IMC IMC-2000BX User manual

International Machine Concepts

Model IMC-2000BX

Air-Cooled Continuous Electromagnetic

Induction Sealing Machine

(Please read the manual carefully before use.)

Operation Manual

1

I. General

The technology, in which aluminum plastic composite materials get heated and

sealed through electromagnetic induction, is a relatively advanced and popular

non-contact sealing technology both at home and abroad. The electromagnetic

induction sealing machine manufactured under this principle has increasingly become

the necessary equipment in medicine, pesticide, grease, subsidiary foodstuff, health

product, beverage, cosmetics, chemical and other industries for high-quality airtight

sealing of plastic, glass and other non-metallic bottles, so as to improve product

quality level, achieve enhanced sealing and shelf-life performance, as well as meet

higher requirements for anti-theft and security.

The company adopts the internationally advanced heating processing

technology, and selects imported OEM components for key electronic components.

Also, through improvements with years of accumulated production experience and

exploration, it now has developed and produced Model LGYF-2000 Series

electromagnetic induction sealing machine, which has made major breakthroughs in

sealing range, machine performance stability and efficiency, becoming a high-quality

but inexpensive induction sealing equipment more popular in the domestic market.

II. Principle:

Based on the principle that metal objects would produce friction and thus

generate heat under the high-frequency electromagnetic field, this machine relies

upon electromagnetic induction aluminum to make foil heat and melt adhesive

membrane on the lower layer of aluminum foil to bond with the sealing surface, to

realize continuous, fast and non-contact sealing work.

III. Characteristics:

★The sealing range of the machine is adjustable, and with either large or small

sealing surface, can get the ideal sealing quality and efficiency.

★In case of the equipment failure of the machine in the course of work, the

conveyor automatically stops working, to realize the function of isolating

the products sealed and those unsealed.

★The conveyor belt adopts electronic step less speed adjustment, and during

the sealing process can based on voltage and current changes make

2

speed adjustment in a timely manner, in order to achieve the best sealing

quality.

★In this machine, the height of sensor head adopts electric adjustment,

capable of sealing the objects within the range of 40 to 400mm in height.

★This machine has supply and voltage meter and sealing ammeter, so that it

can make timely adjustments when voltage and current fails to meet

normal job requirements, to ensure the sealing quality.

VI. Main Technical Parameters

1. Input voltage: AC220V±10%, 50Hz

2. Input voltage: <10A

3. Sealing current: Static<2A Dynamic<10A

4. Operating frequency: 70~80KHz

5. Output power: ≤2000W

6. Enclosure protection class: IP2 I

7. Sealing diameter: Φ20mm~Φ130mm (Optimal diameter: Φ30mm~Φ120mm)

8. Bottles height: 40~400mm

9. Transportation diameter: ≤Φ200mm

10. Sealing speed: 2 to 12 m/min (bottle size, material, and sealing membrane)

11. Conveyor unit bearing load: ≤20Kg

12. External dimensions: 155×55×135cm

13. Net weight: 70Kg

V. Equipment installation and use precautions:

1. It is necessary to connect the ground wire before use , and then switch on the

power.

(The ground wire should not directly use three-phase outlet for grounding, but

a safe and reliable grounding wire should have connected separately, to ensure

safe use of electricity)

2. The cross-sectional area for power cord and ground wire should be not less

than 1.5mm2. In case of use under supply voltage instability, mount AC

automatic regulator, to ensure the quality of sealing and prevent damage to

3

the equipment.

3. The equipment must be used in a dry, clean and ventilated environment,

away from various types of heat sources.

Operating in the wet environment with severe acid corrosion will significantly

shorten the use life of equipment.

For use in places with many dusts, the dusts in the sensor head and the host

must be cleaned regularly.

4. The machine is only applicable for the sealing operations on plastic, glass,

paper and other containers, but NOT suitable for those on metal and other

derivative capacitors.

5. The requirements of induction machine sealing for selection of the sensing

membrane and the bottle cap:

(1) The material of used sensing membrane must be the same as that of the

sealed bottle.

(2) The optimum thickness range of foil on the sensing membrane is between

0.012 and 0.03mm. For the sensing membrane with the aluminum foil being

less than 0.012mm in thickness, sealing speed and quality are not

guaranteed.

(3) The vacuum aluminum plating composite membrane similar to aluminum foil

induction membrane must not used.

(4) When using the sensing membrane without paper pad, the bottle mouth and

cap must be smooth and without deformation.

