imes-icore iVAC eco User manual

Attention! Do not use the device without reading the operating manual

Operating Manual

Extraction Unit iVAC eco

imes-icore GmbH

Competence in CNC & DENTAL-Solutions

Im Leibolzgraben 16

D-36132 Eiterfeld

2

1. Table of content

1. Table of content .......................................................................................................................................................................2

2. EC-Declaration of Conformity......................................................................................................................................................2

3. Technical Specifications...........................................................................................................................................................3

4. Delivery, first use......................................................................................................................................................................3

5. Intended use of the extraction unit............................................................................................................................................3

6. General safety information .......................................................................................................................................................3

7. Filter.........................................................................................................................................................................................4

7.1 Air flow, filter arrangement................................................................................................................................................4

7.2 Red indicator light No. 5.................................................................................................................................................... 4

7.3 Synthetic filter: filter saturation, visual inspection, changing .............................................................................................. 4

7.4 Filter cartridge: filter saturation, visual inspection, cleaning, removing and replacing........................................................ 4

8. Warranty ..................................................................................................................................................................................5

9. Disposal...................................................................................................................................................................................5

10. Troubleshooting checklist.......................................................................................................................................................5

11. Key to illustrations 1-9............................................................................................................................................................6

11. Figures...................................................................................................................................................................................7

Fig. 1-9..............................................................................................................................................................................7-14

12. Circuit Diagram ....................................................................................................................................................................12

2. EC - Declaration of Conformity

We, Messrs. imes-icore GmbH Competence in CNC & DENTAL-Solutions

Im Leibolzgraben 16

D-36132 Eiterfeld

declare at our sole descretion that the following machine

Article designation: ECO serial number:

to which this declaration relates, has been designed, constructed and made in accordance with the

Machinery Directive 2006/42/EC

EMC Directive 2004/108/EC

The following harmonised standards have been applied:

•

DIN EN ISO 12100 part 1 und 2 -

2003-

Safety of machinery – Basic concepts, general principles for design

Part1: Basic Terminology, Methodology (ISO 12100-1:2003)

Part2: Technical principles (ISO 12100-2:2003)

•

DIN EN 349 -2008 -

Safety of machinery; minimum gaps to avoid crushing of parts oft he human

body

•

DIN EN 953 -1997-

Safety of machinery – Guards – General requirements for the design and

construction of fixed and movable guards

•

DIN EN 61010-1:2003

Safety requirements for electrical equipment for measurement, control, and

laboratory use - Part 1: General requirements

•

DIN EN 55022 + A1:2006

Information technology equipment - Radio disturbance characteristics - Limits

and methods of measurement

Eiterfeld, den

imes-icore GmbH

Competence in CNC & DENTAL-Solutions

3

3. Technical Specifications iVAC eco

Air intake

32 mm

Power Unit

1 EC blower (brushless turbine)

Rating / protection type

S1 / IP 20

Output

1.3 kW

Mains voltage

230 V

Frequency

50-60 Hz / single phase

Power requirement

5.7 A

Internal fuse (slow-blow type

16 A

Rate of air flow

115 m³/h

Negative pressure, max.

20.500 Pa / electronically controlled limit – 15.000 Pa

Dimensions: width x depth x height, without accessories,

approx.

290 x 485 x 610 mm

Weight

30.2 kg

Filter

N0. 22: upstream paper filter, No. 14: polyester filter cartridge

1,20 m² filter surface, category M

Ambient temperatures

5° < 1< 40°

Noise level according to EN ISO 3744

62-68 db (A)

4. Delivery, first use

The iVACeco extraction unit (referred as below to the eco) is supplied as ready to use. No special installation work is

necessary. The eco must be handled with due care and consideration during transport, setting up and operation. The eco must

be kept dry when put away or stored during normal operation. Please take steps to prevent any improper use:

- The eco is switched on and off at the power switch No.1 ON/OFF:

Position “0” The device is switched off.

Position “0” The device is switched on.

- When the power switch is on (Position “1”), switch No.2 can be used to operate the turbine function:

Position “0” The turbine is switched off.

Position “1” The turbine is switched on (with remote control via SUB9 input).

Position “2” The turbine is switched on (with remote control).

- For normal operation, the ecoshould be set to the medium potentiometer setting (5-7). This corresponds to a maximum rate of

air flow of approx. 100m³/h.

