IMCA Mini RadaScan User manual

Mini RadaScan Microwave

Radar Sensor for Dynamic

Positioning Operations

IMCA M 229

October 2015

The International Marine Contractors Association

(IMCA) is the international trade association

representing offshore, marine and underwater

engineering companies.

IMCA promotes improvements in quality, health, safety,

environmental and technical standards through the publication of

information notes, codes of practice and by other appropriate

means.

Members are self-regulating through the adoption of IMCA

guidelines as appropriate. They commit to act as responsible

members by following relevant guidelines and being willing to be

audited against compliance with them by their clients.

There are two core activities that relate to all members:

Competence & Training

Safety, Environment & Legislation

The Association is organised through four distinct divisions, each

covering a specific area of members’ interests: Diving, Marine,

Offshore Survey, Remote Systems & ROV.

There are also five regional sections which facilitate work on

issues affecting members in their local geographic area –

Asia-Pacific, Central & North America, Europe & Africa, Middle

East & India and South America.

IMCA M 229

This report has been prepared in order to give IMCA members

an overview and review of the Mini RadaScan position reference

sensor as used within dynamic positioning applications.

Mini RadaScan is a microwave radar sensor system which has

gained wide usage within marine offshore operations.

The major part of the document has been prepared by the

manufacturers of this system, Guidance Marine Ltd. It covers the

components of the system, sensor design, operation including

advantages and disadvantages, servicing and maintenance,

applications and technical specification.

www.imca-int.com/marine

The information contained herein is given for guidance only and endeavours to

reflect best industry practice. For the avoidance of doubt no legal liability shall

attach to any guidance and/or recommendation and/or statement herein contained.

© 2015 IMCA –International Marine Contractors Association

Mini RadaScan Microwave Radar Sensor for

Dynamic Positioning Operations

IMCA M 229 –October 2015

1Preface .................................................................................................................... 1

2Glossary of Terms ................................................................................................. 2

3Overview................................................................................................................. 3

4Components........................................................................................................... 4

5Features .................................................................................................................. 5

5.1 System Advantages.................................................................................................................................................5

5.2 System Disadvantages............................................................................................................................................5

6Installation.............................................................................................................. 6

6.1 Sensor Wiring Diagram ........................................................................................................................................6

6.2 Sensor Placement ...................................................................................................................................................6

6.3 Responder Placement............................................................................................................................................7

6.4 Calibration................................................................................................................................................................7

7System Design........................................................................................................ 8

7.1 Sensor Properties...................................................................................................................................................8

7.2 Measurement Principles........................................................................................................................................9

7.3 Responders ........................................................................................................................................................... 11

8Operation ............................................................................................................. 13

8.1 Dashboard............................................................................................................................................................. 13

8.2 Multiple Sensor/Multiple Target Operation ................................................................................................. 14

8.3 Mini RadaScan Interoperability and Compatibility ...................................................................................... 14

9Servicing and Maintenance................................................................................. 16

9.1 Software Upgrades.............................................................................................................................................. 16

9.2 Recycling and Disposal....................................................................................................................................... 16

10 Applications.......................................................................................................... 17

11 Operational Experience...................................................................................... 18

11.1 Co-location/Sensor Placement ........................................................................................................................ 18

11.2 Performance ......................................................................................................................................................... 18

11.3 Responder Angle of Incidence ......................................................................................................................... 20

11.4 Multi-path Accuracy............................................................................................................................................ 20

11.5 Frequently Asked Questions ............................................................................................................................ 24

11.6 Operational Experience..................................................................................................................................... 26

12 Specifications........................................................................................................ 27

12.1 Computer Specifications ................................................................................................................................... 27

12.2 Sensor Specifications .......................................................................................................................................... 27

12.3 Responder Specifications................................................................................................................................... 28

13 References ............................................................................................................ 29

IMCA M 229 1

1Preface

Reliable and robust methods of positioning are required for safe vessel operations at offshore installations.

The development of dynamic positioning (DP) systems has been gradual over the past 50 years and today, various

manufacturers’ systems are available around the world.

Every measurement technology is bound by limitations (i.e. physics) and external factors (e.g. signal obstruction,

solar activity, weather, sea conditions, range), which makes it difficult for one technology to cover all applications

with uninterrupted service. Hence the growth in the use of DP has been accompanied by the development of

internationally recognised rules, standards and guidelines against which DP vessels are designed, constructed and

operated.

1

2

3

The growth and development of DP systems has stimulated the development of DP position measurement

sensors which have become more sophisticated as technology has allowed. Within the relative position

measurement equipment range the DP market is familiar with the use of laser and microwave sensors.

4

5

6

7

This

document describes the Mini RadaScan product, which is part of the range of microwave relative positioning

systems offered by Guidance Marine (see www.guidance.eu.com).

IMCA has published IMCA M 209 –RadaScan microwave radar sensor for dynamic positioning operations. This

document provides an overview of the Mini RadaScan system.

1

IMO MSC Circ. 645 –Guidelines for vessels with dynamic positioning systems

2

IMCA M 103 –Guidelines for the design and operation of dynamically positioned vessels

3

182 MSF –International guidelines for the safe operation of dynamically positioned offshore supply vessels

4

IMCA M 170 –A review of marine laser positioning systems –Part 1: MK IV Fanbeam® and Part 2: CyScan

5

IMCA M 174 –A review of the Artemis Mark V positioning system

6

IMCA M 209 –RadaScan microwave radar sensor for dynamic positioning operations

7

IMCA M 224 –Guidance on RADius relative positioning system

2 IMCA M 229

2Glossary of Terms

ATEX ATmosphères EXplosibles

CE Conformite Europeenne. Mandatory marking for products sold in the European Economic Area (EEA)

