IMC pc2 series 4 User manual

CHIPPER

INSTALLATION, OPERATING AND MAINTENANCE MANUAL

PLEASE LEAVE WITH OPERATOR

CHIPPER –PC2 SERIES 4

Imperial Machine Company Limited

Unit 1, Abbey Road

Wrexham Industrial Estate

Wrexham LL13 9RF

Tel: +44 (0)1978 661155

Fax: +44 (0)1978 729990

Service Fax: +44 (0)1978 667766

Spares Fax: +44 (0)1978 667759

E-mail: info@imco.co.uk

Website: www.imco.co.uk

A34/001 R15 ECN 8499 May 2016

CHIPPER

EC DECLARATION OF CONFORMITY

(Guarantee of Production Quality)

We, Imperial Machine Company Limited of:

Unit 1, Abbey Road, Wrexham Industrial Estate, Wrexham, LL13 9RF

Declare under our sole responsibility that the machine

CHIPPER –PC2 SERIES 4

As described in the attached technical documentation is in conformity with the Machinery directive

98/37/EC (Formally 89/392/EEC) and is manufactured under a quality system BS EN ISO 9001

It is also in conformity with the protection requirements of the Electro Magnetic Compatibility

Directive 2004/108/EC and is manufactured in accordance with harmonised standards EN61000-6-

1:2001 Immunity and EN61000-6-3:2001 Emissions (plus product specific standards).

IMC’s product range also satisfy the essential health and safety requirements of the Low Voltage

Directive 2006/95/EC and are manufactured in accordance with standards BS EN 60335-1 and

relevant product specific standards.

Approved by E Plumb, Engineering Manager

Signed at Wrexham, Date May 2016

CHIPPER

INDEX

GUARANTEE........................................................................................................ 1

DELIVERY ............................................................................................................ 1

SAMPLE RATING LABEL.................................................................................... 1

INTRODUCTION................................................................................................... 2

CHIPPER DIMENSIONS....................................................................................... 2

INSTALLATION .................................................................................................... 3

ELECTRICITY SUPPLY CONNECTION............................................................... 3

COMMISSIONING ................................................................................................ 4

OPERATION ......................................................................................................... 4

CHANGE CHIP SIZES .......................................................................................... 5

CLEANING............................................................................................................ 5

MAINTENANCE.................................................................................................... 6

ORDERING SPARE PARTS................................................................................. 6

WIRING DIAGRAM FOR CHIPPER...................................................................... 7

EXPLODED VIEW ................................................................................................ 8

PARTS LIST ....................................................................................................... 10

CHIPPER 1

GUARANTEE

This equipment is guaranteed by IMC for 2 years from the date of its purchase

from IMC, or from one of its stockists, dealers or distributors. The guarantee is

limited to the replacement of faulty parts or products and excludes any

consequential loss or expense incurred by purchasers. Defects which arise from

faulty installation, inadequate maintenance, incorrect use, connection to the

wrong electricity supply or fair wear and tear are not covered by the guarantee.

Please observe these instructions carefully.

The guarantee applies in this form to installations within the United Kingdom.

DELIVERY

The packaged machine consists of:

Chipper Unit 1

Instruction Booklet 1

Wall Plaque 1

Guarantee / Registration Card 1

Please notify both the carrier and the supplier within three days of receipt if

anything is missing or damaged.

Check that the correct machine has been supplied and that the voltage, marked

on the rating plate, is suitable for the supply available. The rating plate is

located on the right hand side of the case.

SAMPLE RATING LABEL

2 CHIPPER

INTRODUCTION

The Chipper is intended for cutting peeled potatoes into chips or scallops, in a

batch process.

CHIPPER DIMENSIONS

All dimensions are in mm.

CHIPPER 3

INSTALLATION

For the Installer:

These Instructions contain important information designed to help the user

obtain the maximum benefit from the investment in an IMC Chipper.

Please read them carefully before starting work, and consult with the supplier in

the event of any queries.

Be sure to leave this Instruction Manual with the user after installation of the

machine is complete.

