IMC VENTUS V60 Owner's manual

Page | 1

Installation, Operating and Servicing

Instructions

A34/069 R4 ECN 4825 April 2021

VENTUS V60, V90 & V135 BOTTLE COOLERS

Please make a note of your product details for

future use:

Date Purchased: _________________________

Model Number: __________________________

Serial Number: __________________________

Dealer: ________________________________

________________________________

_______

Page | 2

CONTENTS

WARRANTY............................................................................................................3

DELIVERY...............................................................................................................3

INTRODUCTION.....................................................................................................4

INSTALLATION.......................................................................................................7

REMOVING WOOD DOOR VERSION DOOR FRAME ..........................................8

FITTING WOOD FRONT TO FRAME.....................................................................9

CHANGING AN LED LIGHT FITTING...................................................................10

ELECTRICITY SUPPLY CONNECTION...............................................................11

COMMISSIONING ................................................................................................11

CHANGING THE CONTROLLER SET POINT......................................................12

USING YOUR BOTTLE COOLER.........................................................................12

ECO BUTTON FUNCTION ...................................................................................13

CLEANING............................................................................................................14

CHANGING SHELF POSITION ............................................................................14

MAINTENANCE....................................................................................................15

DO’S AND DON’TS...............................................................................................16

V60 WIRING DIAGRAM........................................................................................17

V90 WIRING DIAGRAM........................................................................................18

V135 WIRING DIAGRAM......................................................................................19

SPARES IDENTIFICATION FRONT.....................................................................20

SPARES IDENTIFICATION REAR .......................................................................21

SPARE PARTS LIST.............................................................................................22

END OF LIFE DISPOSAL .....................................................................................24

MATERIAL CONTENT..........................................................................................24

ORDERING SPARE PARTS.................................................................................25

FURTHER INFORMATION...................................................................................25

Page | 3

WARRANTY

These bottle coolers are guaranteed by Lincat for 2 years from the date of

purchase from Lincat, or from one of its stockists, dealers or distributors. The

guarantee is limited to the replacement of faulty parts or products and excludes

any consequential loss or expense incurred by the purchaser. Defects which

arise from faulty installation, inadequate maintenance, incorrect use, connection

to the wrong electricity supply, or fair wear and tear, are not covered by the

guarantee.

The guarantee applies in this form to installations within the United Kingdom.

Export units carry 2 years “parts only” warranty.

Please observe these instructions carefully.

DELIVERY

The packaged machine consists of:

V60 Bottle Cooler containing:

Shelf (Full size)

Shelf (base ½ size)

Shelf clips

Sets of keys

2

1

8

2

V90 Bottle Cooler containing:

Shelf (Full size)

Shelf (base ½ size)

Shelf clips

Sets of keys

2

1

12

2

V135 Bottle cooler containing:

Shelf (Full size)

Shelf (base ½ size)

Shelf clips

Sets of keys

2

1

16

3

Instruction Booklet

1

Please notify both the carrier and the supplier within 24 hours of receipt if

anything is missing or damaged.

Check that the correct machine has been supplied and that the voltage, marked

on the rating plate, is suitable for the supply available. The rating plate is

located internally on the right hand side of the unit.

Page | 4

INTRODUCTION

The Ventus V60, V90 and V135 are back-bar or under-bar refrigerators

designed for the cooling and storage of beverages.