Clutter Radar signal that is echoed back towards the sensor

DAC Digital to analogue converter

Dashboard Graphical user interface used to control the sensor

DGNSS Differential global navigation satellite system

DGPS Differential Global Positioning System

DP Dynamic positioning

DSB Dual side band

DSP Digital signal processing

EMC Electro-magnetic compatibility

FCC Federal Communications Commission. Among many of its functions it specifies the

electromagnetic interference specification for products manufactured or sold in the United States

FMCW Frequency-modulated continuous wave

FSK Frequency shift key

GPS Global Positioning System

HPR Hydroacoustic positioning reference system

I/O Input/output

IMCA International Marine Contractors Association

IMO International Maritime Organization

IP Internet protocol

LAN Local area network

LED Light emitting diode

mrad milli-radians

OSV Offshore supply vessel

PCI Peripheral component interconnect

PSK Phase shift key

PSV Platform support vessel

RAS Replenishment at sea

RCS Radar cross section

Reflection RF signal received by the sensor from the responder

Responder Purpose built hardware unit mounted on a structure, which retransmits a modulated version of

the signal it receives from a Mini RadaScan sensor

RF Radio frequency

RX Received RF signal

Series1 miniResponders that implement FSK-DSB

Series2 miniResponders that implement PSK-SSB

SSB Single side band

Target A processed and positively identified return from a responder

TX Transmitted RF signal

UL Underwriters Laboratories Inc. The leading North American product safety certification

organisation, whose certifications are recognised world-wide

UPS Universal power supply

VFD Vacuum fluorescent display

1 sigma (1σ) Standard deviation is a measure that is used to quantify the amount of variation of a set of data

values

IMCA M 229 3

3Overview

DP systems using relative position measurement equipment have been used in a wide range of industrial

applications where operation typically requires vessels to perform either:

‘station keeping’; e.g. maintain their position against fixed or moving installations for loading and/or unloading;

‘track and follow’; e.g. maintain the same heading and speed relative to another vessel.

These operations often require sub-metre accurate local reference measurements to be supplied to the DP

system. The Mini RadaScan sensor is a microwave based reference system that has been developed to offer an

accuracy that is comparable to a laser system combined with the capability to work in all weather conditions

where the presence of heavy fog, heavy rain, snow, dust or steam could affect the performance of laser systems.

A typical vessel will utilise a number of sensors simultaneously. Therefore each sensor needs to be capable of

operating without interfering with or suffering interference from other sensors.

8

The Mini RadaScan system builds on the success of RadaScan and is one of the latest developments in local

reference sensor technology. The Mini RadaScan is smaller and lighter than the RadaScan, thus making installation

easier and quicker, whilst providing crucial all-weather operation without compromising on accuracy.

Mini RadaScan has the same friendly and familiar user interface as RadaScan.

In the rest of the document, the term sensor will be used to refer to the Mini RadaScan unit unless stated

otherwise.

8

IMCA M 199 –Guidelines on installation and maintenance of DGNSS-based positioning systems

4 IMCA M 229

4Components

A Mini RadaScan system consists of three main components:

a sensor unit for the detection and processing of reflections;

a responder(s) unit, which reflects the signal from the sensor;

a marine computer used to configure and control the sensor using the dashboard software.

System components are shown in Figure 1.

Figure 1 –Mini RadaScan system components

Mini RadaScan Responders (one

or more) that are mounted on the

fixed platform or mobile object

Mini RadaScan Sensor that is

installed on a vessel equipped with

a DP system

Mini RadaScan Console software

is used by the DP operator to

control the Mini RadaScan Sensor. It

runs on a marine computer installed

on the vessel’s bridge

IMCA M 229 5

5Features

The sensor is a low power (1 watt) all-weather FMCW radar unit operating over a 100 MHz bandwidth in the

licence-free 9.25 GHz maritime radiolocation band. A 360° rotating antenna which is spun at a continuous rate

of 1 Hz provides unrestricted vessel manoeuvrability when trackingF targets, unlike a fixed antenna design.

The sensor works by detecting reflections from one or more ATEX certified responders mounted on a structure

such as an oil rig. The sensor calculates a relative target position which is sent to the DP system and the

dashboard.

A maximum of four responders can be detected by each sensor. They operate in four distinct frequency channels

specifically designed for the sensor and introduce a unique identifying code into the reflection to allow

unambiguous target identification and robust tracking. Each responder can also be used simultaneously by

multiple sensors which allows several vessels to obtain position information at the same time from one set of

responders.

There are two main modes of operation:

Single-target tracking provides target range and bearing measurements. It is mainly used in fixed structure

applications such as drilling rigs and production platforms;

Multi-targets tracking provides target range and bearing measurements and is also capable of calculating

vessel heading. It is mainly used in mobile structure applications such as vessel track and follow.

Once a valid relative position has been calculated, the sensor generates a standard DP telegram every second,

which is compatible with all modern DP systems.

5.1 System Advantages

All-weather operations;

uniquely coded responders ensure reliable tracking;

single or multiple responder capability;

automatic target detection;

full 360° scanning providing an unobstructed field of view;

uses coded responders making the system immune to false reflections;

responders are ATEX certified and intrinsically safe;

compatible with all leading DP systems;

versatile choice of responders to suit all applications (power cell pack powered, mains powered, or

rechargeable battery);

compact and lightweight design for easy transport and installation;

modular design to simplify servicing and maintenance.

5.2 System Disadvantages

Responder location must be selected to ensure line of sight is maintained throughout the operation;

requires the use of manufacturer’s own responders;

like all microwave based sensors, sea reflections can cause problems in still conditions if the

installation instructions are not followed carefully.

