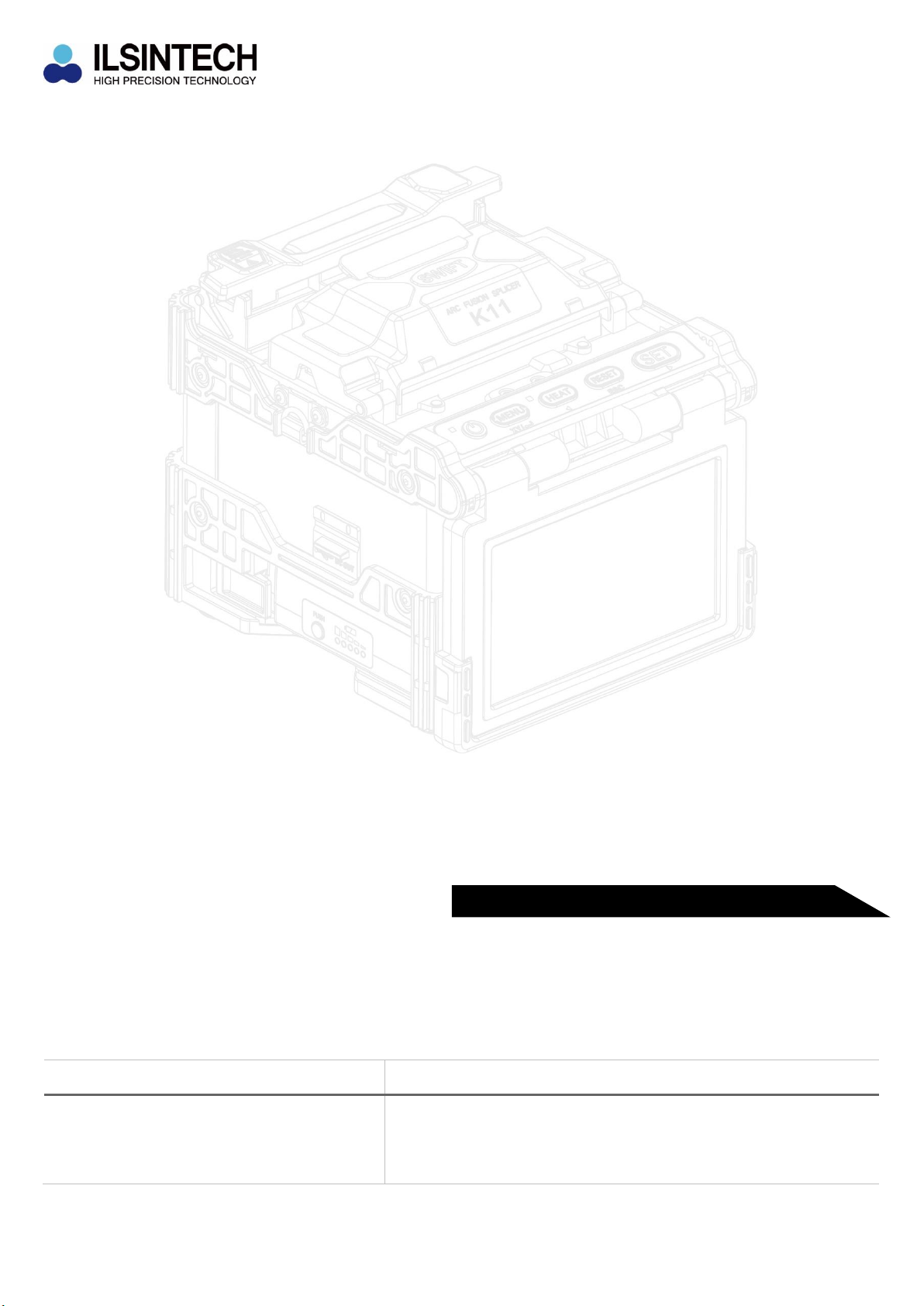

Ilsintech SWIFT K11 User manual

Optical Fiber Arc Fusion Splicer

Read this user manual carefully before running K11

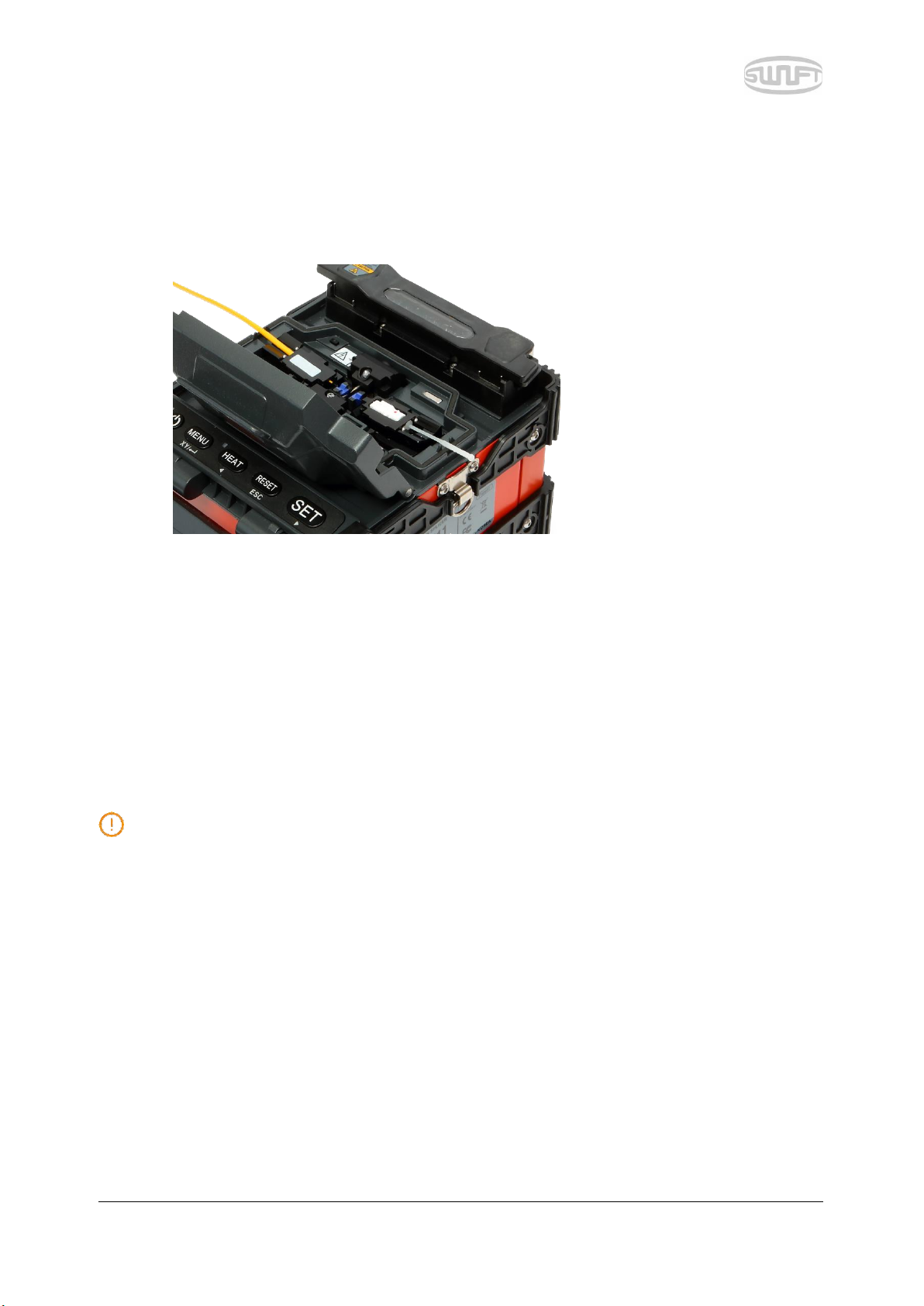

SWIFT K11

SWFIT K11-EN, Rev.A

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) This device may not cause

harmful interference, and (2) this device must accept any interference received, including interference that may cause undesired

operation.

Device Type

Notification

A Class Device

(Broadcasting and communication device,

commercial use)

Users need to understand that this device(A Class) has obtained

EMI(Electromagnetic compatibility) and been designed to be used in

places other than home.

USER MANUAL

WWW.ILSINTECH.COM

SWIFT K11-EN, Rev.A 2

Contents

1. NOTES FOR USERS 5

2. PRODUCT SPECIFICATIONS AND COMPOSITION 8

2.1 PRODUCT SPECIFICATIONS 8

3. PRODUCT OUTLINE 10

3.1 FUNCTION BUTTONS 10

3.2 COMPONENT’S NAME 11

4. INSTRUCTIONS FOR USE 13

4.1 POWER SUPPLY 13

4.2 HOW TO TURN THE POWER ON/OFF 16

4.3 SLEEVE LOADER ASSEMBLY 17

4.4 INSERTING OPTICAL FIBER TO PROTECTING SLEEVE 18

4.5 OPTICAL FIBER CLEANING AND STRIPPING 18

4.6 OPTICAL FIBER CUTTING 19

4.7 INSTALLING OPTICAL FIBER TO SEALER 20

4.8 OPTICAL FIBER CONNECTING PROCEDURE 21

4.9 K11 SLEEVE-HEATER PART 22

4.10 SEPARATION OF CONNECTED OPTICAL FIBER 24

4.11 HEATING FOR PROTECTING SLEEVE 24

5. MAINTENANCE OF SPLICE QUALITY 25

5.1 CLEANING AND INSPECTION BEFORE SPLICE 25

5.2 REGULAR CLEANING AND INSPECTION 27

SWIFT K11-EN, Rev.A 3

6. MENU 30

6.1 SPLICE 37

6.2 HEATER 44

6.3 SPLICE RESULT 48

6.4 OPTION 49

6.5 CALIBRATION 54

6.6 ELECTRODE 59

6.7 SETTING 63

6.8 INFORMATION 67

7. ERROR MESSAGE 70

7.1 OPTICAL FIBER IS TOO DIRTY. 70

7.2 REPLACE THE OPTICAL FIBER. 70

7.3 OPTICAL FIBER IS TOO LONG. 71

7.4 ERROR ON ANGLE OF OPTICAL FIBER 71

7.5 LOSS IS BIG. 72

7.6 OPTICAL FIBER IS THIN. 72

7.7 OPTICAL FIBER IS THICK. 72

7.8 BUBBLE BEING GENERATED 72