5. Intended use of the eco extraction unit

The eco is intended for the continuous separation by mechanical filtration of dry materials / substances ( particles), which

mainly take the form of milling and drilling dust, flour and powder, chips, granulate and fibres.

The eco is suitable for extracting materials such as metals (not fine aluminium grinding dust or magnesium), plastics, paper,

textiles, leather, glass, acrylic glass and mineral substances /ceramic, cement, stone, etc.). If the eco is correctly installed at the

dust source (e.g. milling, drilling, engraving or grinding system, etc.) and operated in accordance with the instructions and

regulations, then the required performance and quality of extraction and separation are guaranteed.

The basic unit incorporates a main filter (filter cartridge, category M) with an upstream paper filter to collect all chips and most

dust particles.

Any use, other than the intended use, is forbidden!

Unintended or improper use leads to:

hazards for life and health

hazards for the machine

hazards for other property

6. General safety information

When using eco, the following must be observed:

- Ensure that no fire hazards (flying sparks), no explosive substances, liquids, combustible dusts or aggressive gases are drawn

in by the extractor.

- All electrically conductive components of the eco must be continuously earthed.

- Insert the mains plug into an earthed socket protected by a 16 amp slow-blow fuse

- Check the mains lead for splits, aging or any damaged caused by wheels or by crushing.

- Always remove the plug from the socket after use. Before transporting, clean the unit, carry out maintenance, empty the

contents, check the filters, etc.

- Only trained and qualified staff may operate, service or repair the eco.

- Connect the eco to the extraction site at the workplace by means of a fixed pipework or hose.

Regular inspection and maintenance tasks include:

- Daily inspection: Check for visible damage; ensure that the dust collector is not full; check upstream filter No. 22 and seal No.

40. Check level indicator light No. 15.

4

- Monthly inspection: Remove deposits in the upstream area of filter chamber No. 15. Remove any major residues. Clean

residues from filter cartridge. Check that the hose connector bush fits tightly in air intake No 27a.

- Six-monthly maintenance: Change the G4 filter mat No 34. If the filter mat becomes clogged, the turbine can be irreparably

damaged through lack of cool air.

- The eco may only be used for dry extraction and not in the open air. The unit must be, of course, be serviced and repaired as

necessary. See also Section 10 / page 5 “Troubleshooting checklist”.

Prevention of mechanical hazards: All moving parts of the machine (e.g. turbine) which are potential hazards are covered by

means of permanent, fixed, protective covers which can only be removed with the use of tools.

Prevention of electrical hazards: All parts of the machine which carry an electric current are insulated by means of

permanent, fixed protective devices which can only be removed with the use of tools.

Other risks: If the above mentions instructions are not observed, there is acute danger for the operating personnel.

7. Filter

7.1 Air flow, filter arrangement

The extracted particles (e.g. dust, flower, powder, chips, granulate) are drawn via air intake No. 27a into the synthetic filter No.

42. The synthetic filter No. 42 serves to relieve filter cartridge No.14 and absorbs the chips and a large portion of the dust.

However, fine dust passes through the synthetic filter. The air flow carries the fine dust to filter cartridge. Here, it is deposited on

the pleated surface of the filter cartridge (air intake area No. 15).

7.2 Red indicator light No. 5

The red indicator light comes on when the performance of the extractor drops significantly at a medium potentiometer setting (5-

7 on the scale). When the red light comes on, the EC blower cuts out immediately. In order to briefly continue to operate the

turbine until the indicator light comes on again, a RESET can be carried out as follows:

1. Set main switch NO.1 to position “0”

2. Set the changeover switch No. 2 position “0”

3. Set main switch No. 1 to position “1”

4. Set the changeover switch No. 2 to position “1” (with remote control via SUB9 port) or position “2” (without remote

control) depending on the function selected.