6 IMCA M 229

6Installation

6.1 Sensor Wiring Diagram

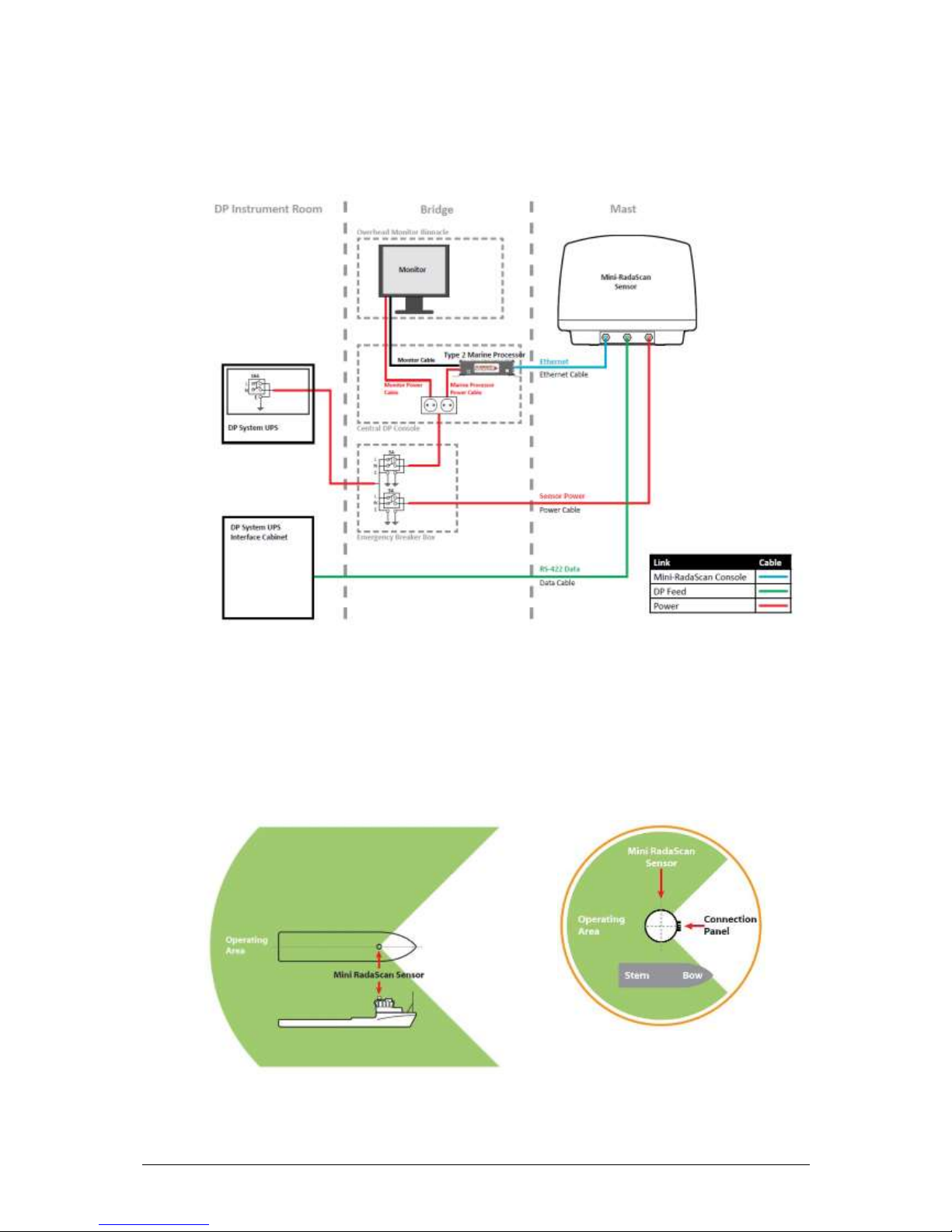

The Mini RadaScan installation cable routing is shown in Figure 2.

Figure 2 –Mini RadaScan components cable routing

6.2 Sensor Placement

Sensor placement varies with each application therefore the information hereafter is provided as a

general guideline.

On a platform supply vessel (PSV), the typical mounting position for the sensor is above the wheelhouse,

with a clear view over the aft deck area or whichever operating area is required.

Figure 3 –Typical sensor mounting position covering deck area

IMCA M 229 7

Ideally the sensor should be mounted:

with the inspection hatch facing towards the bow (opposite the operating area), parallel to the

vessel’s fore and aft centre-line. Any deviation from the centre-line alignment can be corrected in

the dashboard software (see section 6.4);

with an unobstructed view in the expected direction of the target;

above sea-level to prevent swamping or immersion;

on a different vertical level to any radar systems operating in the X-band (see section 11.1);

on a flat, rigid, horizontal surface able to support the sensor weight and receive four M12 fixing

bolts;

allowing for easy access to the connection panel and sensor information display;

high enough to be level with the responder.

6.3 Responder Placement

To ensure highest performance of the system and quality of the relative position data sent to the DP

system, the location, range and orientation of the responders must be optimised.

Ideally responders should be mounted:

within the recommended height difference limits;

within the tilt limits;

facing the sensor directly;

in a permanent location.

Additionally the sensor blanking zone should be configured in the Dashboard software.

Following these guidelines should prevent the sensor detecting any ‘ghost’reflections from metallic

surfaces which may occur from any microwave-based system.

6.4 Calibration

6.4.1 Calibrating the Sensor Range Measurement

The sensor range measurement is factory calibrated and does not require any further steps

during installation or operation.

6.4.2 Calibrating the Sensor Bearing Measurement

Once installed on the vessel, the mounting of the sensor unit may have introduced a bearing

offset between the sensor and the vessel centre-line or heading axis. The dashboard user

interface allows the installation team to enter a fixed offset to the bearing to compensate for

it.

This change requires service access and should be carried out by trained personnel during

installation.

In multi-target tracking mode, the DP system may require that the reported heading is aligned

with the on-board gyro(s). This must be done through the Mini RadaScan user interface9and

repeated prior to commencing any DP operation.