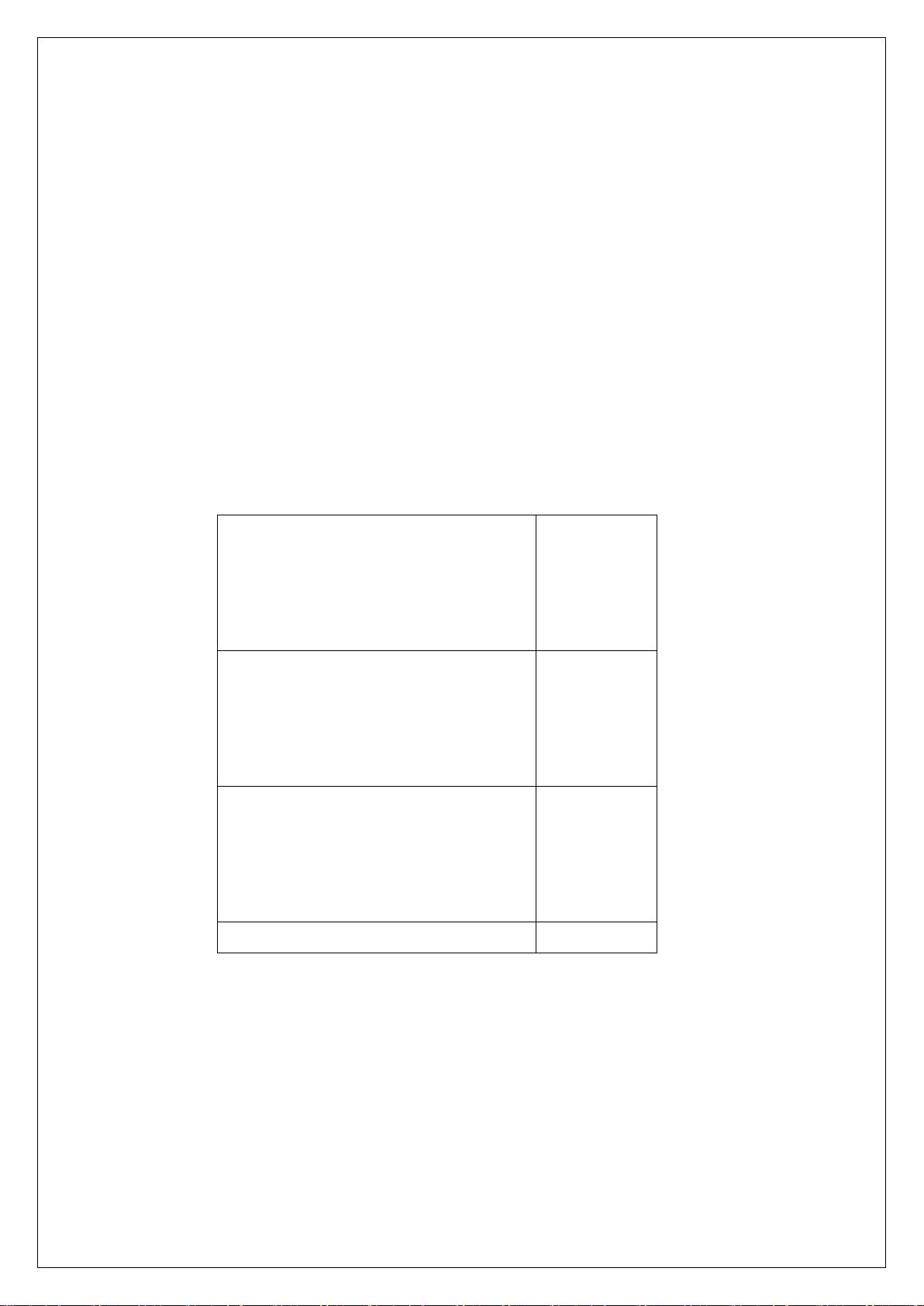

The following quantity of beverage bottles/mixers can be held in each unit:

Bottle Cooler

Capacity

(330ml Bottles / 150ml mixer cans)

V60 (900h x 600w x 500d) std

V60 (850h x 600w x 500d)

V60 (800h x 600w x 500d)

120

72 / 48

72 / 48

V90 (900h x 900w x 500d) std

V90 (850h x 900w x 500d)

V90 (800h x 900w x 500d)

195

117 / 78

117 / 78

V135 (900h x 1350w x 500d)std

V135 (800h x 1350w x 500d)

