Imerge IMerge AX-Platform User manual

Imerge

AX Platform

Service Manual

2

ENGLISH

Important

Servicing of this product in accordance with this service manual

should never be undertaken in the absence of proper tools, test

equipment and the most recent revision to this service manual which

is clearly and thoroughly understood.

This static control precaution symbol appears throughout this manual.

When this symbol appears next to a procedure in this manual, static

control precautions MUST be observed. Use a static control worksta-

tion to help ensure that static charges are safely conducted to ground

and not through static sensitive devices.

CAUTION

Technical Competence

The procedures described in this service manual should be performed by trained and

authorised personnel only. Maintenance should only be undertaken by competent

individuals who have a general knowledge of and experience with devices of this

nature. No repairs should ever be undertaken or attempted by anyone not having such

qualifications. Genuine replacement parts manufactured, sold or specified by Imerge

must be used for all repairs. Read completely through each step in every procedure

before starting the procedure; any exceptions may result in a failure to properly and

safely complete the attempted procedure.

Note: A note provides additional information to clarify a point in the text.

Important:

An Important statement is similar to a note, but is used for greater emphasis.

CAUTION:

A CAUTION statement is used when the possibility of damage to the equipment

exists.

WARNING:

A WARNING statement is used when the possibility of injury to service personnel

exists.

The information contained in this service manual pertains only to the AX platform

manufactured by Imerge as of the effective date of this manual or the latest revision

thereof. This service manual was prepared for exclusive use by appointed service

personnel in light of their training and experience as well as the availability to them of

parts, proper tools and test equipment. Consequently, we provide this service manual

for general information only without warranty of the results with respect to any applica-

tion of such information. Furthermore, because of the wide variety of circumstances

under which maintenance and repair activities may be performed and the unique nature

of each individual’s own experience, capacity, and qualifications, the fact that a cus-

tomer has received such information from us this does not imply in anyway that we

deem said individual to be qualified to perform any such maintenance or repair service.

Moreover, it should not be assumed that every acceptable test and safety procedure or

method, precaution, tool, equipment or device is referred to within, or that abnormal or

unusual circumstances, may not warrant or suggest different or additional procedures or

requirements.

This manual is subject to periodic review, update and revision. Customers are cautioned

to obtain and consult the latest revision before undertaking any service of the equip-

ment.

3

ENGLISH

Warnings

Disconnect the mains power to the unit during disassembly/assembly procedures. Do not perform any

service or maintenance with the power applied unless specifically told to do so in the procedure.

Use extreme care while performing service procedures with the cover removed or while working on the

unit with power connected. An electrical shock hazard does exist, and the power supply heatsinks can

deliver an electrical shock even when mains power is removed from the unit; be certain to observe all

standard safety precautions.

Special Tools and Equipment

The following tools (or their functional equivalents) are required to complete the recommended

service procedures.

Required Tools

No.1 Pozidriv Screwdriver (M3)

No.2 Pozidriv Screwdriver (M4)

Nutspinner M3 (5mm)

Flat nose Pliers

Anti-Static Workstation

Flat Nose Pliers

Pick Up Tool

Digital Multimeter

High grab adhesive (Please read the label for instructions of use)

Online Support

Use the World Wide Web (WWW) to view the latest version of this service manual, check for updates or

download files. The support area on our web site is password protected, please contact Imerge Support

for details.

Service manual address:

http://www.xiva.co.uk/support/servicemanual.html

The XiVA OEM Support Pages:

http://www.xiva.com/support

The XiVA Home Page:

http://www.xiva.com

4

ENGLISH

Table of Contents

Table of Contents

IMPORTANT ...................................................................................................................2

TECHNICAL COMPETENCE............................................................................................................. 2

WARNINGS ....................................................................................................................................... 3

SPECIAL TOOLS AND EQUIPMENT ................................................................................................ 3

ONLINE SUPPORT............................................................................................................................ 3

PAGE REFERENCES ........................................................................................................................ 5

CLEANING THE UNIT ....................................................................................................................... 6

TO CLEAN THE AUDIO CONNECTORS........................................................................................... 6

PACKAGING MATERIALS ................................................................................................................. 6

CLEANING & PACKAGING ...........................................................................................6

HANDLING ELECTROSTATIC DISCHARGE-SENSITIVE DEVICES ................................................ 7

DISASSEMBLY & ASSEMBLY.......................................................................................7

MOTHERBOARD (AX)....................................................................................................................... 8

REMOVING THE LID ....................................................................................................................... 10

FITTING THE LID ............................................................................................................................ 10

REMOVING THE CDROM DRAWER FRONT (METAL VERSION) ................................................. 12

FITTING THE CDROM DRAWER FRONT (METAL VERSION) ...................................................... 13

REMOVING THE CDROM DRAWER FRONT (PLASTIC VERSION).............................................. 14

FITTING THE CDROM DRAWER FRONT (PLASTIC VERSION) ................................................... 15

REPLACING THE CDROM DRIVE .................................................................................................. 16

REMOVING THE HARD DISK BRACKET ....................................................................................... 19

FITTING THE HARD DISK BRACKET............................................................................................. 20

REMOVING A HARD DISK DRIVE (HDD) ....................................................................................... 21

FITTING A HARD DISK DRIVE (HDD)............................................................................................. 22

REPLACING THE FAN .................................................................................................................... 23

REPLACING THE FRONT PANEL DISPLAY BOARD (FPDB) ........................................................ 25

REPLACING THE POWER SUPPLY UNIT (PSU) ........................................................................... 27

REPLACING THE MAINS INLET FILTER ........................................................................................ 28