7.9 ERROR ON CUT SURFACE ON LEFT,RIGHT OR BOTH 72

8. SEALING PROBLEM SOLVING 73

8.1 WHEN LOSS IS BIG 73

8.2 ABNORMAL SEALING OPERATION 74

9. PROBLEM OCCURRENCE AND QUESTION 75

9.1 POWER 75

9.2 SPLICE 76

9.3 SLEEVE HEATER 77

9.4 OTHERS 78

SWIFT K11-EN, Rev.A 4

10. WARRANTY AND REPAIR 79

10.1 INFORMATION NECESSARY FOR REPAIR 79

10.2 TRANSPORTATION 80

10.3 REPAIR 80

SWIFT K11-EN, Rev.A 5

1. NOTES FOR USERS

Swift K11 is designed to be conveniently used both indoor and outdoor work sites so its use is easy

and simple but make sure to read this instructions for use to prevent safety accident and

breakdown before using SwiftK11. The instructions for use provide information necessary for safe

splice.

Ilsintech does not take any responsibility for the equipment’s damage and personal or physical

loss incurred due to improper use or alteration.

WARNINGS

When any of the following occurs during use, turn off the power immediately and contact to Ilsintech.

▪Smoke, disgusting smell, noise or abnormal overheating.

▪When a foreign substance or liquid falls into the equipment

▪When the sealer falls down or it is damaged

Regarding AC power cord, use the one provided with Swift K11. If a power cord other than provided is

used, it may incur fire, electrical shock or injury.

Do not touch the electrode when power of Swift K11 is on. High voltage and high temperature generated

from electrode may incur serious chock or burn.

Connect the provided AC power cord to battery. Check whether there is any

foreign substance on the terminal before connecting to AC power socket.

Incomplete splice may incur smoke, electric shock, fire, damage of equipment, serious injury and even

death.

Use proper power.

AC power for the adapter is AC100-240V, 50~60Hz.

Test the AC power before use. When output voltage of AC power is high or abnormal frequency is

generated, the product is damaged and serious injury or even death may be incurred to the user.