Procedure

The unit is designed to stand on a bench, table, or on a draining board. Ensure

that whatever is used for this purpose is sturdy and rigid and not more than 750

mm high. A higher table makes it difficult to load the machine.

The Chipper should be placed where supplies of peeled potatoes from the

peeling machine are readily accessible, after which the output of chips need to

be in easy reach of the fryer.

The IMC Chipper has a top loading hopper into which potatoes can be tipped

from either side or from the front. It is not handed, and no consideration need be

given to its loading direction. The discharge of chips is from the chute at the

front of the machine, and the machine should be placed so that this chute is

directly over the receiving container.

ELECTRICITY SUPPLY CONNECTION

A Wiring Diagram is shown on Page 7.

Position the Chipper in the chosen site. The electricity supply connection should

be made to a power outlet socket or isolator mounted on the wall close to the

machine. This socket or isolator must be accessible once the machine is

installed. Before connecting, check that the voltage shown on the rating is

correct for the electricity supply you have available. The outlet should be fused

at 13 amps.

NOTE: The plug is fitted with a 10amp fuse.

WARNING: This machine must be earthed

Should the supply cord become damaged then an approved electrician must fit

a replacement. The IEE Codes of Practice must be observed.

An equipotential bonding terminal is provided at the back of the unit near the

cable outlet for external earth bonding. Provision of an earth bond does not

remove the requirement for an earth in the electrical supply.

4 CHIPPER

COMMISSIONING

Open the hopper by fully unscrewing the interlock knob at the front and lifting up

until the hopper is fully resting back on its hinges. Turn the rotor by hand to

ensure that it is completely free to rotate and that the knife block assembly is

properly in position. Replace the hopper and screw down the interlock knob until

it is tight.

It is now safe to switch on at the wall socket and to start the machine by

pressing the start button on the front of the machine (green button). To stop the

machine press the red button.

One of the safety features provided on the IMC Chipper are the interlock

devices that ensures that the machine cannot run unless both the knife block

and the hopper are properly and fully in position. This makes it impossible for

the operator to touch the spinning rotor whilst it is running.

To confirm that the interlock is operating correctly press the start button to

switch the machine on. Then whilst it is still running, unscrew the hopper

interlock knob. After two or three turns the machine should switch off, but there

are still two or three further turns of the knob necessary before the hopper can

be opened. The rotor should be stationary within 2 seconds of the hopper being

opened. If the knife block is not in place, another interlock will prevent the

machine from running.

OPERATION

With the machine running, feed peeled potatoes into the hopper. It will hold

approximately 12kg of potatoes, which self feed into the mechanism of the

machine and discharge as cut chips from the chute.

Some care is necessary when loading, as the rotor will not accept abnormally

large potatoes, so these must be cut into two. The hopper is specially designed

not to pass potatoes which are over size and which could otherwise clog the

mechanism. It is also essential that only potatoes be fed in to this machine.

NOTE: take great care to ensure that there are no stones mixed in with the

potatoes.

A stone or any other foreign object will damage the cutting knives and could

cause the machine to jam. In this event the machine has an inbuilt protection

device, which will switch it off before the electric motor burns out. This overload

protection feature will automatically reset itself when it cools down but it is

necessary to wait a few minutes for this to happen. After clearing the jam

resume operation by pressing the start button. Should a stone damage the

knife blades they must be replaced as further use could break the blades.

CHIPPER 5

This Chipper is designed for batch process work; switch the machine off once

all the potatoes have been cut. The motor is fitted with a thermal trip that will

stop the machine if the motor overheats. This protection feature will

automatically reset itself when it cools down but it is necessary to wait a few

minutes for this to happen.

The machine will switch itself off in the event of failure of the electricity supply

whilst operating. When the supply is restored the machine must again be

switched on. It is fitted with no-volt release.

CHANGE CHIP SIZES

To change to a different size of chip, change the knife block assembly. Spare

knife block assemblies are available from IMC. Open the hopper, lift out the

knife block and replace with the alternative selected. Knife blocks are available

in the following sizes from the standard range: 8mm, 11mm, 14mm and

14x17mm. Scallops can be cut with similar knife block assemblies. The

standard scallop size is 8mm.