6.4.3 Responders

The responders do not require any calibration steps and are ready for use out-of-the-box once

switched on. However the operator should pay great attention to installation guidelines to

maximise responder visibility from the sensor point of view.

8 IMCA M 229

7System Design

7.1 Sensor Properties

Figure 4 shows the internal components of the Mini RadaScan sensor.

Figure 4 –Mini RadaScan dome (left); base (centre); rotor and base (right)

There are three main modules in the sensor.

The rotor includes:

receive (Rx) and transmit (Tx) antenna arrays;

transceiver connected to the antenna arrays;

main DSP circuit board which analyses the output from the transceiver.

The chassis includes:

belt drive, motor and encoder;

bearing, heating element and slipring;

hinge to facilitate access to the elements in the base.

The base and dome assembly includes:

gasket protecting internal elements;

small observation hatch (which includes its own seal);

power supply;

vacuum fluorescent display (VFD);

mounting holes and pressure vent;

I/O for the DP system and the dashboard.

The radar dome is attached to the base by fixing screws while the gasket ensures a tight seal.

The assembly and disassembly of the dome should only be carried out by trained personnel as it may

compromise the seal and cause damage to the sensor electronics.

The antenna arrays have been designed specifically to optimise the radar beam shape for most

applications; specifically the elevation pattern is wider than the azimuth pattern to allow the system to

cope with the pitch and roll of a vessel, and to ensure good bearing accuracy.

7.1.1 VFD –Status Display

The sensor is equipped with a display for diagnostics and fault finding purposes. In particular,

it offers a convenient way for the installer to read the network IP address and the current fault

conditions when the dashboard is unable to initiate a connection to the sensor.

IMCA M 229 9

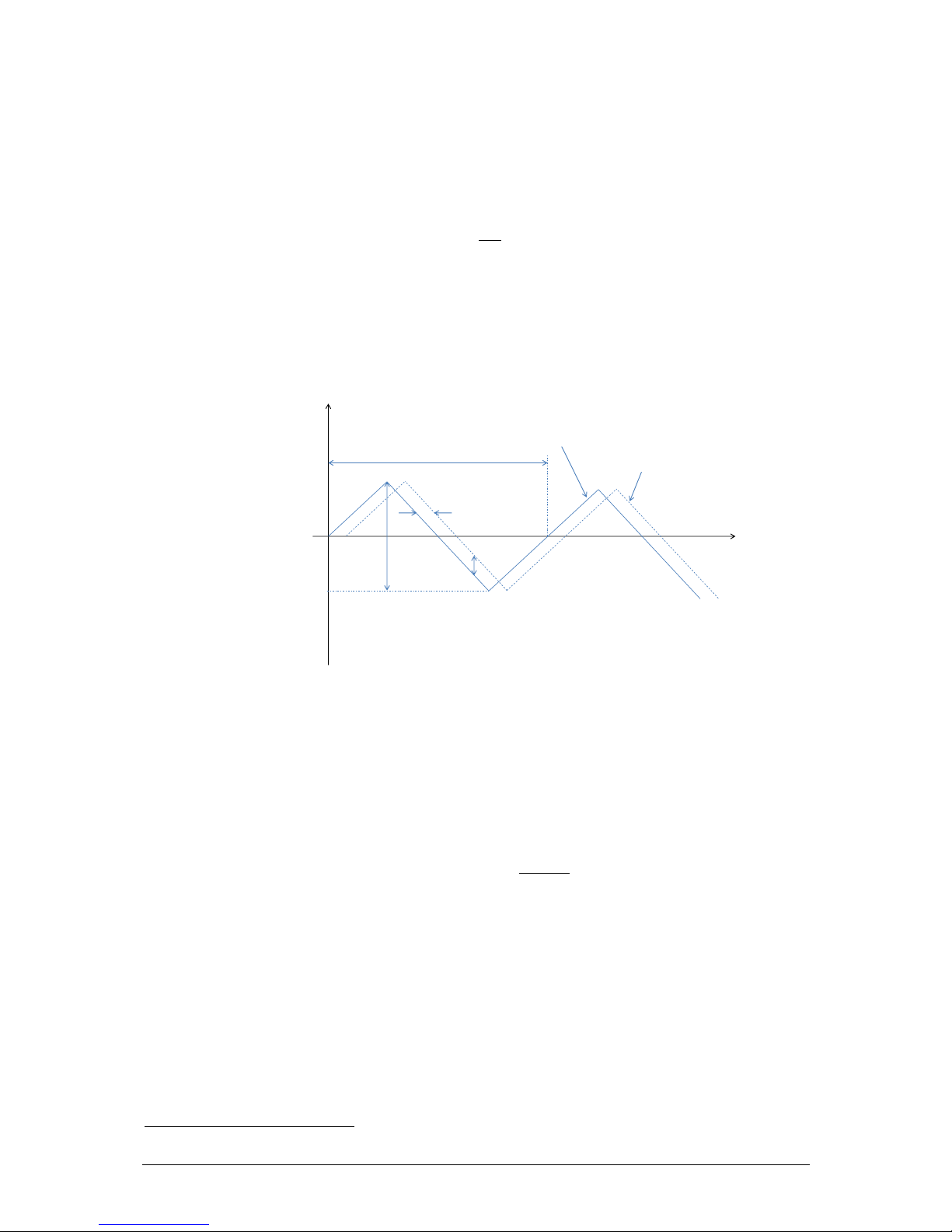

7.2 Measurement Principles

7.2.1 Range

The range measurement is the most important function of traditional radars and it is achieved

by measuring the time TRtaken by a signal to travel to the target and return (i.e. time of travel).

The more accurate the time measurement, the more accurate the range measurement R will

be.

The Mini RadaScan sensor operates using the well-known principles of FMCW radars,

9

where

the difference in frequency between the transmitted (Tx) and the echoed signal (Rx) –fb(beat

frequency) –is proportional to the transit time and c is the speed of light.

