IMC VQ3.5 1 Series User manual

A34/040 R4 ECN 4825 February 2021

Installation, Operating and Servicing

Instructions

VQ3.5 & VQ7 –SERIES 1

Please make a note of your product details for

future use:

Date Purchased:_________________________

Model Number:__________________________

Serial Number:__________________________

Dealer:_________________________________

________________________________

_______

CONTENT

DELIVERY............................................................................................................ 1

INTRODUCTION .................................................................................................. 2

YOUR PEELER.................................................................................................... 2

INSTALLATION.................................................................................................... 2

PROCEDURE....................................................................................................... 3

Work top models............................................................................................. 3

Trolley installation.......................................................................................... 4

Pedestal installation....................................................................................... 4

ELECTRICITY SUPPLY CONNECTION.............................................................. 5

WATER SUPPLY ................................................................................................. 6

WASTE OUTLET CONNECTION......................................................................... 6

Waste ejector (Optional Extra)....................................................................... 6

Waste Ejector adjustments............................................................................ 7

COMMISSIONING................................................................................................ 7

OPERATION......................................................................................................... 8

SAFETY................................................................................................................ 9

CLEANING........................................................................................................... 9

MAINTENANCE ................................................................................................. 10

DO’S AND DON’TS............................................................................................ 10

TROUBLESHOOTING ....................................................................................... 10

WIRING DIAGRAM ............................................................................................ 11

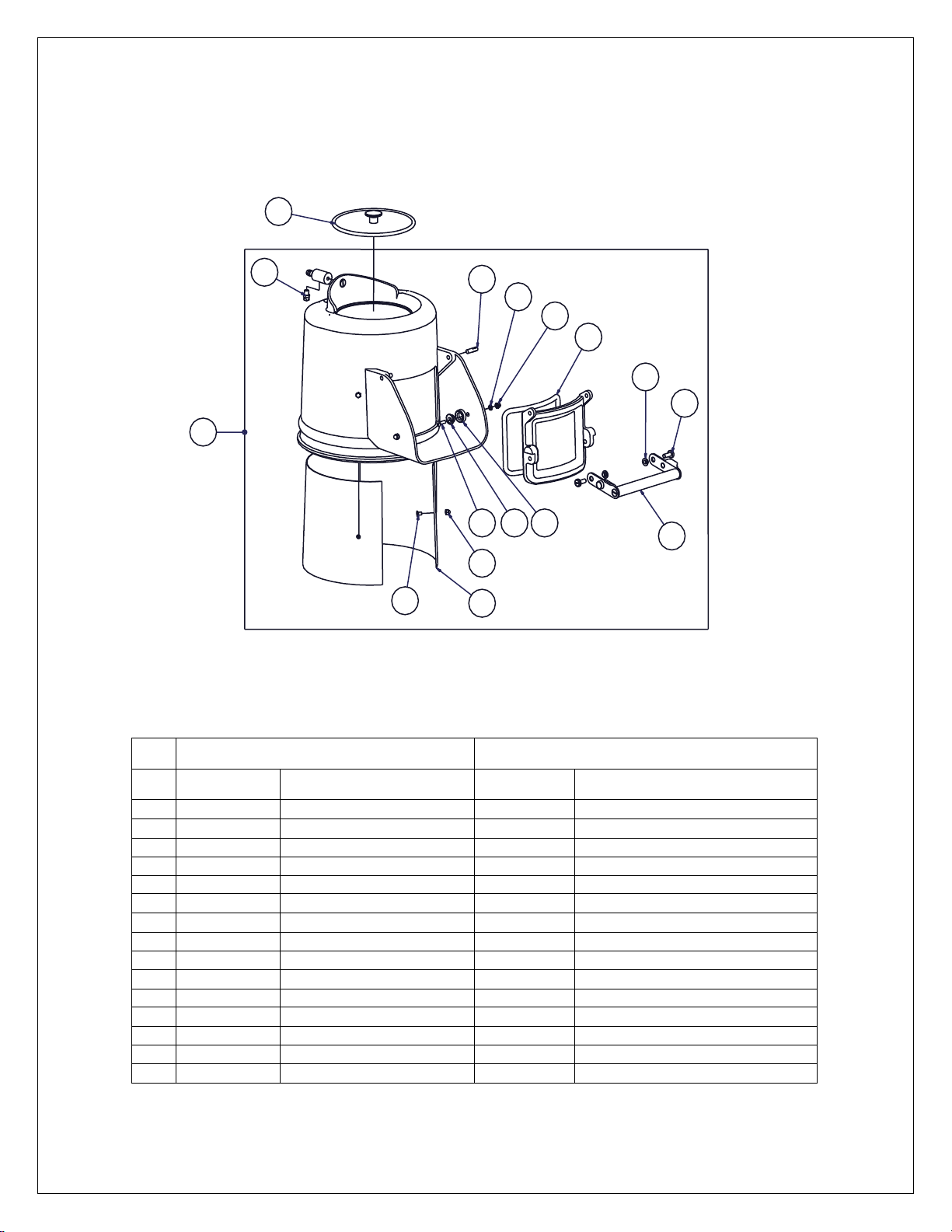

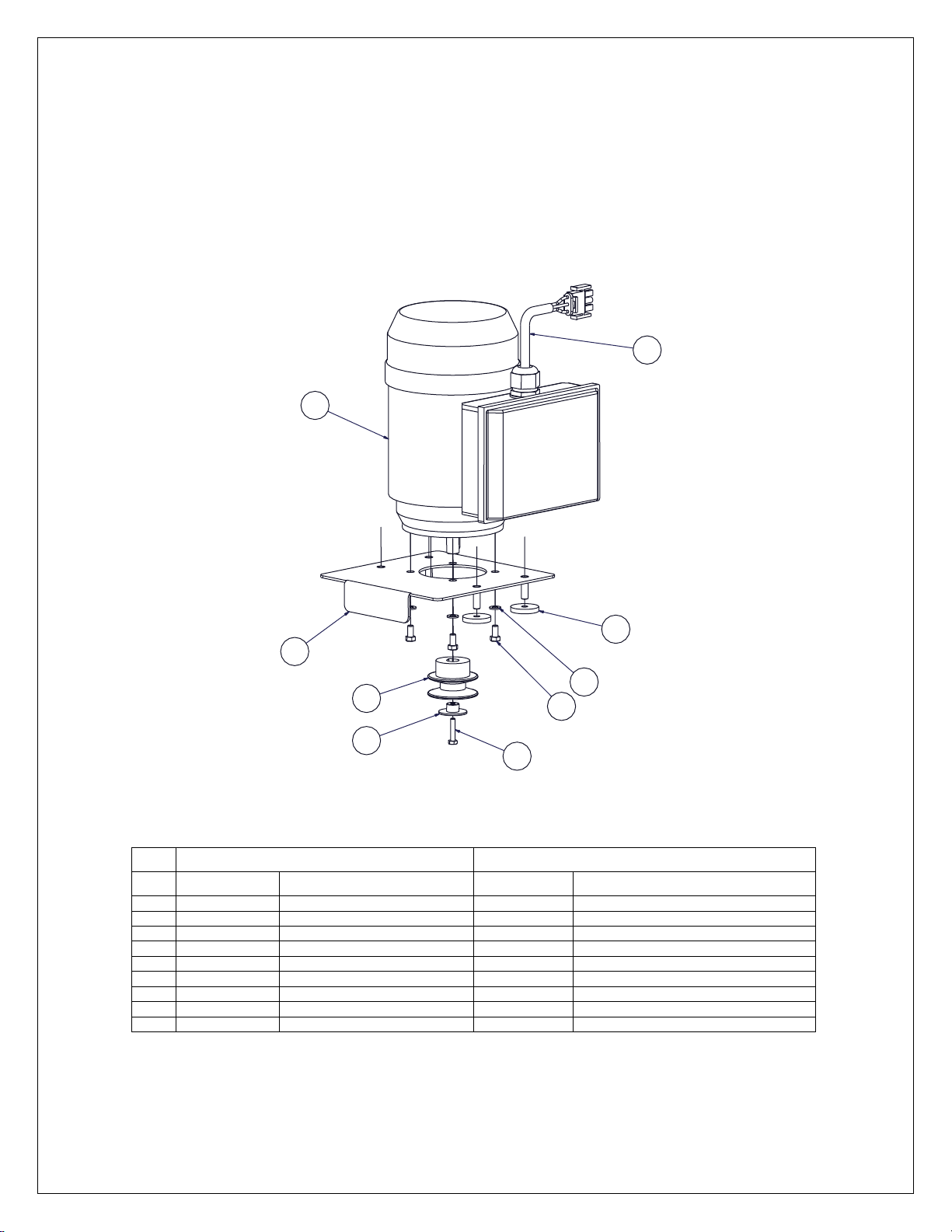

EXPLODED VIEW: EXTERNAL PARTS ........................................................... 12

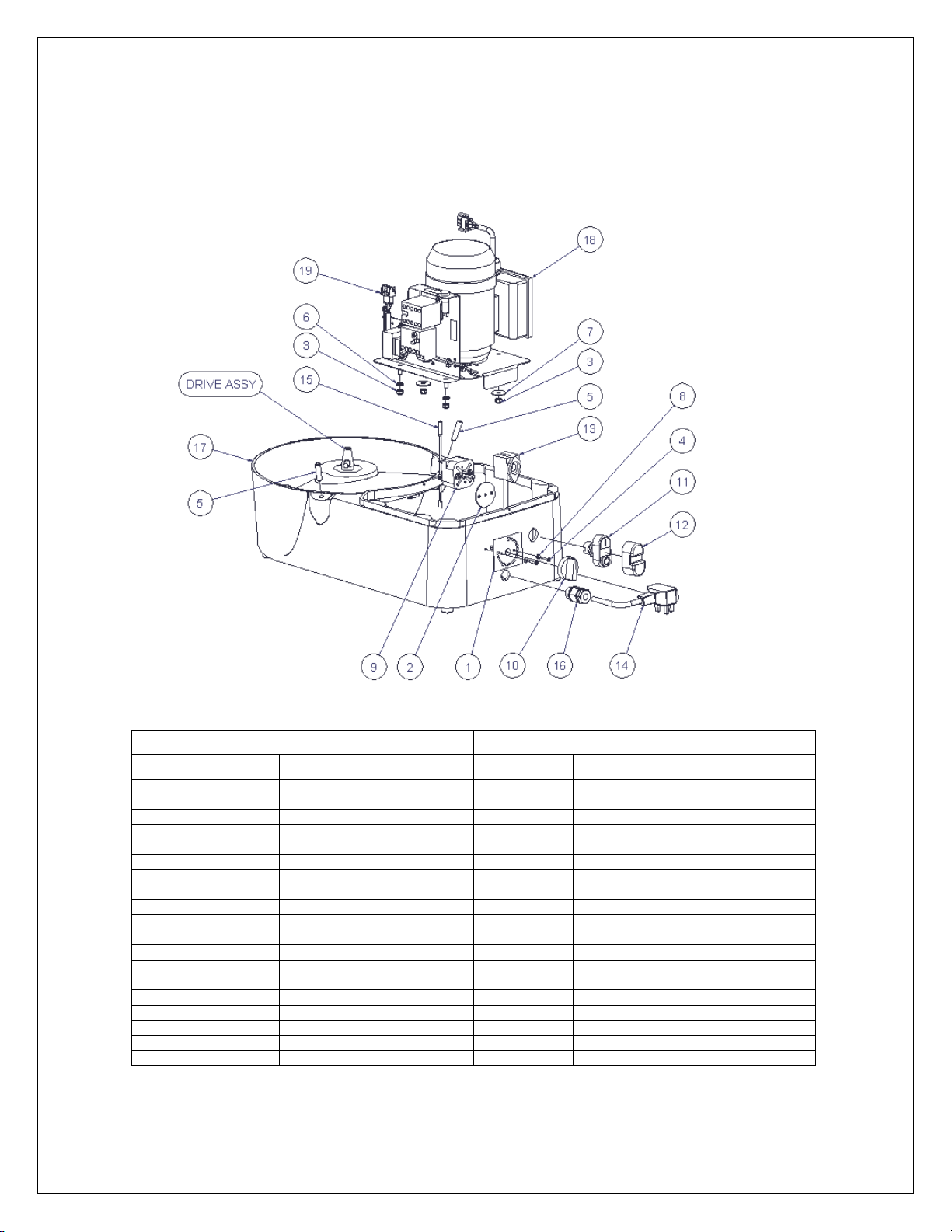

EXPLODED VIEW: CYLINDER ASSEMBLY..................................................... 13

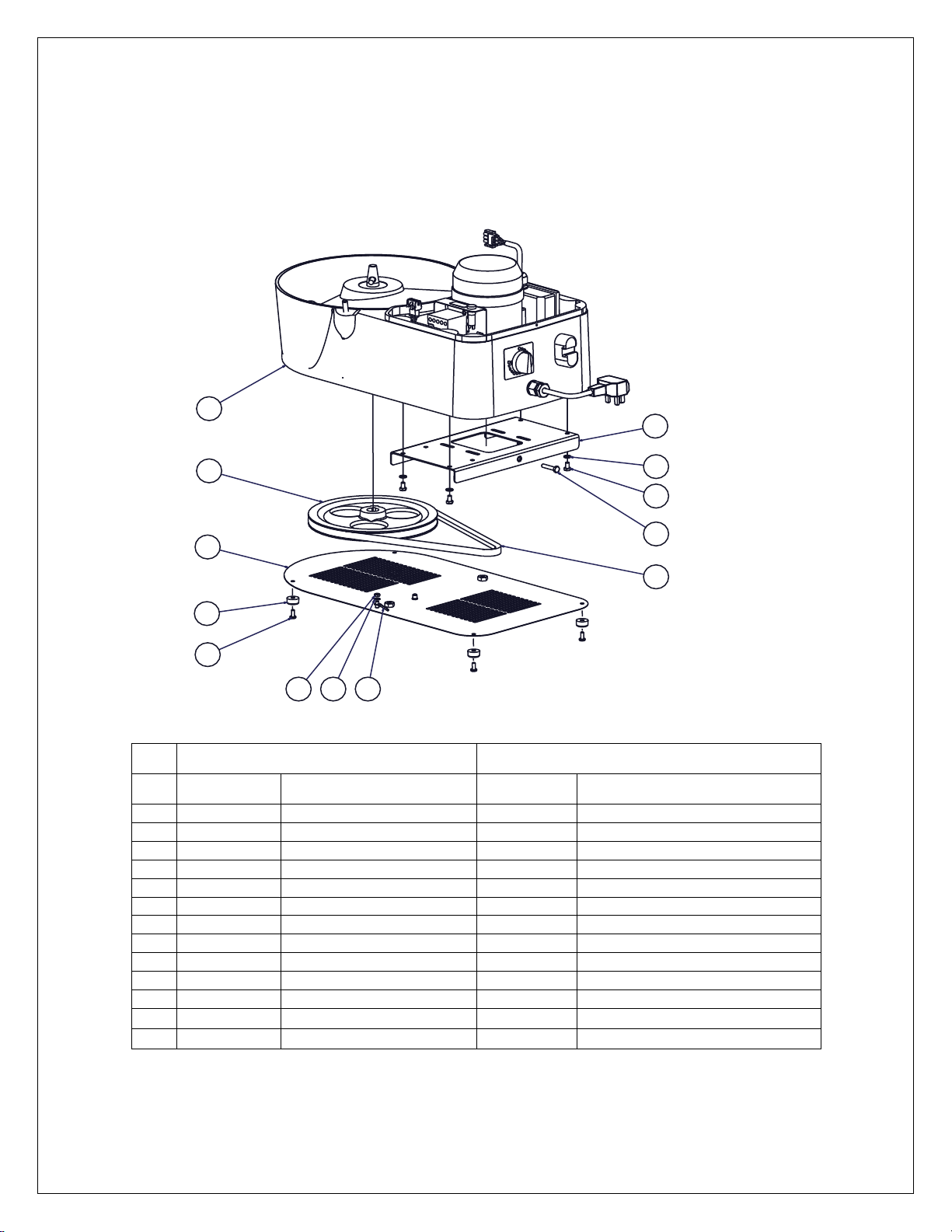

EXPLODED VIEW: INTERNAL PARTS............................................................. 14

EXPLODED VIEWS: MOTOR ASSEMBLY & ELECTRICAL BOX .................. 17

GUARANTEE..................................................................................................... 19

SERVICE INFORMATION.................................................................................. 20

The packaged machine consists of:

Peeler Unit

1

Peeling plate

1

Water supply pipe and 2 hose clips

1

Rubber waste outlet hose

1

Instruction Booklet

1

If any accessories have been ordered they will be supplied in separate packages.