CLEANING

It is essential to clean the machine at least once a day, preferably at the end of

each period of operation.

1. Switch off at the socket or isolator

2. Fully unscrew the interlock knob, open the hopper and lift it out of its hinge

seating at the back

3. Clean the hopper in a sink, dishwasher, pot wash or by hosing with a spray

4. Remove the knife block by lifting upwards, off its locating dowels

NOTE: Take care when handling the knife block. The blades are

sharp.

5. Clean the knife block under a spray or running tap and remove any

residual pieces of potato. DO NOT use any metallic objects, such as a

knife or screwdriver, to un-block the knife block. Visually inspect all blades

for wear or damage, and replace the knife pack as necessary. Do not

attempt to straighten a bent blade - bent blades should be replaced

immediately.

6. Lift the rotor carefully off its spindle.

7. Clean the rotor in a sink, pot wash, etc.

8. Clean out the interior of the base unit and wipe over the exterior with a

damp soft cloth. Do not hose down the exterior of the machine.

DO NOT USE CLEANING MATERIALS CONTAINING ABRASIVES OR

BLEACHES.

9. Reassemble the machine, reversing the above disassembly procedure.

When replacing the rotor, ensure that it is put back square on its spindle.

Make sure that it is properly seated on its cross pin by turning it slowly until

it drops onto this seating. When replacing the knife block it should slip

down easily on to its dowel pins, make certain that it is fully down.