- Important: both filters must now be checked (see 7.3 and 7.4), because

•the synthetic filter may be full

•there may be heavy deposits on the filter cartridge

•the synthetic filter may be full and there may be heavy deposits on the filter cartridge

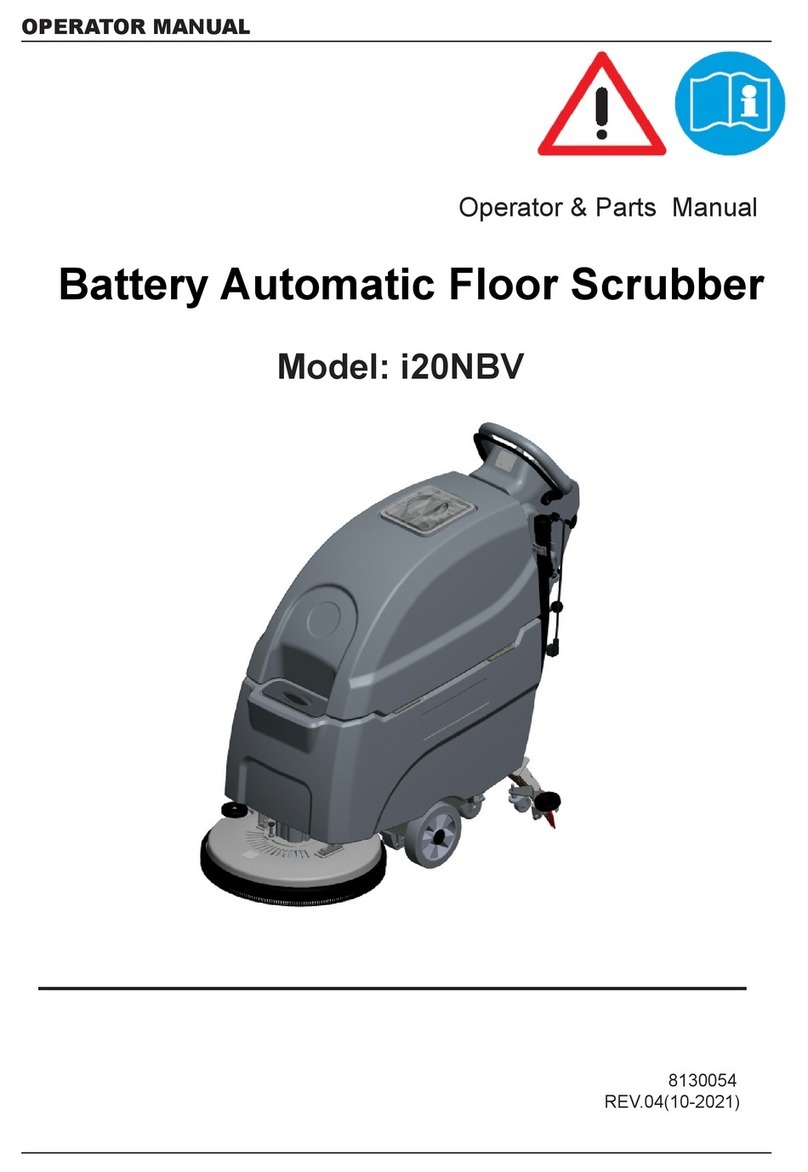

7.3 Synthetic filter: filter saturation, visual inspection, changing

The synthetic filter is a disposable filter and should be changed when it is ¾ full. Depending on the application and the amount

and specification of material to be extracted, it may be necessary to carry this out every day or not for several weeks. The

condition of the synthetic filter can be determined by as follows:

Visual inspection: Release clasp No. 26b, remove filter chamber cover No. 24. The level of the synthetic filter can be seen

through opening No. 35 or feeling by hand. When replacing the filter chamber cover, make sure that both pins No. 23 engage in

holes No. 12 and that both guide lugs No. 25 fit onto pins No.17. Fasten the cover with the clasp. During visual inspection, the

extraction hose must be removed from the air intake.

Changing synthetic filter: Remove the filter chamber cover. Remove Holder of synthetic filter No. 18 complete with synthetic

filter No. 42 from the filter chamber. Pull the synthetic filter out of the slot No. 19 (see also direction of arrow in Fig. 4) and close

synthetic filter with the paper sealing lug No. 44 (turn it down). Insert new synthetic filter Note: tab No. 43 must remain

protruding from slot No. 19 – see Fig. 3). Insert the holder with the synthetic filter. Replace the filter chamber cover as described

under “Visual inspection” and fasten same.