REPLACING THE MEMORY MODULE ........................................................................................... 29

REMOVING THE DAUGHTER EXPANSION BOARD (IF APPLICABLE) ........................................ 30

FITTING THE DAUGHTER EXPANSION BOARD (IF APPLICABLE).............................................. 31

REMOVING THE MODEM ............................................................................................................... 32

FITTING THE MODEM .................................................................................................................... 33

REPLACING THE BATTERY ...........................................................................................................34

REPLACING THE CONTROLLER PORT ........................................................................................ 35

5

ENGLISH

Page References

*DA_REMOVE_LID*

*DA_FITTING_LID*

*DA_REMOVE_CDROM_FRONT*

*DA_FITING_CDROM_FRONT*

*DA_REMOVE_CDROM_DRIVE*

*DA_FITTING_CDROM_DRIVE*

*DA_REMOVE_MODEM_BRACKET_BOARD*

*DA_FITTING_MODEM_BRACKET_BOARD*

*DA_REMOVE_MODEM*

*DA_FITTING_MODEM*

*DA_REMOVE_HARDDISK_BRACKET*

*DA_FITTING_HARDDISK_BRACKET*

*DA_MOTHERBOARD_LAYOUT*

REPLACING THE AX MOTHERBOARD.......................................................................................... 35

PARTS LIST .................................................................................................................39

IMPORTANT .................................................................................................................................... 40

TESTING.......................................................................................................................41

INTRODUCTION.............................................................................................................................. 44

ESSENTIAL PREPARATION............................................................................................................ 44

TROUBLESHOOTING..................................................................................................44

QUESTIONS AND ANSWERS ........................................................................................................ 45

POWER CHECK .............................................................................................................................. 51

MOTHERBOARD CHECK ...............................................................................................................52

EXPANSION BOARD CHECK (IF APPLICABLE) ............................................................................ 54

MODEM PROBLEMS....................................................................................................................... 54

6

ENGLISH

Cleaning the unit

Regular dusting with a dry soft, non-abrasive cloth will generally keep the finish of the front panel and

chassis cover looking like new. Avoid the use of domestic cleaning products.

Dust or finger marks can be removed from the front panel using a soft, slightly damp cloth. Disconnect the

power cord before cleaning the unit. Ensure that no water is allowed to enter the case and do not reconnect

the power cord until you are certain that the unit is completely dry.

At no time should you allow any liquid to enter the unit; it may run into the electronic circuitry and cause

damage that will not be covered under the product warranty.

Note: Do not use abrasive cleaners on any part of the unit.

To clean the audio connectors

The audio sockets on the back of the unit are gold-plated and need no cleaning if gold-plated Phono plugs

are used. Otherwise, it is recommended that the end-user unplugs and reconnects the plugs at least once a

year.

Packaging Materials

We recommend that you retain all of the packing material and shipping boxes for the unit. They are custom

designed to reduce the likelihood of damage during shipping. We will accept no responsibility for any

damage occurring to the unit, or accessory, that is shipped in packing material other than the original

packing material.

Cleaning & Packaging

7

ENGLISH

Handling electrostatic discharge-sensitive devices

Any assembly or component part containing transistors or integrated circuits (ICs) should be considered

sensitive to electrostatic discharge (ESD). ESD damage can occur when there is a difference in charge

between objects.

Protect against ESD damage by equalising the charge so that the machine, the part, the work mat, and the

person handling the part are all at the same charge.

WHEN HANDLING ESD-SENSITIVE PARTS:

• Keep the parts in protective packages until they are inserted into the product.

• Avoid contact with other people.

• Wear a grounded wrist strap against your skin to eliminate static on your body.

• Prevent the part from touching your clothing. Most clothing is insulative and retains a charge even

when you are wearing a wrist strap.

• Use a grounded work mat to provide a static-free work surface.

Disassembly & Assembly

8

ENGLISH

Motherboard (AX)

9

ENGLISH

Whilst working inside the DH9300 we recommend that the PSU is covered with (?) to prevent contact with

the Power Supply Unit (PSU) which can cause an electric shock.