Please notify both the carrier and the supplier within 24 hours of receipt if anything

is missing or damaged.

Check that the correct machine has been supplied and that the voltage, marked on

the rating plate, is suitable for the supply available. The rating plate is located at

the back of the cylinder near the supply cable inlet.

DELIVERY

This machine is intended for peeling potatoes. Its use may be extended to other

root vegetables. It is not recommended to use this machine for peeling onions.

YOUR PEELER

For the Installer:

These Instructions contain important information designed to help the user obtain

the maximum benefit from the investment in an IMC VQ Peeler. Please read them

carefully before starting work, and consult with the supplier in the event of any

queries.

Be sure to leave this Instruction Manual with the user after the installation of the

machine is complete.

INTRODUCTION

INSTALLATION

Cylinder Locking Knob

Motor Cover

Water Inlet

Splash Cover

Chute Door

Discharge Chute

Chute Door Handle

Waste Outlet

Timer

Mains Cable

On-Off Switch

Peeling Cylinder

Work top models

The VQ Range is designed to stand on a bench, table, or on a draining board.

DO NOT mount or operate the unit in a sink.

The peeled potatoes are commonly discharged into a sink and the waste sludge

can be piped away separately, possibly using the waste ejector fitting.

Alternatively, with lightly used machines the waste can be directed into the sink

skip that acts a strainer in the sink. The peeler is not handed and can be located on

a worktop either side of the sink. The discharge cylinder can be rotated to suit the

installation. Ensure that the machine is sited so that the control panel is in easy

reach of the operator.

If it is required to secure the peeler to the worktop then the unit can be bolted down

as described below.

