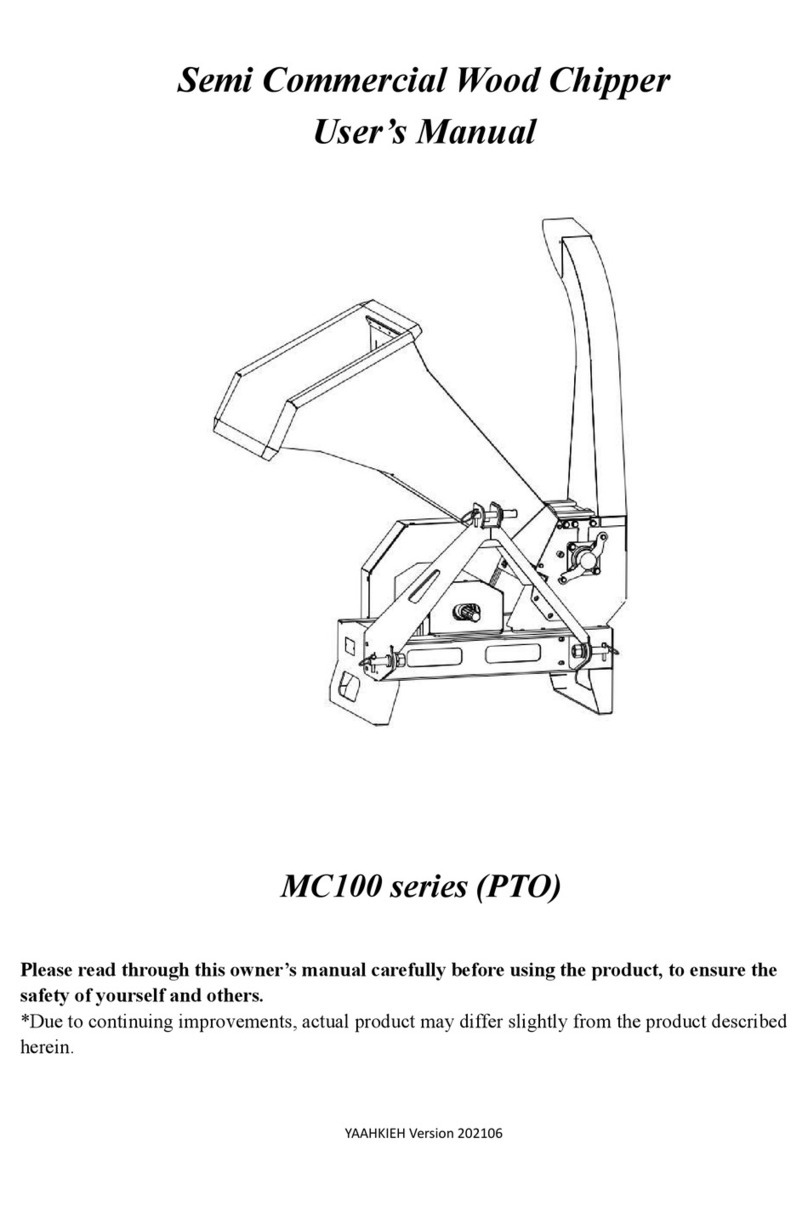

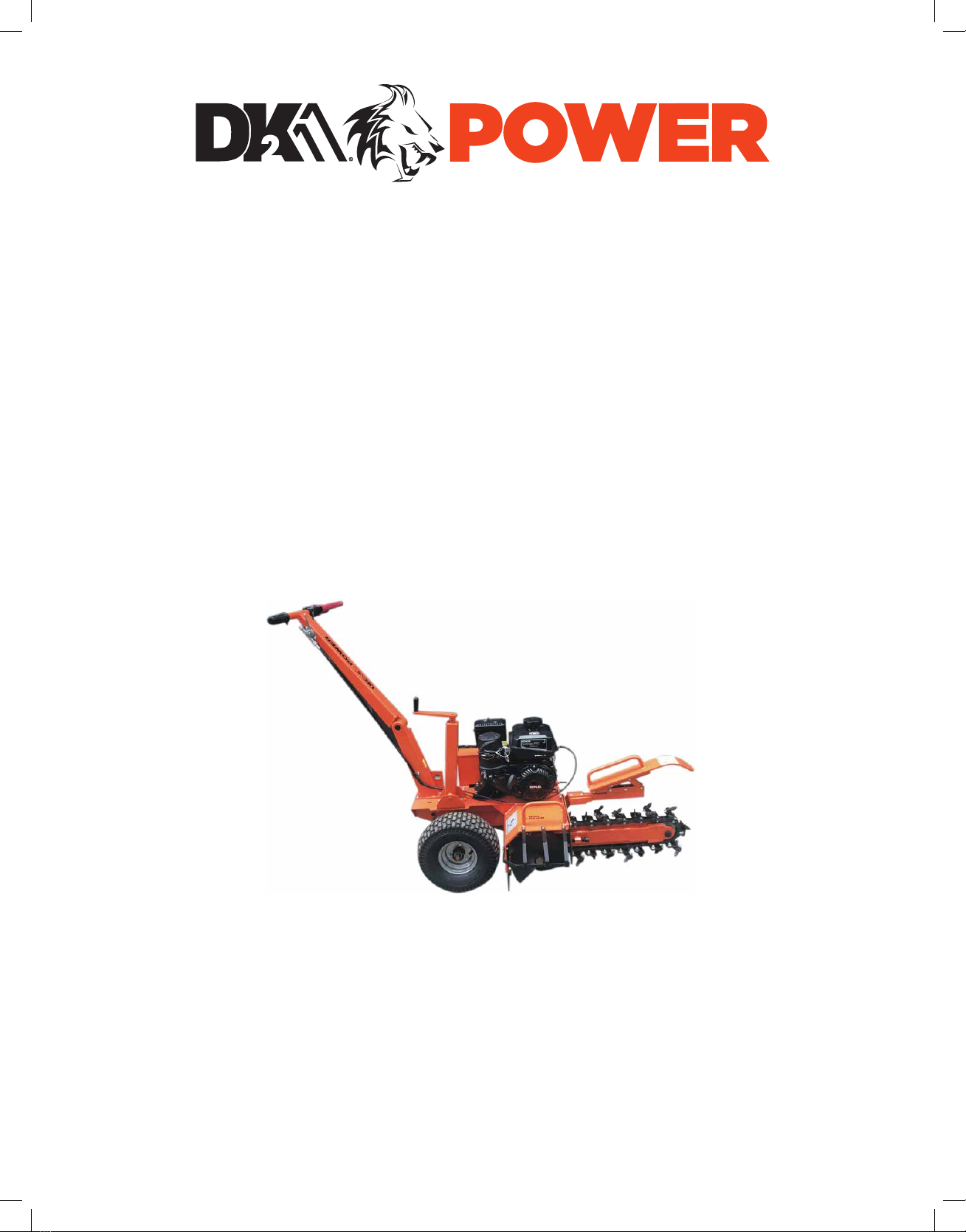

TABLE OF CONTENTS

Check the packing........................................................................................................................................................ 3

Handle assembly........................................................................................................................................................... 4

Depth control handle ................................................................................................................................................... 5

Chain drive bar............................................................................................................................................................... 6

Chain installation........................................................................................................................................................... 7

Safety bar installation................................................................................................................................................... 8

Auger guard.................................................................................................................................................................... 9

Engine operation, safety and maintenance ........................................................................................................... 10

SCHEMATICS AND PARTS

Chain system.................................................................................................................................................................. 11

Gear system.................................................................................................................................................................... 12

Drive system................................................................................................................................................................... 13

Depth control system................................................................................................................................................... 14

Main frame ...................................................................................................................................................................... 15

Ratchet assembly.......................................................................................................................................................... 16

Complete assembly...................................................................................................................................................... 17

Parts list............................................................................................................................................................................ 18

OPERATION

Before starting ............................................................................................................................................................... 19

Quick start and troubleshooting................................................................................................................................ 20

Warranty........................................................................................................................................................................... 21