AC output voltage should be measured using circuit tester before connecting AC power cable and regular

inspection should also be conducted.

Do not pull the provided AC power cord by force or heat or transform it.

Carry the instructions for use with the product at all times.

SWIFT K11-EN, Rev.A 6

WARNINGS

When a damaged power cord is used, it may incur fire or injury.

Use 3-core AC power cord and do not ever use 2-core power cord, cable or plug.

Do not touch AC plug, AC power cord or sealer with wet hands. It may incur electric shock.

Do not disassemble AC adapter, battery or Swift K11. Deformation may incur fire, electrical shock or

injury.

Refer to the following when using the battery.

▪When an improper battery which is not provided by Ilsintech is used, it may incur smoke,

damage of equipment, burn, injury or even death.

▪Do not dispose the battery into fire or incineration plant.

▪Do not charge the battery next to flame.

▪Do not give an excessive shock to the battery.

▪When the battery is not completely charged in 2 hours or green LED is not turned on, stop

charging immediately and contact to Ilsintech.

▪Do not put anything on AC adapter during charging.

Use the exclusive AC adapter (F1-1). Do not use another AC power cord or battery. Excessive current

may incur equipment damage or injury.

Do not use Swift K11 where there is harmful gas or flammable liquid. Explosion or fire may be incurred

due to electrical discharge.

Do not use compressed air or compressed gas when cleaning Swift K11.

Inspect the case belt before transportation. When transporting case is dropped due to damage on belt,

it may incur equipment damage or injury.

Wear safety goggles when working on making splice. It is very dangerous if a piece of optical fiber gets

in skin or eye.

Do not use Swift K11 around high temperature or flame. It may incur injury

or equipment damage.

CAUTION:

HIGH TEMPERATURES

DO NOT SPRAY FREON GAS

CAUTION:

HIGH VOLTAGE

SWIFT K11-EN, Rev.A 7

CAUTIONS

Do not touch sleeve heater or protec sleeve while sleeve heater is operating or right after heating is

completed. It may incur injury due to high temperature.

Do not put Swift K11 at an unstable place. When the equipment is dropped, it incurs injury or equipment

damage.

Swift K11 should be accurately adjusted and treated in arrayal. Do not give it a strong shock, either.

Use transporting case to carry or to keep Swift K11. The transporting case keeps the equipment from

humidity, vibration and shock during storage and transportation and prevents its damage.

Replace the electrode at the right time by referring to the following.

Designated electrode should only be used.

Place a new electrode at a right position.

Replace the electrode in pairs.

Abnormal discharge is incurred when not following the aforementioned caution.

It may incur equipment damage or deteriorated splice.

Do not use any chemical other than ethyl alcohol (96% or higher) to clean object lens, V-Groove, LCD

monitor and main body.

Using other chemicals may incur deformation, discoloration or deteriorated performance.

Do not keep the equipment in environment with high temperature or high humidity. It may incur

equipment damage.

Technical aspects of Swift K11 should be inspected by a qualified expert.

When ignoring this, it may incur fire or electric shock.

Discuss with Ilsintech to use the service.

SWIFT K11-EN, Rev.A 8

2. Product specifications and composition

2.1 Product specifications

ITEM

DESCRIPTION

Fiber alignment

IPAAS core to core alignment

(Image pattern analysis alignment system)

Applicable type of fibers

0.25mm, 0.9mm, 2.0mm, 3.0mm, 4.0mm, Indoor cable

Fiber count

Single fiber

Applicable fiber dimensions

Cladding diameter: 80~150 ㎛, Coating diameter: 100 ㎛~4mm

Fiber setting and cleaved length

7~16mm

Splicing modes

Splice mode: 300, Heat mode: 100

Typical splice Loss

SM: 0.02dB, MM: 0.01dB, DS: 0.04dB, NZDS: 0.04dB

Return loss

> 60dB (Typical)

Splicing time

Typical 6sec. (Quick Mode)

Sleeve heating time

9sec (IS-45 Sleeve, IS-45 mode),

13sec (IS-60 Sleeve, IS-60 mode)

Applicable protection sleeve

40mm, 60mm, 32mm or 28mm for SOC

Storage of splice result

The last 10,000 results to be stored in the internal

memory.(Image 10,000 results)

Tension test

1.96N ~ 2.25N

Dimension

143(W) x 163(L) x 140(H)mm (Without Bumper)

Weight

With battery 2.25kg

Viewing method and display

Two CMOS cameras and 5.0-inch color touch LCD

Fiber view and magnification

X/Y : 200X, Max 400X

Power supply

DC Lithium polymer battery (DC 14.8V, 4700, 6000mAh-option),

100~240V AC Adapter

No. of splice cycles with battery

Typical 250 cycles/ More than 300 cycles(K11-6000)

Electrode life

More than 3,500 times

Terminals

USB

SWIFT K11-EN, Rev.A 9

2.1.1 Basic components

ITEM

MODEL NAME

QUANTITY

Arc Fusion Splicer

SWIFT K11

1

Battery

K11-4700

1

AC Adapter

WDS060190

1

Instructions for use

-

1

Spare electrode

EI-23

1pair

Transporting Case

Hard Case

1

Cooling Tray

CT-01

1

Wrench

LD-3300

1

USB Cable

-

1

DC Output Cable

-

1

Manual Stripper

CF-02

1

Alchol Dispenser

PP

1

Tool Box

-

1

Sleeve Loader

S312

2

Cleaver

CI-03BT

1

2.1.2 Accessories

ITEM

MODEL NAME

Battery

K11-4700 / K11-6000

Cleaver Blade

BI-07

Electrode

EI-23

Work Belt

-

Sleeve

S-160(60mm), S-140(40mm)

Sleeve Clamp

SC-01

SOC Connector

SC, LC, FC, ST(Refer to FTTx Solution catalogue)

Optical Fiber Holder

HS-250, HS-900, HS-2.5F, HS-IN, HS-SC/FC, HS-ILC, HS-ST, LS-

900(Loose)