10

ENGLISH

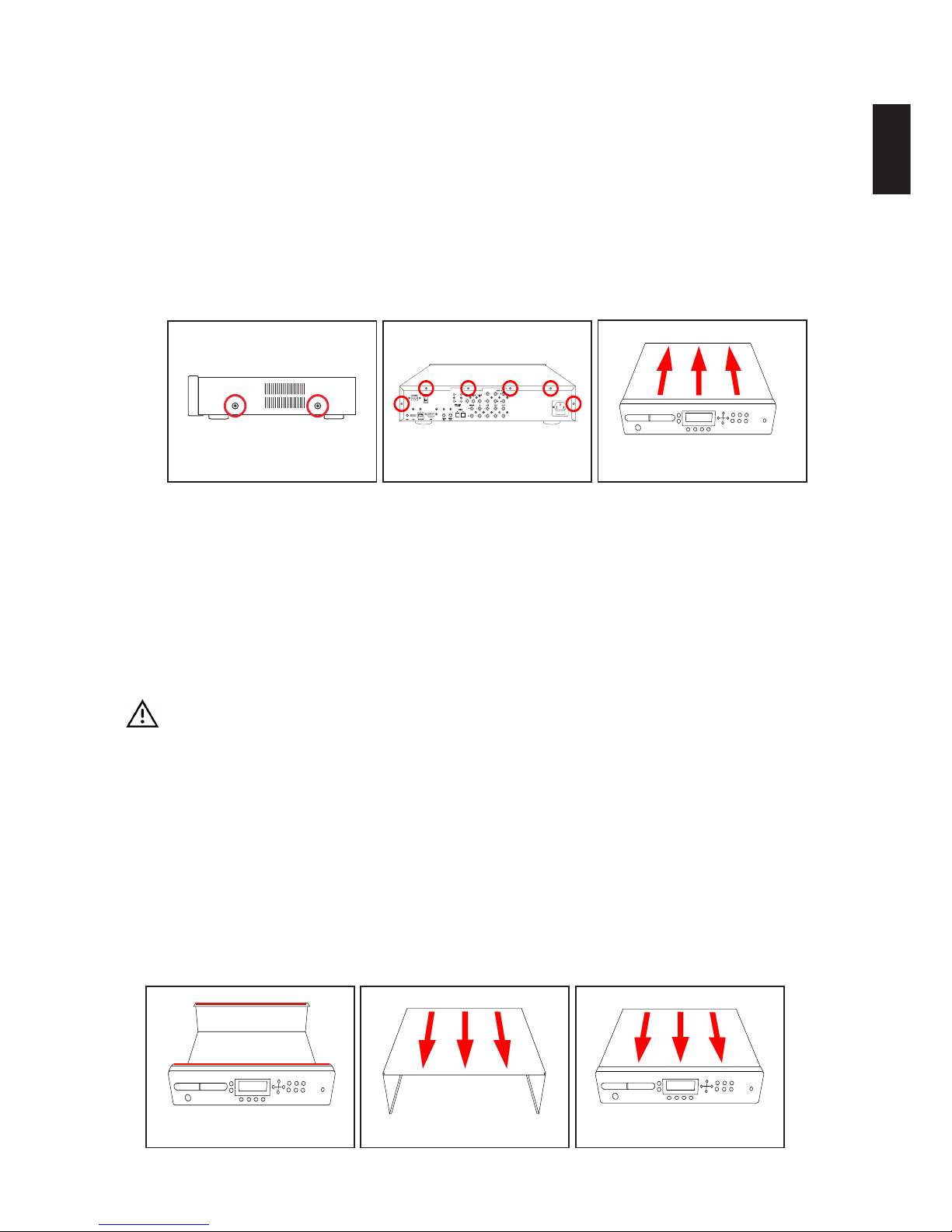

Removing the Lid

TOOLS:

Pozi-driv No.1 screwdriver

PARTS USED:

MW00113-01 Cover (Black) MW00036-01 6x M3 (6mm) Black Screws

MW00105-01 4x Copper M3 (6mm) screws

PROCEDURE:

1. Remove the 4x M3 (Copper) screws from the left and right side of the unit. See figure 1.

2. Remove the 6x M3 (Black) screws from the rear of the unit. See figure 2.

3. Gently slide the lid towards the rear then lift up to remove, store in a safe place to prevent

damage. See figure 3.

