IMAYCC VI Series User manual

4500 PSI/300Bar Built-in Conveter

12V Air Compressor

Instruction Manual

12V compressor VI Series

TXET062-1 Shutoff compressor manually

TXET062-2 Shutoff compressor automatically

Rev 1.1 2020

2

INTRODUCTION

Thank you for choosing IMAYCC Air Compressor.

Follow the instructions when operating this compressor. It will allow you to fill

your PCP storage reservoirs or air cylinders easily. Please read the manual very

carefully before use. Any damage or injury resulting from misuse or incorrect

handling is the sole responsibility of the owner and/or operator.

For your own safety and the safety of others, carefully following warning

&important bellows.

Warning& Important

1. Please use in a well-ventilated area. Do not operate in an area where

liquid contaminants can be drawn into the compressor.

2. Do not operate near some places with smoke or open flame.

3. This compressor generates pressurized air; it will cause heat and noise.

Gloves & hearing protection & safety glasses should always wear

during use.

4. The compressor should only be dismantled by a competent technician;

or serious damage/injury may be caused to you or others.

5. Improper disassembly and reassembly will result in leaks, damage, and

may void your warranty.

6. Never attempt to dismantle any portion of this compressor when it is

pressurized or is hot after running.

7. This compressor is designed to produce dry compressed air only. Do

not attempt to feed other gases or pressurized air through for

compression. No other gas or gas combination can be used.

8. Do not operating temperature of 185°F / 85°C. Long time continually

running is not suggested, it will cause the temperature rising, and

then to cause parts damaged and the machine life shortened.

9. Make sure the compressor voltage meets your local power supply

10. Make sure it has already added the lubricate oil before using

11. Make sure the power cord is fine before use (No wear and tear or

heat damage)

12. Make sure do not operate air compressor with the shell removed

13. Make sure keep eyes on the compressor when it’s running, do not let

the compressor overfill

14. Avoid your body too close the compressor when it is running

15. Failure to follow instructions and heed warnings may result in

damage, serious injury.

Danger: DO NOT OVERFILL, DO NOT fill the pressure above 4500PSI/300Bar/30Mpa

3

Contents

Specifications...........................................................................….4

Assembly/Operation Instructions…….………….........…..…..5-6

TXET062-2 model function…….…………………..…….….7

Maintenance……………………………………………………8

Troubleshooting.....................................................................….9-10