7.4 Filter cartridge: filter saturation, visual inspection, cleaning, removing and replacing

Filter cartridge No. 14 is upstream of the turbine and fastened onto retaining bolt No. 13 by means of nut No. 13b (with silicone

seal and washer). The filter cartridge (category M filter material) is designed for fine dust.

Visual inspection: When the filter level light described in 7.2 comes on, the filter cartridge must be checked. Remove filter

chamber cover (as described in 7.3). The filter cartridge is pleated. Check for dust deposits between the pleats and for dust

accumulation on the floor on the filter chamber. If this is the case, the filter cartridge must be cleaned.

Cleaning/removing and replacing the filter: Use a size 10 open-ended spanner to undo M6 No. 13b. Put a sufficiently large

plastic bag (e.g. 30 or 50 litre rubbish back over the filter cartridge). Pull out the filter cartridge with the plastic bag over the

threaded bar (retaining bolt), No. 13a. Close the plastic bag around the filter cartridge. The fine dust can now be shaken out of

the pleats by shaking the filter cartridge several times. Replace the filter cartridge over the threaded bar and position it over

cantering plate No. 38. Tighten the silicone seal, washer and nut.

Fasten filter chamber cover (as described in 7.3)

The filter cartridge can be re-used several times. After a long service life, the cartridge must be replaced by a new one. This is

because the pores of the filter material gradually seal up over time and can no longer be cleaned by shaking. It is necessary to

replace the (shaken) filter cartridge if the red light comes on again after a fairly short time.

5

N.B. Irrespective of the condition of the filter cartridge, the red indicator light may come on if the synthetic filter is full.

Important

•do not wet clean filter cartridge. Do not blast filter cartridge with compressed air

•when shaking the filter cartridge, be careful not to damage the surface

•in particular, check whether the outside edges of the pleats are roughened. If this is the case, replace the filter

cartridge.

N.B. (referring to 7.3 and 7.4):

- switch the eco off before opening filter chamber cover No. 24. Set main switch No.”1” to position “0” and remove the mains

plug from the socket outlet.

- Dust deposits can build up on the floor of the housing and on the walls in the region of air intake No. 15. Clean off these

deposits before inserting a cleaned or new filter cartridge before changing the synthetic filter.

- If the instructions in this user manual regarding disposal are not allowed (e.g. the use of suitable face masks and adequate

protective clothing) this can lead to dust being inhaled during closing and changing the synthetic filter and the filter cartridge.

Dispose of the synthetic filter to be done properly in accordance to local regulations!

8. Warranty

The unit is covered by guarantee in accordance with statutory regulations. Any defects arising must be reported to the seller

immediately. Claims under guarantee are excluded in respect of any faults or defects attributable to overheating, excessive

external temperature, inclement weather, incorrect or faulty connections, incorrect positioning, operation or maintenance,

unsuitable or improper use, improper modifications or repair work carried out at his or her own risk by the owner or any third

party, in the event of machine overload, etc. Parts subject to wear (e.g. filter inserts, turbine) which in any case have only a

limited useful life, and all service, setting and adjustment work is completely excluded under the terms of the warranty.

9. Disposal

Equipment, devices and machinery which are permanently taken out of use, must be disposed of in accordance with statutory

requirements. In particular, the individual components of such equipment, devices and machinery must be separated according

to their material and substance groups, e.g. metals (aluminium, steel), plastics, rubber, electrical components, and taken to the

appropriate collection depots for recycling.