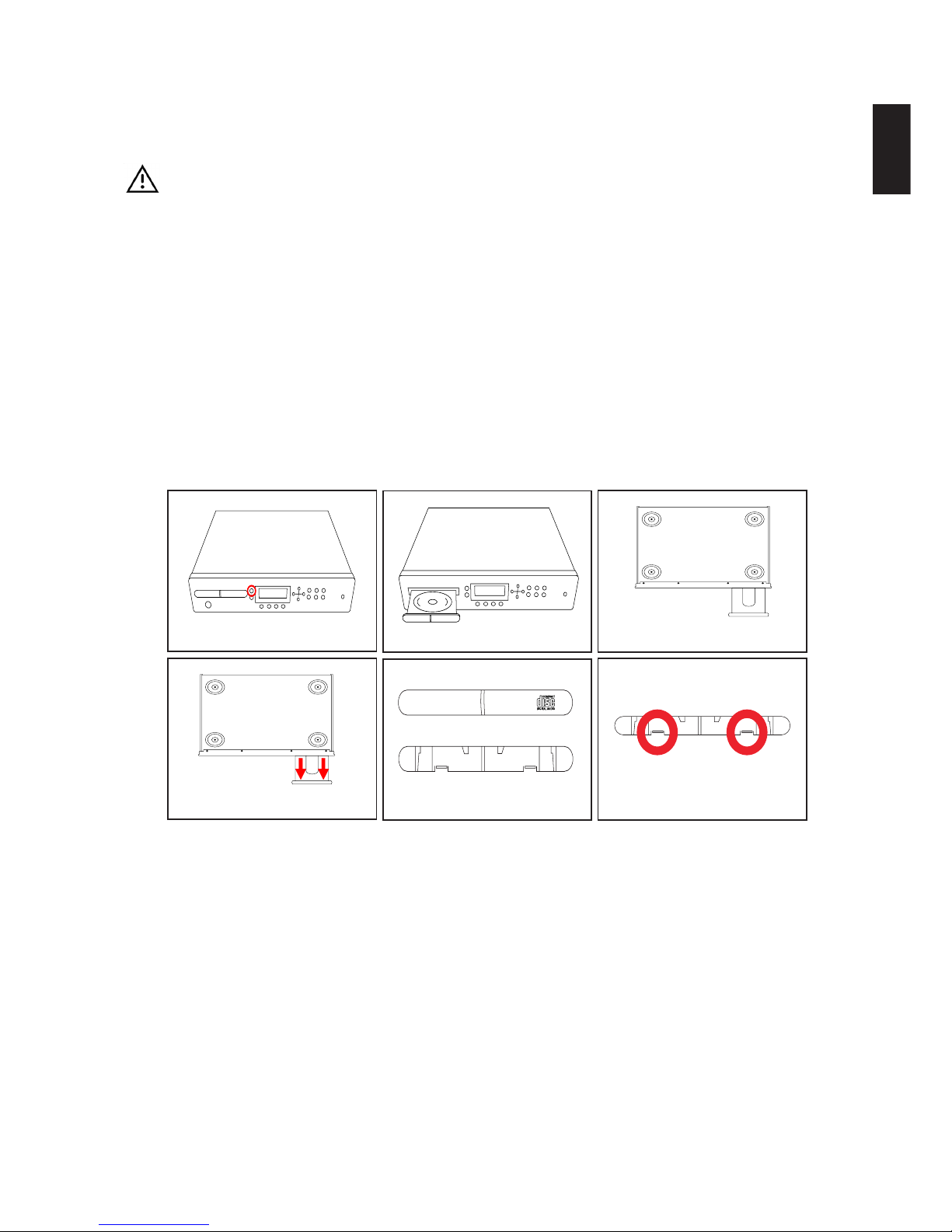

Fitting the Lid

CAUTION:

EMC stripes are used along the top front and back edges of the chassis which can make the lid

difficult to fit. Do not try to force the screws into the holes as this can cause either damage to the

chassis or the screws thread which may prevent you from removing the lid again. Apply a little

downward pressure on the lid at the rear to help line up the holes.

TOOLS:

Pozi-driv No.1 screwdriver

PARTS USED:

MW00113-01 Cover (Black) MW00036-01 6x M3 (6mm) Black Screws

MW00105-01 4x Copper M3 (6mm) screws (if applicable)

PROCEDURE:

figure 1 figure 2 figure 3

figure 1 figure 2 figure 3

11

ENGLISH

1. EMC stripes are used along the top front and back edges of the chassis. See Caution and

Figure 1.

2. The lip on the lid fits neatly under the top of the front panel (See figure 2). Insert the lids’ lip into

the top of the front panel at a 35oangle and slowly sit the lid down at the rear (See figure 3).

3. You may have to apply a little downward pressure on the lid at the rear to align up the screw

holes.

4. Secure and tighten 6x M3 (Black) screws on the rear of the unit. See figure 4.

5. Secure and tighten 4x M3 (Bronze) screws on the left and right side of the unit. See figure 5.

figure 4 figure 5

12

ENGLISH

Removing the CDROM Drawer Front (Metal version)

CAUTION:

The CDROM drawer is likely to break if excessive force is applied during this procedure.

TOOLS:

Small flat bladed screwdriver Pin or Straighten out Paper clip (if necessary)

PARTS USED:

PL00010-01 CD Drawer Front

<P/NBR> 3M Double sided sticky pads

PROCEDURE:

This procedure covers the removal of the painted metal CDROM drawer front that is clipped to the

tray. See ‘Removing the CDROM Drawer Front (Plastic version)’ for the removal of the plastic

variant.

1. With the lid on and while the unit is powered, press the eject button to open the CD tray (See

figure 1).

In the unlikely event that you are unable to eject the CD tray, you can try the following methods.

Below the right hand corner of the CD drawer is a small manual eject pin hole, inserting a pin or

straightened out paper clip into this hole should open the drawer whilst the power is applied. If

this fails then you will need to remove the CDROM drive (See page

*DA_REMOVE_CDROM_DRIVE*) to gain access to the CD drawer front.

2. With the drawer still open (see figure 2), place the unit into standby and then remove the power.

3. The drawer front is attached to the drive’s plastic drawer front using 2x 3M double sided sticky

pads.

4. Using the flat bladed screwdriver, gently prise the metal drawer front from the CDROM’s

original drawer front. See figure 3.

5. After the metal drawer front has been removed, completely remove any traces for the double

sided sticky pads as new pads will need to be used to fit it again.

figure 1 figure 2 figure 3

13

ENGLISH

Fitting the CDROM Drawer Front (Metal version)

CAUTION:

The CDROM drawer is likely to break if excessive force is applied during this procedure.

TOOLS:

Pin or Straighten out Paper clip (For manual eject if necessary)

PARTS USED:

PL00010-01 CD Drawer Front

PROCEDURE:

This procedure covers the fitting of the painted metal CDROM drawer front that is clipped to the

tray. See ‘Removing the CDROM Drawer Front (Plastic version)’ for the removal of the plastic

variant.

1. With the lid on and while the unit is powered, press the eject button to open the CD tray (See

figure 1).

In the unlikely event that you are unable to eject the CD tray, you can try the following methods.

Below the right hand corner of the CD drawer is a small manual eject pin hole, inserting a pin or

straightened out paper clip into this hole should open the drawer whilst the power is applied. If

this fails then you will need to remove the CDROM drive (See page

*DA_REMOVE_CDROM_DRIVE*) to gain access to the CD drawer front.

2. With the drawer still open (see figure 2), place the unit into standby and then remove the power.

3. The drawer front is fitted to the CDROM drive with 2x 3M double sided sticky pads on the rear

side of the metal drawer. If the drawer front has been used before then remove all traces of the

double sided sticky pads before proceeding.