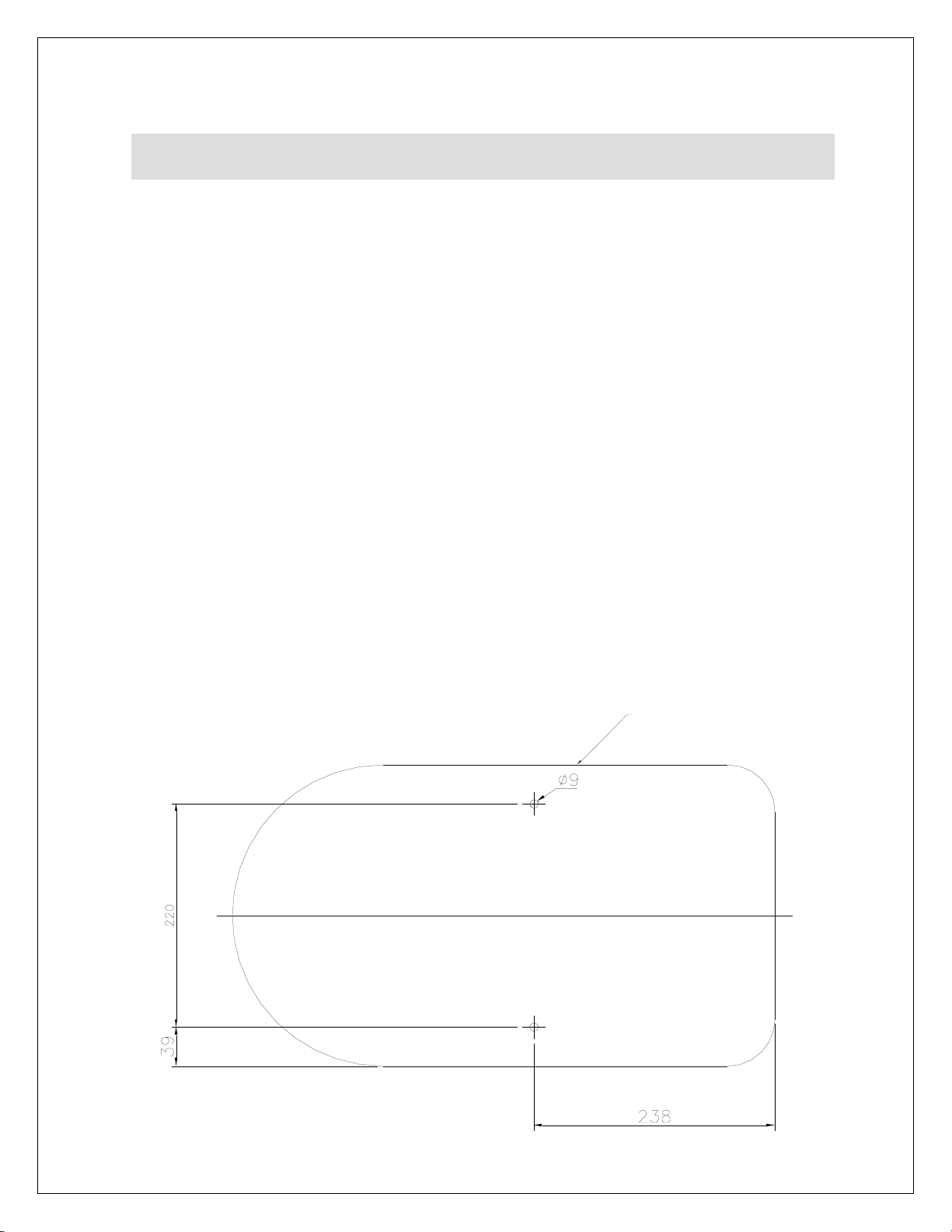

The diagram shows the position and size of the holes required in the worktop.

Ensure that whatever is used for the worktop is sturdy and rigid and not more than

900 mm high. A higher table makes it difficult to load the machine. Place peeler

over the fixing holes and secure to the worktop using M8 screws (Not included)

that are 10mm longer than the thickness of the worktop.

Bench securing points

Procedure

Peeler Outline

Trolley installation

The peeler can be mounted onto a trolley. If ordered, the trolley will be supplied in

separate packaging. Mounting the peeler to the trolley is straightforward as follows:

First it is advisable to remove the cylinder pot assembly and peeler plate

before mounting on trolley.

Place the peeler base onto the trolley and carefully tilt to one side and screw

the 2 off adaptor spacers supplied into the holes provided on the base plate.

Feed the adaptor spacer fixing screws through the 2 holes provided @ 220

mm centres).

Note: Top plate is multi functional so please be aware of which holes to use

prior to fitting.

Secure the peeler to the trolley with the 2 off Nyloc nuts provided.

Reassemble the peeler plate and cylinder pot assembly.

Pedestal installation

The peeler can be mounted onto an adjustable pedestal. If ordered, the pedestal

will be supplied in separate packaging. Securing the pedestal to the floor and

mounting the peeler to the pedestal is straightforward as follows:

Place the assembled pedestal from the packaging to the required peeling

position and marked on the floor the positions of the fixing holes in the feet.

Drill holes at these marks and secure the pedestal to the floor using rawl

bolts or other suitable floor fixings.

Select the height of the pedestal required for peeling and secure with the

fasteners supplied.

For mounting the peeler to the pedestal top it advisable to remove the

cylinder pot assembly and peeler plate.

Place the peeler base onto the pedestal top and carefully tilt to one side and

screw the 2 off adaptor spacers supplied into the holes provided on the base

plate. Feed the adaptor spacer fixing screws through the holes in the

pedestal top.

Secure the peeler to the pedestal with the 2 off nuts provided.

Reassemble the peeler plate and cylinder pot assembly.

The discharge chute heights possible with the pedestal are as follows:

Locating hole

Min

2nd

3rd

4th

Max

Chute height (mm)

750

800

850

900

950

Before connecting, examine the rating plate attached to the machine to ensure that

the characteristics shown are correct for the supply available. Any changes to the

supply or fitting new mains cable runs should be carried out by a qualified

electrician and in accordance with the IET Codes of Practice.

Single-phase machines come supplied with a moulded three-pin plug fitted with a

10A rated fuse. The socket used should be away from any splash area.

The supply to the machine must also be protected by a 30mA RCD.

The mains lead fitted to the machine is the minimum required for individual

connection to the mains supply. Site conditions may vary with additional length of

cable run, encapsulation in trunking, bunched with other cables, etc, being

required. Should this apply, the qualified electrician must alter the lead in

accordance with the IET Codes of Practice.

WARNING: This machine must be earthed

The wires in the mains lead for single-phase supply are coloured:

Green and Yellow

Earth

Brown

Live

Blue

Neutral

ELECTRICITY SUPPLY CONNECTION

WATER SUPPLY

Connect the water supply pipe to the hose tail located on the top of the cylinder.

Fit the other end of the supply pipe to a cold water supply.

PLEASE NOTE: these machines are fitted with an air-break to prevent back

syphonage into the mains supply, but some local authorities may nevertheless

require connection to a storage cistern rather than direct to the mains supply.

This applies to UK installations only. Overseas customers should install the

machine in accordance with local regulations.

IF IN DOUBT, CHECK WITH YOUR LOCAL AUTHORITY

WASTE OUTLET CONNECTION

If empting the waste into a sink is not desired then the peeler can be plumbed into

the waste pipes. The waste outlet pipe fits over standard 2” pipe and should be

secured by a jubilee clip. The length of the pipe should be kept to a minimum and

the size must not be reduced. The pipe must have a fall of at least 1:15 and

changes of direction should be made by swept bends rather than elbows.

Cleaning eyes should be fitted where possible in accordance with standard

plumbing practice.

Waste ejector (Optional Extra)

The waste ejector is a fitting that dilutes the waste sludge to enable it to flow easily

through the drains.

Waste Ejectors are not recommended in the follow circumstances;

A pipe run exceeding 15m between the machine and main drain

When a fall of 1:15 cannot be achieved

When piping is exceptionally complex

In any of the above cases an interceptor tank is recommended.