310

185 / 125

Page | 5

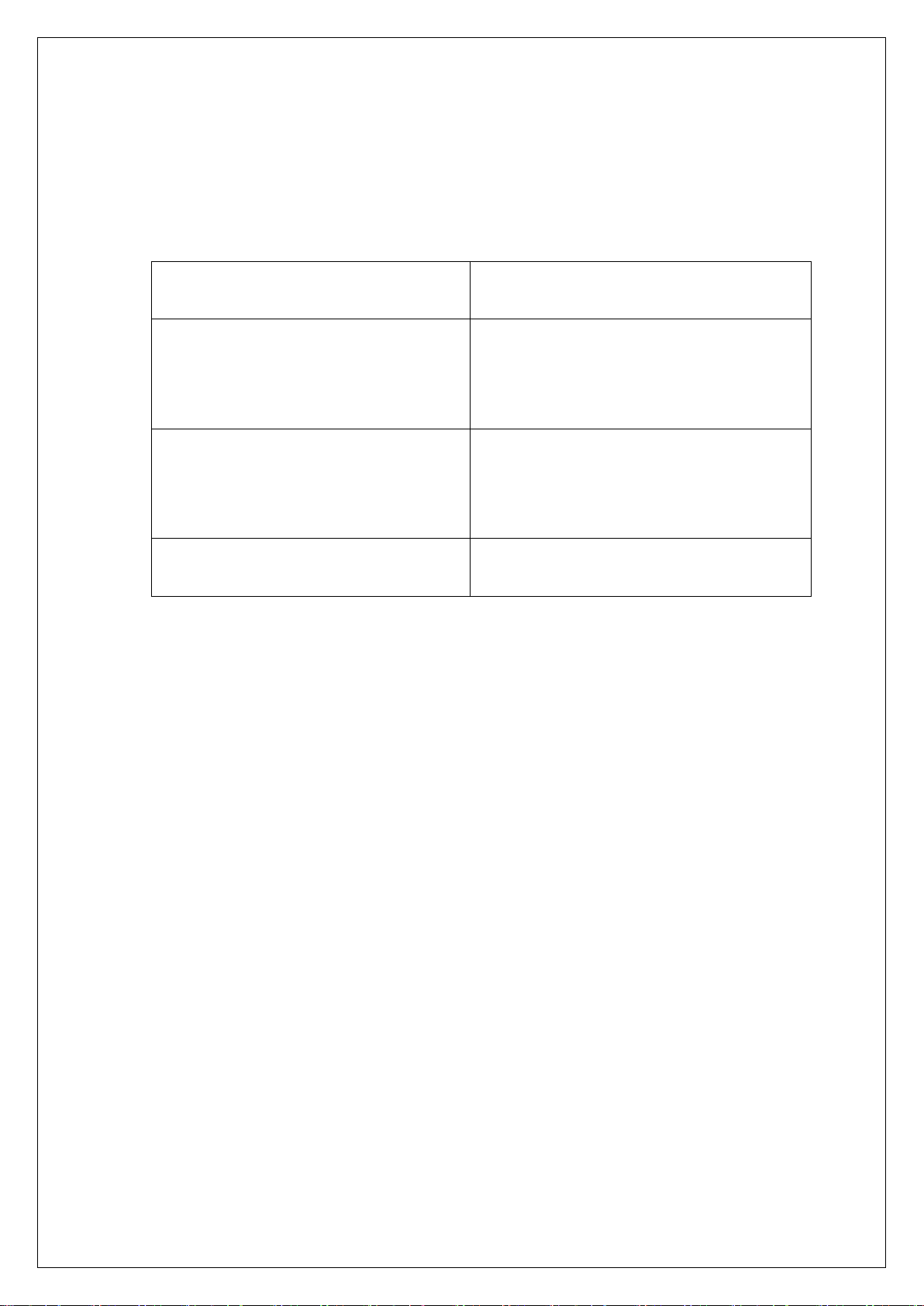

Ventus Dimensions:

MODEL

X

Y

V60 STANDARD

500

900

V60 850 SHORT

500

850

V60 800 SHORT

500

800

V90 STANDARD

500

900

V90 850 SHORT

500

850

V90 800 SHORT

500

800

V135 STANDARD

500

900

V135 800 SHORT

500

800

X mm

Y mm

600mm

900mm

X mm

Y mm

V60

V90

This manual suits for next models

10

Table of contents

Other IMC Accessories manuals