External Power

DC 12V Available for car cigar jack

SWIFT K11-EN, Rev.A 10

3. Product outline

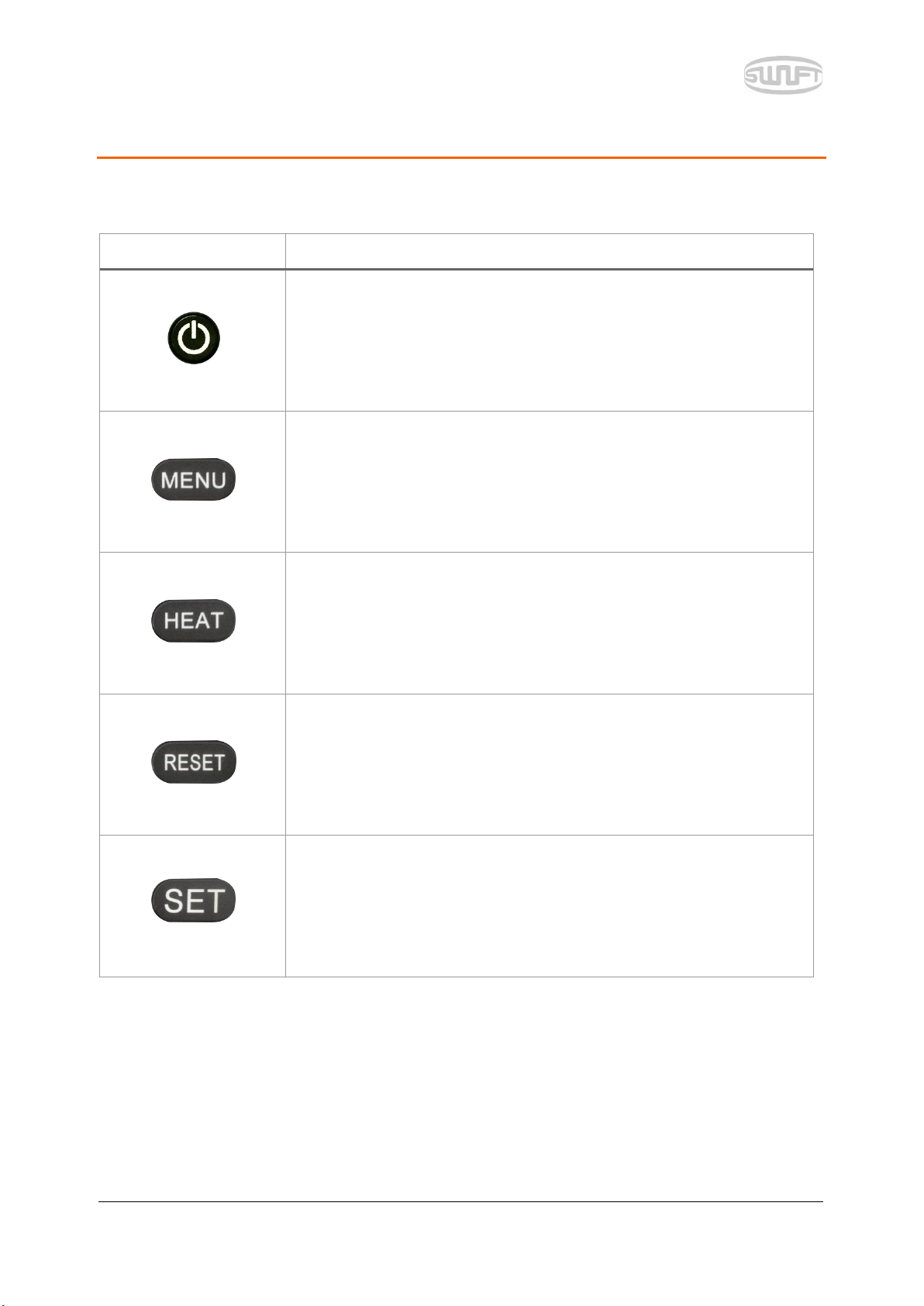

3.1 Function buttons

BUTTON

DESCRIPTION

Press about for 1 second to turn the power ON/OFF.

Press about for 1 second when power is on and the LCD monitor is

turned off and so is power after 2~3 seconds.

Key to load menu screen

It switches to splice screen. Every time it is pressed, it switches to X

screen, Y screen and X, Y sync screen.

It operates sleeve heater.

When it is ON, the lamp on the left is turned on red.

Press once more when it is ON and the heater is turned off.

It goes back go initial screen. It initializes splice function.