After-sales contact information........................................... ….11

4

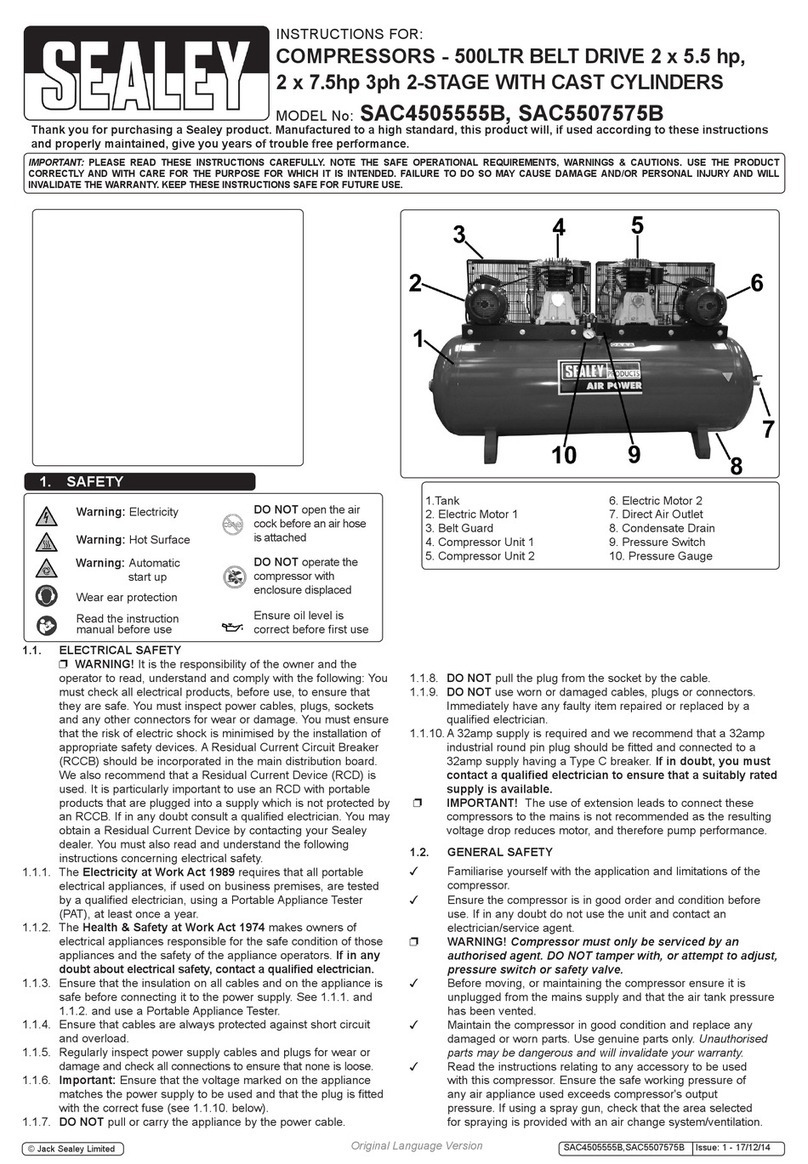

Specifications

Model number

TXET062-2

Function

Shut off the compressor automatically

Input Voltage

100~130V or 12V

Features

Built-in transformer

Size

33*26.5*33.5cm/ 13*10.43*13.19 inch

Weight

9.5KG/20.9lb

Working pressure

4500PSI /30Mpa /300Bar

Cooling system

Fan cooling

Charging rate

20min /0.45L tank

Motor power rating

250W

OEM

YES

Certification

CE

The other model:

TXET062-1: Manual version: When it reaches the pressure value you set,

it needs to be closed manually

5

Assembly/Operation Instructions

(1) This transformer has been built into the machine

Note: The voltage of this product has been adjusted to 110V. Please make

sure that the voltage in your area is suitable. The voltage of the transformer is

adjustable. We have adjusted the transformer to 110V before leaving the

factory to ensure the smooth operation of the machine. (If 220V is required,

please purchase the corresponding model)

Important: Make sure the converter is suiting your local power voltage.

(2) Tighten the screw below the compressor. Install the hose and tighten the

release valve

(3) Connect the compressor filling hose to the air tank or other devices.

(4) Turn on the compressor fan by press the switch (Right side button); Let the

compressor fan running around 2 minutes. Turn on the compressor (Left side

button)

IMPORTANT: Fan work first, then compressor.

6

(5) Turn off the compressor when the desired pressure is finished.

Note: Still let the compressor fan running for around 2~3 minutes.

(6) Turn off the fan finally

(7) Disconnect the fill hose from your tank, air cylinder.

The other way operation: 12V battery / Car battery drive

compressor

(1) We can use 12V battery to drive this compressor. Be sure the voltage is

around 12V.

(2) While use the car engine operation, connect the compressor to the car battery

using the cables provided. The car battery must be a 12V-DC power source.

Red connects to the positive (+) terminal and black connects to the negative (-)

terminal. When connected correctly, the compressor fan will start automatically.

Otherwise the cooling fan will not work, which will cause the machine to be

damaged at high temperature.

(3) Connect the compressor filling hose to the air tank or other devices.

(4) Turn on the compressor fan by press the switch; Let the compressor fan

running for a while

(5) Turn on the compressor

(6) Turn off the compressor when the desired pressure is finished. Still let the

compressor fan running for around 2~3 minutes, for cooling down the

compressor

(7) Turn off the fan finally

(8) Separate the tank or other devices from the compressor

7

TXET062-2 model function

Model number: TXET062-2 compressor

Setting Pressure Version

The compressor will auto when it reaches the pressure you set.

A B C D

1= Fill Pressure Adjustment (Desired pressure pointer)

2=Starting pressure (Pressure pointer)

3= Adjustment Knob

Procedure

(1) Picture B, it tells us we using adjustment knob. This will engage the adjustment

and allow you to move the fill pressure adjustment pointer to the right. Set to

your desired max fill pressure.

(2) Picture C, the pointer stays status:

Starting pressure shows 0 (zero) condition

Desired Pressure pointer we set at 4500PSI

(3) Picture D, it shows when it reaches the pressure we set, it can shutoff

automatically.

IMPORTANT: Don’t set the output pressure above 4500PSI(300Bar)

(4) When running the compressor, it shows the starting pressure pointer reaching

the desired pressure pointer. That is the pressure we want.

(5) If you adjust the output pressure too high, you can bring it back down by simply

moving the adjustment knob to the left.

NOTE: DO NOT adjust the output pressure setting once the compressor is

running.

(6) When the compressor reaches the desired pressure we want (the intended

max fill pressure) it will shut off automatically.

(7) Be aware that the compressor switch will still be in the “ON “position after it

auto stops. You will need to turn it “OFF” before bleeding the pressure via the

pressure release valve.

8

Maintenance

We suggest after fill 40 bottles of 0.5L air bottle, we need to maintenance it.