Figure 5 –FMCW beat frequency illustration (no Doppler shift)

While DP operations are usually executed at low-speed, the vessel movements are still

significant enough to introduce a non-negligible Doppler frequency shift.

If the frequency is modulated at a rate fmover a range ∆f(Figure 5), the beat frequency can be

expressed as a function of the range:

By measuring the beat frequency within a few Hz and compensating for the Doppler shift, the

Mini RadaScan sensor is able to measure the range with great accuracy. However it should be

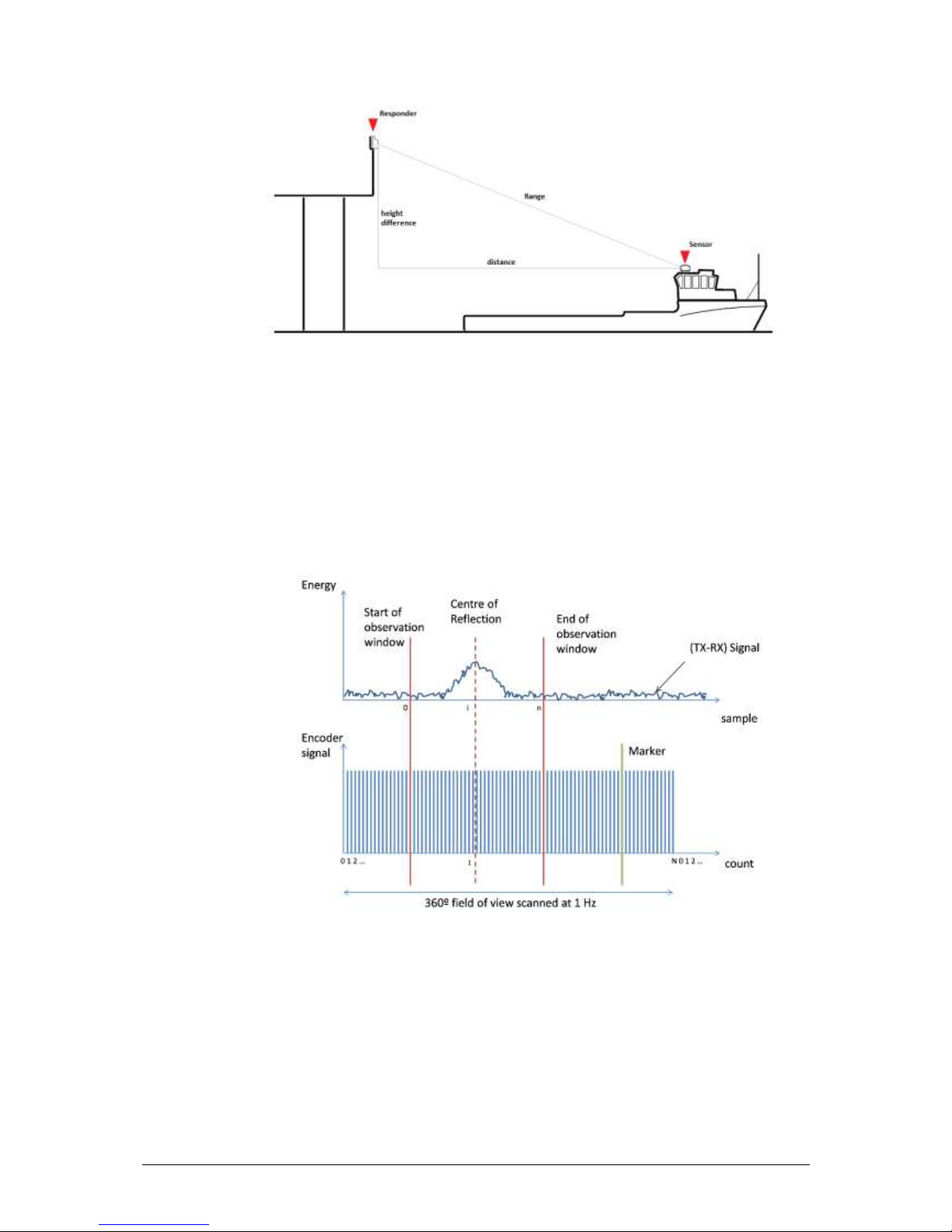

noted that the sensor only reports the range from the sensor to the responder and not the

horizontal distance to the structure (see Figure 6).

9

Skolnik MI, 1981, Introduction to Radar Systems, McGraw-Hill Book Co., Singapore

Time

Freq

TX

RX

10 IMCA M 229

Figure 6 –Operation geometry and reported range

7.2.2 Bearing

The bearing measurement is derived from the energy peak of the reflection as detected by the

360º rotating antenna.

The combination of the angular position of the rotor (measured by the encoder disc) and the

reflection data (sensed by the antenna) allows for an accurate and consistent bearing

measurement.