HOSE CLIPS

The waste ejector fits onto the waste outlet boss in place of the waste outlet hose,

as shown below. Ensure that the ejector body is vertical and secure in place with

the jubilee clips supplied. The water supply to the ejector is via the hose tail on top

of the waste ejector. The ejector unit has a 2” BSP connection for the waste piping.

Waste Ejector adjustments

When the pipe-work is complete set the ejector adjustments to give the correct

water flow though the machine. Two adjusting screws and lock nuts are provided

for this purpose. The top one controls the flow though the peeler and the lower one

controls the jet to the waste pipe. Adjust the top screw until the flow through the

machine is between 2.25 and 7 litres per minute, and then tighten the lock nut. Set

the lower screw to allow a jet of water into the waste pipe of 2.25 to 3.5 litres per

minute, and then tighten the lock nut.

After making the electrical connection, switch on the machine, and ensure that the

unit will only run with cylinder in position. Then check that the direction of rotation

of the shaft is CLOCKWISE when viewed from above.

The direction of rotation of single-phase units is set at the factory. If it is not rotating

in the correct direction, contact Lincat.

COMMISSIONING

CONNECTION HOSE

WASTE EJECTOR

1. Fit the peeler plate, ensuring that it is properly located on the drive shaft.

2. Fit the cylinder and rotate into the required position. Lock into position with

the two locking knobs.

3. Measure out the potatoes into a container that holds a known measured

weight, and check for any stones that could damage the abrasive.

Should this happen, the noise will indicate the presence of stones.

Switch off immediately and remove them.

4. Set the time required on the timer –two to two and a half minutes is

normally more than adequate - and press the upper GREEN start button on

the on-off switch. Turn on the water supply.

5. Ensure that the chute discharge door is closed. Load the potatoes into the

peeler and place the splash cover onto the top of the cylinder.

6. The machine is now operating. The splash cover can removed to check the

progress of the peeling process. The peeler can be stopped before the end

of any timed cycle by pressing the lower Red stop button on the on-off

switch

7. On completion of the cycle the peeler will stop. Turn off the water supply,

Set the timer for 30 seconds and press the upper GREEN start button, then

open the chute door slowly to evacuate the potatoes, press the lower RED

stop button on the on-off switch when the peeler is empty.

8. When moving the machine to its working or storage place it is advisable to

remove the cylinder assembly first before attempting to carry. This will make

the machine lighter and easier to handle.

ON NO ACCOUNT put a hand or any implement into the machine,

or wedge the door open while discharging.

OPERATION

SAFETY

All VQ-Range machines are fitted with a number of safety features to prevent

operator injury.

Interrupt protection: If the electricity supply is interrupted the machine will not

restart until the upper GREEN button on the on-of switch is pressed again.

Cylinder interlock: If the cylinder is removed the motor will not start until it is

replaced, and the green start button has been pressed.

It is essential to clean the machine at least once a day, preferably at the end of

each period of operation.

1. Switch off at the socket or isolator.

2. Disconnect the water supply from the tap.

3. Remove the peeling cylinder.

4. Lift out the peeling plate.

5. Clean the peeling plate and cylinder in a sink, potwash or by hosing with a

spray.

6. Rinse the inside of the base with warm water, using a mild detergent if

necessary.

7. Wipe the exterior of the machine with a damp cloth, again using a mild

detergent if required.

DO NOT USE CLEANING MATERIALS CONTAINING ABRASIVES OR

BLEACHES.

DO NOT STEAM CLEAN

CLEANING

Other than regular cleaning the VQ-Range of peelers require no maintenance by

the end user. It is recommended that a Lincat approved engineer services the unit

at least once a year.

Details of Lincat Service Contracts are available on application.

DO’S AND DON’TS

Do Install on a level surface.

Do Ensure power supply isolator or socket is accessible with the peeler

installed.

Do Clean the machine after each period of use.

Don’t Site the peeler in a sink.

Don’t Sit or stand on top of the peeler.

Don’t Place hands inside unit while discharging or peeling.

Don’t Use the unit outside.

TROUBLESHOOTING

Problem

Potential Reason

Solution

Excessive water spillage

Door is not closed

Ensure handle is pushed down

firmly and secured at stops

Splash lid not seated

properly

Ensure top of cylinder is clean

allowing lid to sit correctly

Water pressure too

high

Reduce water pressure

If you experience any problems that cannot be resolved by following these

solutions, please contact the Lincat Service Department –details on the last page.