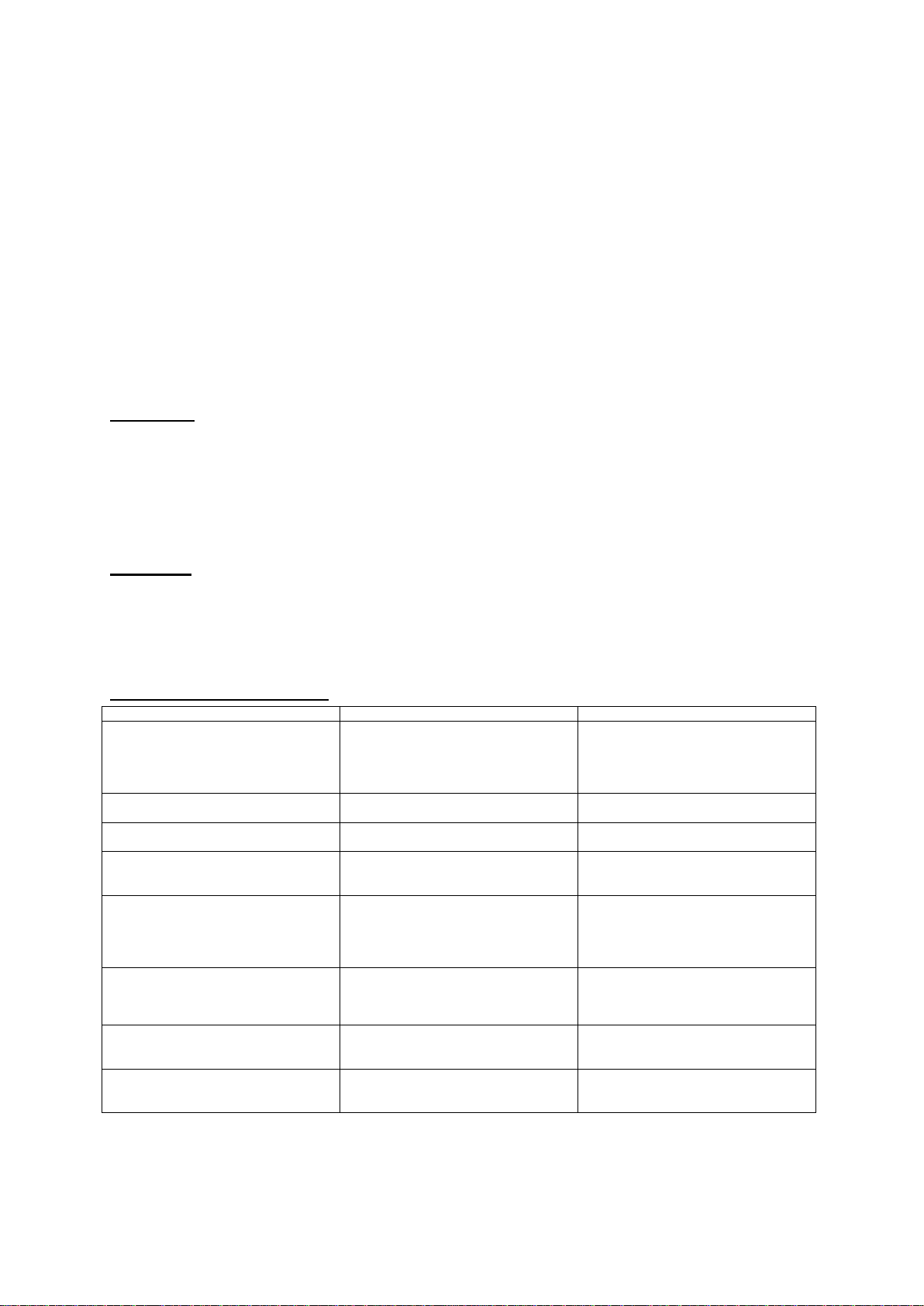

10. Troubleshooting checklist

Fault

Cause

Remedy

Turbine motor not working

- mains cable not plugged in

- Faulty cable

- Faulty filter cartridge; fine dust

penetrating into the clean air section –

faulty turbine

- Insert plug

- Replace mains cable

- Replace turbine, replace filter cartridge

Red indicator light No. 5 comes on,

turbine motor not working

Check condition on filter, see 7.2 to 7.4

Clean filter, replace filter, see 7.2 to 7.4

Dust penetrating into the clean air

section

Filter cartridge worn or damaged

Replace filter cartridge immediately

Heavy accumulation of dust and/ or

chips on the surface of the filter

cartridge

Synthetic filter leaking or torn

Immediately replace synthetic filter.

Dispose of old one clean filter

cartridge and replace if necessary

Dust escaping in the area of the air

intake/ hose connector or filter chamber

cover

- Leaking caused by loose hose

bushing

- Leaking caused by deposits on seal

No. 40

- Rubber seal damaged, torn or missing

- hose fastening

- clean deposits

- fix / replace rubber seal

Noise level increases

- Component(s) loose

- potentiometer turned up to position

“10” on the scale

- Check that all mechanical parts are

firmly in place

- Reset potentiometer to recommended

operating setting (5-7 on the scale)

Turbine overheating

Inadequate cooling because the outside

of G4 filter mat No. 34 is saturated with

dust deposits

- Replace filter mat. See maintenance

instructions, section 6.0

Problem dust with properties such as

highly adhesive, agglomerating, sticky,

etc.