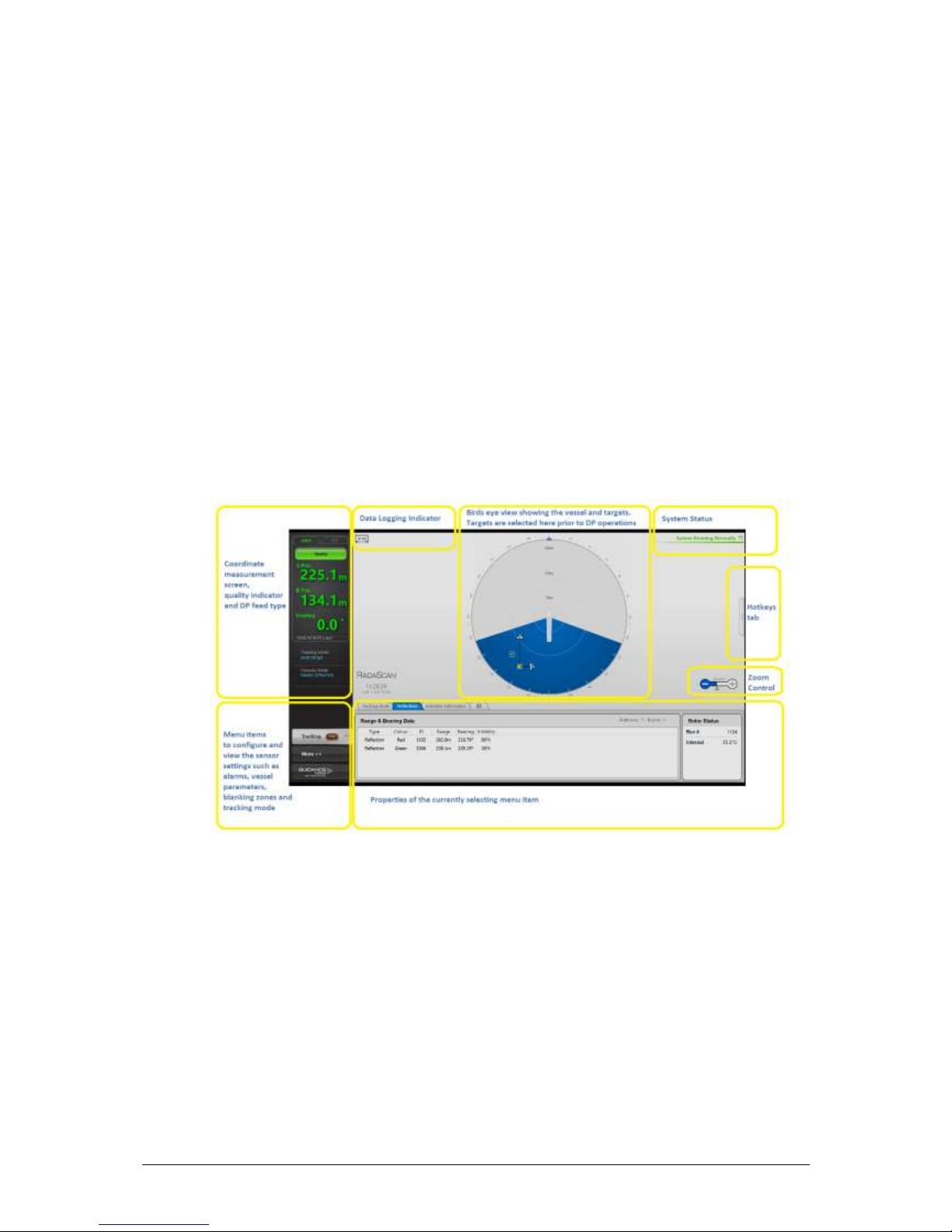

Figure 7 –Bearing measurement

The (Tx-Rx) FMCW signal generated by the transceiver is sampled and processed so that the

energy peak can accurately be measured by a sample position i(Figure 7), which is then

converted to a bearing measurement using the corresponding encoder count I.

The encoder also provides a fixed marker position, which is indicated by the direction of the

connection panel on the sensor. It represents a fixed reference point (reference bearing) used

to provide a consistent relative bearing measurement. The convention is that the bearing

reported by the sensor shows 0º when the antenna is facing the connection panel and increases

in a clockwise direction.

IMCA M 229 11

The reported result is the calculated bearing compensated by any other bearing offset to align

the result with the vessel’s gyro (if required).

7.2.3 Target Detection and Tracking

The range and bearing are the main measurements used to form the telegram provided by the

sensor to the DP system. However there are important internal algorithms that evaluate the

quality of each reflection in order to decide if a target is acquired (i.e. acceptable for tracking)

or lost.

The target detection process has been illustrated in Figure 8. Note that the same target

detection algorithm is used during tracking when a target is lost and needs to be automatically

reacquired.

Figure 8 –Sensor processing states

For a DP operation to be initiated the operator needs to select a reflection or a number of

reflections among all the detected responders and then start tracking using the dashboard

interface.

Once a responder has been detected, motion tracking is achieved using both range and bearing

predictor algorithms. These predictors are used to optimise the observation window position

(Figure 7) to provide the best possible observation of the target during each antenna revolution.

The algorithms use gating and validation functions and do not alter the data transmitted to the

DP system. It is important for the Mini RadaScan to provide unfiltered measurements to avoid

adding any unnecessary lag or delay in the DP control loop. Any filtering/smoothing on the

data should be carried out by the vessel DP system if required.

The prediction algorithms are optimised to track responders in an environment with the

velocity and acceleration characteristics of a typical DP equipped vessel.

7.3 Responders

Figure 9 shows the components of the responder. Responders are typically permanently mounted on

platforms and are available in a number of varieties with various mounting bracket options depending

on the installation requirement.

12 IMCA M 229

Figure 9 –Responder internal view

7.3.1 Responder Antenna

The responder has been uniquely developed in conjunction with the radar sensor to ensure

that the system as a whole is easy to set up and resilient to other microwave emissions in the

operating frequency band. The responder allocated channel frequency (identifiable by the

colour) allows the sensor signal processing software to effectively reject the background clutter

normally encountered by any traditional radar system. This includes the signature of nearby

structures, such as other vessels.

Although the antenna is designed to have a wide acceptance angle (see section 12) to facilitate

target detection in a wide range of DP operations, it is strongly recommended to follow the

installation procedure (see section 6.3) to optimise the signal quality and achieve the maximum

range specified.

7.3.2 Power Source

The system offers three different types of power sources for the responders:

rechargeable battery pack;

mains power;

non-rechargeable battery primary cell pack.

The responders feature one or more status LEDs offering a convenient indication of the state

and charge level. The battery powered responder will switch itself off when it reaches critical

battery level to avoid unreliable performance.