4. Place one at each end at about 1cm from the edge.

5. Centrally align the metal drawer front with the CDROM drawer front and carefully apply pres-

sure so that the pads to stick.

figure 1 figure 2 figure 3

14

ENGLISH

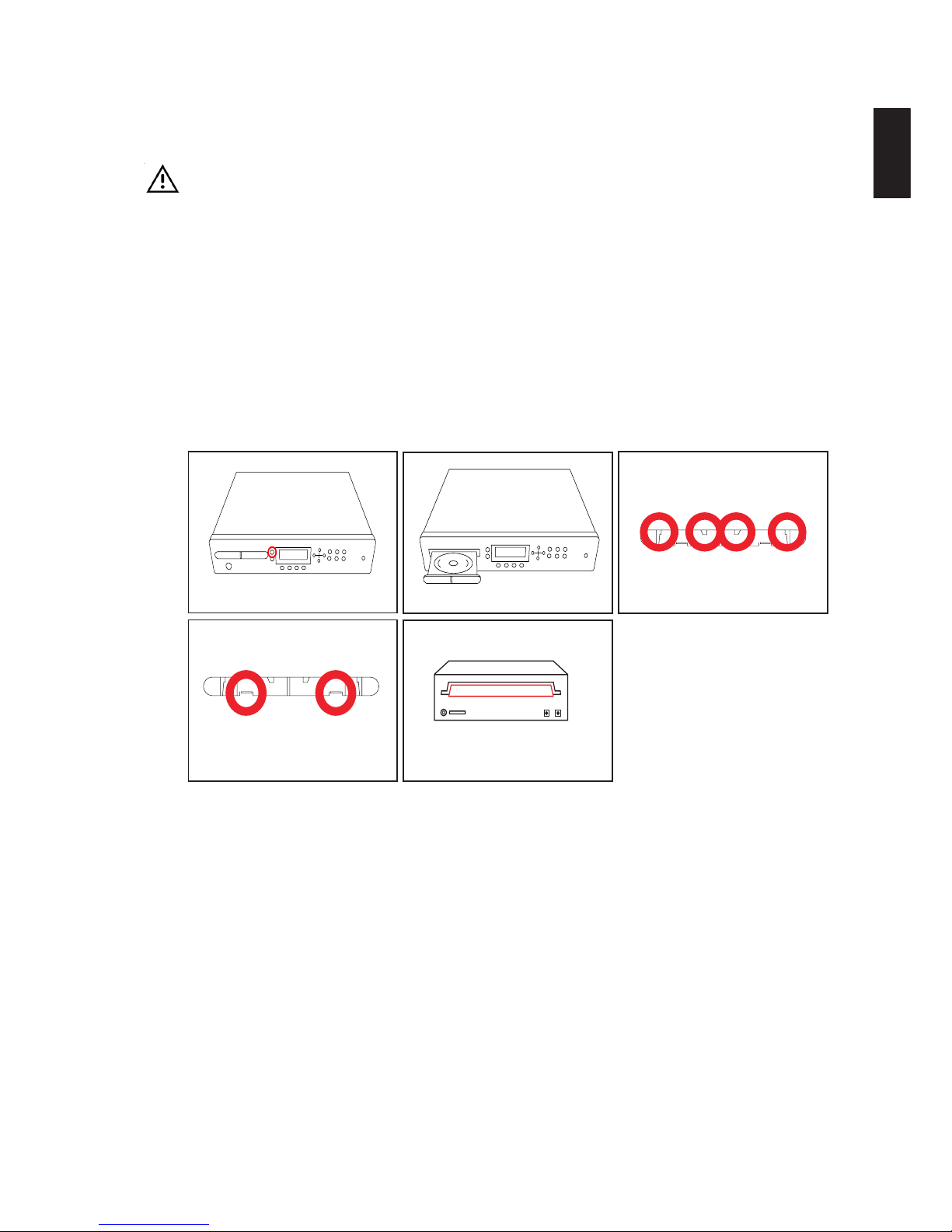

Removing the CDROM Drawer Front (Plastic version)

CAUTION:

The CDROM drawer is likely to break if excessive force is applied during this procedure. The

drawer front must be removed before the drive can be taken out of the unit.

TOOLS:

Small flat bladed screwdriver Pin or Straighten out Paper clip (if necessary)

PARTS USED:

PL00010-01 CD Drawer Front

PROCEDURE:

This procedure covers the removal of the plastic CDROM drawer front that is clipped to the tray.

See ‘Removing the CDROM Drawer Front (Metal version)’ for the removal of the painted metal

variant.

1. With the lid on and while the unit is powered, press the eject button to open the CD tray (See

figure 1).

In the unlikely event that you are unable to eject the CD tray, you can try the following methods.

Below the right hand corner of the CD drawer is a small manual eject pin hole, inserting a pin or

straightened out paper clip into this hole should open the drawer whilst the power is applied. If

this fails then you will need to remove the Front Panel (See page

*DA_REMOVE_FRONTPANEL*) to gain access to the CD drawer front.

2. With the drawer still open (see figure 2), place the unit into standby and then remove the power.

3. Turn the unit upside down for easier access (see figure 3).

4. On the underside of the CD drawer front you will see two clips (see figure 4).

5. Figure 5 shows the front (top) and back (bottom) of the drawer front.

6. Gently prise off the drawer front by carefully releasing the two clips (see figure 6) on the under-

side with a small flat bladed screwdriver.

7. Turn the unit upright.

8. Applying power to the CDROM drive will automatically close the drawer (if required).

figure 1 figure 2 figure 3

figure 4 figure 5 figure 6

15

ENGLISH

Fitting the CDROM Drawer Front (Plastic version)

CAUTION:

The CDROM drawer is likely to break if excessive force is applied during this procedure.