Filter cartridge becomes very heavily

soiled in a short time can only be

cleaned to a limited extend

Consult service agent for details of

alternative filters

6

11. Key to illustrations 1-9

No.

Part name, description

Quantity

Illustration

1

Main switch:

- Position “0” ….eco is off

- Position “1” ….eco is on

1

1

2

Changeover switch:

Position “0” turbine off

Position “1” turbine on (remote control via SUB9 port)

Position “2” turbine on (direct control by eco)

1

1

3

Potentiometer

1

1

4

Indicator light, main switch (green)

1

1

5

Indicator light, filter level (red)

1

1

6

Suction unit housing

1

2, 3

7

Handle

2

3

8

SUB9 port

1

2

9

Mains connection 230V

1

2

10

Adjustable foot

4

2, 6

11

Filtered air outlet

1

2

12

Connector for guide pin No. 23 for fixing the filter chamber cover

2

3, 9

13

a) Threaded bar for holding the filter cartridge

b) Nut M6

c) Washer

d) Silicone seal

1

1

1

1

3, 8

3

3

3

14

Filter cartridge

1

3, 8

15

Filter chamber air intake area

1

3

17

Guide pin for fixing the synthetic filter holder

2

3

18

Holder for synthetic filter

1

3, 4

19

Holder guide slot for changing the synthetic filter

1

4

21

Hole for guide pin No. 17

2

4

23

Pin for fixing the chamber filter cover

2

5, 9

24

Filter chamber cover

1

2, 5, 9

25

Filter chamber fixing lug for fitting onto guide pin No. 17

2

5

26

a) Clip for clasp

b) Clasp for filter chamber cover

2

2

2, 3

2

27

a) Air intake adaptor, diameter 32 mm

b) Duct to synthetic filter opening

1

1

2, 5

5

28

screws for front cover

4

-

29

Front cover

1

1

30

Cooling vent for turbine

1

6, 7

31

Display

1

1

32

Turbine compartment cover

1

6

33

Screw M4. 12

4

6

34

G4 filter mat

1

7

35

Synthetic filter opening

1

3

36

Turbine outlet, cool air

1

2

37

Turbine inlet, cool air

1

6, 7

38

Metal ring for fixing the cartridge

1

8

39

Sound insulation

--

5, 8

40

Seal filter chamber cover

1

8, 9

41

Seal Cooling vent No. 30

1

7

42

Synthetic filter

1

4

43

Synthetic filter paper tab

1

4

44

Synthetic filter paper closing lug

1

4

7

11. Figures

Fig. 1

Fig. 2

1

29

2

31

3

4

5

24

11

6

26b

27a

9

8

10

36

26a

8

Fig. 3

Fig. 4

6

17

26a

40

18

17

35

7

15

7

13a – 13d

12

43

44

19

18

21

42

21

14

9

Fig. 5

Fig. 6

27a

27b

10

23

24

39

25

25

32

37

33

30

10

Fig. 7

Fig. 8

37

14

41

34

30

39

13a

40

38

11

Fig. 9

24

23

12

40

12

23

12

12. Circuit Diagram, MINI

M1

EC blower 220V/240V, 5,8 A 50/60 Hz, 1300 W

Type “H”

Ametek

B2

Electronic control unit 250 V / 16A

Urban

S1

Main switch 230 V / 6A

Moeller

S2

Changeover switch 1-0-2, 230V / 15A

Moeller

H1

LED 3V - red

GM

H2

LED 3V - green

GM

R1

Potentiometer

Tesla

B1

RF suppressor 250V / 10A

Domel

Table of contents

Popular Scrubber manuals by other brands

Wetrok

Wetrok Wetrok Sprinter XR 70 operating instructions

Hydro-Force

Hydro-Force Nautilus MX3-1200JP operating manual

Imac

Imac NGS 1000 Installation, operation & maintenance instructions

Tennant

Tennant Alfa Mini LPTB02097 Operator's manual

Ice

Ice i20NBV Operator's & parts manual

Ace

Ace 73-201 Safety & instruction manual