1. Mainly clean these 4 connections; it can reduce the chance of malfunctioning

2. Replace the filter cotton core inside,we have put extra cotton fillers in our

packing list

3. Drain the waste oil and water from oil drain valve every time to make sure

compressor not in load status.

9

Troubleshooting

Issue - Compressor will not start

Possible (1) Connect failure (2) Fuse broken or fuse burning

Resolution: (1) Make sure power converter is plugged into a functional electrical outlet and

make sure power converter is properly plugged into the compressor.

(1) Change the fuse.

Note: If using a 12V battery, make sure the jumper cables are properly connected

Issue - Compressor cannot reach high pressure air

Possible (1) Air leaking (2) Seal balls problem

Resolution – (1) Check all joints, connections, and screws to see if there is air leaking

(2) Change the seal balls inside

Issue –The air pressure rising slowly or can not reach

200Bar

Possible (1) Air leaking (2) Second piston rings wear out (3) Check valve problem

Resolution – (1) Check all joints, connections, and screws to see if there is air leaking

10

(2) Replace the second piston rings

(3)Clean the check valve,especially these connectors. Change the corresponding check valve

Issue -Operating temperature too high

Possible:(1) long time use or bad ventilation (2) Fan rotary direction

Resolution –(1) No let the compressor continuously work, cool the compressor if it is hot

(2) Fan should be in the right rotary direction in good ventilation condition

This manual suits for next models

2

Table of contents

Popular Air Compressor manuals by other brands

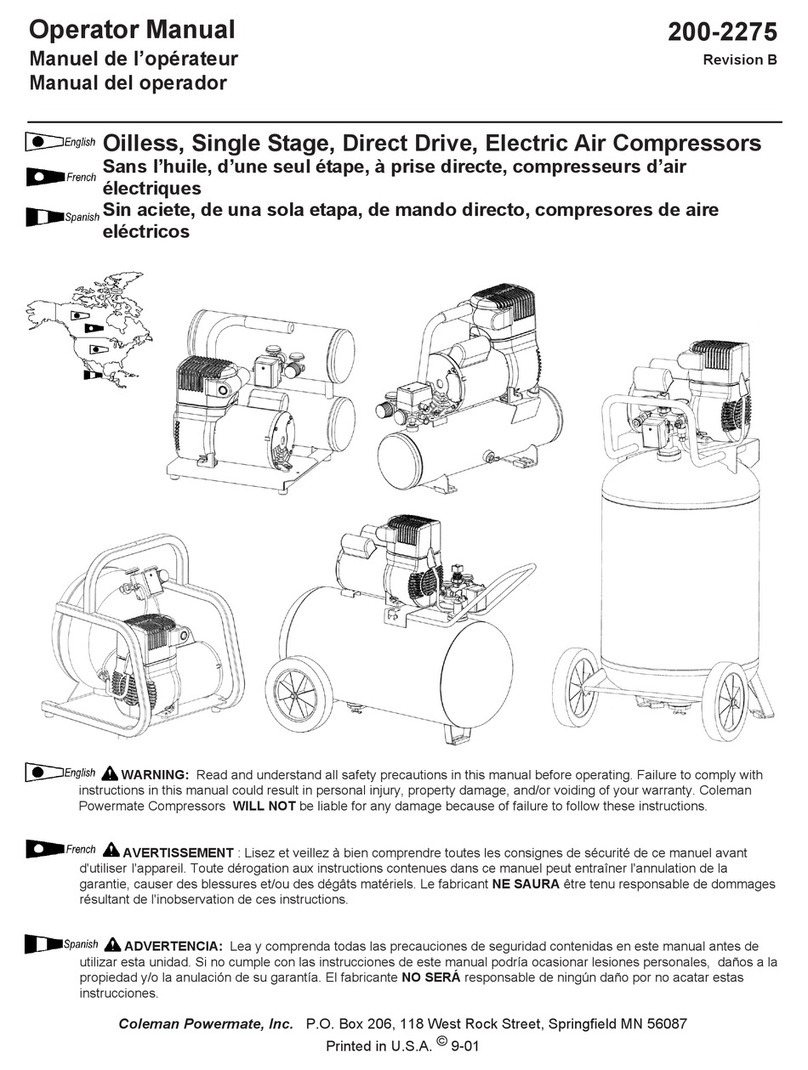

Coleman

Coleman Air Compressors Operator's manual

American Geo Thermal

American Geo Thermal CHILLBATCH AMC-20 Installation, operation and maintenance

Craftsman

Craftsman 921.153120 owner's manual

Crown

Crown CT33131 Original instructions

Rockford Fosgate

Rockford Fosgate CAT1040 Operations & parts manual

Powerex

Powerex SED1007HP manual