There is no indicator to advise nearby personnel that the responder is in DP operation and

being tracked by a sensor. It is therefore important for personnel not to alter the position of

the responder once installed and it is recommended that a notice to this effect is posted next

to the responder.

IMCA M 229 13

8Operation

The operator uses the dashboard to automatically find and identify all available responders. Upon detection

these are displayed on the screen for the operator to select. Once selected and confirmed the system is switched

into tracking mode by the operator.

The Mini RadaScan blanking zone is configured once during the installation and determined by the field of view

where responders can be observed by the sensor (i.e. not obstructed by the vessel structure or any other metallic

surface).

Once installed and configured the sensor can typically be brought online using the user interface in three easy

steps:

sensor start-up and target detection;

target selection;

initiate tracking.

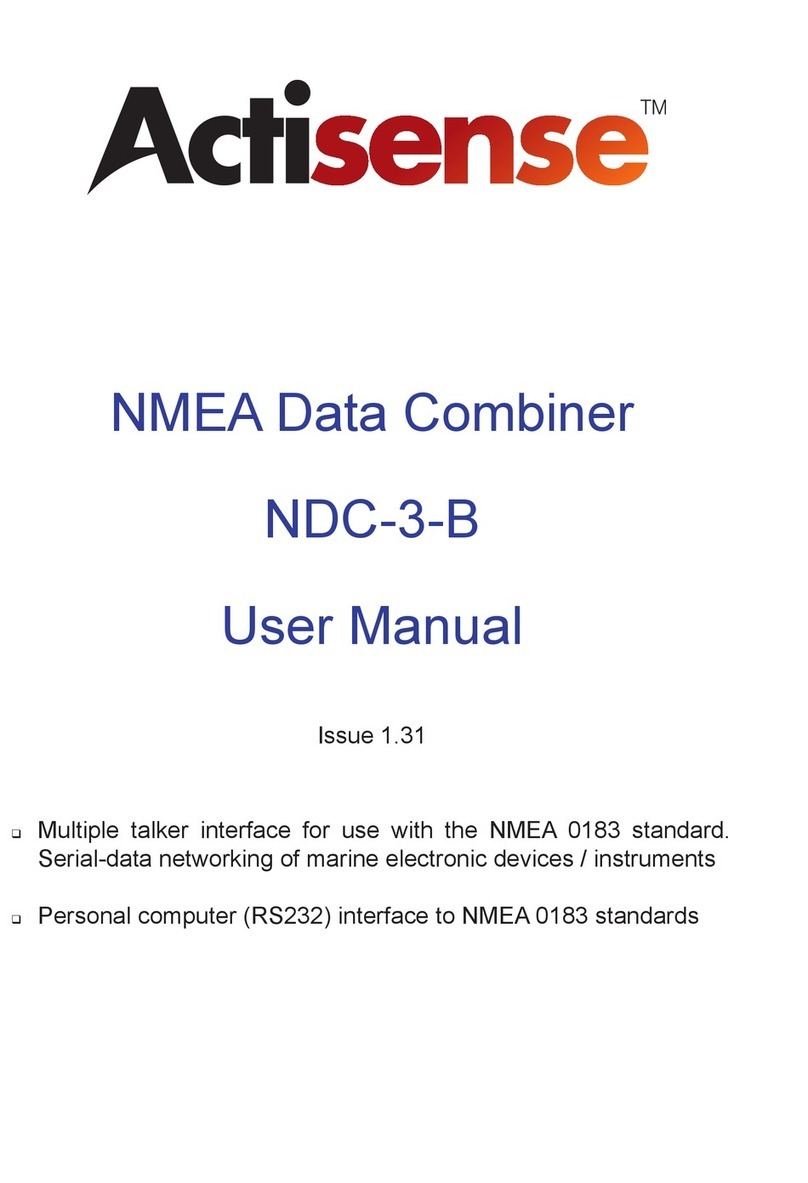

8.1 Dashboard

The dashboard is the graphical user interface needed to operate the Mini RadaScan. It can be controlled

using a mouse/keyboard or a touch screen display.

During normal operation the sensor updates the dashboard scanner display (Figure 10).

Figure 10 –Mini RadaScan dashboard

When a target has been detected, the display shows the relative position of the vessel to the

responder(s) together with any selected blanking zone. Real-time numerical values of range, bearing

and, where appropriate, heading are shown. A health bar shows the quality of the overall position

measurement.

The health is an indicator to help the operator assess the quality of the signal received by the sensor,

i.e. precursor to address any poor responder placement or vessel angle of approach.

The dashboard can be operated using two different levels of credentials:

user access level –this provides enough credentials for the user to perform most DP operations

using an already installed/configured sensor;

service access level –this offers the same credentials as the user access level but also allows the

operator to change configuration settings related to the sensor installation and the DP

configuration.

14 IMCA M 229

Multiple client dashboards can be connected to the same sensor in a master/slave configuration. This

feature provides redundancy around the vessel bridge where it is often important for multiple crew

members to have access to the Mini RadaScan data. In order to enhance safety during operations, slave

consoles are only able to view the current status of the sensor and are unable to gain service access,

start tracking or change the blanking zone. Any slave can request to be the master.

When the console is connected to a sensor and navigating, it autonomously collects detailed logs. These

logs offer valuable information to the support team to quickly diagnose any issues reported by

customers.

8.2 Multiple Sensor/Multiple Target Operation

The Mini RadaScan sensor automatically detects and identifies responders within the maximum range

and where a line of sight exists between the sensor and a responder. Each responder has a unique ID

and will respond to multiple sensors simultaneously allowing multiple vessels to operate in the same

region independently (Figure 11).

Figure 11 –Multi-responder multi-sensor operation

As illustrated in Figure 11, a DP operator can track more than one responder at the same time, whilst

another DP operator can track one or more of the same responders. Both operators can track the

same responders simultaneously.