(5) It is not applicable to non-threaded object sealing using the cover, as the

cover can not completely press the sensing membrane flatly and tightly,

resulting in the phenomenon of loose sealing closure.

4

VI. Operation steps:

1. Turn on the power switch (look at whether the voltage is normal), start the

cooling fan, delay for 5 seconds and make the main circuit work, press the

seal switch to make the seal work.

Note: it is prohibited to continuously and rapidly switch on and off the power

supply and seal switch! Wait for at least 5 seconds after turning off the power

switch, then re-open the power supply, or else, it would be easy to damage the

equipment.

2. Adjust the sensing head to make it higher than the sealed object by 1 to 3mm.

Place the sealed objects on both ends of the sensor head, and check whether

the sensor head and the conveyor belt are parallel. If not parallel, adjust the

pillar below the conveyor belt to make it parallel.

3. According to the bottle diameter, select the sealing range of the sensor head.

4. Press down the sealing switch, and try sealing. If the sealing is not firm,

reduce the speed of conveyor belt. If the sealing membrane is burnt, increase

the conveyor speed or increase the sensor head. After the requirements on

sealing quality are met, continuous automatic sealing operation can start.

5. To ensure that the seal will be always in the best working condition, conduct

the sealing process test, to identify the optimum process parameters and

make records. After debugging is done, prevent accidental changes in the

normal production. Also conduct regular sampling, to avoid sealing of the

substandard products.

6. When the operating current is excessive, the machine’s over-current

protection function is activated, and the conveyor belt automatically stops

working. At this time, appropriately pull up the spacing between sensor head

and sealed object, to reduce the operating current. After adjustment, re-boot

the machine to proceed with the sealing operation.

7. When the temperature of main circuit of the equipment is excessively high,

the thermal overload protection function is activated, and the equipment

automatically stops working. After the temperature drops to the normal state,

5

the equipment will automatically start the sealing operation.

VII. Maintenance and repair:

1. The machine is electromechanical integration equipment. In order to avoid the

equipment appliance from premature aging and damage, the working

environment must remain clean and dry. Also, it is prohibited to use the

machine in environment of high humidity, high corrosion, and high dust.

2. The instrument switches on the operator control panel shall not be immersed

with water or other liquids, so as not to cause damage or leakage. During

operation, do not use excessive force, so as to extend the service life.

3. The transmission part should be often added with the proper amount of

lubricants, and no phenomena of blockade or serious friction should exist.

4. The sensor head and the electrical appliance in the chassis have high-voltage

electricity. The untrained professional electrician shall not open the sensor

head and the back cover of the electrical box, to avoid electric shock

accidents.

VIII. Warranty period:

1. The machine has a warranty period of one year. During the warranty period, if

the equipment quality problem arises during operation in accordance with

requirements of this manual, the company is responsible for free repair,

replacement of parts and original device until the replacement of a new

machine.

2. The purchaser of this equipment shall request the Company or the local

dealer to issue equipment warranty card and keep them in proper custody, as

the future warranty certificate.

IX. Not under warranty responsibility:

6

1. There is no warranty proof.

2. The user has disassembled and repaired the machine on its own.

3. The user has caused equipment failure, damaged parts and electronic

components for not operating as per the requirements in this manual.

4. Damages are resulted out of too low or too high supply voltage.

5. The warranty period expires.

6. Damages are caused due to human factors.

When the above situation occurs, the Company provides paid repair services.

7

X. Packing list:

No.

Name

Model Specification

Qty

1

Host

Model IMC-2000BX

1

2

Power cord

1

3

Fuse pipe

10A

3

4

Hexagon wrench

6”, 8”

1 Each

5

Screwdriver

4” (Cross)

1

6

Machine Test Bottle

Φ40

20

7

Operation Manual

1

8

Ex-factory Certificate

1

9

Warranty Card

(Triple sheets)

1

Note: The above are essential spare parts attached. Other customized

accessories, if required, can be specified in the order contract.

