OPERATION

(Fig. 1)

The Chipper can handle a MAXIMUM 5” DIAMETER branches. Warm engine at half throttle

without load for 2 minutes. Increase the engine to full throttle to start work.

Check the reverse operation of the hydraulic feed roller by pushing the operating lever towards the

engine. Do not press the lever beyond the reverse position otherwise the emergency stop switch

will be activated which will stop the engine.

Set the speed of the hydraulic feed rollers by adjusting the setting knob up or down the adjusting slot

as required.

It is best to start off the rollers on a slow setting - the speed can be increased for small branches if

required but for the large branches it must be reduced.

Gently feed in the timber until it is gripped by the feed rollers - once gripped,let go of the timber and

the machine will feed itself at the pre-set roller speed.

Feed only one branch at one time - NEVER PUT TWO OR MORE BRANCHES INTOGETHER.

If the rollers jam push the operating lever forwards towards the engine to reverse the rollers and

drive the branch back out.

In the event of any serious occurrence press the operating lever fully to activate the Emergency

Stop.

Attempting to overfeed the machine with too large a branch or too high feed roller speed may cause

damage. The machine is designed to handle only timber - DO NOT PUT ANY OTHERTYPE OF

MATERIAL INTOTHE MACHINE.

FINISHING WORK

Once the work has finished,allow the machine to continue running at full speed for one minute to

ensure the rotor housing is completely clear of debris.

Slowly reduce the engine throttle to tick over then switch off the ignition switch. BE C AREFUL OF

HOT EXHAUST.

NB Rotor will continue to rotate silently fora short time after the engine is switched off. Ensure

the rotor is stationary before attempting any cleaning oropening of rotor housing.

ENSURETHATTHE IGNITION SWITCH IS LEFT IN THE OFF POSITION. Stopping the engine

by using the emergency stop switch and leaving the ignition switched on will result in a flatbattery.

BEFORE STARTING

Ensure the machine is on firm,level ground and that the handbrake is ON. DO NOT USE MACHINE

ONASLOPE. (Fig. 1)

Lower the rear stabiliser onto the ground and lock in to place. (Fig. 1)

Remove the clips retaining the infeed chute extension and lower the chute to the operating position.

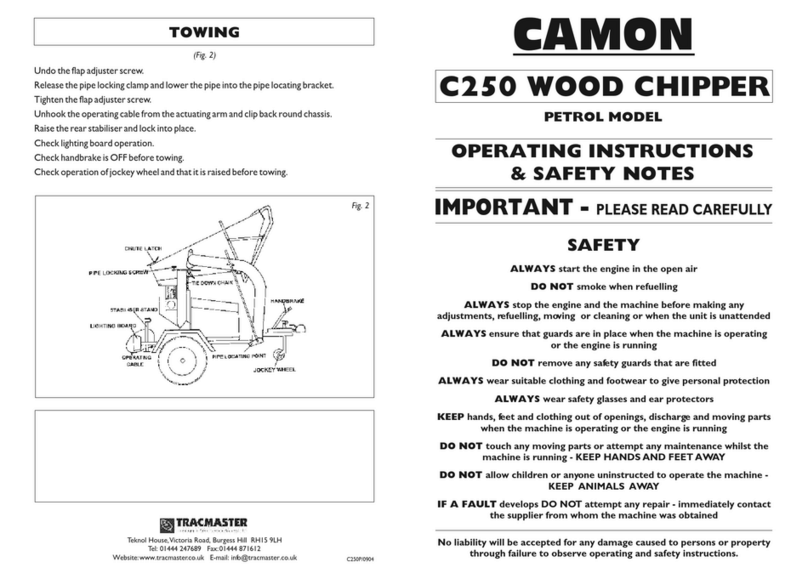

Secure in place with the retaining clips. (Fig. 2)

Connect the operating cable to the actuating arm. (Fig. 1)

Undo the flap adjuster screw. (Fig. 2)

Unhook the discharge pipe from its transport position. Raise the pipe and secure it into the

operating position with the pipe locking clamp. (Fig. 1)

Set the discharge pipe in the required direction of discharge and set the angle of the outlet flap.

Tighten the flap adjuster screw. (Fig. 2)

Check the engine oil level. (Fig. 1)

Check the hydraulic oil level in header tank. (Fig. 1)

Check fuel level.Only use diesel from a clean container. (Fig. 1)

TO START ENGINE

(Fig. 1)

Ensure the emergency stop switch is released and the “No-Stress” Control panel is switched on.

Check fuel lever is set to ‘ON’.

Set the throttle to half speed.

Turn ignition key clockwise to first position, then turn key further clockwise to “preheat” position

and hold to allow the glow plug heater light to go out. Turn the key fully clockwise to start the engine

and release the key immediately the engine starts.

NB If the engine does not start after 10 seconds of cranking, wait 30 seconds then repeat the

starting sequence. Do not allow the starter motor to run continuously for more than 20 seconds.

The engine cannot be started unless the intake chute is latched down and the engine cover is down.

Lock-out switches on the chute and cover prevent this.

Fig. 1

Noise emissions up to 104dB(A)

Ear defenders to be worn to BS 6344

GOGGLES

must be worn when

using this machine

Wear

ear protectors