Key for splice executive command

SWIFT K11-EN, Rev.A 11

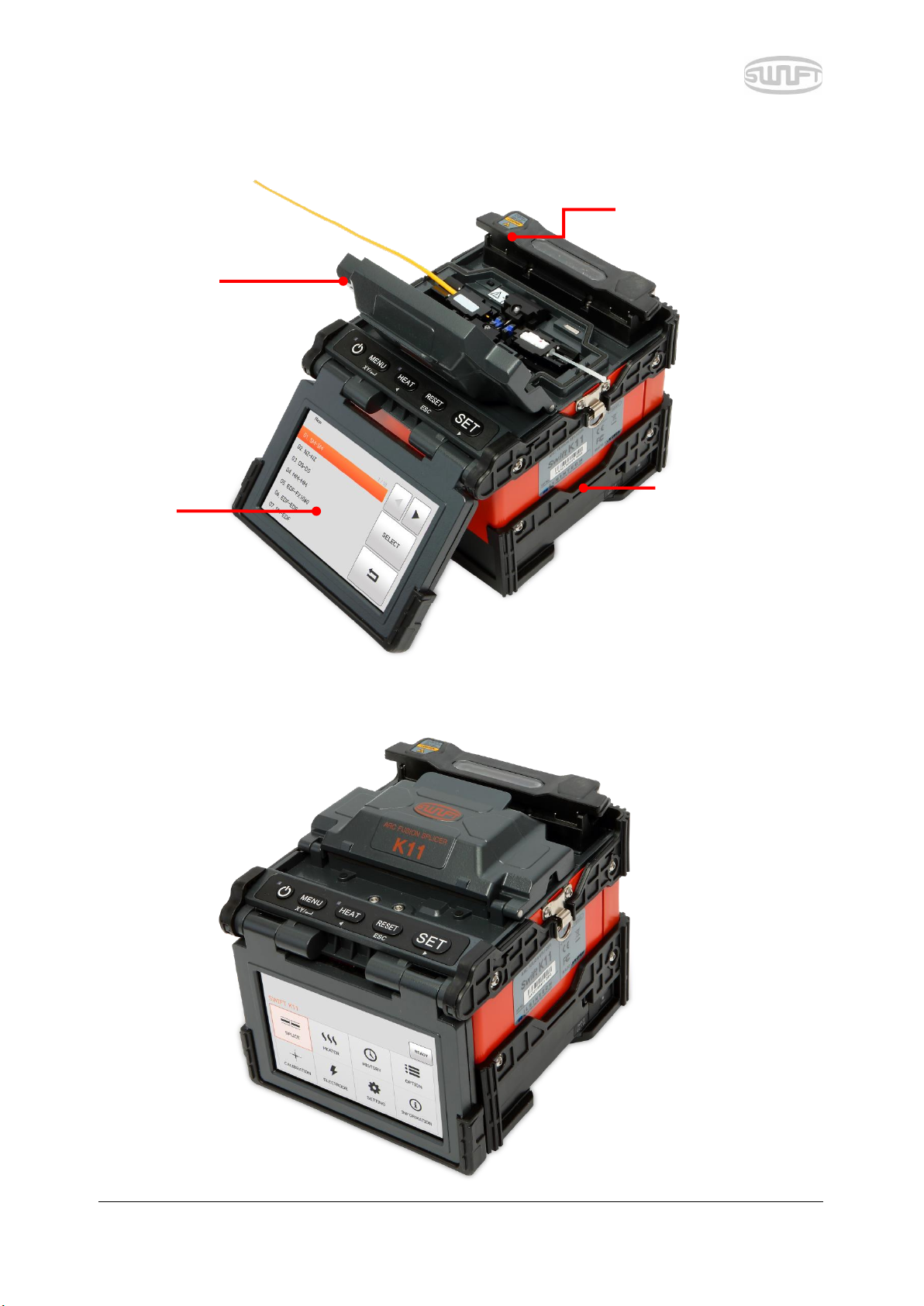

3.2 Component’s name

Windbreak cover

Battery

Monitor

Sleeve heater

SWIFT K11-EN, Rev.A 12

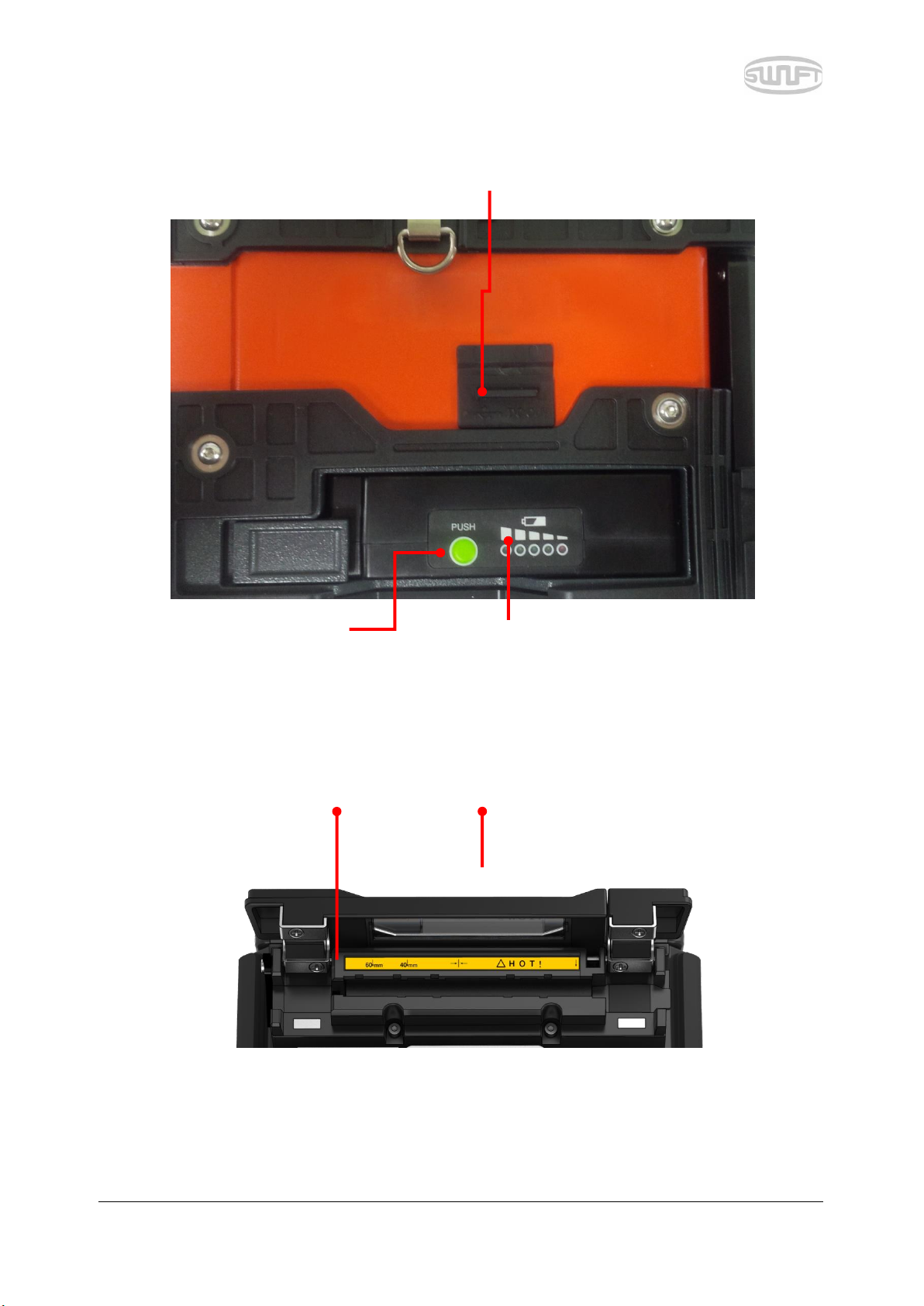

Button to show

remaining battery

Remaining battery indicator

Heater cover

Heater

USB, DC OUT

SWIFT K11-EN, Rev.A 13

4. Instructions for use

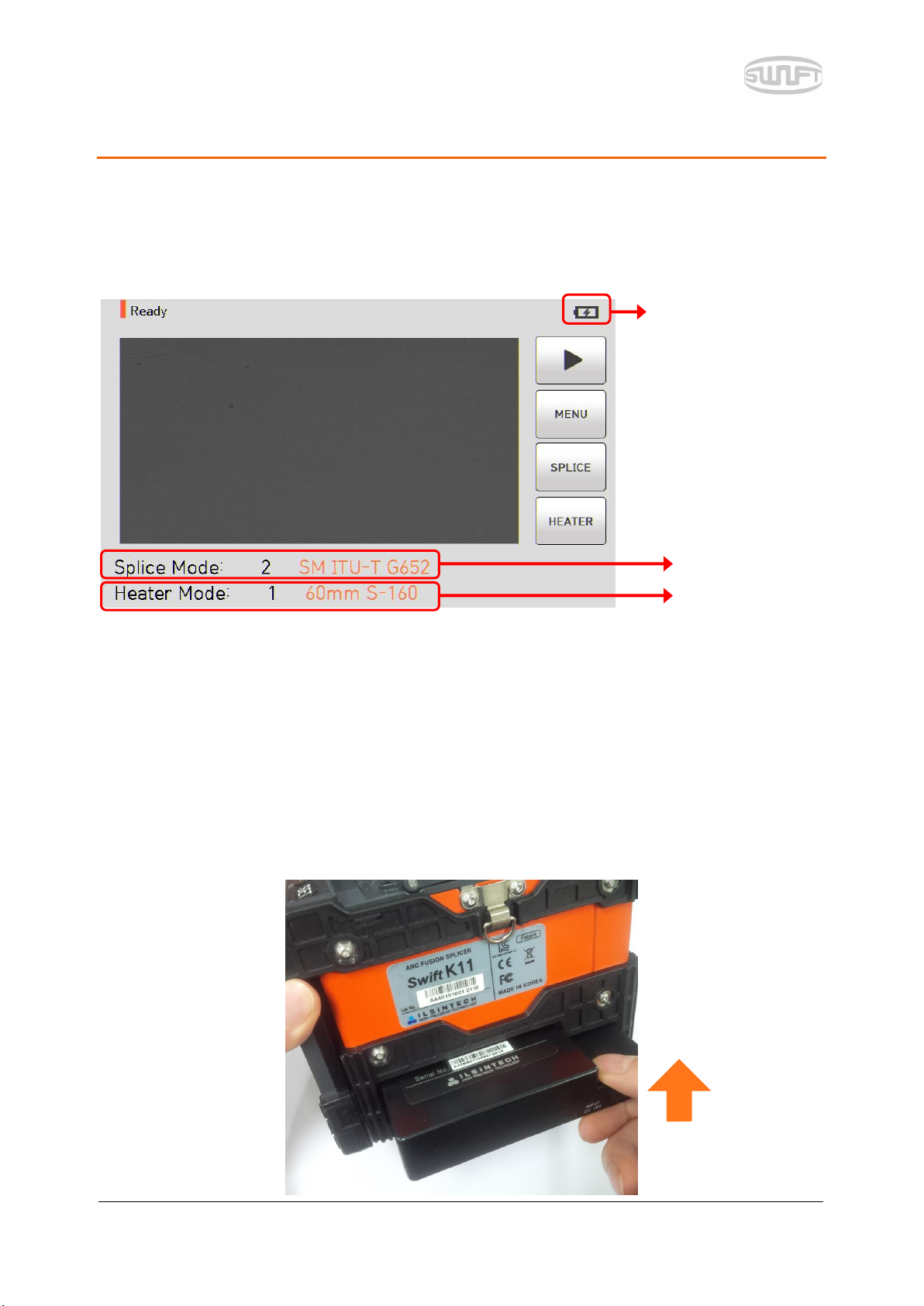

The following is the initial screen of Swift K11. For accurate splice result, splice mode and heater

mode should be properly selected. Basic information on Swift K11 is displayed on the initial screen.

Check whether a proper mode is selected before splice.

4.1 Power supply

Use the AC adapter (WDS060190) and battery provided with the product. Using other products

may incur fire, equipment damage or accident.