TOOLS:

Pin or Straighten out Paper clip (For manual eject if necessary)

PARTS USED:

PL00010-01 CD Drawer Front

PROCEDURE:

This procedure covers the fitting of the plastic CDROM drawer front that is clipped to the tray. See

‘Removing the CDROM Drawer Front (Metal version)’ for the removal of the painted metal variant.

1. While the unit is powered on, press the eject button to open the CD tray. See figure 1

In the unlikely event that you are unable to eject the CD tray, you can try the following methods.

Below the right hand corner of the CD drawer is a small manual eject pin hole, inserting a pin or

straightened out paper clip into this hole should open the drawer whilst the power is applied. If

this fails then you will need to remove the Front Panel (See page

*DA_REMOVE_FRONTPANEL*) to gain access to the CD drawer front.

2. With the drawer still open, place the unit into standby and then remove the power.

3. On the top of the drawer front are two prongs (see figure 3) and two clips at the bottom (see

figure 4).

4. There is a ridge at the front of the drawer where the part is fitted (see figure 5). Clip the drawer

front on the top first then gently lift the prongs over the bottom ridge of CD drawer.

5. Applying power to the unit will automatically close the CD drawer.

figure 1 figure 2 figure 3

figure 4 figure 5

16

ENGLISH

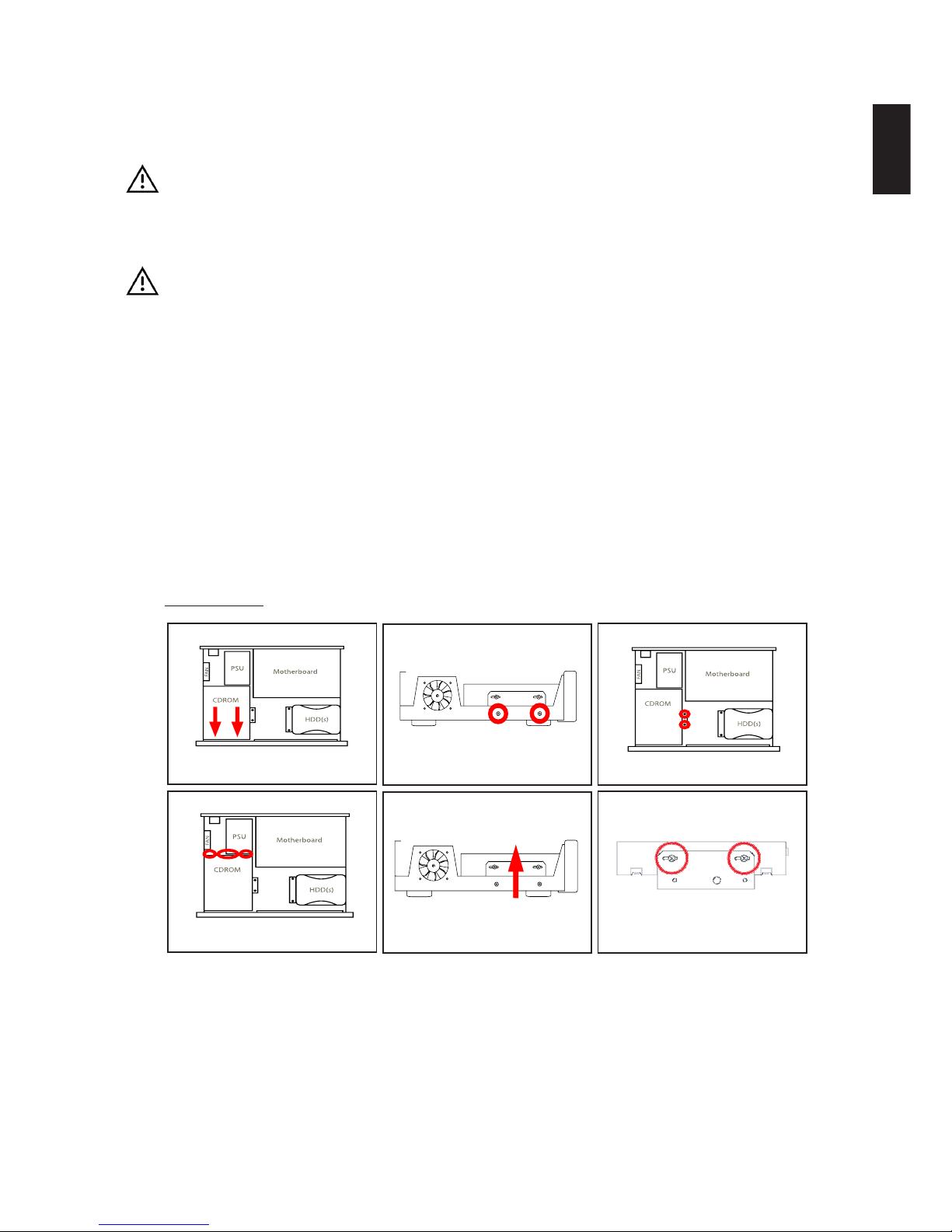

Replacing the CDROM drive

WARNING:

There is a risk of electrical shock, the power supply can deliver an electrical shock even when the

mains power is removed from the unit; be certain to observe all standard safety precautions.

CAUTION:

The motherboard front panel display socket carries additional power, do not under any circum-

stances attempt to connect a cable plugged in this socket into the hard disk drives or CDROM drive.

This will short circuit the attached device and/or motherboard rendering it inoperable.