MAINTENANCE

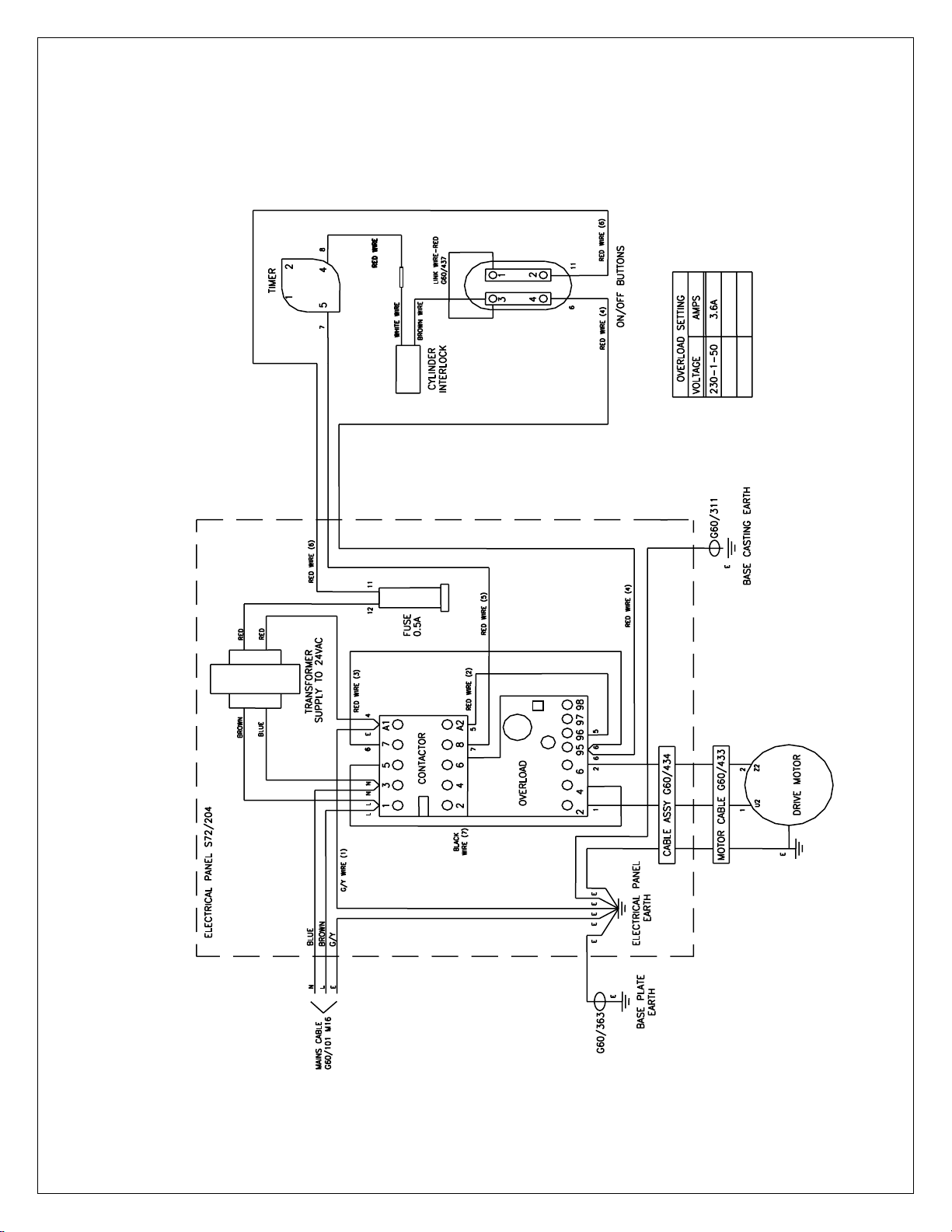

WIRING DIAGRAM

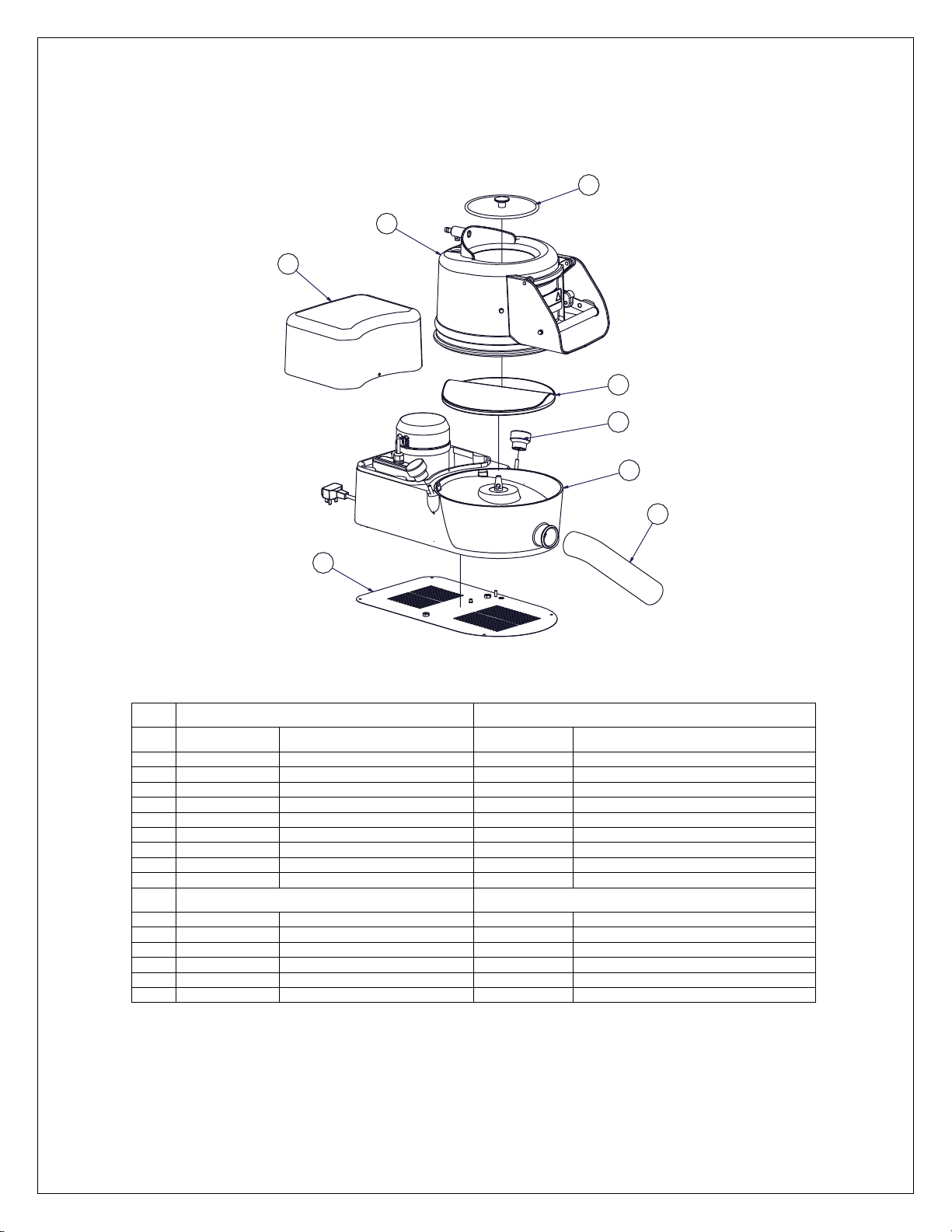

EXPLODED VIEW: EXTERNAL PARTS

When ordering spare parts or accessories always quote the SERIES AND

SERIAL NUMBER of the machine, found on the rating label.

VQ3.5

VQ7

Item

Part No

Description

Part No

Description

1

C72/202 M1

Motor Cover

C72/202 M1

Motor Cover

2

E72/208

Base Plate

E72/208

Base Plate

3

L72/023

Cylinder Locking Knob

L72/023

Cylinder Locking Knob

4

M72/001

Waste Outlet-Moulded

M72/001

Waste Outlet-Moulded

5

S72/012

VP Splash Cover

S72/012

VP Splash Cover

6

S72/013

Peeler Plate

S72/013

Peeler Plate

7

S72/205

Base Assembly

S72/205

Base Assembly

8

S72/210

VQ3.5 Cylinder Assembly

S72/211

VQ7 Cylinder Assembly

VQ3.5 ACCESSORIES

VQ7 ACCESSORIES

A29/003

Splash Cover Retaining Strap

A29/003

Splash Cover Retaining Strap

S58/569

Floor Standing Interceptor Tank

S58/569

Floor Standing Interceptor Tank

S72/023

Waste Ejector

S72/023

Waste Ejector

S72/220

Wheeled Trolley

S72/220

Wheeled Trolley

S72/221

Adjustable Pedestal

S72/221

Adjustable Pedestal

E72/011

Stainless Steel Sink Skip

E72/011

Stainless Steel Sink Skip

5

8

1

2

4

3

6

7

EXPLODED VIEW: CYLINDER ASSEMBLY

When ordering spare parts or accessories always quote the SERIES AND

SERIAL NUMBER of the machine, found on the rating label.