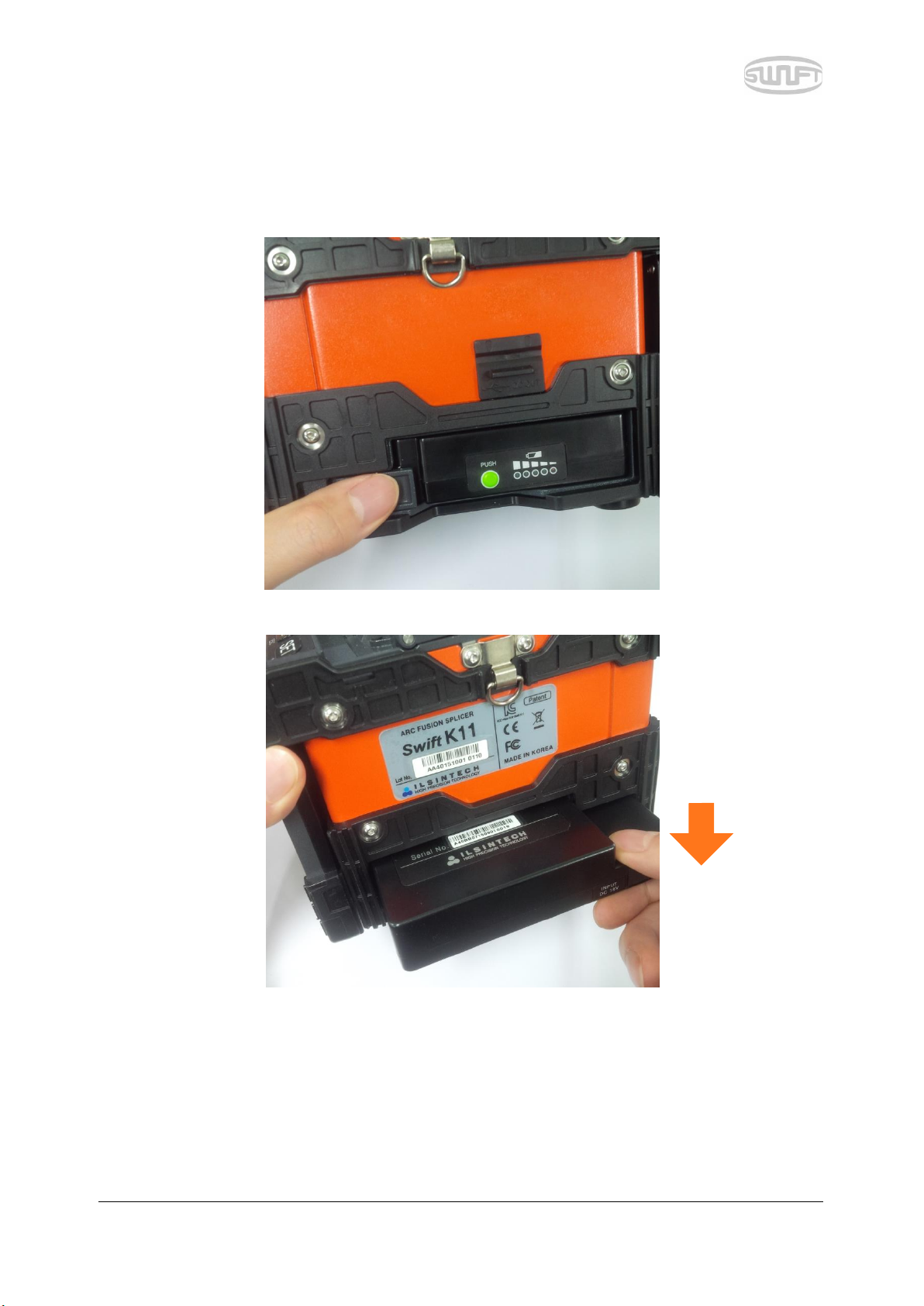

4.1.1 Battery installation

Push the battery in until it is completely installed.

Battery status indicator

Current splice mode

Current heater mode

SWIFT K11-EN, Rev.A 14

Check whether the power is off before removing the battery and press the locking lever to remove

the battery.

4.1.2 Battery charging

Check the voltage and frequency and connect DC jack of battery and DC cable of AC/DC adapter.

When battery is fully charged, its LED turned green and power is disconnected upon protective

action with built-in overdischarge, overcharge and overload protection circuit. In this case, the

power is turned back on and charging resumes when DC cable of adapter is connected to DC jack

of the battery again.

SWIFT K11-EN, Rev.A 15

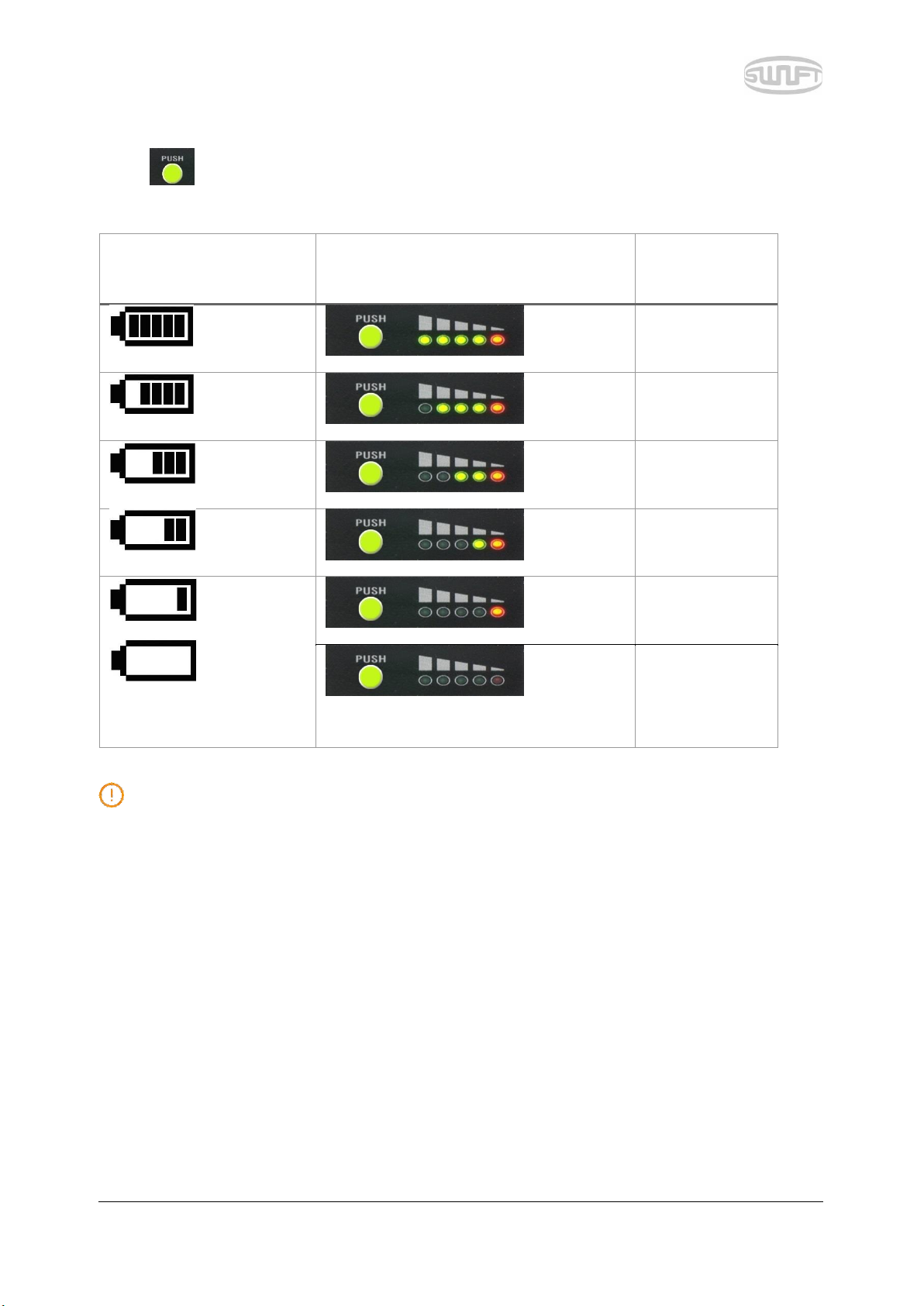

4.1.3 Battery capacity check

Press and the current remaining amount is displayed.