6 CHIPPER

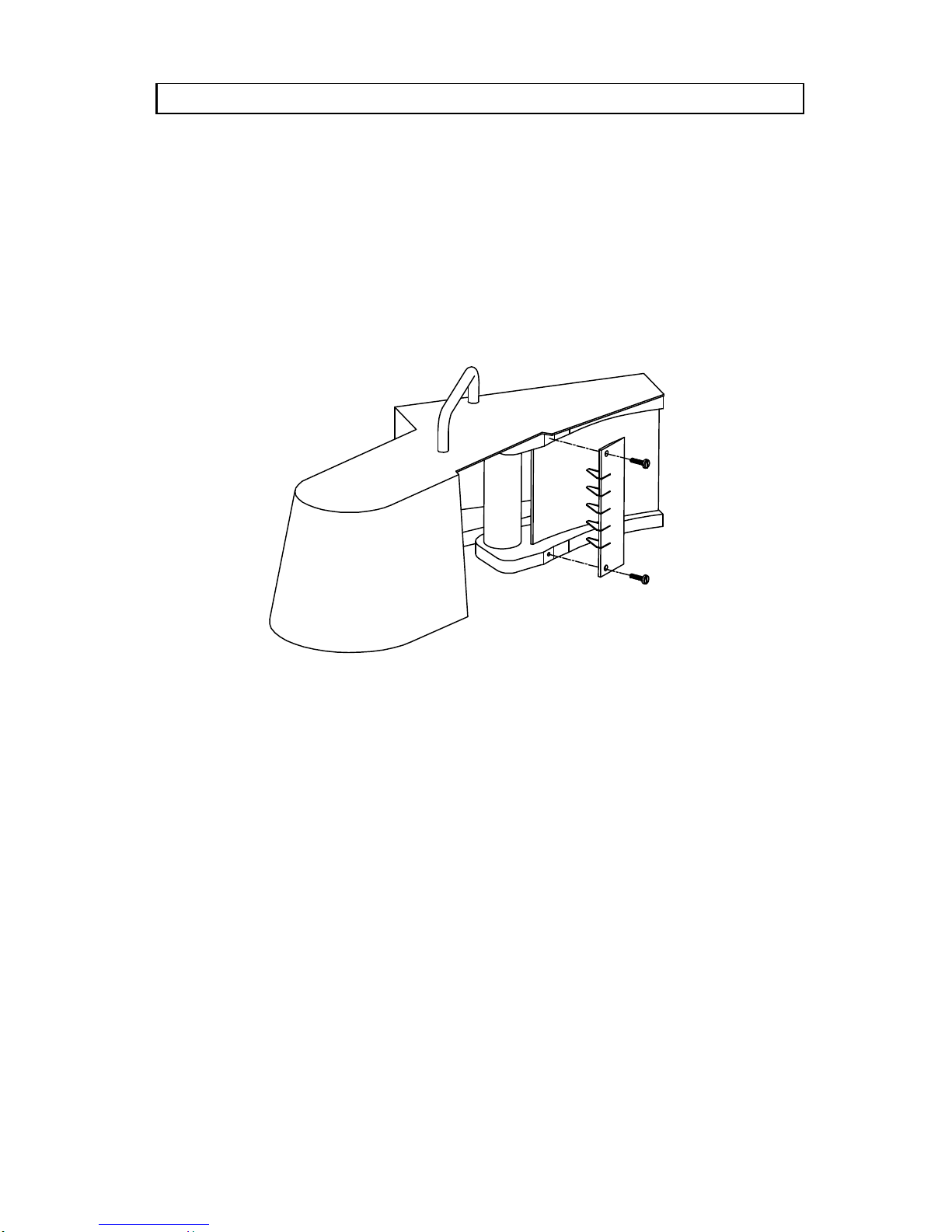

CHANGING KNIFE BLADES

The knife blades are supplied as a pack and individual blades cannot be

changed. Change the knife blade pack as soon as it is damaged or blunt. To

change the knife blade pack remove the knife block and undo the two screws

securing the knife blade pack. Dispose of the old blades carefully and screw

the new knife blade pack in place. See diagram below.

For optimum performance IMC recommend changing the blade pack every 6

months, or sooner depending on usage.

NOTE: Take care when handling the knife block. The blades are sharp.

MAINTENANCE

Details of IMC Service Contracts are available on application.

ORDERING SPARE PARTS

In the event that spare parts or accessories need to be ordered, please always

quote the SERIES AND SERIAL NUMBER of the machine. This is to be found

on the rating plate located near the supply cable.

For installations outside the UK please contact your supplier.

For information on IMC spares and service support (if applicable), please call

IMC on +44 (0)1978 661155. Alternatively, contact us via email or fax:

IMC Service Desk Fax: +44 (0)1978 667766

E-mail: service@imco.co.uk

IMC Spares Desk Fax: +44 (0)1978 667759

E-mail: spares@imco.co.uk

CHIPPER 7

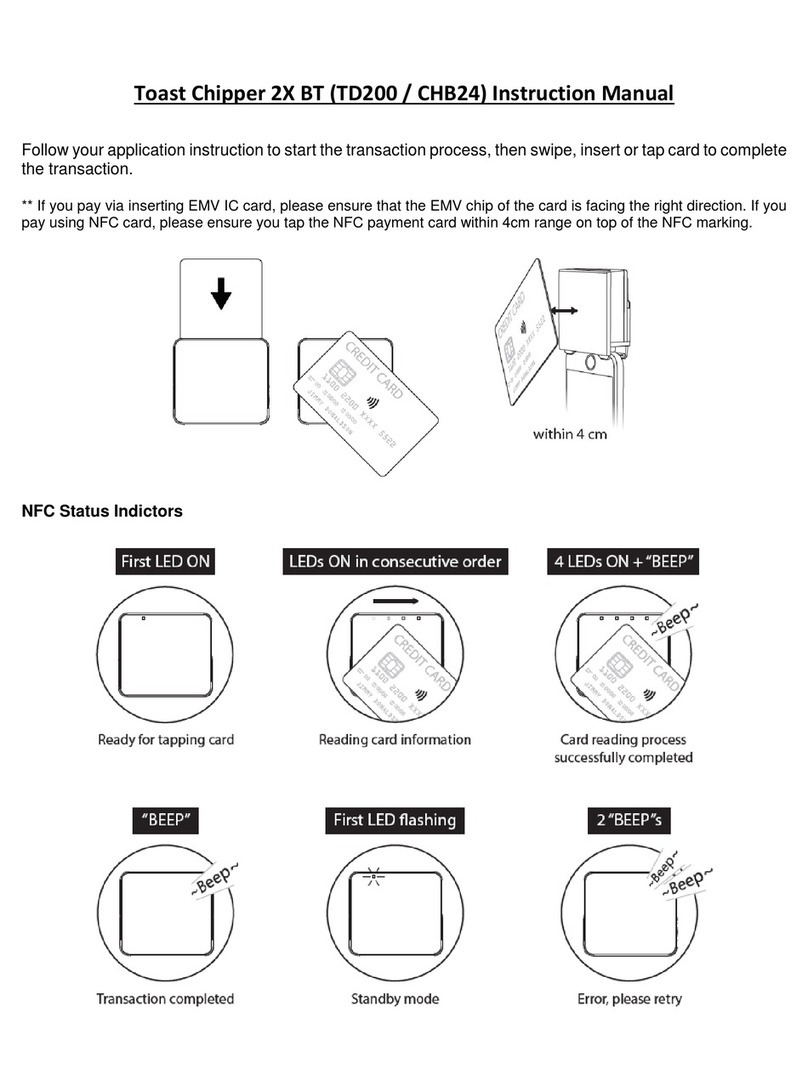

WIRING DIAGRAM FOR CHIPPER

8 CHIPPER

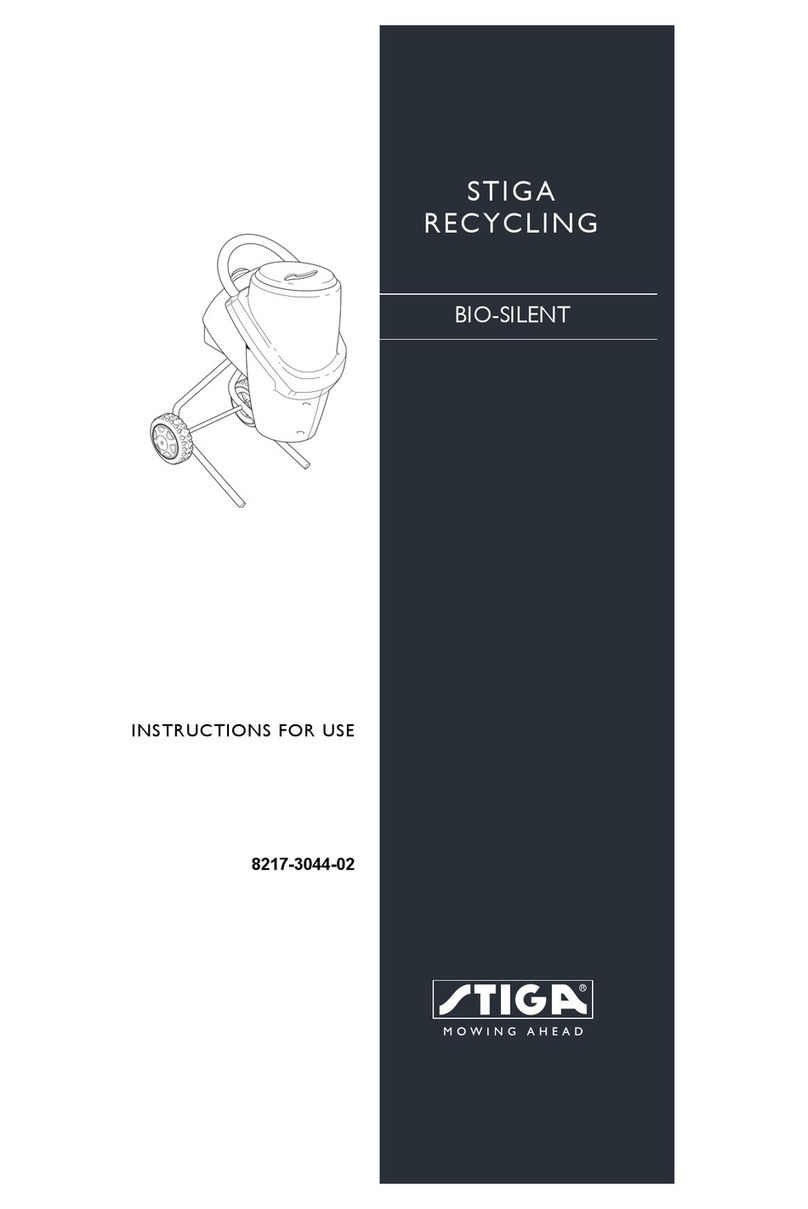

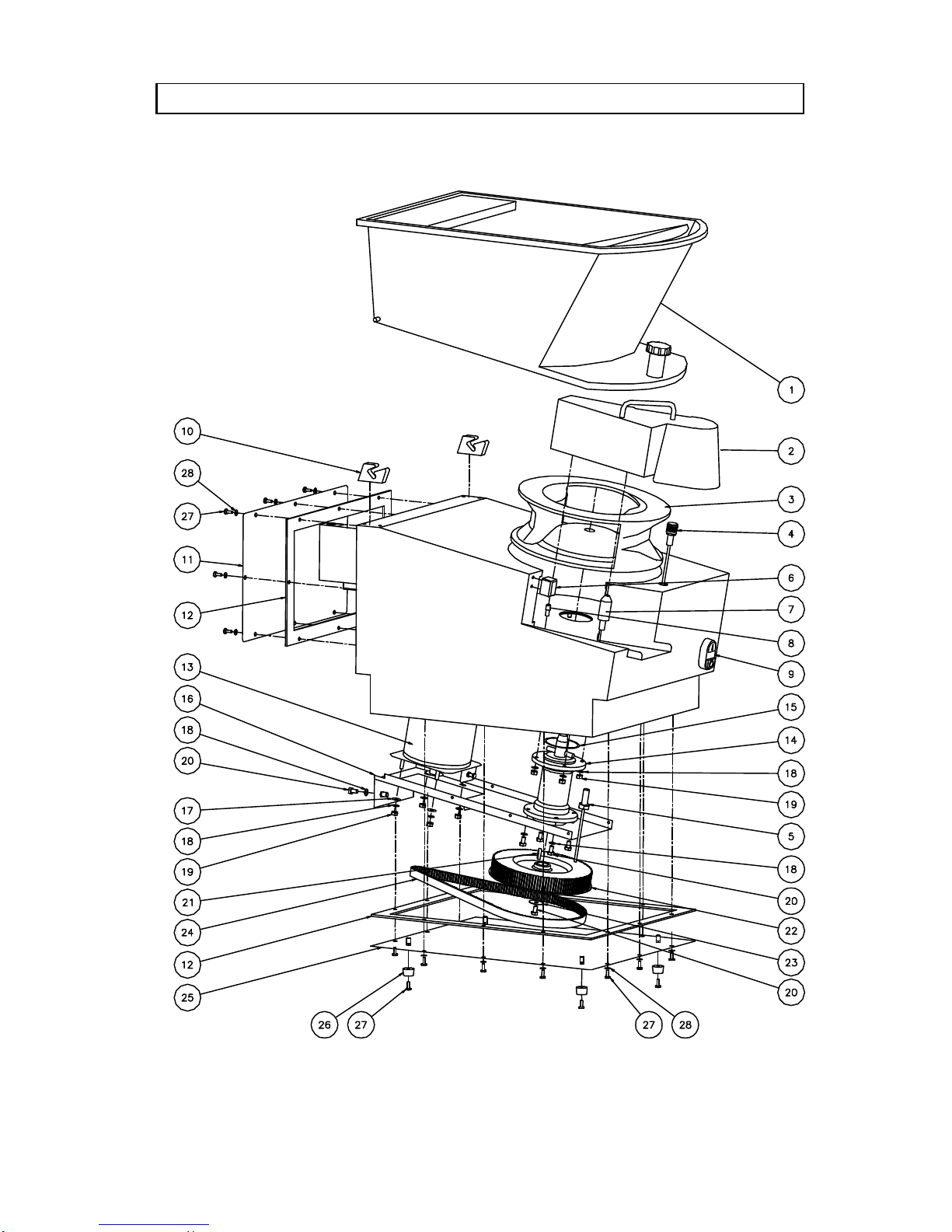

EXPLODED VIEW

CHIPPER 9

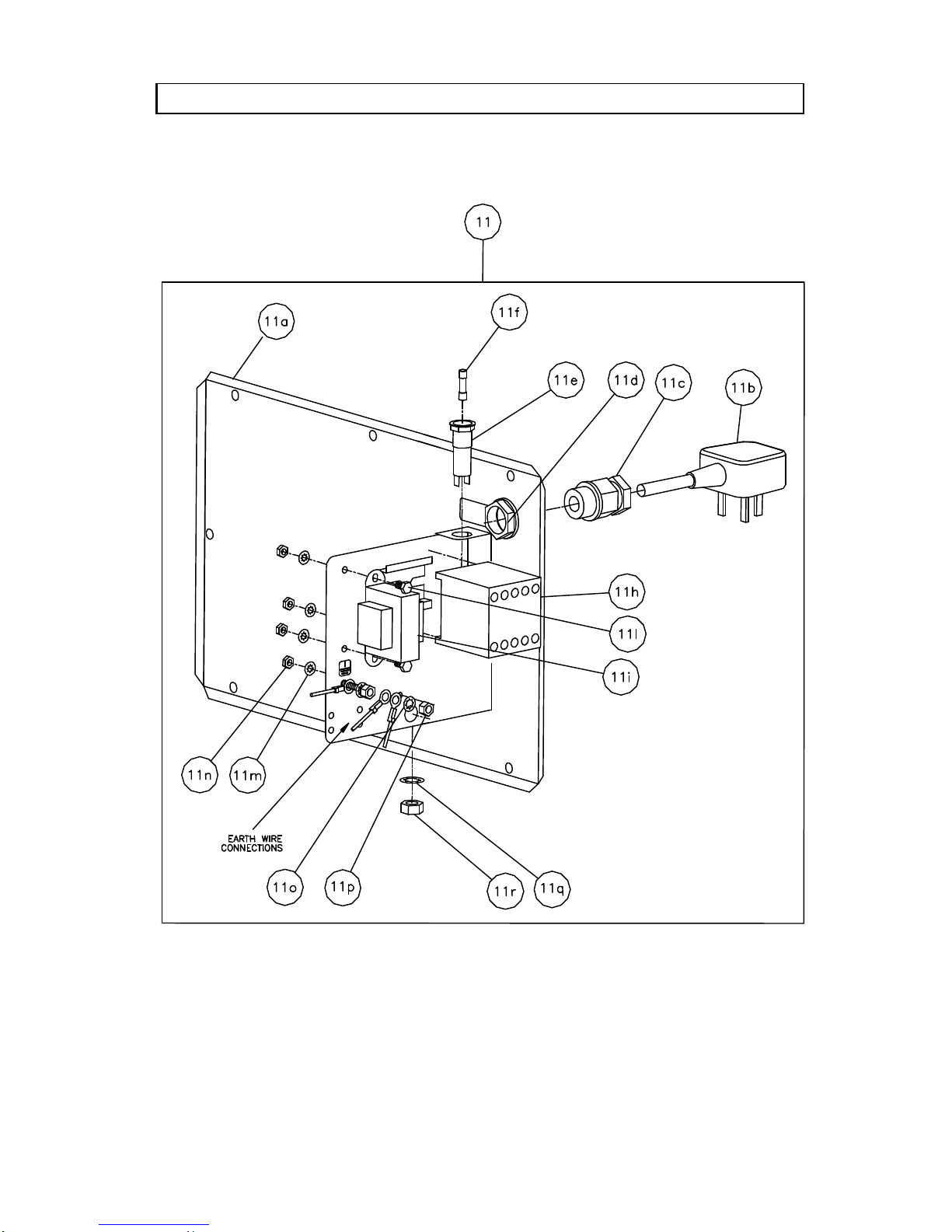

Electrical control parts

10 CHIPPER

PARTS LIST

ITEM PART NO DESCRIPTION ITEM PART NO DESCRIPTION

1

S61/121

Hopper assembly

11h

G30/343

Contactor 24V ac

M81A

Interlock body

11i

G60/

427

Transformer terminated

A12/011

Interlock spring

11m

D25/033

M4 Shakeproof washer SS

M69

Interlock knob

11n

D20/011

M4 Full nut SS

D26/017

Interlock pin

11o

D2

5/004

M5 Shakeproof washer SS

M48

Interlock knob cap

11p

D20/038