VQ3.5

VQ7

Item

Part No

Description

Part No

Description

1

A00/058

Nylon Shoulder Washer

A00/058

Nylon Shoulder Washer

2

A13/078 M5

Neoprene Door Gasket

A13/078 M5

Neoprene Door Gasket

3

D18/050

Screw M6 x 16 CSK SS

D18/050

Screw M6 x 16 CSK SS

4

D18/051

Screw M6 x 20 CSK SS

D18/051

Screw M6 x 20 CSK SS

5

D20/031

M6 Dome Head Nut

D20/031

M6 Dome Head Nut

6

D21/057

Screw M8 x 20 Pan SS

D21/057

Screw M8 x 20 Pan SS

7

D25/005

M6 Shakeproof Washer SS

D25/005

M6 Shakeproof Washer SS

8

D26/037

Grooved Pin 8 Dia x 30

D26/037

Grooved Pin 8 Dia x 30

9

E72/209 Z1

VQ3.5 Cylinder Liner

E72/210 Z1

VQ7 Cylinder Liner

10

E72/211

Door Handle VQ

E72/211

Door Handle VQ

11

J04/322

Spray Nozzle

J04/322

Spray Nozzle

12

L21/048

Eccentric

L21/048

Eccentric

13

M79

Door Roller

M79

Door Roller

14

S72/012

Splash Cover

S72/012

Splash Cover

15

S72/210

VQ3.5 Cylinder Assembly

S72/211

VQ7 Cylinder Assembly

2

5

7

6

1

5

4

12

13

15

10

3

9

14

11

8

EXPLODED VIEW: INTERNAL PARTS

BASE ASSEMBLY-UPPER

When ordering spare parts or accessories always quote the SERIES AND

SERIAL NUMBER of the machine, found on the rating label.

VQ3.5

VQ7

Item

Part No

Description

Part No

Description

1

A08/295

Timer Label

A08/295

Timer Label

2

A11/219

Timer Rubber Washer

A11/219

Timer Rubber Washer

3

D20/043

Nut M6 Nyloc SS

D20/043

Nut M6 Nyloc SS

4

D21/034

Screw M3 x 16 Pan SS

D21/034

Screw M3 x 16 Pan SS

5

D23/044

Screw M8 x 35 Skt Set Cup SS

D23/044

Screw M8 x 35 Skt Set Cup SS

6

D25/008

Washer M6 Plain SS

D25/008

Washer M6 Plain SS

7

D25/019

Washer 25 X 6 X 1 Steel ZP

D25/019

Washer 25 X 6 X 1 Steel ZP

8

D25/066

Washer M3 Seloc

D25/066

Washer M3 Seloc

9

G34AL

Timer 4 mins

G34AL

Timer 4 mins

10

G45/066

Timer Knob

G45/066

Timer Knob

11

G45/109

On-Off Switch-Pushbutton

G45/109

On-Off Switch-Pushbutton

12

G45/110

Boot-On-Off Switch

G45/110

Boot-On-Off Switch

13

G45/111

Contactors-On-Off Switch

G45/111

Contactors-On-Off Switch

14

G60/101 M16

Mains Cable with Plug

G60/101 M16

Mains Cable with Plug

15

G60/423

Proximity Sensor Assy

G60/423

Proximity Sensor Assy

16

G80/029

Cable Gland

G80/029

Cable Gland

17

S72/201

Base Sub-Assy

S72/201

Base Sub-Assy

18

S72/202

Motor Sub-Assy

S72/202

Motor Sub-Assy

19

S72/204

Electrics Box Assy

S72/204

Electrics Box Assy

BASE ASSEMBLY-LOWER

When ordering spare parts or accessories always quote the SERIES AND

SERIAL NUMBER of the machine, found on the rating label.

