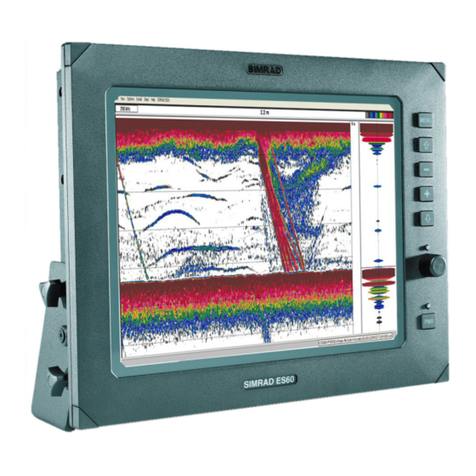

WIRING: Wiring diagram

14

9

15 16

Switch the autopilot to Power Steer mode.

Press and hold the arrow keys on the Autopilot controller in steps less

than 3 seconds at a time, until the cylinder reaches max travel in both

directions. The screenshots above are examples from HDS and NSS

evo2.

Continue to run the pump in both directions until no air bubbles are

left in the transparent tube.

IMPORTANT: Check uid level

MOUNTING: Bleeding the hand steering

Turn the wheel until the cylinder reaches max travel in both directions,

and rell oil.

Keep turning and relling oil until the oil level is stable and the

outboard engine responds rmly.

If air bubbles still remain in the system, follow the bleeding procedure

described for the outboard cylinder.

¼Note: It is recommended to use a threaded ller tube if available.

MOUNTING: Bleeding Pump-1

CORRECT

FLUID LEVEL

12

MOUNTING: Identify Type of Fitting Required

PORT

STB

STB

PORT

IMPORTANT: TRANSPARENT HOSE

+

_

12 V DC

MAIN

POWER

SWITCH

0.9 m (3 ft)

FUSE,

20 AMP 2 m (6 ft)

1 m (3 ft)

2 m

(3 ft)

5 m

(15 ft)

0.6 m

(2 ft)

1.8 m (6 ft)

T T

3 AMP

AUTO/STBY

BUTTON

POINT-1AP 1.2 m (4 ft)

Precision-9 4.5 mm (15 ft)

POINT-1AP

RED

BLACK

YELLOW

BLUE

Precision-9

ECHO

VIDEOIN

NMEA2K

NETWORK

POWER

ECHO

VIDEOIN

NMEA2K

NETWORK

POWER

PORT

13

MOUNTING: Pump-1, Connect hoses

IMPORTANT: TRANSPARENT HOSE

Conguration

Compliance Statements

Refer to your Autopilot controller’s documentation for setup

instructions.

The Outboard and the DrivePilot:

•Comply with CE under EMC directive 2004/108/EC

•Comply with the requirements of level 2 devices of the

Radiocommunications (Electromagnetic Compatibility) standard

17

11

MOUNTING: Disconnecting the hoses from helm

pump

1

2

3

STB

PORT

10

Installing with optional Verado tting kit for

Pump-1

310 mm

930 mm

VERADO STEERING

CYLINDER VOLUME

APPROX. 9ci - 150 cc

VERADO ELECTRO

HYDRAULIC POWER PACK

VERADO HELM

HIGH PRESSURE

STEERING LINES

LOW PRESSURE

RETURN LINE

HIGH PRESSURE

SUPPLY LINE

RETURN LINE

EXTENSION

HIGH PRESSURE

SUPPLY LINE

HIGH PRESSURE

STEERING LINES

STEERING LINES

RETURN LINE

LOW PRESSURE

RETURN LINE

STEERING LINE

EXTENSION

STB

ORB Fittings

NPT Fittings

DO NOT USE NPT FITTINGS

The drawing shows a SeaStar helm pump which identies ttings using

text engraved on the back.

¼Note: Helm and ttings required may vary by manufacturer.

¼Note: ORB and NPT tting kits are supplied in separate bags. Discard

the ttings not used.

¼Note: Pay attention to the ports on the helm pump to ensure you are

using the correct ttings.

MOUNTING: Connect hoses to helm pump

Check all ttings for leaks.

Shop for other marine electronics & navigation on our website.