TOOLS:

Pozi-driv No.1screwdriver Small flat bladed screwdriver

High Grab Adhesive PSU (Power Supply Unit) or another unit

PARTS USED:

MW00036-01 4x M3 (6mm) Black MW00038-01 4x M3 (6mm) Black

IC00097-01 CD-ROM ASUS CD-S520 MW00114-01 CD Support Bracket

MW00043-01 4x M3 Shakeproof Washers (Black)

PROCEDURE:

Disassembly

1. Remove the Lid. (See page *DA_REMOVE_LID*)

2. Remove the CDROM drawer front (See page *DA_REMOVE_CDROM_FRONT*)

3. Carefully peel off the EMC tape from the CDROM which is fixed between the drive and chassis

front panel, try not to damage the tape as it can be reapplied again.

4. Using a Pozi-driv No.1 screwdriver, remove 2x M3 screws from each bracket that mount the

drive and brackets to the chassis. You may need to move the front panel and hard disks cables

aside for easier access.

5. Lift the drive up slightly at the rear to release the power cable from the cable retaining bunny

clip. Carefully remove the IDE ribbon (black connectors), Power and Audio cables from the rear

figure 1 figure 2 figure 3

figure 4 figure 5 figure 6

17

ENGLISH

of the drive. Be careful not to touch the power supply unit as it may still hold charge or break

any of the attached cables.

6. Gently lift the CDROM along with the bracket out of the unit.

7. Remove 4x M3 screws securing the CDROM drive to the bracket.

8. The CDROM is glued to the mounting brackets with a high grab adhesive to prevent it from

slipping forwards or backwards whilst in transit. The brackets can be removed by carefully

prising them away from the drive using a thin flat bladed screwdriver.

Preparing a new CDROM drive

1. Brand new CDROM drives are supplied with their facia fitted, in order to use the drive this must

be removed first.

2. To remove the CDROM facia you must open the CDROM’s drawer to take off the drawer front.

This can be achieved by applying power to the unit and by pressing the eject button (See figure

1). The power can be supplied by either temporarily connecting the drive to the unit and turning

the unit on or by connecting the drive to an external PSU (Power Supply Unit). Make sure that

the power is disconnect after the drawer is opened and before proceeding to the next step.

3. The original CDRom drawer front is clipped on to the drawer in much the same way as it’s

replacement (See page *DA_REMOVE_CDROM_FRONT*) if using the plastic version. It can

be easily removed without the use any tools, simply lift the bottom of drawer front to release the

clips and gently slide it up, Please note: The CDROM drawer is likely to break if excessive force

is applied during this procedure.

4. Figure 3 shows the location of plastic tabs that fix the facia to the drive. You will need a flat-

bladed screwdriver to carefully prise the facia off

5. If the unit is going to be fitted with a metal CD drawer front then fit the original drawer front back

on again.

figure 1 figure 2 figure 3

18

ENGLISH

Assembly

1. Ensure that the CDROM’s facia has been removed, if not then carefully prise off the facia with a

small flat bladed screwdriver (See ‘Preparing a new CDROM drive’ before this section).

2. Set the jumper on the rear of the drive to master, a diagram of the jumper settings can either be

found on a rear or top label.

3. In order to make sure the CDROM drive does not move from it’s position in transit, put two

small beads (3mm in diameter) of high grab adhesive in between the drives mounting holes

(perform on each side). See figure 1.

4. The CDROM bracket is not symmetrical, the flat edge fits to the front left hand side of the

chassis and the angled part is secured to the two mounting pillars opposite within the chassis.

Mount each side of the CDROM drive to the bracket using 2x M3 screws. See figure 2.

5. Gently place the drive into the chassis making sure that the foam EMC gasket (between the

front panel and CDROM drive) does not obscure the CDROM’s play and eject buttons. Not

correctly positioning the drive can also result in the EMC gasket pushing the front of the drive

up, mis-aligning the CDRom drawer front. See figure 3.

6 Align the drive holes with those on the bracket, making sure its flush against the front panel

metalwork then insert and tighten the 4x M4 screws. See figures 3 & 4.

7. Clean any excess adhesive that may have smeared above the bracket with a damp cloth.

8. Connect the IDE cable from Secondary IDE socket (marked PL9) on the motherboard to the

CDROM drive. Do not plug the IDE cable in to the socket marked ‘Front Panel’ as this will

damage the drive. (See page *DA_MOTHERBOARD_LAYOUT* for motherboard layout)

9. Connect the Power cable and Audio lead to the drive and ensure the power cable is neatly

retained by the bunny clips.