VQ3.5

VQ7

Item

Part No

Description

Part No

Description

1

A05/007

V Belt

A05/007

V Belt

2

A13/048

Rubber Foot

A13/048

Rubber Foot

3

C07/004 M2

Driven Pulley-Machined

C07/004 M2

Driven Pulley-Machined

4

D19/037

Screw M6 x 10 Hex SS

D19/037

Screw M6 x 10 Hex SS

5

D19/115

Screw M6 x 30 Hex SS

D19/115

Screw M6 x 30 Hex SS

6

D20/038

Nut M5 Full SS

D20/038

Nut M5 Full SS

7

D21/044

Screw M5 x 12 Pan SS

D21/044

Screw M5 x 12 Pan SS

8

D25/004

Washer M5 Shakeproof SS

D25/004

Washer M5 Shakeproof SS

9

D25/008

Washer M6 Plain SS

D25/008

Washer M6 Plain SS

10

E72/207

Support Mounting Plate

E72/207

Support Mounting Plate

11

E72/208

Base Plate

E72/208

Base Plate

12

G60/310

Earth Cable Assy

G60/310

Earth Cable Assy

13

S72/205

Base Sub-Assembly

S72/205

Base Sub-Assembly

10

1

3

11

2

7

8

12

6

4

5

13

9

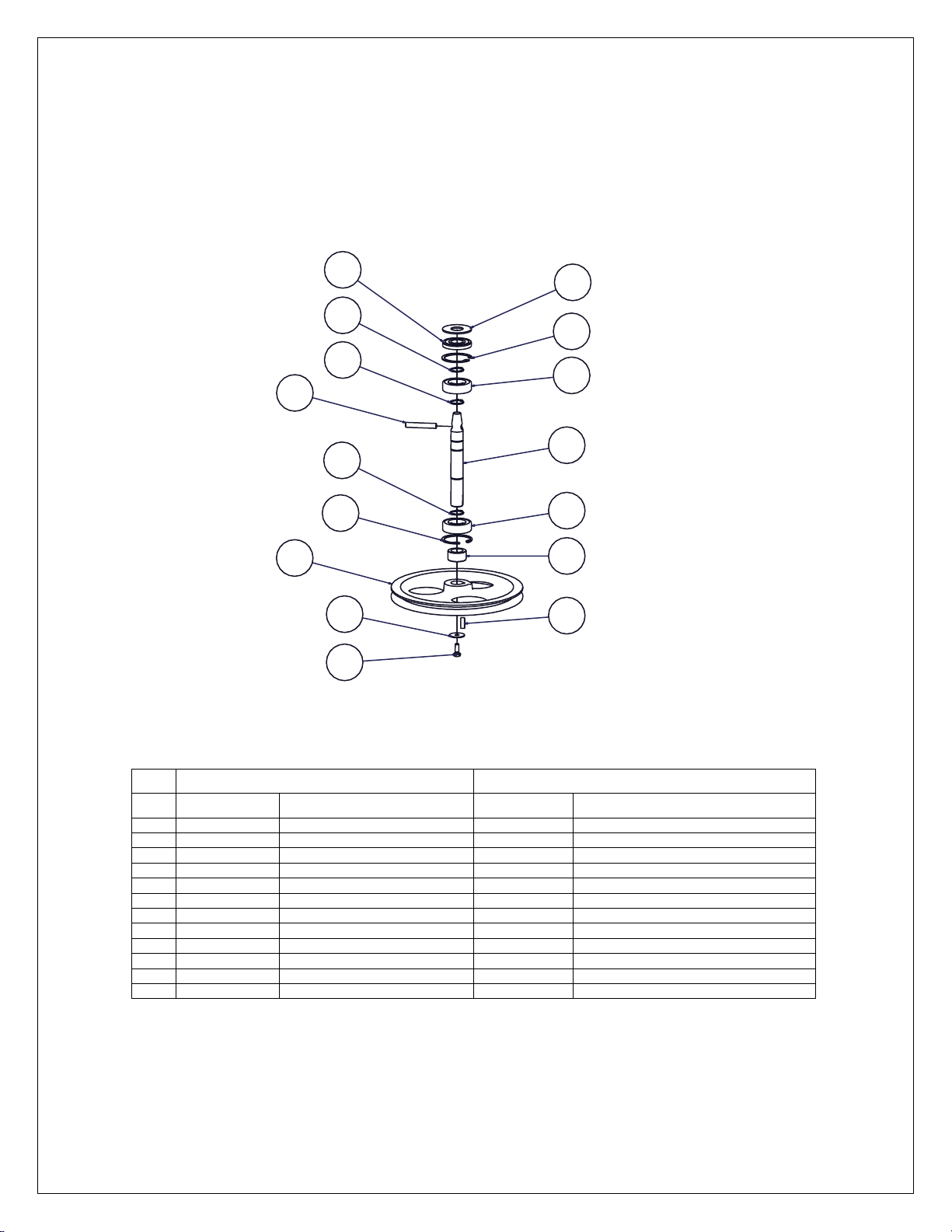

DRIVE ASSEMBLY

When ordering spare parts or accessories always quote the SERIES AND

SERIAL NUMBER of the machine, found on the rating label.

VQ3.5

VQ7

Item

Part No

Description

Part No

Description

1

A01/032

Ball Bearing 47 x 20 x 14

A01/032

Ball Bearing 47 x 20 x 14

2

A02/037A

Oil Seal 47 x 20 x 7

A02/037A

Oil Seal 47 x 20 x 7

3

C07/004 M2

Driven Pulley-Machined

C07/004 M2

Driven Pulley-Machined

4

D19/039

Screw M6 x 16 Hex SS

D19/039

Screw M6 x 16 Hex SS

5

D25/019

Washer 25 x 6 x 1 Steel ZP

D25/019

Washer 25 x 6 x 1 Steel ZP

6

D27/005

Circlip-External 20 Dia

D27/005

Circlip-External 20 Dia

7

D27/016

Circlip-Internal 47 Dia

D27/016

Circlip-Internal 47 Dia

8

D27/031

Drive Key 6 x 6 x 18

D27/031

Drive Key 6 x 6 x 18

9

D28/019

Grooved Pin 8 Dia x 50

D28/019

Grooved Pin 8 Dia x 50

10

E59/149

Seal Protector

E59/149

Seal Protector

11

L72/201

Drive Shaft

L72/201

Drive Shaft

12

L72/204

Spacer-Driven Pulley

L72/204

Spacer-Driven Pulley

11

9

1

7

10

6

6

6

1

7

12

3

8

5

4

2

EXPLODED VIEWS: MOTOR ASSEMBLY & ELECTRICAL BOX

MOTOR ASSEMBLY

When ordering spare parts or accessories always quote the SERIES AND

SERIAL NUMBER of the machine, found on the rating label.

VQ3.5

VQ7

Item

Part No

Description

Part No

Description

1

D08/096

Rubber Washer 25x5.5x4

D08/096

Rubber Washer 25x5.5x4

2

D19/032

Screw M5x12L Hex SS

D19/032

Screw M5x12L Hex SS

3

D19/143

Screw M4x20L Hex SS

D19/143

Screw M4x20L Hex SS

4

D25/021

Washer M5 Plain SS

D25/021

Washer M5 Plain SS

5

E72/202

Motor Plate VQ3.5

E72/202

Motor Plate VQ3.5

6

G40/183

Motor 1 Phase with Key 4x4x18

G40/183

Motor 1Phase with Key 4x4x18

7

G60/434

Motor Cable Assy

G60/434

Motor Cable Assy

8

L72/202

Motor Drive Pulley

L72/202

Motor Drive Pulley

9

L72/205

Spacer Washer

L72/205

Spacer Washer

6

7

5

1

2

4

8

9

3

ELECTRICAL BOX

When ordering spare parts or accessories always quote the SERIES AND

SERIAL NUMBER of the machine, found on the rating label.

VQ3.5

VQ7

Item

Part No

Description

Part No

Description

1

D20/011

Nut M4 Full SS

D20/011

Nut M4 Full SS

2

D20/038

Nut M5 Full SS

D20/038

Nut M5 Full SS

3

D25/004

Washer M5 Shakeproof SS

D25/004

Washer M5 Shakeproof SS

4

D25/014

Washer M4 Plain SS

D25/014

Washer M4 Plain SS

5

D25/033

Washer M4 Shakeproof SS

D25/033

Washer M4 Shakeproof SS

6

E72/206

Control Box-Electrics

E72/206

Control Box-Electrics

7

G30/462

Overload Relay 3.1/4.2A

G30/462

Overload Relay 3.1/4.2A

8

G30/343

Mini Contactor 24V AC

G30/343

Mini Contactor 24V AC

9

G35/004

Fuse 5 X 20 0.5A Semi-Delay

G35/004

Fuse 5 X 20 0.5A Semi-Delay

10

G35/012

Fuse Holder

G35/012

Fuse Holder

11

G60/434

Electrics Motor Cable

G60/434

Electrics Motor Cable

12

G60/435

Transformer 6VA 24V

G60/435

Transformer 6VA 24V

10

9

6

11

12

1

5

4

8

7

2

3

This manual suits for next models

1

Table of contents

Other IMC Kitchen Appliance manuals