The DP operator should refer to the Mini RadaScan documentation or contact the service team for

details to make sure the DP telegram data matches expectations of their DP system.

8.3 Mini RadaScan Interoperability and Compatibility

The performance of the Mini RadaScan is determined by the target choice. There are two formats of

target currently in field, a transponder and a responder as shown in Figure 12.

The transponder is an older generation target and its modulation type differs from the currently

manufactured responder. The modulation type of the transponder is referred to as series 1, the

modulation type currently used is referred to as series 2.

The responders are the latest generation of target and are capable of being programmed as series 1 or

series 2 or series 3. Responders are much smaller, lighter and give better performance than the earlier

transponders. The older generation transponders may not provide the maximum range performance

of the Mini RadaScan sensor.

IMCA M 229 15

Figure 12 –Target devices: transponder (left); responder (right)

When using multiple targets, because of the differing modulation types, certain rules must be adhered

to. A comprehensive guide to the differences between these targets is available.

10

10

94-0271-4-A RadaScan Series 2 Responder Buying Guide.pdf

16 IMCA M 229

9Servicing and Maintenance

The Mini RadaScan moving mechanical parts such as bearings, belt and motor should provide service free

operation for the typical DP operation usage over a period of up to 10 years. To further enhance the product

life expectancy the software will automatically initiate a suspend command and stop rotating the sensor if the DP

operator has not initiated tracking after a certain period of time.

Once installed, the sensor and responder units do not require cleaning under normal conditions. However, it is

recommended that the vessel owner carries out regular visual inspection for damage that may compromise the

integrity.

9.1 Software Upgrades

Mini RadaScan owners have access to the latest Guidance Marine software release through a web interface

or by contacting the Guidance Marine customer support team (customerservices@guidance.eu.com).

Both the Mini RadaScan sensor firmware and the dashboard can be upgraded in the field using a USB

memory stick or by transferring release files on the local network (e.g. marine computer). The two-

step procedure involves:

Remote installation of the sensor software on the sensor unit. This requires a LAN connection to

the sensor and the IP address of the sensor unit. The upgrade process is fully automated except

for the first time installation, which requires user configuration input. The installation software can

be executed using the installer user interface or a Windows command line.

Local installation of the dashboard on the marine computer. The dashboard installation works like

any standard Windows software using the supplied executable.

9.2 Recycling and Disposal

Guidance Marine employs the philosophy that supplied products do not contain hazardous substances.

A record of Mini RadaScan unit material content is available upon request.

When disposing of a Mini RadaScan sensor or responder, Guidance Marine recommends that

Mini RadaScan owners contact an electronics recycler that follows environmentally sound recycling

practices in accordance with the local rules.

Table of contents

Popular Marine Equipment manuals by other brands

Simrad

Simrad Pump-1 installation guide

Actisense

Actisense NDC-3 user manual

Simrad

Simrad EY500 instruction manual

Seastar Solutions

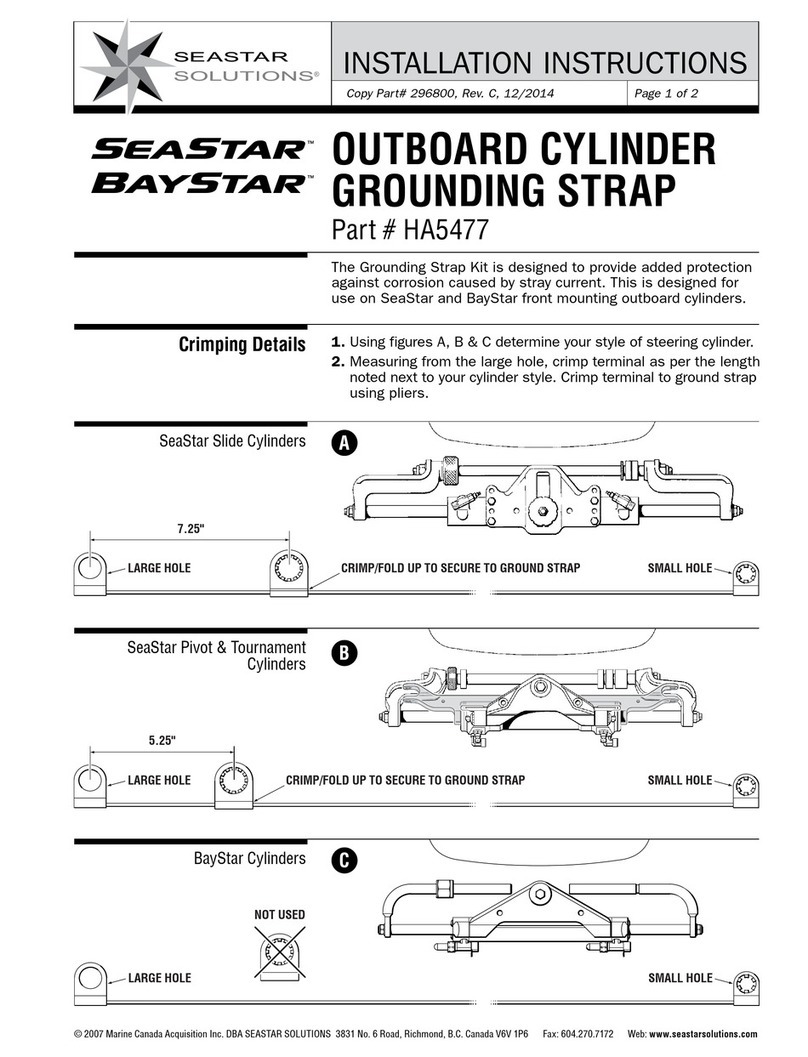

Seastar Solutions HA5477 installation instructions

INIM

INIM IVY Series Installation and programming manual

Francis Searchlights

Francis Searchlights LX300RC User instruction & installation manual