M5 Full nut SS

2

S61/111

8mm Scallop knife block

11q

D25/062

M8 Lock washer SS

S61/129

Knife blade pack 14mm

11r

D20/014

M8 Full nut SS

S61/128

Knife blade pack 17mm

12

K08/043

Gasket

strip

S61/114

14mm Knife block

13

S61/177

Motor assembly

S61/115

14x17mm Knife block

13a

E61/014

Motor mounting plate

L61/004

Scallop slicing blade

13b

D19/032

M5x12 Hex screw SS

D22/060

No 6 Self tapping screw SS

13c

D19/115

M6x30 Hex screw SS

3

C61/002 M1 Z

Rotor

13d

D20/013

M6 Full nut SS

4

S61/123

Hopper switch assembly

13e

A06/099

Drive pulley (keyed)

5

S61/127

Knife block switch assy

13f

L61/041

Bush (for drive pulley)

6

L61/013

Anti deflection block

13g

D19/142

M4x25 Hex screw SS

D2

5/004

M5 shakeproof washer SS

13h

G60/323

Motor Cable Assy

D19/032

M5x12 Hex Screw SS

14

S61/118

Bearing housing assembly

7

L61/009

Knife block locating pin

15

A02/068

O

–

Ring

D25/003

M10 spring washer SS

16

E61/015

Drive plate

D20/015

M10 full nut

SS

17

D25/052

M6 Plain washer SS

8

L34/005

Knife block short pin

18

D25/005

M6 Shakeproof washer SS

D25/052

M6 Plain washer SS

19

D20/013

M6 Full nut SS

D20/013

M6 Full nut SS

20

D19/038

M6x12 Hex screw SS

9

G45/109

On / off button

21

D27/031

Drive

key

G45/110

Button protective boot

22

A06/090

Driven pulley 114

-

5M

-

25

G45/111

Button contacts NO & NC

23

D25/019

M6 25OD plain washer

10

A13/024

Hopper hinge

24

A05/041

Timing belt 850

-

5M

-

2

5

D25/033

M4 Shakeproof washer SS

25

E61/007

Base plate

D1

9/120

M4x8 Hex screw SS

26

A13/108

Plastic foot

11

S61/172

Rear panel assembly

27

D21/044

M5x12 Pan screw SS

11a

E61/033

Rear panel

28

D25/004

M5 shakeproof washer SS

11b

G60/101 M4

Mains cable with plug

11c

A10/266

Strain relief gland

11d

A10/

224

Back nut

11e

G35/012

Fuse holder

11f

G35/004

Fuse 5x20 0.5A

Note

The parts list is for 230V 1ph 50Hz machines. For electrical parts for other

voltages please contact our spares department.

This manual suits for next models

1

Table of contents

Other IMC Chipper manuals

Popular Chipper manuals by other brands

MTD

MTD 246-315B000 Illustrate parts list

TruYard

TruYard CM90 Series Safety, operation & maintenance instructions

Tracmaster

Tracmaster Camon C275 Operating instructions & safety notes

Echo

Echo Bear Cat CH922DH Specifications

McCulloch

McCulloch Pro Mac 8000i owner's manual

Lumag

Lumag Rambo HC15 Operator's manual