Packed by: DD__ MM__ YYYY____

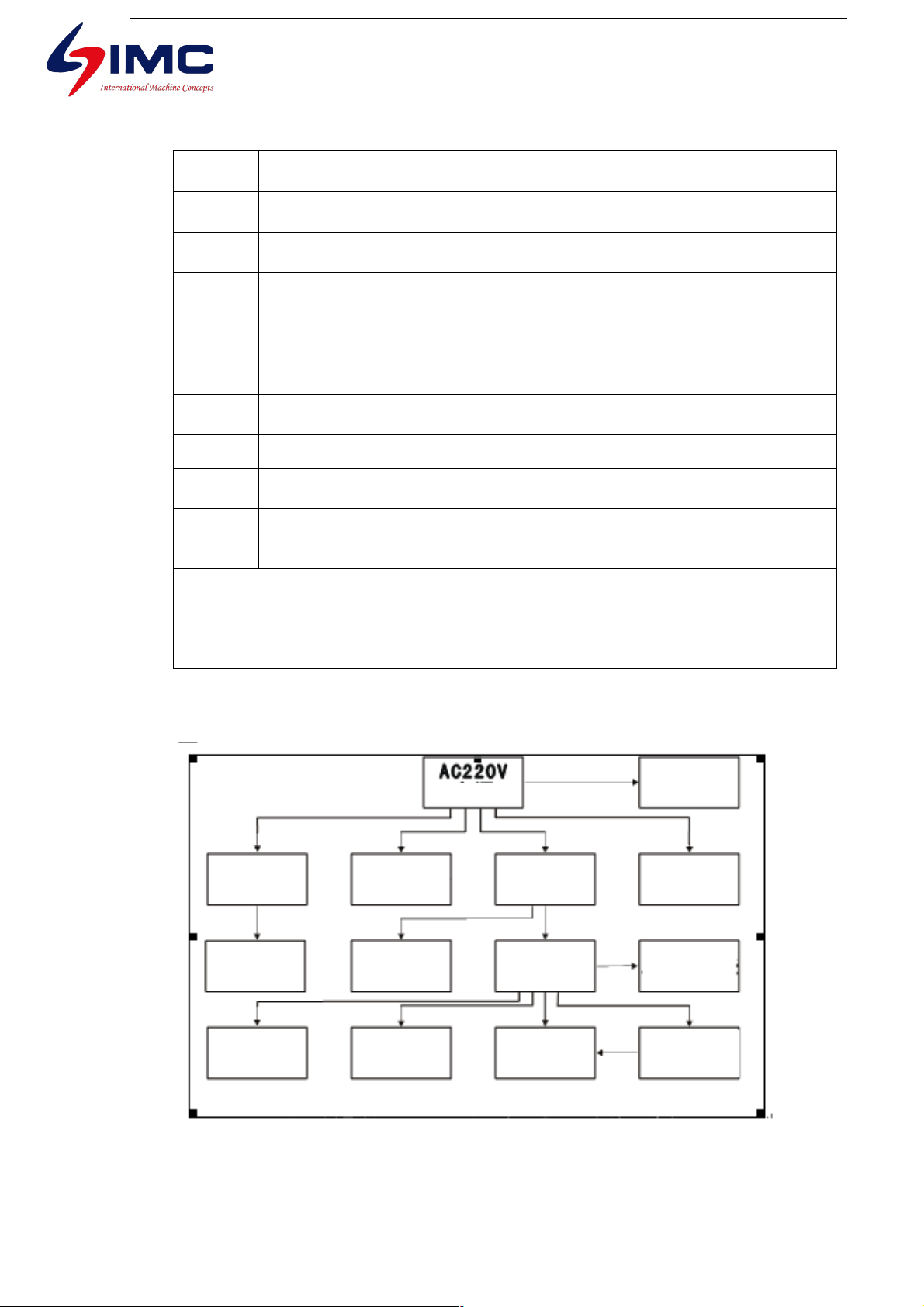

Attached drawings:

Power

Lift of

sensor head

Low voltage

power supply

Control circuit

Overheat

protection circuit

Power

voltmeter

Start-up delay

circuit

Over-current

protection

circuit

Rectifier

filter

Speed control

Circuit on

conveyor belt

Inverter circuit

(air-cooled)

PLL Control

circuit

Sensor head

(air-cooled)

Work

ammeter

Circuit Schematic Diagram of Air-Cooled Continuous Electromagnetic Induction Sealing Machine

Other IMC Kitchen Appliance manuals

Popular Kitchen Appliance manuals by other brands

KRHÜNER

KRHÜNER 53212 instruction manual

Black & Decker

Black & Decker HGS200 Series use and care manual

Cuizimate

Cuizimate RBSJUICEEXNEW instruction manual

Krampouz

Krampouz CSRS4 operating instructions

Cuisinart

Cuisinart Tazzaccino FR-10C Series INSTRUCTION AND RECIPE BOOKLET

Eurotech

Eurotech ED-WD45BCSS instruction manual