Remaining battery display

(Monitor)

Remaining battery indicator

(Battery LED)

Remaining

battery

(5 bars)

5 LED

80 ~ 100%

(4 bars)

4 LED

60 ~ 80%

(3 bars)

3 LED

40 ~ 60%

(2 bars)

2 LED

20 ~ 40%

(1 bar)

(No bar)

1 LED

10%

0 LED

No display on LED

5% or none

When the remaining battery is indicated 10% or below, charge the product for use. It may

affect splice quality.

SWIFT K11-EN, Rev.A 16

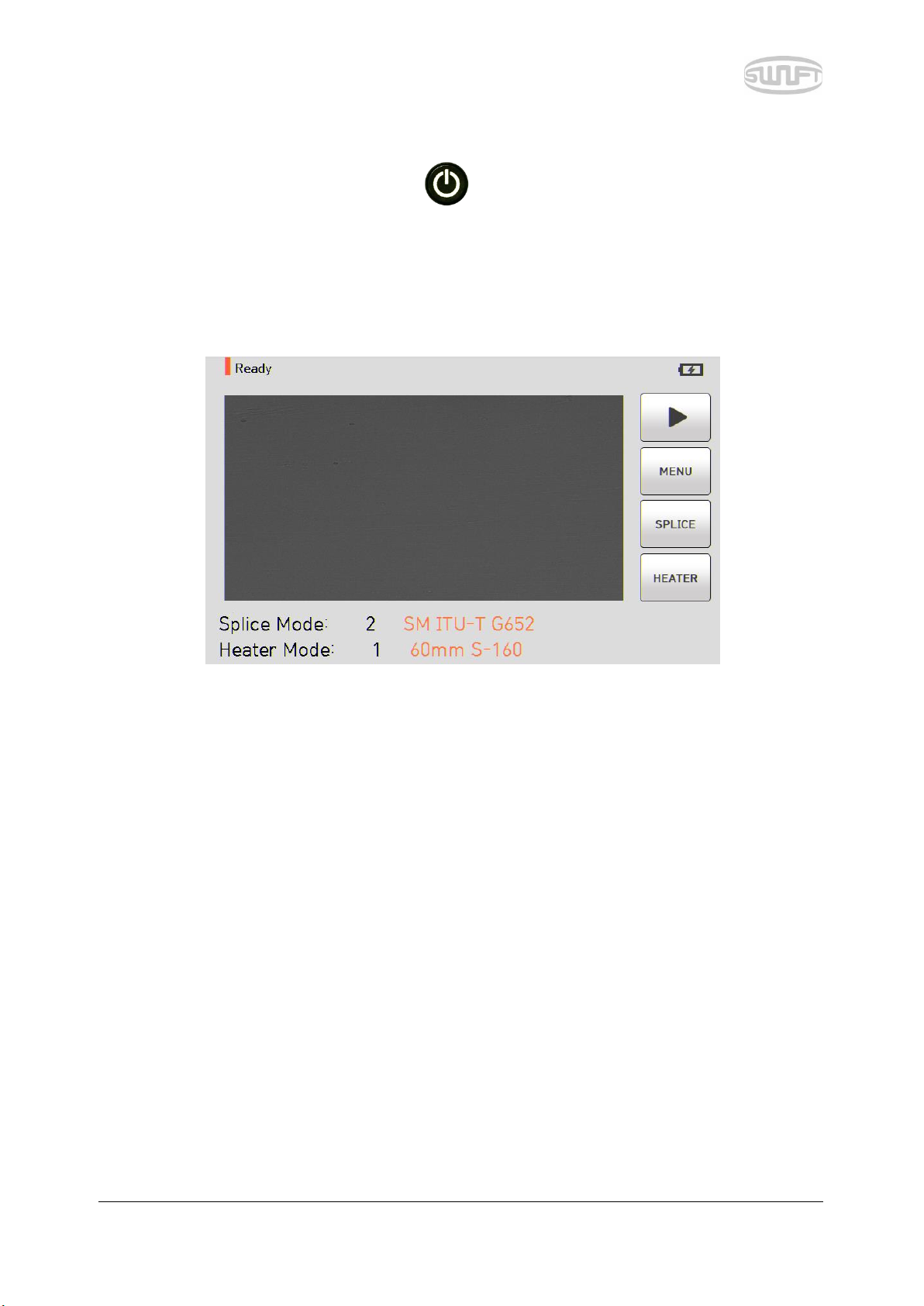

4.2 How to turn the power ON/OFF

To turn on the power of Swift K11, press for about 1 second with the windbreak cover

being closed. After the entire functions including motor are initialized, the initial screen is

subsequently displayed as follows. For accurate splice, splice mode and heater mode should be

properly selected. Current splice mode, stripping mode and heater mode are displayed at the

bottom of the screen.

SWIFT K11-EN, Rev.A 17

4.3 Sleeve loader assembly

Insert the sleeve loader at the left/right grooves as shown in the figure below.

SWIFT K11-EN, Rev.A 18

4.4 Inserting optical fiber to protecting sleeve

Put optical fiber in protecting sleeve.

4.5 Optical fiber cleaning and stripping

Do stripping procedure on about 4cm from the end of optical fiber by using sheath stripper.

And wipe the optical fiber clean with soft cloth or cotton moistened with alcohol.

Use ethyl alcohol with purity of 96% or higher.

SWIFT K11-EN, Rev.A 19

4.6 Optical fiber cutting

i. Install the optical fiber on cutter as shown in the figure below and check optical fiber’s

state and cutting length. When optical fiber is not properly installed, problems may be

incurred on cutting procedure.

ii. Push the cutting lever down and the optical fiber is being cut.

iii. Lift the cutting lever and take the optical fiber out.

iv. Remove the cut pieces of optical fiber and dispose in a proper container.

For the detailed use of cutter, refer to the instructions for cutter use.

SWIFT K11-EN, Rev.A 20

4.7 Installing optical fiber to sealer

i. Open the windbreak cover and optical fiber clamp.

ii. Put optical fiber between V-Groove and electrode. Be careful not to make the tip of

prepared optical fiber bump against other objects.

iii. Fix the optical fiber with hands to prevent its move and close the clamp with care.

iv. Install the optical fiber on the opposite side in the same way.

v. Close the windbreak cover with care.

The better the optical fiber is installed at a proper location, the shorter it takes for arrayal.

Other manuals for SWIFT K11

1

Table of contents