10. Replace / Fix the EMC tape from the front panel to the top of the CDROM drive See figure 6.

11. Finally, fit the CDROM drawer front, if required (See page *DA_FITTING_CDROM_FRONT*)

figure 1 figure 2 figure 3

figure 4 figure 5 figure 6

19

ENGLISH

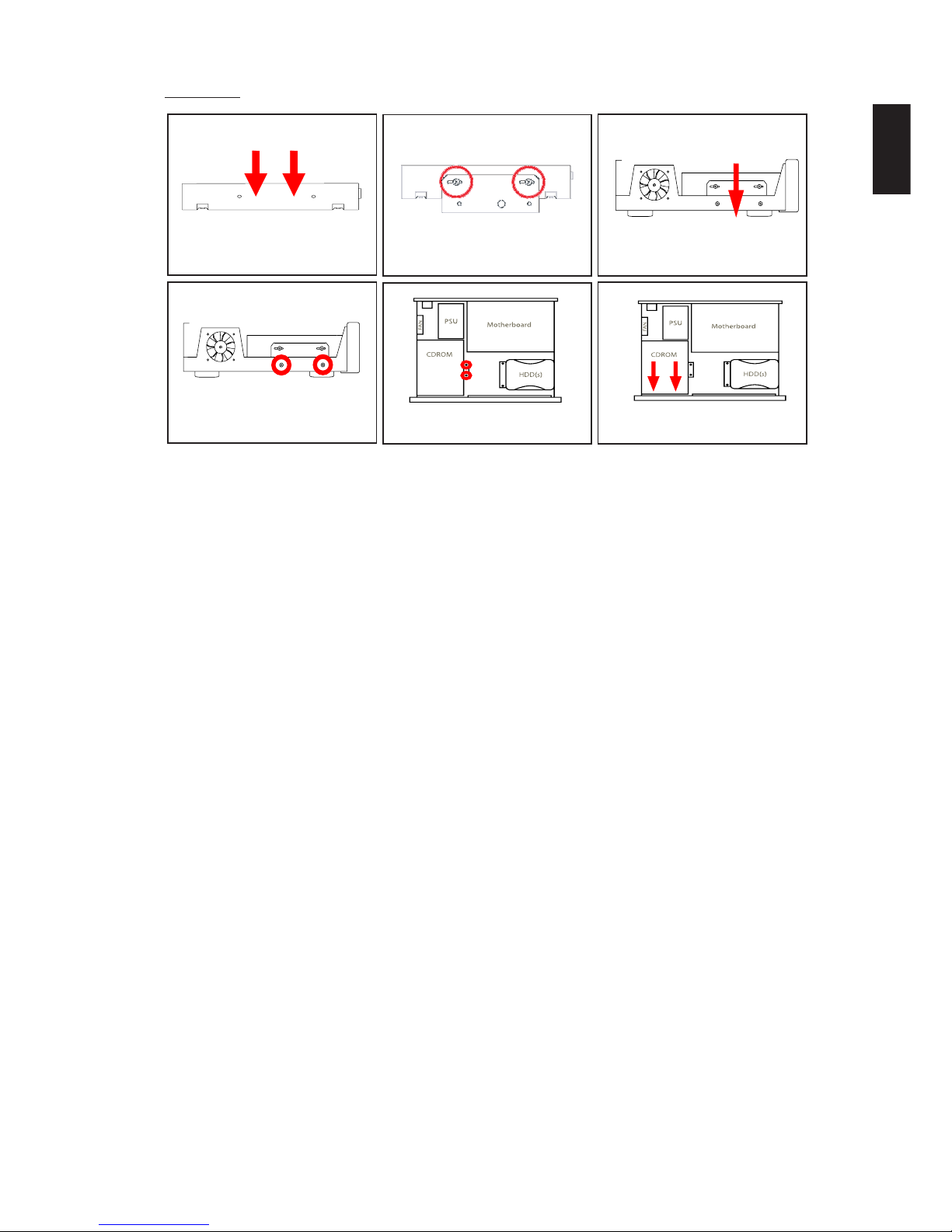

Removing the Hard Disk Bracket

CAUTION:

The motherboard front panel display socket carries additional power, do not under any circum-

stances attempt to connect a cable plugged in this socket into the hard disk drives or CDROM drive.

This will short circuit the attached device and/or motherboard rendering it inoperable.

TOOLS:

Pozi-driv No.2 screwdriver

PARTS USED::

<P/NBR> 2x M4 6mm MW00109-01 M4 Shakeproof Washers Zinc

<P/NBR> 2x M3 6mm MW00043-01 M3 Shakeproof Washers Black

PROCEDURE:

1. Remove Lid (See page *DA_REMOVE_LID*)

2. Remove the Power cables and IDE ribbon (black connectors) if connected from the hard

disk(s). See figures 2 and 3.

3. Locate and remove the two M4 screws beneath the hard disk cable end that fix the metal

bracket to the bottom of chassis. See figure 4.

4. On the front right side of the chassis you will find a second pair of M4 screws to remove. See

figures 5 and 6.

5. Carefully lift the hard disk and bracket assembly from the unit.

figure 4 figure 5 figure 6

figure 1 figure 2 figure 3

20

ENGLISH

Fitting the Hard Disk Bracket

CAUTION:

The motherboard front panel display socket carries additional power, do not under any circum-

stances attempt to connect a cable plugged in this socket into the hard disk drives or CDROM drive.

This will short circuit the attached device and/or motherboard rendering it inoperable.

TOOLS:

Pozi-driv No.2 screwdriver

PARTS USED::

<P/NBR> 2x M4 6mm

<P/NBR> 2x M3 6mm

PROCEDURE:

1. The hard disk drive bracket is fitted in the front right hand corner of the unit (figure 1), one side

is secured against the front right side of the chassis.

2. Position the bracket over the screw holes ensuring the up folded metal is flush against the front

right side (figures 2 & 3) of the unit.

3. Insert and tighten the two M4 screws beneath the hard disk cable end (figure 4) and then the

pair of M3 screws that secure the bracket to the front right side of the unit (figure 3).

4. Fit the IDE ribbon (black connectors) into the hard disk(s) (figure 6) and motherboard socket

marked PL8.

5. Fit the Power cable(s) to the hard disk(s) (figure 6) and motherboard socket marked PL12.

figure 4 figure 5 figure 6

figure 1 figure 2 figure 3

Table of contents